ABSTRACT

This paper presents a comprehensive study on the integration of 3D printing technology in biomedical robotics education with undergraduate students learning about the design of robotic systems. The research investigated the effectiveness of this new teaching strategy in enhancing students’ understanding of complex engineering principles by comparing their learning experiences, and academic performance with results from traditional teaching methods. The students’ learning and performance were evaluated through a survey and grade analysis. The Mann – Whitney U test was used to analyse the data, revealing statistically significant improvements in both student satisfaction and grades. The Mann-Whitney U test results show a clear preference for the 2017 3D printing and project-based learning strategy over the 2016 traditional method. With a U-value of 0 and a critical U-value at p < 0.05 being 23, coupled with a z-score of −3.742, the data significantly indicates enhanced student outcomes with the newer teaching approach compared to conventional methods. The study also found that 3D printing technology fostered creativity, critical thinking, and enhanced spatial visualisation skills among students. However, we also identify potential challenges, including equipment maintenance, safety concerns, and the need for faculty expertise. The study concludes by providing potential strategies to overcome these challenges. This research offers valuable insights for educators and policy-makers in leveraging technology for improved learning outcomes in engineering education.

Introduction

Traditional pedagogical methods in engineering education rely heavily on theoretical lessons, two-dimensional diagrams, and infrequent physical models or labs. This approach is often abstract and doesn’t allow students to experience the practical side of engineering. Concepts can be challenging to visualise, hindering students from applying their knowledge in real-world scenarios. Additionally, due to the high cost of materials and equipment, hands-on experiences are scarce. Traditional manufacturing methods in engineering education can be costly and time-consuming, often requiring expensive tools, skilled labour, and significant manufacturing and prototyping time. This lack of practical engagement can limit students’ understanding of how different parts come together to form a functioning whole (Chen et al., Citation2021; Hadgraft & Kolmos, Citation2020; Hernández de Menéndez et al., Citation2019). Another issue with traditional pedagogy is that it offers little room for iterative design experiences, a key aspect of engineering. Resources are often limited, preventing students from testing and improving upon their designs. Furthermore, these methods assume that students learn at a uniform pace, neglecting the varied learning needs and paces among different individuals (Munir et al., Citation2018).

The introduction of 3D printing technology into the classroom has the potential to address these challenges. By turning abstract concepts into tangible models, 3D printing, a hands-on experience, allows for a more concrete understanding of theory and bridges the gap between theory and practice. For example, where previously students might only engage with complex engineering systems theoretically or through observing pre-built models, they can now construct and interact with their own models, like building a scaled-down engine or a section of a mechanical joint. This shift from observation to active creation makes it easier for students to visualise how components interact within a system (Song, Citation2018). It’s a relatively affordable technology that facilitates active learning. Students can design, print, and test their own models, deepening their understanding of engineering principles (Şen et al., Citation2020).

The technology promotes iterative design as well. With 3D printing, students can readily create and then modify their designs, learning from their mistakes, and improving their work – an integral part of the engineering practice. Additionally, students can work at their own pace, spending more time on complex concepts, and advancing swiftly on topics they grasp easily (Capel et al., Citation2018). Lastly, 3D printing allows for rapid prototyping and testing. Students can quickly turn their designs into prototypes, testing them for functionality, durability, and effectiveness. Overall, the introduction of 3D printing in engineering education has the potential to revolutionise the field by providing experiential learning opportunities (Assante et al., Citation2020).

A critical literature review regarding the use of 3D printing in engineering education shows both its positive impacts and potential limitations. Many studies showed positive impacts. For example, Huang and Lin (Citation2017), and Besançon et al. (Citation2021) highlighted how 3D printing enhanced spatial visualisation skills. Szymanski (Citation2018), and Trust and Maloy (Citation2017) emphasised how 3D printing fostered creativity, innovation, and critical thinking as students designed prototypes and iterated improvements. Pearson and Dubé (Citation2022), and Maynard et al. (Citation2021) underscored how students applied theoretical concepts to real-world situations. Furthermore, Long and Davis (Citation2017), and Garrick et al. (Citation2017) revealed that the adaptability of 3D printing provided opportunities for differentiated instruction, catering to various learning paces and styles.

