?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

Chrysotile was formerly used in the manufacture of casting ring liner (CRL) and periodontal dressing powder (PDP). The purpose of this study was to describe the potential for airborne asbestos exposure among dental professionals who may have used these products and to assess their risk of asbestos-related disease (ARD). Task-specific exposure data associated with CRL and PDP were identified and compared to regulatory standards for asbestos and health-based benchmarks. Personal airborne fiber concentrations ranged from 0.008–3.5 f/cc by PCM (duration: 3–420 minutes) for CRL (tearing, placement), and from <0.0044–<0.297 f/cc by PCM (duration: 5–28 minutes) for PDP (mixing). Eight-hour time-weighted average (TWA) exposures were calculated using the reported task-based airborne fiber concentrations and associated sampling durations. For CRL tasks, the upper-bound calculated 8-hour TWA of 0.022 f/cc (tearing, placement) did not exceed regulatory standards for asbestos (≥0.1 f/cc). All samples collected during the mixing of PDP resulted in non-measurable fiber concentrations. The greatest estimated cumulative asbestos exposure for dental professionals using CRL (tearing, placement) of 0.33 f/cc-years is well below “best estimate”, published chrysotile no-observed-adverse-effect-levels (NOAEL) for ARD (lung cancer = 89–168 f/cc-years; pleural mesothelioma = 208–415 f/cc-years). As such, the use of asbestos-containing CRL and/or PDP is not expected to pose an increased risk of ARD among dental professionals. This conclusion is consistent with the lack of an increased risk of ARD reported in epidemiological studies of these occupations.

Introduction

In 1950, approximately 157,000 individuals worked in dental offices in the U.S., over half of whom were dentists (51%; n = 80,070), 2% (3,140) were dental hygienists, 35% (54,950) were dental assistants, and 11% (17,270) were “other staff”, including secretaries, receptionists, office managers, etc. (Solomon Citation2012, p. 1031). The number of dentists in the U.S. has doubled since 1950, with even sharper increases in the number of dental hygienists and dental assistants (Solomon Citation2012). To the best of our knowledge, historical employment data for dental laboratory technicians is not readily available.

According to the U.S. Bureau of Labor Statistics (BLS), as of 2018, there were approximately 802,300 dental personnel, including dentists (155,000), dental laboratory technicians (81,500), dental hygienists (219,800), and dental assistants (346,000), in the U.S. (Bureau of Labor Statistics [BLS] Citation2019a, 2019b, 2019c, 2019d). Dentists diagnose and treat medical issues in patients’ teeth, gums, and other parts of the mouth, typically in an office setting (Bureau of Labor Statistics [BLS] Citation2019d). These professionals may also undergo training during dental school to learn how to create dental fixtures like crowns and bridges, and may perform such tasks while practicing as a licensed dentist. Dental laboratory technicians are mainly responsible for constructing, fitting, and/or repairing dental fixtures in laboratories (Bureau of Labor Statistics [BLS] Citation2019a). Dental hygienists largely work in dentists’ offices, where they examine patients for indications of oral disease and provide oral hygiene preventive care (Bureau of Labor Statistics [BLS] Citation2019c). Dental assistants generally provide patient care, take X-rays, maintain records, and perform other administrative tasks in dentists’ offices, such as scheduling appointments (Bureau of Labor Statistics [BLS] Citation2019b).

At various points in time, dental professionals may have experienced a variety of chemical exposures, including potential exposure to alginate powders, nitrous oxide, mercury, asbestos, beryllium, other non-precious metal alloys, silica, methylmethacrylate, and formaldehyde (Woody et al. Citation1977; Setcos et al. Citation1983; Rom et al. Citation1984; Wagner Citation1985; Persson and Brune Citation1989; Palmen Citation2005; Torbica and Krstev Citation2006). Of note, chrysotile was historically used in the manufacture of various dental products, including casting ring liner (CRL; i.e. dental tape), between approximately 1930 and 1987 (Taylor et al. Citation1930; Naylor et al. Citation1987), investment material (i.e. refractory material) from an unspecified year until 1930 (Broomell Citation1908; Souder and Sweeney Citation1930; Taylor et al. Citation1930), and periodontal dressing powder (PDP) between approximately 1923 and 1976 (Dyer Citation1967; Council on Dental Therapeutics [CDT] Citation1976; Cook Citation2008; Baghani and Kadkhodazadeh Citation2013).

Casting ring liner (CRL) and investment material

CRL and investment material are two products typically used by dental professionals during the “lost-wax” casting process. This method dates back to ancient Egypt, and was also used by early Chinese civilizations, as well as the Etruscans, Romans, Aztecs, Mayans, and Phoenicians (Hollenback Citation1962; Morey Citation1991a). The casting process that is used in dentistry, however, was first developed in 1907 by Dr. W. H. Taggart (Taggart Citation1907). The “lost-wax” casting process is used by dental professionals to create crowns, bridges, and other dental fixtures by forming and then filling imprints of wax models or inlays in hardened investment material. The use of a wetted asbestos CRL as part of the “lost-wax” method was used to allow for the proper expansion of the investment material during the casting process to ensure accuracy of the metal casting (Souder and Paffenbarger Citation1942; J. F. Jelenko & Co. Citation1963; Skinner Citation1963). Although the use of asbestos-containing CRL was first described by Taylor et al. in 1930, it became a universally adopted casting technique in 1960 when it was introduced by Dr. Wilmer A. Souder of the U.S. National Bureau of Standards (NBS) (Taylor et al. Citation1930; Hollenback and Rhoads Citation1960; Earnshaw Citation1988).

In 1976, the Council on Dental Therapeutics (CDT) and the Council on Dental Materials and Devices (CDMD) reported that personnel could be exposed to airborne asbestos in dental laboratories where asbestos-containing CRL was stored in large rolls and subsequently used in the casting process. This potential asbestos exposure was due to “the tendency for personnel to carelessly cut sections off these rolls and thus release asbestos into the ambient air” (Council on Dental Therapeutics [CDT] Citation1976, p. 777). Despite these concerns, however, CRL was not removed from the CDT’s “Acceptance Program” at the time. Instead, the CDT and CDMD recommended that wet methods be used when handling and manipulating asbestos-containing CRL in dental laboratories.

Since at least the mid-1970s, ceramic, cellulose, and ceramic-cellulose CRLs, and even “strips of card obtained from a breakfast cereal packet”, have been assessed and utilized as product substitutes for asbestos-containing CRLs, though a consensus has not been formed as to which products produce the most accurate castings (Burnett Citation1976; Priest and Horner Citation1980; Yli-Urpo et al. Citation1982; Brantley et al. Citation1986; Naylor et al. Citation1987; Earnshaw Citation1988; Morey Citation1992b). By 1987, the use of asbestos-containing CRLs was noted to have been “virtual[ly] eliminat[ed]” (Naylor et al. Citation1987, p. 413).

The investment material, which was used to create the casting during the “lost-wax” method, possibly also contained asbestos for an unspecified period of time to aid in heat resistance and to prevent fracturing of the material (Broomell Citation1908). In July 1930, the U.S. NBS approved the American Dental Association’s (ADA) specification for dental inlay casting investment (Souder and Sweeney Citation1930; Taylor et al. Citation1930). According to the specification, the investment material “shall be a powder composed essentially of plaster of Paris and silica, or other material of these types” and “free of foreign material”, excluding coloring material (Taylor et al. Citation1930, p. 2284). Per the ADA specification, the presence of asbestos in an investment material product precluded it from being approved (Broomell Citation1908; Souder and Sweeney Citation1930; Taylor et al. Citation1930). Whether the ADA’s specification that investment material not contain asbestos fibers was based on health concerns or if it was simply thought to negatively affect the nature of the investment material remains unclear, however. Notably, it has been demonstrated that both the composition of the investment material and the allotted amount of setting time affect the total expansion of investment material, which is a key factor in the creation of a precisely-sized dental prosthesis (Asgarzadeh et al. Citation1954).

Periodontal dressing powder (PDP)

PDP, also referred to as asbestos resin dressing and gingivectomy packs, was first used beginning in 1923 following periodontal surgery to treat patients’ wounds (Dyer Citation1967; Cook Citation2008; Baghani and Kadkhodazadeh Citation2013). In Citation1976, the CDT and CDMD determined that the “potential danger to dental personnel in preparation of asbestos-containing periodontal packs [was] of sufficient concern”, such that PDP was no longer considered eligible for the CDT’s Acceptance Program as of this same (1976) year (Council on Dental Therapeutics [CDT] Citation1976, p. 777). This decision to remove asbestos-containing PDP from the Acceptance Program was commended by the National Institute for Occupational Safety and Health (NIOSH) at the time (Infante and Lemen Citation1976). While officials were concerned with potential health risks posed to dental professionals from the use of PDP, the risk of asbestos exposure in patients was not of concern. Indeed, in 1976, the CDT and CDMD noted that “[t]here [was] no apparent health danger from inhalation to patients for whom asbestos-containing periodontal dressings [were] used, since the fibers cannot be appreciably released from the dressings once they [were] mixed and applied. In addition, present information indicates that there [was] little danger to patients should the dressings be accidentally swallowed” (Council on Dental Therapeutics [CDT] Citation1976, p. 778).

