Open access

474

Views

1

CrossRef citations to date

0

Altmetric

Research Article

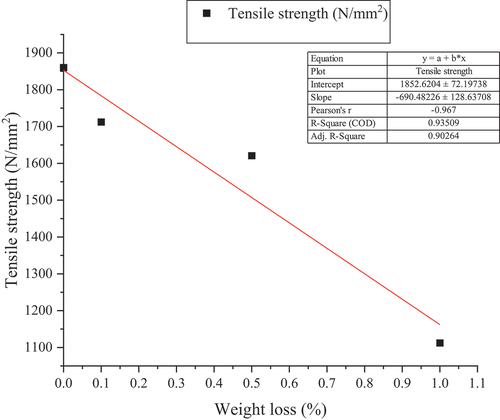

Influence of corrosion-based section loss on morphology and tensile capacity of pre-stressing strands

Aishwarya Lakshmia Department of Civil Engineering, Manipal Academy of Higher Education, Manipal, India

, Poornachandra Pandita Department of Civil Engineering, Manipal Academy of Higher Education, Manipal, IndiaCorrespondence[email protected]

, Gopinath Nayaka Department of Civil Engineering, Manipal Academy of Higher Education, Manipal, India

, Yamuna Bhagwata Department of Civil Engineering, Manipal Academy of Higher Education, Manipal, India

& Sooraj Kumarb Department of Civil Engineering, SMVIT, Visvesvaraya Technological University, Udupi, India

|

Published online: 21 Feb 2024

Related research

People also read lists articles that other readers of this article have read.

Recommended articles lists articles that we recommend and is powered by our AI driven recommendation engine.

Cited by lists all citing articles based on Crossref citations.

Articles with the Crossref icon will open in a new tab.