Despite these advantages, certain limitations and challenges exist. Hossain et al. (Citation2020), and Inoma et al. (Citation2020) discussed the high initial high costs of 3D printing hardware, software, and materials, straining institutional resources. Another concern raised by Ngo et al. (Citation2018) involved the steep learning curve for lecturers associated with the operation and maintenance of 3D printers, potentially causing delays and frustrations among students and educators. Ngo et al. (Citation2018), and Novak et al. (Citation2021) highlighted another potential problem, the limited diversity of materials available for 3D printing, restricting the range of possible projects. Finally, Mikula et al. (Citation2021), and Bhagia et al. (Citation2021) pointed out the environmental and health concerns related to 3D printing, such as emissions from certain types of 3D printers and the disposal of non-biodegradable materials. Despite the identified limitations, the overall consensus indicated a positive impact of 3D printing on engineering education.

The primary objective of this article is to evaluate how 3D printing, coupled with a project-based learning approach, can aid learners’ comprehension of complex concepts in the design and creation of biomedical robotics systems, gauging this through comparative student surveys and grade analysis. The article presents challenges and suggests potential solutions and strategies to overcome them. It is hoped that the findings will guide educators in integrating 3D printing technology into biomedical robotics education effectively, and foster future research in this area.

Theoretical framework and pertinent learning theories

Several theoretical frameworks and theories can be applied to analyse the role of 3D printing in engineering education such as Constructivism, Experiential Learning, TPACK (Technological Pedagogical Content Knowledge) Framework, Active Learning Theory and Situated Learning Theory. We discuss each of these next.

Constructivism asserts that learners build their own understanding and knowledge through direct experiences and subsequent reflection on those experiences. It emphasises active learning as opposed to being passive recipients of information (Gordon, Citation2009; Seaman, Citation2008). This theory suggests that biomedical engineering students can more effectively comprehend engineering principles by actively engaging in the creation and modification of 3D models. For example, students studying the principles of robotic prosthetics design can move from theoretical textbooks or lectures to use 3D printing to design and create their own prosthetic models, getting practical experience of joint articulation, weight distribution, or materials’ strength. As students design, create, and manipulate these 3D models, they are essentially involved in a constructivist learning process. This active learning process makes the abstract concepts more concrete, fostering a deeper understanding. Furthermore, students learn as their designs fail or succeed, reflecting and refining their understanding of the underlying principles through real-world experiences.

Experiential Learning theory emphasises the role of direct experience in the learning process, typically defined by a four-stage learning cycle: Concrete Experience, Reflective Observation, Abstract Conceptualisation, and Active Experimentation (Fry & Kolb, Citation1979; Kolb, Citation1976). For example, there is concrete experience designing a robotic prosthetic limb; reflective observation leading to abstract conceptualisation, and active experimentation as newfound understanding leads to improving their original design and 3D print of a revised model. This hands-on, iterative learning process fosters critical thinking and problem-solving skills, invaluable for aspiring engineers.

The Technological Pedagogical Content Knowledge (TPACK) framework is apt for 3D printing into biomedical robotics education (Kessler et al., Citation2017). For instance, an educator could devise a project where students design and 3D print a prosthetic limb, allowing them to apply biomedical robotics principles directly (CK), engage in experiential learning (PK), and gain firsthand experience with 3D printing technology (TK). This intersection of the three domains creates an enriching, holistic learning experience, showcasing the practical application of the TPACK framework in biomedical robotics education.

Active Learning Theory advocates that active learning is more effective than passive (Fernando & Marikar, Citation2017). 3D printing demands active learning. A hands-on design and print project necessitates active research into anatomy, use of design software for 3D modelling, and careful oversight of the 3D printing process. Through this experiential learning, students gain a deeper understanding of the body’s complexities but also of biomedical robotics. Bioengineering learners actively confront and resolve issues, developing problem-solving skills and critical thinking.

