Figures & data

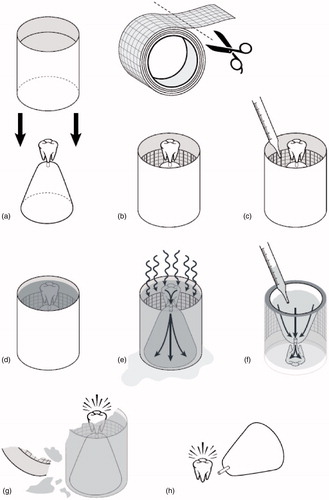

Figure 1. Per the “lost-wax” casting method, a wax model is first hand-crafted, mounted onto a base by a sprue wire, and surrounded by a metal ring (a). A piece of asbestos casting ring liner is cut, wetted for approximately one minute, and formed around the inside of the metal ring (b). Investment powder is then mixed with water to the desired consistency, poured around the wax model inside of the casting ring (with the ring liner in place), vibrated to ensure complete filling of the ring, and then allowed to harden for approximately 30 min to one hour (c and d). After the investment material hardens, the wax is subsequently burned out of the investment material in a heat treatment process lasting from 45 min to two hours, and reaching temperatures of approximately 250–900 °C (approximately 500–1650 °F), depending upon the composition of the investment material (e). Molten metal, typically gold, is then used to fill the negative space left by the burned out (or “lost”) wax in order to form the desired dental fixture (f). The invested casting is cooled for approximately six minutes at room temperature prior to being quenched in a cold-water bath, allowing for further setting of the investment material; the investment material and casting ring liner are subsequently cleaned from the final product with an abrasive sandblaster or a hand-finishing tool (g and h).

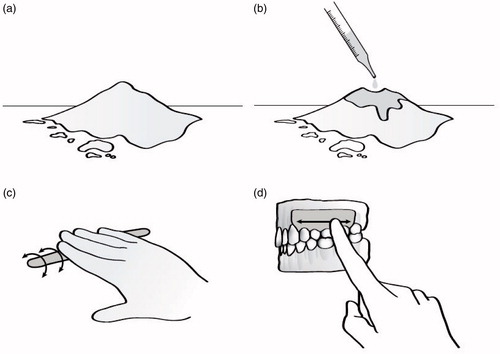

Figure 2. Periodontal dressing powder (a) is mixed with eugenol (b), rolled into a “sausage shape” (c), and applied to a patient’s gums to assist with the healing process by protecting the wound from physical trauma and providing stability at the surgical site (d).

Table 1. Summary of asbestos bulk analysis data for casting ring liner.

Table 2. Summary of asbestos bulk analysis data for investment material.

Table 3. Summary of asbestos bulk analysis data for periodontal dressing powder.

Table 4. Summary of glovebox fiber release data for casting ring liner.

Table 5. Summary of exposure study data for casting ring liner – all tasks.

Table 6. Summary of exposure study data† for periodontal dressing powder – all tasks.

Table 7. Summary of mesothelioma case reports among asbestos-containing dental product users.

Table 8. Cumulative exposure estimates for various dental professionals.