The purpose of the present study was to characterize the potential for historical airborne asbestos exposure in dentists and other dental professionals, including dental laboratory technicians, dental hygienists, and dental assistants, who personally used or were bystanders to the use of these products on a regular basis in an occupational setting. Specifically, a literature review was performed in order to estimate potential airborne asbestos exposures of dental professionals during typical use and manipulation of CRL, investment material, and PDP. Eight-hour time-weighted average (TWA) exposure estimates were calculated for each product-specific task for which measurable data were available, and compared to historical and current regulatory standards for asbestos. The upper-bound 8-h TWA for each product-specific task was then used to estimate cumulative asbestos exposures, which were ultimately compared to health-based, chrysotile no-effect levels for asbestos-related disease (ARD), specifically lung cancer and pleural mesothelioma. Although non-asbestos risk factors for lung cancer and pleural mesothelioma have been previously described (Pesch et al. Citation2012; Attanoos et al. Citation2018), the scope of the current risk assessment was limited to potential lung cancer and pleural mesothelioma risk from asbestos exposures among dental professionals.

Methods

Literature search

A comprehensive literature search was performed to identify published studies regarding asbestos in dental products in order to characterize potential asbestos exposures associated with the typical use of these products. A PubMed database search was performed using the following search terms in the specified combinations: (“asbestos” AND “dental”); (“asbestos” AND “dentist”); (“asbestos” AND “casting”); (“asbestos” AND “ring liner”); (“asbestos” AND “periodontal dressing”). If additional studies were identified during review of cited references, but not captured in the original database search, they were also included in the analysis. Unpublished reports received through litigation and their references were also reviewed and those that were found to be relevant to our analysis are included as Supplemental Material. Dental textbooks, as well as dental professional association standards and specifications, were also consulted to determine typical product use. After each relevant study and/or report was identified and reviewed, it was included in one or more of the following categories based on its content: (1) Product Use, (2) Bulk Product Analyses, (3) Animal Inhalation Toxicity Studies, (4) Fiber Release Studies, (5) Exposure Studies, and/or (6) Human Health Studies, which is how each study and/or report is presented herein.

Exposure assessment

Cumulative asbestos exposure estimates (f/cc-years) were derived by first calculating personal 8-h TWA exposures (f/cc) based on the measured airborne fiber concentration data identified in the published and unpublished literature. Any area samples reported in the literature were also used to approximate bystander 8-h TWA exposures in environments where these dental products were typically used. To calculate 8-h TWA concentrations, airborne fiber concentrations and the associated sampling durations for each discrete sample collected and reported in the literature were used. Short-term exposure measurements were converted to 8-h TWA concentrations according to EquationEquation (1)(1)

(1) . It was assumed that there was no other asbestos exposure throughout the day except during the sampling duration.

(1)

(1)

where CTWA=8-h TWA concentration (f/cc); CT=Task-based airborne fiber concentration (f/cc); TD=Task-based exposure duration (min).

An upper-bound 8-h TWA concentration, defined as the greatest 8-h TWA in the available dataset (both reported and calculated values), was then identified for each product-specific task for which measurable data were available for the purpose of calculating a cumulative asbestos exposure estimate. Cumulative asbestos exposures (f/cc-years) were specifically calculated by multiplying the upper-bound 8-h TWA (f/cc), which was calculated from airborne fiber concentration/sampling duration pairs reported in the available literature as described above, by mean duration of employment (years) for each profession (i.e. dentist, dental laboratory technician, dental hygienist, and dental assistant), according to Maguire (Citation1993), assuming a workday duration of 8 h (480 min) and an occupational year of 250 days (EquationEquation (2)(2)

(2) ). Potential asbestos exposures to dental patients were outside the scope of this analysis and were therefore not evaluated.

(2)

(2)

where CE=Cumulative asbestos exposure (f/cc-years); CTWA,MAX=Upper-bound 8-h TWA concentration (f/cc); EF= Exposure frequency in number of years of product use (years); ED=Exposure duration per day (8 h/day); FD=Conversion factor for working days per occupational year (250 days/year); FH=Conversion factor for working hours per occupational year [based on an 8-h workday, 5 days/week, 50 weeks/year] (1 year/2000 h).

When calculated, upper-bound 8-h TWA exposures for a product-specific task were compared to current and historical occupational exposure limits and guidelines for asbestos (0.1 f/cc or greater). These exposures were also categorized into one of the five exposure profile categories (0, 1, 2, 3, 4) according to the methodology set forth by the American Industrial Hygiene Association (AIHA) (Jahn et al. Citation2015, Chapter 5). Briefly, using this recommended strategy to determine compliance to an occupational exposure limit (OEL), the true 95th percentile of the exposure dataset (X0.95) is compared to varying percentages of the target OEL; specifically, X0.95≤1% of OEL (Category 0, trivial to non-existent exposure), 1%<X0.95≤10% of OEL (Category 1, highly controlled exposure), 10%<X0.95≤50% of OEL (Category 2, well controlled exposure), 50%<X0.95≤100% of OEL (Category 3, controlled exposure), and X0.95>100% of OEL (Category 4, poorly controlled exposure) (Hewett et al. Citation2006; Jahn et al. Citation2015, Chapter 5). An “unacceptable” exposure occurs when X0.95 exceeds the OEL (Hewett et al. Citation2006, p. 570). The X0.95 point estimate was calculated from the product-specific 8-h TWA datasets using AIHA’s IHSTAT© tool (AIHA, Falls Church, VA, USA). Using this tool, the available dataset was first assessed for lognormality. The data were determined to be lognormal and so the X0.95 point estimate using lognormal parametric statistics was reported.

Estimated cumulative asbestos exposures were also benchmarked against published “best estimate” no-observed-adverse-effect-levels (NOAEL) of 89–168 f/cc-years for lung cancer and 208–415 f/cc-years for pleural mesothelioma, which were based on exposure-response relationships identified among predominantly chrysotile-exposed cohorts (Pierce et al. Citation2016). In their analysis, Pierce et al. (Citation2016) specifically defined the NOAEL “as the highest estimated cumulative exposure at which no increased risk was reported” for lung cancer and mesothelioma in the cohorts evaluated (Pierce et al. Citation2016, p. 562). Additionally, in instances in which a study did not provide a risk estimate or confidence interval, Pierce et al. (Citation2016) calculated an estimate and/or associated confidence intervals based on the available data using a Fisher’s exact test. Further, in instances in which no incidence of cancer was reported in a cohort, Pierce et al. (Citation2016) considered the NOAEL to be the highest exposure group reported in a given study. It should therefore be noted that the chrysotile NOAEL values reported by Pierce et al. (Citation2016), and relied on in the current analysis, are indicative of minimum cumulative exposures without observed effects, and “whether or not these exposures truly represent ‘thresholds’ below which effects do not occur cannot necessarily be discerned due to [underlying] study limitations” (Pierce et al. Citation2008, p. 193).

National Occupational Mortality Surveillance (NOMS) database search

The Centers for Disease Control and Prevention’s (CDC) National Occupational Mortality Surveillance (NOMS) database monitors changes in the cause of death by occupation for various industries in the U.S. The proportionate mortality ratio (PMR) Query System from the NOMS database allows users to search calculated PMRs by cause of death and either occupation or industry, with ratios adjusted for age and, if desired, stratified by race and sex. Separate PMR search engines are available for the time period from 1985 to 1998, and for the combined time period of 1999, 2003–2004, and 2007–2014.

In a NOMS PMR query (accessed 27 November 2019) of both time periods as described above, the following parameters were selected: both “Black” and “White” for race; both “Female” and “Male” for sex; “18–64”, “65–90”, and “18–90” for age group; “Dentists”, “Medical, Dental, Optical Lab Technicians”, “Dental Hygienists”, and “Dental Assistants” for occupation; and “MN Trachea, Bronchus and Lung”, “MN Peritoneum and Pleura”, “MN Pleura (80% Mesothelioma in Males)”, “MN Mesothelioma (no codes before 1999)”, “Pneumoconioses (Occupational Lung Diseases) (Coal, Asbestos, Silica, Dust, Cotton, Other)”, and “Asbestosis” for cause of death.