Situated Learning Theory emphasises that learning is more effective when it is contextual and applied in real-life situations (Chiou, Citation2020; Choi & Hannafin, Citation1995). Students are situated within real-life learning when they design and print 3D prototypes of medical devices. In doing so, they are immersed directly in the practical aspects of biomedical engineering. They grapple with real-world constraints and considerations such as material choice, balance, durability, and user comfort.

Case study

This article presents a case study from the University of Wollongong, Australia, focusing on a 15-credit biomedical robotics course, offered as an elective to fourth-year Mechanical and Mechatronics Engineering students in 2016 and 2017. It should be duly noted that the conventional teaching methodology was employed in 2016, while the 3D printing instructional approach was adopted in 2017. In 2016 there were 47 students enrolled in the biomedical robotics course, while in 2017 the number of enrolled students increased to 53. The course combined weekly lectures and lab sessions facilitated through SolidWorks software. After initial learning, a nine-week group project was assigned, with a report submission in the 13th week. Group sizes were limited to two members to minimise interaction issues, following Caulfield and Caroline (Citation2006)‘s recommendations.

Problem statement

While engineering curricula have made significant strides in adopting experiential learning strategies, students continue to face challenges in comprehending and applying complex 3D concepts, especially in courses like biomedical robotics. Traditional methods of instruction involving mechanical workshops have proven to be labour-intensive, somewhat limited in their capacity to create intricate 3D components, and less effective in promoting a deep understanding of the design principles behind the constructed devices.

Case description

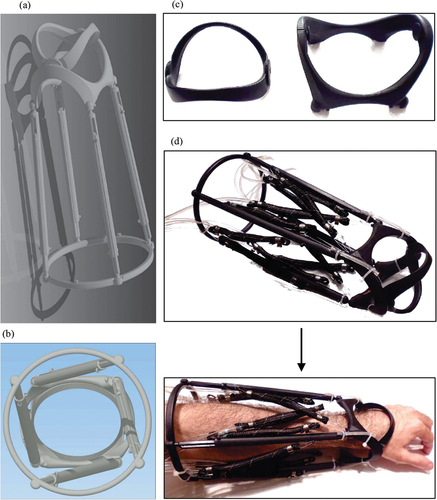

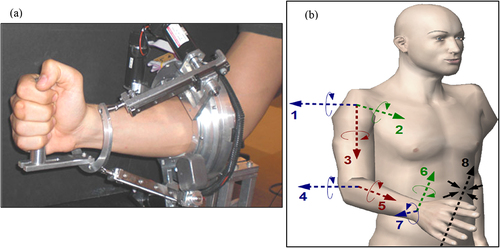

In this study, as part of the biomedical robotics course, students were assigned a project to design a wearable robotic device intended for wrist rehabilitation using 3D printing technology, as seen in . illustrates the degrees of freedom inherent in the human upper limb.

Figure 1. Wrist limb rehabilitation, (a) wearable robotic device for wrist rehabilitation (Pehlivan et al., Citation2014), (b) degrees of freedom in human body upper limb.

In the traditional approach of 2016, students designed a wrist rehabilitation robot in SolidWorks, providing three degrees of freedom – flexion/extension, pronation/supination, and ulnar/radial deviation – for patients with neurological impairments (). The simulated Computer Aided Design (CAD) designs were given to workshop technicians for aluminium prototype production using various machinery. Students assembled the fabricated parts provided. The 2017 course maintained the project’s essence but enhanced its execution. Students initiated their design in SolidWorks () and ran simulations (), then converted their designs into 3D printer-compatible files. These files were 3D printed using a ProJet HD 3500 Plus printer and carbon polymeric composites (). Students assembled these parts and used Pneumatic Muscle Actuators (PMAs) to power the robot. PMAs, a modern, lightweight actuator type, simulate skeletal muscles and provide unidirectional pulling forces used in pairs for a single degrees of freedom (DOF). An assembled prototype is displayed in .

