Figures & data

Table 1. Designations and composition of the samples.

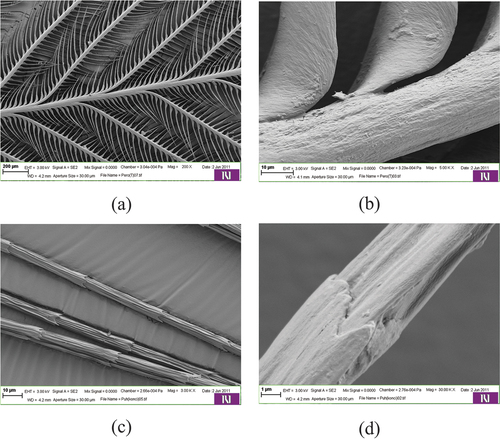

Figure 4. Scanning electron micrographs of chicken feathers: whole feather (a), rachis and barb (b), barbules (c and d).

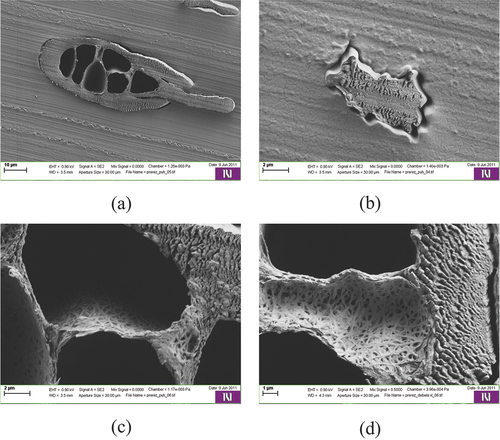

Figure 5. Scanning electron micrographs of cross-sections of a barb (a) and barbule (b) showing the details of the walls of the internal “honeycomb” structure (c and d).

Figure 6. Scanning electron micrographs of the sepiolite specimen at 50x (a) and 2500x (b) magnification.

Figure 9. Zeta potential as a function of pH for feather marked as x) and sepiolite (marked as o) samples.

Table 2. Viscosity (η), Density (ρ), Surface tension (SFT) of test liquids and their corresponding dispersive (Dis) and polar (Pol) contributions, and polarity.

Table 3. The surface tension ( and its dispersive (

and polar (

contributions of sample diesel oil.

Table 4. The total surface free energies (SFE) and their dispersive and polar contributions estimated by OWRK model for sepiolite (S), feathers (F) and polyester fabric (PET).

Table 5. Gibbs free energy of wetting (G) and work of adhesion (Wsl) for the solid/liquid systems (feathers/oil (F/oil) and sepiolite/oil (S/oil)).