Results

Product use

CRL and investment material

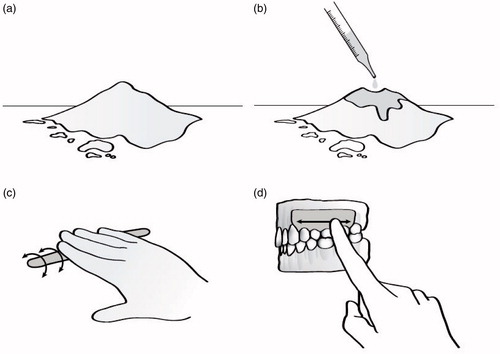

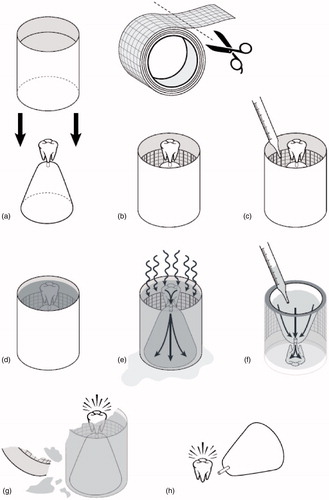

As briefly mentioned, asbestos-containing CRL was historically used in dentistry during the “lost-wax” casting method. This process, which is still utilized today, but without the use of asbestos CRL, is used to create various dental prostheses. According to this method, a wax model is first hand-crafted, mounted onto a base by a sprue wire, and surrounded by a metal ring (). When asbestos CRL was used, it was specified that the dental professional should cut a piece of CRL, wet it for approximately one minute, and form it around the inside of the metal ring, as demonstrated in (Taggart Citation1907; Coleman Citation1928; Brennom Citation1973). The use of a full-length “soft cushioning” asbestos CRL, situated flush with the end of the metal ring, greatly increased the accuracy of the molds by allowing the investment material to undergo a full cycle of thermal expansion (Taylor et al. Citation1930; Hollenback and Rhoads Citation1960; Hollenback Citation1964, p. 28; Shell Citation1968a, Citation1968b, Citation1969; Swartz Citation1969; Ohno et al. Citation1982; Morey Citation1992a, Citation1992b; Shibuya et al. Citation1997). The asbestos CRL, therefore, allowed for the proper expansion of the investment material during the casting process in order to ensure the proper size and physical properties of the metal casting (Souder and Paffenbarger Citation1942; J. F. Jelenko & Co. Citation1963; Skinner Citation1963). Asbestos-containing CRL was not required if a ring was not used or if a rubber ring was used in place of a metal one (Shell Citation1968a).

Figure 1. Per the “lost-wax” casting method, a wax model is first hand-crafted, mounted onto a base by a sprue wire, and surrounded by a metal ring (a). A piece of asbestos casting ring liner is cut, wetted for approximately one minute, and formed around the inside of the metal ring (b). Investment powder is then mixed with water to the desired consistency, poured around the wax model inside of the casting ring (with the ring liner in place), vibrated to ensure complete filling of the ring, and then allowed to harden for approximately 30 min to one hour (c and d). After the investment material hardens, the wax is subsequently burned out of the investment material in a heat treatment process lasting from 45 min to two hours, and reaching temperatures of approximately 250–900 °C (approximately 500–1650 °F), depending upon the composition of the investment material (e). Molten metal, typically gold, is then used to fill the negative space left by the burned out (or “lost”) wax in order to form the desired dental fixture (f). The invested casting is cooled for approximately six minutes at room temperature prior to being quenched in a cold-water bath, allowing for further setting of the investment material; the investment material and casting ring liner are subsequently cleaned from the final product with an abrasive sandblaster or a hand-finishing tool (g and h).

During the next step in the “lost-wax” casting process (), investment powder is mixed with water to the desired consistency, poured around the wax model inside of the casting ring (with the CRL in place), vibrated to ensure complete filling of the ring, and then allowed to harden for approximately 30 min to one hour (Moyer Citation1959; Dinger Citation1963; J. F. Jelenko & Co. Citation1963; Brennom Citation1973). Brennom (Citation1973) suggested that after filling the casting ring with investment material and while the material initially set, an approximately two-inch square piece of asbestos liner could be placed on top of the ring; however, this step may not have been performed consistently.

After the investment material hardens, the wax is subsequently burned out of the investment material in a heat treatment process () lasting from 45 min to two hours, and reaching temperatures of approximately 250–900 °C (approximately 500–1650 °F), depending upon the composition of the investment material (Taylor et al. Citation1930; Anderson Citation1956; Moyer Citation1959; Brecker Citation1961; Hollenback Citation1962; J. F. Jelenko & Co. Citation1963; Shell Citation1968a; Cutright et al. Citation1980; Brune and Beltesbrekke Citation1981; Yli-Urpo et al. Citation1982; Lacy et al. Citation1983; Takahashi et al. Citation1983; Rom et al. Citation1984; Morey Citation1991a, Citation1991b). Notably, it has been demonstrated that chrysotile is progressively converted to predominantly forsterite beginning at 400 °C (approximately 750 °F) with complete conversion at temperatures of ≥700 °C (approximately ≥1300 °F) (Dellisanti et al. Citation2001–2002).

Molten metal, typically gold, is then used to fill the negative space left by the burned out (or “lost”) wax in order to form the desired dental fixture (). The invested casting is cooled for approximately six minutes at room temperature prior to being quenched in a cold-water bath, allowing for further setting of the investment material (Dinger Citation1963). The investment material and CRL are subsequently cleaned from the final product () with an abrasive sandblaster or a hand-finishing tool (Delgado and Peyton Citation1953; Hollenback Citation1962; Dinger Citation1963; Hollenback Citation1964; Rom et al. Citation1984). Chrysotile asbestos fibers would have likely been converted to other magnesium silicates during the heat treatment process, resulting in minimal, if any, asbestos exposure to the dental professional who divested the casting (Tulachka et al. Citation1987; Dellisanti et al. Citation2001–2002).

As noted previously, the use of asbestos-containing CRL ceased by 1987, as alternative materials became more readily available (Burnett Citation1976; Priest and Horner Citation1980; Yli-Urpo et al. Citation1982; Brantley et al. Citation1986; Naylor et al. Citation1987; Earnshaw Citation1988; Morey and Earnshaw Citation1992). Yet, investigators expressed doubt as to the safety of ceramic liners, for instance, as an alternative, since “[f]ibers from ceramic ring liners closely resemble the fibers of blue [crocidolite] and brown [amosite] asbestos in size and shape and should be expected to behave similarly in depth of penetration and migration in human lungs” (Davis Citation1987, p. 368; Naylor et al. Citation1987; Tulachka et al. Citation1987). Shortcomings also exist in the physical properties of these substitute materials. Cellulose CRLs, for example, are prone to degradation at the high burnout temperatures required for “lost-wax” casting, and ceramic liners are hydrophobic (Davis Citation1995).

PDP

Until 1976, asbestos-containing PDP was used in the U.S. to heal patients’ wounds following periodontal surgery (Dyer Citation1967; Council on Dental Therapeutics [CDT] Citation1976; Cook Citation2008; Baghani and Kadkhodazadeh Citation2013). As demonstrated in , PDP was mixed with eugenol, rolled into a “sausage shape”, and applied to a patient’s gums (Cook Citation2008, p. 224). These dressings, once applied, assisted with the healing process by protecting the wound from physical trauma and providing stability at the surgical site (Baghani and Kadkhodazadeh Citation2013). Yewe-Dyer (Citation2008) reported that after his 1967 article, which described the potential asbestos-related health hazards associated with the use of PDP, was published, the use of asbestos-containing PDP in dental schools throughout the U.K. “ceased almost immediately” (Dyer Citation1967; Yewe-Dyer Citation2008, p. 544).

Bulk product analyses

Regarding the asbestos content of various dental products, three studies and one unpublished report were identified for CRL, one unpublished report for investment material, and five studies for PDP.

Generally, study samples were analyzed according to differing methods, specifically transmission electron microscopy (TEM), scanning electron microscopy (SEM), energy-dispersive X-ray microanalysis (EDS), polarized light microscopy (PLM), X-ray powder diffraction (XRD), and standard, direct preparation procedures (AHERA/ASTMD6281/ISO10312) in conjunction with the Addison and Davies procedure. Each of these methods have distinctions in the way asbestos fibers are detected or counted that need to be considered when interpreting and comparing the results reported in each study.

CRL

Bulk product analyses indicated that CRL contained 40–95% chrysotile, and potentially trace levels (≤0.1%) of amphiboles (specifically, tremolite and actinolite) ().

Table 1. Summary of asbestos bulk analysis data for casting ring liner.