Data collection and statistical analysis methods

Data for this study was collected through student surveys and grade data. Anonymous surveys, conducted twice in each semester (weeks 7 and 14) evaluated the traditional method in 2016 and the new teaching method in 2017, so gathered students’ feedback on both methods. The entire student cohort, 47 in 2016 and 53 in 2017, participated in both surveys, conducted after ethical approval from the Social Sciences Human Research Ethics Committee. Each survey consisted of five questions (detailed in ) with three possible responses to gauge satisfaction levels with the pedagogy used in the courses: a) agreed (A), b) neutral (N), c) disagreed (DA). It is noteworthy that students had the option to opt out at any time.

Table 1. Survey questions and responses for evaluating traditional teaching efficacy.

Table 2. Survey questions and response choices for assessing the impact of 3D printing in the course.

The set of questions employed for both surveys in 2016, during the implementation of the traditional teaching method, were alike. Similarly, the 2017 survey, designed to assess the effectiveness of the proposed teaching strategy, employed comparable questions. The only distinguishing factor between the two years’ courses was the teaching methodology mentioned.

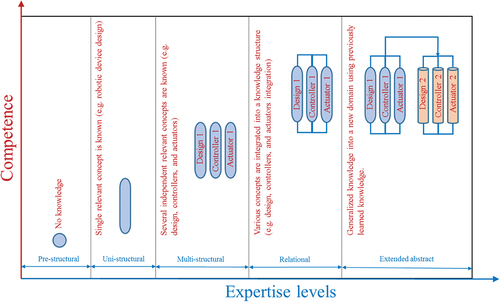

To assess students’ performance across both teaching methods, the SOLO taxonomy was employed, allowing for a hierarchical understanding of students’ learning from basic to complex tasks. It divides students’ understanding into five levels: pre-structural, uni-structural, multi-structural, relational, and extended abstract, as shown in and detailed by Biggs and Collis (Citation2014).

Figure 3. SOLO taxonomy framework for assessing student evaluations (Biggs & Collis, Citation2014).

The teacher’s objective was for most students to reach all five SOLO taxonomy levels; hence the course’s learning outcomes, project-based learning activities, and assessment were constructively aligned and students were briefed on this aspect of course design in the project description statement.

A statistical Mann-Whitney test compared the two independent student groups (2016 and 2017). Non-parametric statistical tests are often employed for qualitative data or questionnaire analysis, as they don’t assume any specific data distribution, making them distribution-independent. The Mann-Whitney test, an alternative to the independent t-test for non-parametric data, operates by ranking data, with the lowest score ranked ‘1’, the next lowest ranked ‘2’, and the highest 3. It works on the assumption that the sum of ranks of evaluations should be comparable if the two compared groups originate from the same population. The ultimate goal is to compute a statistic, U, using the following steps:

Label the sample with the smaller ranks as ‘Sample 1’ and the other as ‘Sample 2’.

For every observation in Sample 1, determine the number of observations in Sample 2 with a lower rank (assigning half numbers for equal ranks), and the sum of these forms the statistic U.

Results and discussion

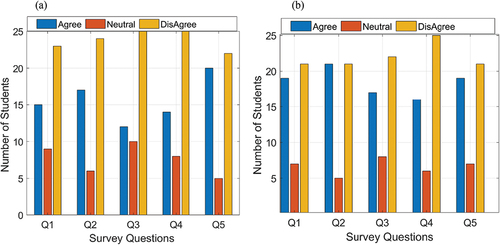

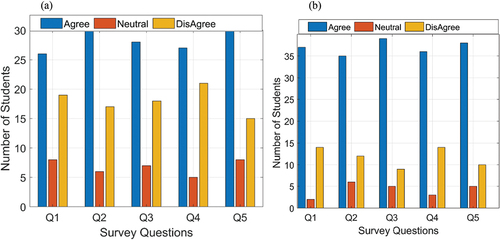

presents the distribution of students’ responses to survey questions, with data displayed as a count of student responses. For clarity, provides the same data as percentages. Initial analysis focuses on comparing data within the same year, with showing a 2–10% increase in student agreement with the proposed teaching pedagogy after the mid-term exam and a 2–7% decrease in disagreement. Despite these changes, they may not be statistically significant and warrant further scrutiny. However, when comparing responses between different academic years, the ‘percentage of students agreeing’ clearly improves. shows that the proposed method elicited more agreement and less disagreement in 2017 compared to the traditional method in 2016.

Table 3. Distribution of responses to student survey questions.

Table 4. Distribution of the number of students who agreed and disagreed.

Visualisation of the survey data through bar charts, as in for Survey-I results, reveal similar trends in student agreement or disagreement before the mid-term and final exams. , presenting results from Survey-II conducted before the mid-term exam in 2017, shows an increase in student agreement with the 2017 teaching strategy compared to 2016’s survey. Concurrently, in 2017 there is a significant decrease in disagreement evident in . Further, comparing Survey-II results in shows an up to 10% increase in agreement with the project-based approach after the first survey in 2017. Despite having limited knowledge about the course transformation and execution, there was an up to 15% increase in student agreement with the proposed teaching approach. This percentage further increased in the survey conducted before the final exam in 2017.

Figure 4. Distribution of responses from survey I prior to the mid-term exam (a), and prior to the final exam (b).

Figure 5. Distribution of responses from survey II conducted prior to the mid-term exam (a), and prior to the final exam (b).

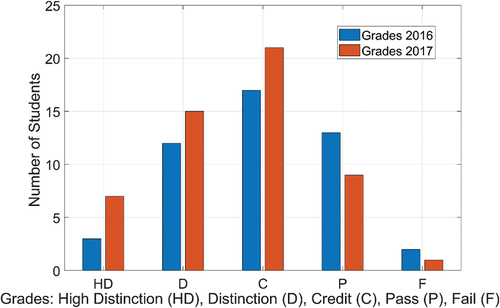

The students’ grades, as per the Australian grading system, were documented and presented in for further evaluation.

Table 5. Student’s scores and their dispersion.

The grade data is further depicted in bar charts for enhanced clarity and analysis, . Observations from these visuals allow us to draw conclusions about the grade distribution across the two years under study. The rise in students’ interest in the course, spurred by the new teaching strategy, led to an elevation in grades. The noticeable increase in the count of the top three evaluation grades in 2017, compared to the figures from 2016, can be clearly seen in .

Survey outcomes can be initially examined using frequency or cross tables (). Yet, the impact of an intervention, here the incorporation of 3D printing, can only be determined through suitable statistical analysis. Given the small and non-normally distributed dataset in this case, a non-parametric test is a superior choice. These tests are typically more apt for questionnaire and qualitative data. Literature lists several such tests including Chi-Square, Spearman’s correlation, Wilcoxon, and Mann-Whitney U test among others (Sharpe, Citation2015; Tallarida et al., Citation1987). The Mann-Whitney U test, a substitute for the independent t-test, is suitable here our intention to observe differences due to changed teaching methods. Data from both years, 2016 and 2017, were compared. Due to the challenge in comparing qualitative survey data, it was resolved to compare the count of students agreeing to the surveys pre and post-intervention (introduction of 3D printing and project-based learning).

The Mann-Whitney U test results () clearly demonstrate that students agreed with the 2017 teaching strategy (3D printing and project-based learning combo) more than they agreed with the 2016 traditional method. The U-value is 0, signifying all data points from 2017 were higher than those from the prior year. The critical U-value at p < 0.05 is 23, indicating a significant data difference at p < 0.05. The z-score of −3.74185, leading to a two-sided p-value of 0.00018, further indicates this. This provides robust evidence that the integration of 3D printing technology with project-based learning has positively impacted both student learning and grades compared to the conventional teaching approach, which involves mechanical workshops and traditional lectures.

Table 6. Results from the Mann-Whitney U test.

This enhancement could be attributed to the user-friendly nature of 3D printing technology, its ability to improve the understanding of the visual mechanics of robotic devices, the prospect of learning a market-demanded technology, and reduced reliance on technical workshop staff, potentially shortening project completion times. This is similar to the findings reported by Besançon et al. (Citation2021), and Szymanski (Citation2018).