Cutright et al. (Citation1980) analyzed asbestos CRL particle debris by SEM and EDS following tearing and heating. The authors reported that chrysotile asbestos fibers were identified in samples taken with the use of acetate tape from the thumbs and index fingers of the two laboratory workers who tore the asbestos CRL. Chrysotile was also identified in samples collected from a bench top upon which investment molds were separated from asbestos-lined rings, as well as from a wall adjacent to the bench top, a casting machine, and a drawer where the asbestos CRL was stored. The authors did not quantify the asbestos content of any of these samples.

Sichletidis et al. (Citation2009) performed XRD and SEM analyses on a sample of CRL and identified chrysotile as the “exclusiv[e]” fiber type (Sichletidis et al. Citation2009, p. 929). A percent asbestos content was not reported for this sample of CRL.

In an unpublished report, Millette (Citation2013) reported bulk analysis results for three samples of CRL. Specifically, the three samples were described as (1) “Roll of asbestos tape used as a soldering block. Approx. 6.5 inch diameter metal can. Approx. 15/16 to 1 inch high”, (2) “Piece of asbestos tape approx. 3 inches long by 1.25 in wide. Labeled ‘Asbestos flask liner’”, and (3) “Roll of off-white fibrous tape on sheet metal base” (Millette Citation2013, p. 4). The samples were previously analyzed by PLM (method not reported) and later analyzed by TEM following an Addison and Davies acid/base digestion procedure and standard, direct preparation procedures (AHERA/ISO10312). For these three samples, the authors reported a range of 60–90% chrysotile by PLM and 0.0002–0.02% amphibole (tremolite and actinolite) by TEM; the habit of the amphibole minerals was not specified.

Furthermore, Millette et al. (Citation2019) published bulk analysis results for 10 separate CRL samples. The authors reported that the CRL samples were initially analyzed by stereomicroscope and that all of the samples displayed a “felted nature … with probable asbestos fibers protruding from the surface. None of the samples showed evidence of deterioration or brittleness” (Millette et al. Citation2019, p. 102). One sample of CRL was further tested for friability in a glovebox. The authors also reported that all 10 CRL samples were additionally tested for fiber releasability from the surface of the product, which was determined by SEM analysis after touching the product and then pressing the same finger onto “an adhesive-coated SEM stub” (Millette et al. Citation2019, p. 102).

Regarding the bulk analyses, all 10 samples were analyzed by PLM, which “generally follow[ed] the analytical procedures recommended by the U.S. Environmental Protection Agency for bulk building materials” (Millette et al. Citation2019, p. 102). The authors also used an Addison and Davies acid/base digestion procedure to “eliminate the soluble fractions” in order to “concentrate possible amphibole material for analysis on one sample” (Millette et al. Citation2019, p. 102). After drying, the filters were prepared for TEM analysis using standard, direct preparation procedures (AHERA/ASTMD6281/ISO10312); the authors noted that “amphibole asbestos fibers were counted according to the standard methods if [the fibers] were longer than 0.5 µm in length and had at least a 5:1 aspect ratio and substantially parallel sides” (Millette et al. Citation2019, p. 102).

Millette et al. (Citation2019) concluded that the results of the bulk analyses ranged from 40–95% chrysotile by volume by PLM with “small amounts of amphibole asbestos” identified by TEM, which were identified as “primarily tremolite” and also a “few actinolite fibers” (Millette et al. Citation2019, p. 105). Whether the amphibole fibers identified were of the asbestiform mineral habit, however, was not specified. The authors stated that “[a]ll the amphibole asbestos fibers were found by TEM after acid/base digestion”, explaining that the products they sampled contained Canadian chrysotile and may have therefore been “contaminated with amphiboles” (Millette et al. Citation2019, p. 105–106). The authors also stated that they were able to crush one of the CRL samples “into dust with hand pressure”, and therefore concluded that CRL “is a friable material that can release asbestos fibers readily” (Millette et al. Citation2019, p. 106). Quantitative data regarding their SEM analyses was not provided, however.

Investment material

Asbestos contents for investment material, or lack thereof, are summarized in .

Table 2. Summary of asbestos bulk analysis data for investment material.

As explained previously, some investment materials may have contained asbestos prior to July 1930, when the ADA’s specification for dental inlay casting investment was approved by the U.S. NBS (Broomell Citation1908; Souder and Sweeney Citation1930; Taylor et al. Citation1930). This specification detailed the material and performance requirements for investment material, and did not include any mention of asbestos with specific regard to investment material content (Souder and Sweeney Citation1930). Following a survey of 39 investment material samples, one sample was reported to contain 58.5% insoluble matter (silica and other siliceous materials) and a single “asbestos fiber” (Taylor et al. Citation1930, p. 2267). This sample was classified as a soldering investment by the manufacturer and was determined to not meet the ADA’s dental use specifications.

Further, in a 2012 unpublished report by MVA Scientific Consultants, a sample of “Dental Casting Plaster” did not contain any detectable asbestos when analyzed by PLM following EPA Method 600/R-93/116 (Compton and Millette Citation2012, p. 2).

PDP

Various bulk product analysis studies indicated a range of 3–14.29% chrysotile in PDP ().

Table 3. Summary of asbestos bulk analysis data for periodontal dressing powder.

Guglani and Allen (Citation1965) noted that a basic zinc oxide preparation of a PDP contained “6 parts asbestos” (Guglani and Allen Citation1965, p. 19). In an animal toxicity study performed by Legan et al. in Citation1973, the PDP used by the investigators contained 7.5% asbestos by weight. While the asbestos fiber type was not specified, 15% of the particles in the PDP were less than 10 µm in diameter (Legan et al. Citation1973). PDP evaluated by Otterson and Arra (Citation1974) contained 7.1%–12.8% asbestos by weight. The asbestos content for one of the samples was not quantified, however, and the asbestos fiber type was not provided for any of the PDP samples (Otterson and Arra Citation1974).

Bakdash and Frydman (Citation1976) conducted a survey to identify the types of PDP used by dental professionals in the Minneapolis-St. Paul, Minnesota, area. The authors found that of 13 dentistry practices surveyed, six exclusively used PDP that contained asbestos (fiber type not specified), four used PDP that did not contain asbestos (for “environmental reasons” or “reasons unrelated to the presence of asbestos”), and the remaining three used a combination of asbestos- and non-asbestos-containing PDP (Bakdash and Frydman Citation1976, p. 62). On average, the practices using asbestos-containing PDP each used approximately 3600 g of powder per year. Three distinct PDP products were identified and were reported to have contained 3, 7.1, and 14.29% asbestos by weight; the authors calculated that at these percent by weight contents, a total of approximately 110, 255, or 510 g of asbestos, respectively, were used in these practices per year. The authors concluded that dental professionals using asbestos-containing PDP “may be exposed to considerable quantities of asbestos” and recommended various precautions, such as the use of surgical gloves and masks, not shaking the PDP prior to mixing, and mixing the powder in a well-ventilated area (Bakdash and Frydman Citation1976, p. 63).

Fulton et al. (Citation1989) reported that the PDP used in their animal toxicity study (described in further detail below) contained 7.1% “[s]hredded [a]sbestos” by weight, per the manufacturer (Fulton et al. Citation1989, p. 195). The authors identified the asbestos fibers as chrysotile using SEM with EDS.

Animal inhalation toxicity studies

No animal inhalation toxicity studies evaluating potential health effects associated with exposure to asbestos-containing CRL or investment material were identified. It should be noted, however, that inhalation exposure to chrysotile in animals has been extensively investigated (Agency for Toxic Substances and Disease Registry [ATSDR] Citation2001). Two studies were identified in which the potential toxicity of asbestos-containing PDP following inhalation was evaluated in animals.

PDP

Acute toxicity of PDP was assessed by exposing 18 male mice to PDP (concentration and asbestos fiber type unspecified) via inhalation by a particle nebulizer for approximately four minutes (n = 6 animals), eight minutes (n = 6), or 12 min (n = 6) on a daily basis for five days; the powder was not pulverized prior to initial exposure (Legan et al. Citation1973). No histopathological changes were observed on exposure days one, two, or three. A cellular response was observed on day four in all subgroups, and the response was “greater” on day five (Legan et al. Citation1973, p. 912). The histopathologic tissue response consisted of “marked hyperplastic change in the nuclei of the cellular walls of the small terminal ducts and bronchioles associated with small localized inflammatory exudates” (Legan et al. Citation1973, p. 913). The cellular changes were confined to the bronchiolar-alveolar epithelial cells and consisted of altered morphology and staining characteristics of enlarged hyperchromatic nuclei, increased nuclear-cytoplasmic ratio, and abnormal nuclear shapes and sizes, which were reported to all be “indicative of the dysplastic process” (Legan et al. Citation1973, p. 913).

Fulton et al. (Citation1989) exposed 72 mice to 11 g of nebulized asbestos-containing PDP (referred to by the authors as Periodontal Pack Powder, PPP) for 12 min, twice a week, for a maximum period of four weeks, followed by eight weeks of no exposure; an additional 50 animals were exposed to non-asbestos-containing PDP and 43 animals were utilized as non-exposed controls. The exposure chamber had a capacity of 61.8 L, resulting in an air concentration of 178 mg/m3 of PDP, which could have possibly resulted in lung overload among the treated animals, though Fulton et al. (Citation1989) did not explicitly report such an observation. The investigators observed early interstitial pneumonia in both treatment groups, as well as a generalized resolution of the pneumonia later on in the no exposure period. In the asbestos-exposed animals, residual diffuse interstitial fibrosis, persistence of asbestos fibers within tissue, and early asbestos body formation were noted. The investigators concluded that the asbestos contained within the PDP was respirable, and suggested that dentists who have used this product “should consider themselves to have been exposed to asbestos” (Fulton et al. Citation1989, p. 199).

Fiber release studies

One study, summarizing the results of four separate fiber release analyses involving the manipulation of asbestos-containing CRL, was identified. Studies evaluating asbestos fiber release potential of investment material or PDP were not identified.

CRL

Millette et al. (Citation2019) reported airborne fiber concentrations measured during various fiber release (i.e. sealed glovebox) studies. According to the authors, airborne fiber concentrations ranged from 0.33–4.0 f/cc by phase contrast microscopy (PCM), following TEM adjustment. It should be noted that the authors reported some samples as a range even though the samples were collected during the same sampling event. Thus, for the purpose of this assessment, we averaged the two reported airborne fiber concentrations (when reported as a range for an individual study), which resulted in an overall airborne fiber concentration range of 0.33–3.1 f/cc by PCM, following TEM adjustment ().

Table 4. Summary of glovebox fiber release data for casting ring liner.

It should be noted that the glovebox and handling practices used in these fiber release analyses are not representative of the occupational environment and practices typically associated with CRL material. Specifically, samples collected from a sealed glovebox measure the airborne fiber concentrations at the source of release, and not in the breathing zone of someone performing the task (i.e. glovebox studies are designed to produce maximum peak concentrations). Thus, the sealed gloveboxes used by Millette et al. (Citation2019) are not representative of a laboratory environment, as they do not necessarily account for ventilation rates, room size, or air movement. For example, the gloveboxes were reported to have a volume of 365 L (approximately 13 ft3), whereas exposure simulations (as described in the exposure studies detailed below) were conducted in room sizes, when reported, of up to approximately 1590 ft3 (Davis Citation1995), assuming a ceiling height of eight feet. The results of these glovebox fiber release analyses were, therefore, not considered in our current exposure assessment.

Exposure studies

A total of eight asbestos exposure studies involving CRL (n = 6) and PDP (n = 2) were identified. One exposure study regarding CRL use (Jung Citation2011) was written in Korean and was translated into English prior to inclusion in our analysis. There were no studies identified in which potential asbestos exposures associated with the use of investment material were evaluated.

CRL

Airborne fiber concentrations during the manipulation of asbestos-containing CRL are summarized in . One personal sample was collected during CRL placement over 60 min and one area sample was also collected during CRL placement over 480 min (Tulachka et al. Citation1987). Notably, no fibers were detected by SEM in either sample and results were reported as <0.01 f/cc. During combined tearing and placement of CRL, personal airborne fiber concentrations ranged from 0.061 f/cc (duration: 30 min) to 3.5 f/cc (duration: 3 min) by PCM for nine task-based samples and from 0.008 to 0.0251 f/cc by PCM (duration: 240–420 min) for three longer-term samples; area concentrations ranged from <0.07–0.7 f/cc by PCM (duration: 3–6 min) for five task-based samples and 0.005 f/cc (duration: 90 min) for two longer-term samples (Davis Citation1995; Millette Citation2005c; Compton and Millette Citation2010b, Citation2010d, Citation2011a, Citation2011c; Jung Citation2011; Millette et al. Citation2019; Sichletidis et al. Citation2009). It should be noted that the NIOSH 7400 PCM results for personal air concentrations reported by Millette et al. (Citation2019) were adjusted based on their NIOSH 7402 TEM results.

Table 5. Summary of exposure study data for casting ring liner – all tasks.

Finally, personal airborne fiber concentrations during dismantling, when sampling durations were reported, ranged from 0.0046–0.0067 f/cc, on average, by PCM (duration: 420 min), and one area concentration of <0.01 f/cc by SEM over 480 min was reported (Tulachka et al. Citation1987; Jung Citation2011).

Brune and Beltesbrekke (Citation1981) measured airborne fiber concentrations during the dismantling of dental molds associated with the gold casting process. Although the study was conducted in Norway, the authors noted that an asbestos-containing CRL from the U.S. was used. During the casting procedure, the CRL allowed for expansion of the investment material during heat treatment at approximately 850 °C (approximately 1600 °F). The authors reported that the CRL becomes “brittle” at this temperature (Brune and Beltesbrekke Citation1981, p. 113). Air samples were collected on a membrane filter placed approximately 30 cm away from the workpiece during and following mold dismantling, then analyzed by light microscopy. The authors reported that dismantling “may account for a time of about 5 min.”, although they did not specify the sampling duration (Brune and Beltesbrekke Citation1981, p. 115). It was noted that there was no access to local ventilation during the procedure. Concentrations of 21 and 27 f/cc were reportedly measured during two dismantling procedure events. According to the study, fiber concentrations declined to levels less than 2 f/cc approximately 10 min after the dismantling procedure ended. Because no further information was provided on the fiber counting protocol or sampling durations, it is not possible to compare these values to current or historical occupational exposure limits, or to health-based, no-effect levels for asbestos.

Tulachka et al. (Citation1987) measured the concentration of airborne fibers generated from ceramic ring liners during simulated dental laboratory conditions and used an asbestos-containing CRL as a “control liner” (Tulachka et al. Citation1987, p. 108). The CRLs were manipulated according to the manufacturers’ instructions and were in their “usual wet condition” (Tulachka et al. Citation1987, p. 110). A single strip of CRL measuring six inches by two inches was fitted to the casting ring using finger pressure for three minutes, and then the ring was filled with investment material. The ring was heat treated to 1400 °C (approximately 2600 °F), then “water-quenched” before the investment and CRL were broken into fragments (Tulachka et al. Citation1987, p. 108). This heat treatment temperature is much higher than the temperature range described previously. Air samples were collected using membrane filters and fibers were counted using an “optical microscope … according to the rules used by the Occupational Safety and Health Agency (OSHA) for monitoring asbestos” (Tulachka et al. Citation1987, p. 109). A high-volume pump collected personal air samples “adjacent to the work space” at a rate of 23 L/min for one hour during the placement procedure and for one hour during the breakout procedure (Tulachka et al. Citation1987, p. 109).

Additionally, area samples were collected with a low-volume pump at a rate of 2 L/min over an 8-h period. Samples found to contain fibers were further analyzed using SEM. The fiber concentrations reported in the study were from the SEM results only, not the optical microscopy results. Personal fiber concentrations of less than the analytical limit of detection (LOD), or <0.01 f/cc, were reported during asbestos CRL placement. No fibers were identified during the optical microscopy analysis of the personal breakout samples, so there was no SEM analysis and no further quantitative fiber concentrations reported for these samples. Area fiber concentrations of <0.01 f/cc were reported during placement and breakout. However, the authors noted that fibers were detected in the baseline samples prior to breakout, suggesting that residual fibers remained in the air from the placement task, which occurred the day prior, such that “one cannot conclude that the liner break-out actually produced fibers” (Tulachka et al. Citation1987, p. 110).