Case study findings and interpretations

In this case study, a fusion of 3D printing technology with a project-based learning method was utilised to assist biomedical robotics students in comprehending intricate robotic system design concepts. The data gathered through student surveys and grade assessments revealed that the novel teaching strategy outperformed the traditional pedagogical approach. The students expressed more satisfaction with their learning experience under this new methodology, which also resulted in improved grades compared to the conventional teaching system. The statistically significant outcomes, as demonstrated by the Mann-Whitney U test results, bolster these findings. The insights gleaned from this study may serve as a valuable resource for engineering educators seeking to harness technology and project-based learning more effectively to boost student engagement, critical thinking, problem-solving skills, and overall learning.

The findings of this study echo and corroborate the beneficial effects of 3D printing on engineering education, as previously reported in Section 1 by Trust and Maloy (Citation2017), Maynard et al. (Citation2021), and Pearson and Dubé (Citation2022).

Challenges and possible solutions

In making the change to include 3D printing, we were fortunate in having a team with the various expertise needed, funding and institutional support. However, being aware of what we needed to set up, we elucidate the major hurdles experienced throughout the implementation of 3D printing and the methods adopted to overcome them. We suggest at the same time that taking a cohort of students through these challenges enhances their learning experience – we found that explaining how to set up was another benefit of the change because it showed the practicalities of bioengineering.

Technical and logistical challenges

Equipment maintenance and troubleshooting

We realised from experience that maintenance and troubleshooting of 3D printers play a pivotal role in biomedical robotics (Shahrubudin et al., Citation2020). Regular cleaning and maintenance of the printer, from the nozzles to the build plates, routine calibration process enabled the accuracy demanded of biomedical robotics, whether it be printing a prosthetic limb or a surgical tool. Calibration checks for axis movements, bed levelling, and extruder feed rate are therefore integral to the process. Someone with proficiency in handling the slicing software is necessary to prevent design file misinterpretations of design files leading to print errors. Similarly, a hardware troubleshooter is needed to deal with a clogged extruder or issues with the heating bed. A teaching team that included combined knowledge of mechanical and electronic components aids was able to resolve these issues swiftly.

Ensuring safe use of 3D printers

The inherent heat involved in 3D printing processes presents burn hazards, mitigated by proper safety training and automated shut-off mechanisms. Ultrafine particles and volatile organic compounds during printing necessitates sufficient workspace ventilation or air filtration systems (Bharti & Singh, Citation2017; Randolph, Citation2018). When it comes to the creation of biomedical robotics components, safety extends to the safety of the end product, avoiding sharp edges. Adherence to safe handling, storage, and usage guidelines of biomedical is imperative. In sum, comprehensive safety training is needed, with the benefit that graduates have higher awareness of how to approach practice.

Sourcing materials and managing waste

Sourcing materials and managing waste are crucial aspects to manage in the biomedical 3D printing (Ngo et al., Citation2018). For instance, materials like polylactic acid (PLA) or Acrylonitrile Butadiene Styrene (ABS) filaments demand strategic procurement and supply chain management (Manoj et al., Citation2021). A reliable supply of such materials is necessary. Moreover, misprints waste, support structures, and leftover filaments need appropriate disposal or recycling measures. Furthermore, the type of material used can present potential environmental and health concerns. Thus, efficient strategies for material sourcing and waste management can contribute to a safer, more productive, and eco-friendly learning environment.

Focus on developing cost-effective 3D printing solutions

Bulk purchasing of printing materials can lead to substantial cost reductions as suppliers often offer volume discounts. Reusing or recycling failed prints and excess material decreases spending on new materials. Regular maintenance of 3D printers prevents expensive repairs, while advanced slicing software can minimise material usage and enhance print speed. A print-on-demand approach reduces storage costs and stock waste. Look for educational discounts on printers and materials. Opt for cost-effective materials like PLA over ABS or specialised materials when possible (Liaw & Guvendiren, Citation2017). Simultaneously, progress in open-source 3D printing technology seen in initiatives like the RepRap project can cut costs (Arnott, Citation2008). Lastly, sharing a central 3D printing facility across different departments can decrease departmental costs.

Recent technological advancements in 3D printing

Recent advancements in 3D printing, particularly over the last decade, have greatly impacted biomedical robotics education. Modern printers offer faster, more detailed outputs, crucial for intricate biomedical projects. The availability of new biocompatible materials has broadened project possibilities, enhancing both safety and applicability. The integration of AI into design software has streamlined the prototyping process, reducing errors and improving efficiency. This progress has enhanced not only the technical skills of students but also their creative and analytical abilities, better preparing them for the demands of the biomedical field (Bozkurt & Karayel, Citation2021).

Pedagogical and institutional challenges

Resistance to Change in Teaching Practices

Many educators may be reluctant to adopt innovative approaches due to concerns over the time and effort required to learn new skills. Furthermore, there may be scepticism regarding the pedagogical value of these new techniques compared to the challenges of change (Branko et al., Citation2023). Institutional support is crucial. By sharing success stories such as ours, educators have evidence of the benefits of 3D printing in enhancing biomedical learning experiences (Love et al., Citation2022).

Need for faculty training and support

Faculty training would help educators to master the operation of 3D printing equipment and incorporate the technology into teaching practices to maximise its learning potential. To ensure the seamless adoption of 3D printing, institutions should have a dedicated support team with regular updates on the latest advancements in 3D printing technology (Pearson & Dubé, Citation2022).

Integrating 3D printing projects into grading and assessment frameworks

Traditional exams or tests may not fully capture the skills developed during these hands-on projects, such as practical application of theory, problem-solving, or teamwork. This includes factors such as originality of design, functionality of the end product, the application of biomechanics principles, and troubleshooting skills during the print process. Furthermore, the grading framework could reward critical thinking, creativity, and good collaboration. The challenge lies in developing an assessment rubric that can effectively measure these skills, ensuring that the educational benefits of 3D printing are fully recognised and appreciated in the overall grading (Zhou et al., Citation2022).

Potential solutions and strategies

Effective planning and resource allocation

Effectively incorporating 3D printing into biomedical robotics education necessitates thorough planning and efficient resource allocation. That involves a comprehensive assessment of the financial cost and sufficient time within the curriculum. For example, where students are tasked with designing and 3D printing a scale model of a robotic surgical instrument, educators need to account for the cost of 3D printers, software licences, and printing materials in the course budget. They have to allot class time to teach 3D printing skills, design process, and any technical issues that emerge. Arrangements must also be made for students to access 3D printers outside of class hours. It is important to provide a suitable workspace accommodates multiple student groups working concurrently. The project timeline should be planned with buffers to account for potential technical issues or unforeseen learning hurdles.

Collaboration between faculty, administrators, and technical staff

The successful integration of 3D printing into biomedical robotics education necessitates a robust collaboration among faculty, administrators, and technical staff. Faculty members drive the pedagogical side, administrators ensure appropriate resource staff allocation for maintaining 3D printing equipment and supplying the necessary materials, and technical staff with expertise keep the 3D printers operational. This collaborative synergy sparks creativity and innovation, as ideas from different stakeholders converge.

Continuous evaluation and improvement

Continuous evaluation and improvement are vital. This entails a consistent review and refinement of teaching methods, technological resources, and learning outcomes. Instructors can collect student feedback to evaluate the role of 3D printing in understanding complex robotics concepts, learning from student experiences. In tandem, educators and technical staff can examine the efficiency and maintenance of the 3D printers, potentially optimising operational settings or considering new printer models. Periodic assessments also allow for adjustments in educational objectives and curricula to maximise the use of 3D printing technology in enhancing biomedical robotics education.