Davis (Citation1995) evaluated the concentration of asbestos fibers released into the air during manipulation of asbestos-containing CRL material for dental castings. For each of three 30-min sampling events, pieces of the dry CRL measuring approximately 90 mm long, 38 mm wide, and 0.6 mm thick were torn from rolls and manually adapted to the inside circumference of 10 metal casting rings. The CRLs were then removed and disposed of, and the process was repeated for a total of 30 min. During the first sampling event, 80 CRL manipulations were performed (referred to as “extreme manipulation” by the author); the number of manipulations performed in the second and third sampling events was not reported (Davis Citation1995, p. 297). The author noted that in a true laboratory environment, the CRLs would have been wetted after they were placed in the rings rather than subjected to further manipulation via removal and disposal. The simulation was reportedly conducted in a 3.9 m long by 4.8 m wide (approximately 18.7 m2) laboratory under poor ventilation conditions. Personal samples were collected at a flow rate of approximately 2.4 L/min and analyzed according to NIOSH 7400, A counting rules, as well as by TEM according to the EPA Interim Transmission Microscopy Method (1987), and by EDS. By PCM analysis, personal fiber concentrations were reported to range from 0.061 (± 0.044) to 0.092 (± 0.051 or 0.065) f/mL (i.e. f/cc). The author calculated 8-h TWA concentrations of 0.004–0.006 f/mL from these values. Furthermore, the author reported that in each of the three sampling events, the airborne fiber concentration associated with manipulation of a single CRL was 0.001 f/mL. When analyzed by TEM and EDS, the fibers in the three 30-min personal samples were identified as chrysotile in concentrations of 0.200 structures ≥5 µm/mL, 0.025 structures ≥5 µm/mL, and <0.025 structures ≥5 µm/mL. The author further noted that upon examination of all the breathing zone filters, only one of 28 contained a “true, free fiber” representing 3.6% of the total material (Davis Citation1995, p. 297). As such, a maximum value for fiber concentration “to maximally assess the potential risk of mesothelioma” was calculated to be 0.0005 f/mL. In addition, area samples were collected from “across the laboratory bench away from the investigator” at an unspecified distance (Davis Citation1995, p. 295). These samples were taken over 90 min prior to the start of the experiment and again for 90 min during the experiment at a flow rate of 10 L/min. By PCM, both area fiber concentrations were 0.005 (± 0.005 to 0.006) f/mL, and 8-h TWA concentrations of 0.001 f/mL were calculated by the author for both samples. It was therefore concluded that “the concentration of asbestos fibers generated was too low to present any reasonable risk for mesothelioma induction from the manipulation of asbestos ring-lining material used in a normal manner” (Davis Citation1995, p. 296–297).

Sichletidis et al. (Citation2009) performed an air sampling survey during the manipulation of dental tape (i.e., CRL) as part of the casting procedure. Air samples were collected on membrane filters and analyzed by PCM “as described by the Asbestos International Association/RTM 1” (Sichletidis et al. Citation2009, p. 929). An air pump operating at a flow rate of 1 L/min was set 15–20 cm above the work bench at approximate breathing level. The authors noted that “[t]he experiment took place in a room with approximately the same surface area (about 5 m2) as the dental laboratories used by the three dentists”, who were the subjects of the authors’ case series included in this study, which is described in greater detail below (Sichletidis et al. Citation2009, p. 928–929). There was reportedly no ventilation in the room. The authors stated that “[f]irst, pieces of paper that contained asbestos were torn from dental tape rolls and then placed into water; a mold was shaped using the mass of wet asbestos. The structure was dried out in a furnace. Then a piece of gold was put in the asbestos mold” with borax and subsequently burned out (Sichletidis et al. Citation2009, p. 929). The procedure was repeated continuously for four hours, representing the approximate time that dentists worked in their laboratories each day. The total number of CRL tears or molds produced, however, was not quantified. By PCM, airborne fiber concentrations were 0.008 f/cc during the 4-h sampling period. The authors noted, however, that “it is possible that the actual concentrations of fibers in the atmosphere of a small enclosed laboratory were greater than those achieved in [their] experiment of only 4 h” (Sichletidis et al. Citation2009, p. 930).

Jung (Citation2011) conducted air sampling in 10 dental laboratories across Daegu, South Korea, between December 2010 and January 2011. Air sampling and analysis were conducted according to NIOSH 7400. Briefly, air samples were collected on a 25-mm cellulose ester membrane filter using an open-face, three-piece cassette with an extension cowl. The pump was set to a flow rate of 1.7 L/min. Samples were collected on top of a workbench (approximately 1–1.5 m from floor) over a period of approximately seven hours, and were analyzed by PCM. The investigators collected a total of 40 air samples (four per site); however, only 32 of the 40 samples were collected during the use of asbestos-containing (fiber type not specified) CRL. Half of the samples (n = 16) were collected in a room during preparation in which the dental laboratory technician tore or cut CRL, inserted it inside a metal ring containing a wax model, and then filled in the ring with plaster, which was allowed to dry prior to being burned out in a furnace. The other half of the samples (n = 16) were collected in a second room where burnout and plaster removal occurred. It was estimated that burnout occurred one to two times per day on average, and two to four prosthetics were produced for each burnout. Average (geometric mean) airborne fiber concentrations ranged from 0.0162–0.0251 f/cc by PCM in the preparation room, and from 0.0046–0.0067 f/cc by PCM in the burnout room. It was noted that there was natural ventilation (i.e., windows), as well as local exhaust ventilation in the burnout room, which the authors hypothesized contributed to the lower air concentrations in the burnout room compared to the preparation room; ventilation in the preparation room was reportedly described as insufficient.

Millette et al. (Citation2019) reported the results of six separate chamber studies involving the handling, cutting/tearing, and placement of CRL into metal cylinders. Although the authors did not cite any of the unpublished reports upon which their analysis was based, we were able to identify all but one (the bulk analysis detailing sample ID 11081-AA1451) of these underlying reports (Compton and Millette Citation2010a, Citation2010b, Citation2010c, Citation2010d, Citation2011a, Citation2011b, Citation2011c, Citation2011d, Citation2011e, Citation2012; Millette Citation2004, Citation2005a, Citation2005b, Citation2005c, Citation2005d, Citation2008). Regarding the chamber studies detailed by Millette et al. (Citation2019), the authors did not report any of the area sample results for these experiments; however, these data were included in their unpublished reports, so we have chosen to present these data in our analysis and these results are detailed below. Further, Millette et al. (Citation2019) reported air concentrations as ranges in their published study; however, based on the respective underlying unpublished reports, these air samples do not appear to be independent samples, but rather samples that were collected simultaneously on both lapels of the individual performing the given task. We therefore averaged the two reported airborne fiber concentrations in our analysis whenever Millette et al. (Citation2019) presented them as a range.

Two of the chamber tests entailed the “wet press” of CRL after tearing (Millette et al. Citation2019, p. 103). The test chamber was approximately 9 feet high by 10 feet wide by 12 feet long, and had a HEPA-equipped device that was used to clean the area before the tests. The HEPA unit was also operational during the studies at a flow rate of 45 cubic feet per minute (CFM), which was equal to approximately 2.5 ACH. Personal air samples were collected on “standard” air filter cassettes at flow rates of 1–5 L/min, and were analyzed by PCM (NIOSH 7400) and TEM (NIOSH 7402); one air sample was also analyzed according to the AHERA TEM method (Millette et al. Citation2019, p. 105). Personal air concentrations ranged from 0.69–3.5 f/cc by PCM, following TEM adjustment (). It was noted that the “PCM fibers counted in the air samples contained primarily chrysotile asbestos with one exception. One tremolite asbestos bundle was found in one of the air sample[s] collected during [one of the tests]. This bundle was 5.7 µm long and 0.38 µm wide” (Millette et al. Citation2019, p. 107). Notably, however, in the underlying unpublished report in which this “tremolite asbestos bundle” was initially reported, Compton and Millette (Citation2010b) stated that this “bundle” was identified in the area sample collected while the tape was being torn. As noted, Millette et al. (Citation2019) made no reference to any area samples collected from the studies. In addition, one “bundle of tremolite asbestos fibers” was also reported to have been identified in an air sample by Compton and Millette (Citation2010d), though the investigators did not specify if this bundle was found in the personal samples or area sample; further, Millette et al. (Citation2019) did not report this bundle for this specific chamber study in their Table 1.

In the five underlying unpublished reports we identified in which the investigators reported the results from area sampling during the respective chamber studies, the area sample air concentrations ranged from <0.07–0.7 f/cc by PCM (duration: 3–6 min) (Compton and Millette Citation2010b, Citation2010d, Citation2011a, Citation2011c; Millette, Citation2005c).

PDP

Potential airborne asbestos exposure associated with PDP could occur when opening a bottle containing PDP, as well as during the mixing of PDP with liquid (Dyer Citation1967; Bakdash and Frydman Citation1976; Reid et al. Citation1991). However, potential asbestos exposure from opening bottles of PDP was not well characterized in the available literature. The available studies report that breathing zone fiber concentrations during mixing of PDP ranged from <0.0044–<0.297 f/cc by PCM, while area concentrations during mixing ranged from <0.0054–<0.396 f/cc by PCM (). None of the samples in any of the studies identified resulted in detectable fiber concentrations above the LOD.

Table 6. Summary of exposure study data† for periodontal dressing powder – all tasks.

Dyer (Citation1967) collected samples during the use of gingivectomy packs (i.e., PDP). Microscope slides covered in egg albumin were placed at table height and at breathing zone height (three feet above the table) in the pack mixing area. It was noted that a chairside assistant “usually shakes the bottle containing the dry constituents of the pack so that on opening the bottle a cloud of dust is emitted” (Dyer Citation1967, p. 507). The gingivectomy packs in this study were therefore prepared with and without shaking the bottle. An unspecified concentration of asbestos fibers was reportedly observed on slides at both heights, as well as with and without shaking of the bottle, “demonstrating that the distribution of asbestos fibre in air is not dependent on shaking the bottle” (Dyer Citation1967, p. 507). The method of asbestos fiber identification was not described. Further, additional slides were introduced five minutes after pack mixing had begun, and remained in place for an additional five minutes. Asbestos fibers were not observed on these slides. Dyer concluded that a dentist and his assistant may be exposed to “considerable quantities” of asbestos during a lifetime of practice and therefore suggested that the use of gingivectomy packs containing asbestos be discontinued (Dyer Citation1967, p. 507). Subsequent investigators commented on this study, noting that “this method of evaluation deviates from the sampling procedure being used by OSHA industrial hygienists” (Otterson and Arra Citation1974, p. 436).

Otterson and Arra (Citation1974), employees of the Section of Occupational Health and Section of Dental Health of the Wisconsin Division of Health, performed three studies to evaluate exposures to airborne asbestos fibers during the preparation of periodontal packs; two studies were performed at periodontists’ offices, and the third study was conducted at a dental assisting technical college. Samples were collected on open-face membrane filters at a flow rate of 2 L/min. Fibers greater than 5 µm in length were counted using PCM; it was noted that the sampling and analytical procedures were “in accordance with [the] method and practices specified by [OSHA]” (Otterson and Arra Citation1974, p. 436).

In the first dental office, the periodontal pack powder was mixed with a “small” amount of 2% thymol in eugenol into a ball of “putty-like” consistency, which was wrapped in plastic and stored for use throughout the week (Otterson and Arra Citation1974, p. 436). The powder reportedly contained approximately 13% asbestos by weight, and the task lasted approximately 30 min. Airborne concentrations of <0.0044 and <0.0063 f/cc were reported for the two personal samples collected during mixing of 28- and 20-min samples, respectively, while one ambient air sample collected from four feet behind the technician at breathing level for 23 min resulted in an airborne concentration of <0.0054 f/cc.

In the second office, powder containing 7.1% “[s]hredded” asbestos by weight was mixed with a “small” amount of 2% thymol in eugenol (Otterson and Arra Citation1974, p. 436–437). Mixing lasted four minutes and the product was prepared in the office “as needed” rather than in advance for the week (Otterson and Arra Citation1974, p. 436). An airborne fiber concentration of approximately <0.297 f/cc was reported for the 5-min personal sample during mixing. Additionally, one ambient air sample collected from four feet behind the technician during mixing (<0.396 f/cc) was collected for four minutes.

At the technical college, three students and the instructor each simultaneously mixed a “thimbleful” of powder of unspecified asbestos content “gradually” with a “few” drops of 2% thymol in eugenol (Otterson and Arra Citation1974, p. 437). It was noted that this task typically took four minutes, but the participants were asked to continue mixing for a “minimum of 15 minutes” in this simulation (Otterson and Arra Citation1974, p. 438). Fiber concentrations were reported as <0.070 (instructor’s breathing zone sample taken over 18 min) to <0.074 f/cc (three students’ breathing zone samples taken over 17 min each) for the four personal samples. One ambient air sample taken for 23 min resulted in a fiber concentration of <0.054 f/cc. For all three studies, “not one fiber” was detected on any of the filters (Otterson and Arra Citation1974, p. 437).

Otterson and Arra (Citation1974) concluded that the “mixing and kneading of the packs with a spatula and hands does not seem to be conducive to dispersing any detectable number of fibers into the laboratory air”, indicating that there was no potential hazard from airborne asbestos fibers when periodontal packs were prepared under conditions existing during these studies (Otterson and Arra Citation1974, p. 437). However, the authors ultimately recommended that unspecified precautionary measures be taken when using PDP.

Human health studies

Mesothelioma

No cases of death or disease in dentists or dental laboratory technicians from asbestosis, mesothelioma, or bronchogenic lung cancers induced by asbestos were reported in the literature as of 1987, according to a personal communication between Drs. Davis and Selikoff, although CRL containing chrysotile had been in use for approximately 50 years by this time (Davis Citation1986, Citation1987; Earnshaw Citation1988). Various epidemiological studies have evaluated cancer risk among dentists; mesothelioma was not a disease outcome of interest evaluated in any of these studies (Eriksson et al. Citation1998; Shimpo et al. Citation1998; Simning and van Wijngaarden Citation2007; Koifman et al. Citation2014). Interestingly, in a large-scale cohort study performed from 1961–2005 across five Nordic countries including 15 million people, four cases of mesothelioma (pleural and peritoneal combined) in male dentists (Standardized Incidence Ratio [SIR] = 0.37 [95% Confidence Interval (CI)=0.10 − 0.94]) among 13,539 male dentists (contributing a total of 191,711 person-years of observation), and two cases of mesothelioma in female dentists (SIR = 1.36 [95% CI = 0.16 − 4.92]) among 8,702 female dentists (contributing a total of 215,346 person-years of observation) were reported, but no significantly increased risk was found (Pukkala et al. Citation2009). Another cohort study evaluating cancer risk by occupation and socioeconomic status among Swiss men was conducted from 1980 to 1993 (Bouchardy et al. Citation2002). Out of 58,134 incident cases of cancer, 249 cases were classified as “dentists, veterinarians, and pharmacists”. While there were no cases of pleural mesothelioma or cancer of the pleura in this group, two cases of cancer of the peritoneum were observed, resulting in a non-significant odds ratio (OR) of 2.1 (95% CI = 0.5 − 8.8) after adjusting for registry, age, civil status, period of diagnosis, nationality, and type of habitat. Upon further adjustment for socioeconomic status, an OR of 3.1 (95% CI = 0.6 − 16.8), which was also not statistically significant, was calculated.

Upon review of the available literature, a total of 12 cases of mesothelioma in dental professionals and their relatives who used and/or were bystanders to the use of potentially asbestos-containing dental products were identified (Reid et al. Citation1991; Ogus and Bourne Citation2007; Fry Citation2008, Citation2009; Markowitz and Moline Citation2017; Mensi et al. Citation2017). These cases are described in detail in .

Table 7. Summary of mesothelioma case reports among asbestos-containing dental product users.

Lung cancer

Researchers have generally concluded that dentists are not at an increased risk of lung or respiratory cancer (Glass Citation1966; Hill and Harvey Citation1972; Blair et al. Citation1985; Sankila et al. Citation1990; Rix and Lynge Citation1996; Eriksson et al. Citation1998; Haldorsen et al. Citation2004; Simning and van Wijngaarden Citation2007; Pukkala et al. Citation2009; Koifman et al. Citation2014). One study of dentists in Tokyo (Shimpo et al. Citation1998) found that standardized mortality ratios (SMR) for lung, tracheal, and bronchial cancers in this worker population were higher than in the general population of Tokyo, but these differences were not statistically significant. Nishio et al. (Citation2004) concluded that male dentists in Japan did not have a significantly different risk for lung cancer than the general population. However, the authors did not control for smoking. Instead, they noted that their subjects likely had a lower smoking rate compared to the general population, such that the occupational lung cancer risk they calculated for dentists was underestimated.

In an additional study conducted in Los Angeles, California, the investigators reviewed 2,161 death certificates from 1968–1970 that mentioned lung cancer, as well as 1,777 incident cases of lung cancer from 1972–1973, in white males aged 20–64 (Menck and Henderson Citation1976). SMRs were calculated for various occupations; dental laboratory technicians were reported to have an excess risk of lung cancer (SMR = 405), whereas dentists were not (SMR= <70). Neither confidence intervals nor p-values were provided; as such, statistical significance could not be readily determined. The investigators reported that “[m]ost of the risk to lung cancer associated with the high risk occupations and industries … may be related to exposure to asbestos or polycyclic aromatic hydrocarbons (PAH) or both”; the authors noted that dental laboratory technicians specifically were thought to have been previously exposed to PAH (Menck and Henderson Citation1976, p. 799).

In the Swiss cancer incidence study conducted by Bouchardy et al. (Citation2002), 33 cases of lung cancer were observed among “dentists, veterinarians, and pharmacists”. The authors calculated a non-significant OR of 0.8 (95% CI = 0.5 − 1.2) after adjusting for registry, age, civil status, period of diagnosis, nationality, type of habitat, and socioeconomic status. However, a statistically significant decreased risk of lung cancer (OR = 0.4; 95% CI = 0.3 − 0.6; p < 0.001) was calculated after adjusting for registry, age, civil status, period of diagnosis, nationality, type of habitat, histological confirmation of tumor, and death certificate.

Furthermore, one case report of lung cancer in a dentist was identified in the literature. Sichletidis et al. (Citation2009) described the medical histories of three Greek men who had been employed as dentists for 35–45 years. All three dentists previously used asbestos-containing dental tape during regular casting operations and had no other reported asbestos exposures apart from the potential exposures they experienced as dentists. All three of these individuals had pleural plaques. One of the patients was also diagnosed with lung cancer. The authors hypothesized that the patient’s lung cancer “may be the result of synergic action of cigarette smoking with asbestos exposure” (Sichletidis et al. Citation2009, p. 930). This individual had a smoking history of 80 pack-years.

Nonmalignant respiratory disease (NMRD)

The prevalence of pneumoconiosis in domestic and international populations of dental laboratory technicians has been extensively characterized, and the generally increased risk of pneumoconiosis and decreased lung function observed in this worker population is thought to be caused by complex dust exposures to a variety of agents, including silica, metal alloys, acrylic plastics, asbestos, and alginate powders (Tuengerthal et al. Citation1983; Morgenroth et al. Citation1985; Loewen et al. Citation1988; Barrett et al. Citation1989; Sherson et al. Citation1990; Choudat et al. Citation1993; Choudat Citation1994; Selden et al. Citation1995; Choël et al. Citation1999; Froudarakis et al. Citation1999; Nayebzadeh et al. Citation1999; Radi et al. Citation2002; Kartaloglu et al. Citation2003).

Rom et al. (Citation1984) conducted a case-control study of 178 dental laboratory technicians and 69 controls in Utah; they identified eight cases of pneumoconiosis and found that this cohort also had decreased pulmonary function compared to a non-exposed group, after controlling for smoking status. The authors noted that the cases of pneumoconiosis may have been related to prior silica or non-precious metal alloy dust exposures. They also performed full-shift personal air sampling for nickel, chromium, cobalt, beryllium, silica, and methyl methacrylate in 42 dental laboratories. Although it was noted that the production of crowns and bridges using the “lost-wax” casting method was performed at these laboratories, the authors did not sample for any potential airborne asbestos concentrations (Rom et al. Citation1984).

Sherson et al. (Citation1988) performed a case-control study of 31 Danish dental laboratory technicians. The authors identified six cases of pneumoconiosis, and noted that the 13 technicians who fabricated any type of prostheses for at least 15 years had consistently lower lung function than controls, although these differences were not significant. Silica, beryllium, chromium, or cobalt exposures were hypothesized to be causative agents; asbestos was not mentioned as a possible cause. The authors further noted that four of the 31 technicians and one of the 30 controls had small opacities (≥category 1/0), indicating an increased relative risk in dental laboratory technicians for developing these opacities (Sherson et al. Citation1988).

Tuengerthal et al. (Citation1983) performed lung biopsies on 20 dental laboratory technicians. Interstitial fibrotic lesions characteristic of pneumoconiosis were observed in 20 workers, while “asbestos fibers” were identified by energy-dispersive X-ray spectroscopy (EDXA) in one individual (Tuengerthal et al. Citation1983, p. 1207).

De Vuyst et al. (Citation1986) identified two cases of pneumoconiosis in dental laboratory technicians. The first case was a 49-year-old man who worked as a dental laboratory technician from 1949–1982. It was noted that he had biapical pleural thickening, a 3.5 pack-year smoking history, and spontaneous pneumothorax, in addition to chromium-cobalt-molybdenum alloy, silicon carbide, and asbestos exposures. Regarding his use of asbestos, it was reported that he cut “asbestos foils to coat molds during casting operations”, and used these foils to protect furniture on which prosthetic parts were ground and soldered (De Vuyst et al. Citation1986, p. 316). Whether the “asbestos foils” referenced by De Vuyst et al. were asbestos-containing CRL materials was not clear. Analysis by light microscopy and SEM with EDS of this individual’s bronchoalveolar fluid (BAF) and lung tissue revealed 22–68 asbestos bodies/mL and 160 asbestos bodies/g of wet lung, respectively; ferruginous bodies were also observed in the fibrotic areas. The authors noted, however, that the asbestos bodies detected in the lung tissue corresponded “to a low concentration that appeared insufficient to provoke asbestosis” (De Vuyst et al. Citation1986, p. 316). The second case was a 30-year-old woman who worked in a dental laboratory from 1972 until 1979, during which she was exposed to chromium-cobalt-molybdenum alloy; she had no known contact with asbestos and had a 2 pack-year smoking history. No asbestos bodies were found in her BAF, and her lung tissue was not sampled.

In 1999, Nayebzadeh et al. reported a case of pneumoconiosis in a dental laboratory technician in Quebec, Canada. The 51-year-old male worked as a dental laboratory technician for approximately 30 years prior to his diagnosis, and did not have any other employments during his lifetime. Based on a lung burden analysis, chrysotile asbestos fibers, and silica, chromium-cobalt, clay, mica, iron, and aluminum particles were observed. No amphibole asbestos fibers were identified, nor was any formation of ferruginous bodies by PCM. The authors concluded that “[t]he concentration of [chrysotile] asbestos fibers indicates occupational exposure to asbestos fibers”, and noted that chrysotile asbestos-containing materials, including CRL, were used in dental laboratories in Quebec (Nayebzadeh et al. Citation1999, p. 351). However, the authors acknowledged that the use of CRL during casting “did not involve significant generation of dust from the asbestos sheet” (Nayebzadeh et al. Citation1999, p. 353). Yet, they did not provide any additional explanation for the presence of occupational levels of chrysotile in this patient’s lungs.

Kartaloglu et al. (Citation2003) also identified two cases of pneumoconiosis in dental laboratory technicians who each worked in a laboratory for eight years prior to their respective diagnoses. The authors noted that “the typical radiological appearance of asbestosis was absent and asbestos was not detected by mineralogical examination” (Kartaloglu et al. Citation2003, p. 172).

Other nonmalignant respiratory conditions apart from pneumoconiosis have also been described in dental professionals and their family members. Sichletidis et al. (Citation2009) described three cases of pleural plaques in Greek dentists. In addition to the lung cancer case reported by these authors, as noted above, a patient with obstructive lung disease was also identified. The authors attributed this patient’s lung disease to an extensive smoking history. In a case series published by Markowitz and Moline in 2017, two of the patients were diagnosed with pleural plaques and an additional two were diagnosed with pleural thickening (Markowitz and Moline Citation2017). Three cases of pleural thickening, as well as one case of fibrosis, were reported by Mensi et al. (Citation2017) in their case series. In a survey of 731 male and female Swedish dental laboratory technicians, 224 individuals reported experiencing respiratory tract irritation and reactions; the authors also identified one case of “pleuratic plaque”, which they attributed to asbestos exposure (Jacobsen et al. Citation1996, p. 140).

NOMS database search

The NOMS PMR Query System search indicated that the PMR for malignant neoplasms of the trachea, bronchus, and lung in medical, dental, and optical lab technicians was significantly (p < 0.05) elevated for white females aged 65–90 (PMR = 139; 95% CI: 110 − 175) and for white females aged 18–90 (PMR = 127; 95% CI: 105 − 152) from 1999, 2003–2004, and 2007–2014. The statistically significant findings for neoplasms of the trachea, bronchus, and lung were not adjusted for smoking status. In white male dentists, the PMR for malignant neoplasms of the trachea, bronchus, and lung was significantly (p < 0.01) decreased for all age groups and all time periods. Furthermore, the PMR for pneumoconioses in dentists was significantly (p < 0.01) decreased in white males aged 65–90 (PMR = 59; 95% CI: 38 − 87) and in white males aged 18–90 (PMR = 59; 95% CI: 38 − 86) from 1999, 2003–2004, and 2007–2014. Notably, the PMRs for mesothelioma and asbestosis in all occupations assessed (i.e., dentists; medical, dental, and optical lab technicians; dental hygienists; and dental assistants) for all time periods were not statistically significant, suggesting that these occupations are not at an increased risk of developing these diseases.

Exposure assessment

Personal and area (bystander) exposure scenarios were evaluated to characterize potential asbestos exposures generated during the typical use of asbestos-containing CRL and PDP. The number of years of product use for each profession were based on mean employment tenures as reported by Maguire (Citation1993) for dental assistants (5.4 years), dental hygienists (10.6 years), dental laboratory technicians (12.9 years), and dentists (15.1 years). When calculated, estimated 8-h TWA concentrations for CRL and PDP are presented in and , respectively. Cumulative asbestos exposure estimates are presented in .

Table 8. Cumulative exposure estimates for various dental professionals.

CRL – placement