Conclusions and future research directions

This study gives empirical evidence from student surveys and grade data that incorporating 3D printing technology and project-based learning in biomedical robotics education has demonstrably enriched student understanding of intricate engineering concepts, ultimately leading to improved academic performance. In our case study, with the integration of 3D printing and project-based learning, students were empowered to create a physical prototype of their designs. This allowed them to tangibly experiment with their devices, make necessary modifications based on their tests and, in the process, gain a profound understanding of the mechanical, electrical, and software components that are integral to biomedical robotics. The 3D printed prototypes provided the students with the ability to visualise and comprehend the spatial aspects of the design, facilitating better grasp over intricate details. They were also able to observe the direct impact of theoretical principles on the functioning of their designs, helping to solidify their conceptual knowledge.

However, advice to readers comes from understanding gained from our experience: positive outcomes were achieved, but the study also encountered challenges, including equipment maintenance, ensuring safe usage of the 3D printers, resource management, and some resistance to change. The experiences and findings from this study offer valuable insights for educators and academic institutions looking to incorporate innovative technologies like 3D printing in their curriculum to foster experiential learning and improve educational outcomes.

Looking ahead, several research directions emerge from this study to further explore the role of 3D printing in biomedical robotics education.

Expanded Application Scenarios: This study primarily focused on the design aspect of biomedical robotics. Future research could explore additional applications, such as using 3D printing for creating patient-specific anatomical models for preoperative planning or training medical professionals. For example, 3D printed models of complex anatomical structures or pathological conditions could offer students more practical, hands-on experience in understanding and tackling real-world biomedical challenges.

Longitudinal Studies: The current study was short-term in nature. Longitudinal studies could provide insights into the long-term effects of the integration of 3D printing and project-based learning on student performance, retention of knowledge, and career choices in the field of biomedical robotics.

Comparative Studies: Future research could involve comparative studies across different institutions or countries to understand the broader impact and challenges of integrating 3D printing in engineering education.

Exploring Other Innovative Technologies: While this study focused on 3D printing, future research could investigate other emerging technologies like virtual reality, augmented reality, or machine learning in biomedical robotics education.

Assessing Impact on Soft Skills: This study focused on the impact of 3D printing on students’ understanding of engineering principles and academic performance. However, future research could also explore how the integration of 3D printing and project-based learning can foster other important skills, like teamwork, problem-solving, creativity, and critical thinking, which are crucial in the real-world biomedical robotics industry.

Policy and Curriculum Development: Given the positive impacts observed, future research could focus on how to optimally integrate 3D printing into existing curricula and the policies required to support such technological incorporation at an institutional level.

Such studies would help ongoing development of best practices and strategies for effective teaching and learning.

Acknowledgments

The authors would like to express their sincere gratitude to the University of Wollongong, the University of Canberra Australia, Nazarbayev University Kazakhstan, the University of Auckland New Zealand, and the American University of the Middle East Kuwait for their invaluable support.

Disclosure statement

No potential conflict of interest was reported by the author(s).

Additional information

Notes on contributors

Muhammad Tajammal Munir

Muhammad Tajammal Munir is an Associate Professor in Chemical Engineering at the American University of the Middle East, Kuwait. Specialising in sustainable waste management, he has published over 80 journal articles and secured significant research funding. He holds a PhD from the University of Auckland and is noted in Stanford’s Top 2% Scientists list.

Prashant K. Jamwal

Prashant Jamwal is an Associate Professor at Nazarbayev University, specialising in robotics and rehabilitation systems. His work focuses on developing intelligent robotic aids for gait rehabilitation and modelling the human musculoskeletal system. He collaborates internationally, contributing significantly to robotic engineering and rehabilitation technologies.

Bing Li

Bing Li is an Associate Professor at Tsinghua University’s Shenzhen International Graduate School, specialising in nutrient management and recovery. He holds a PhD from the University of Auckland and develops thermodynamic models for phosphorus recovery technologies. He is a registered engineer and reviews for top journals.

Susan Carter

Susan Carter is an honorary associate professor at the University of Auckland, specialising in doctoral education. She focuses on the dynamics of doctoral writing feedback, emphasising effective communication and emotional management in academic supervision. Her work is pivotal in shaping feedback mechanisms that enhance doctoral writing capabilities.

Shahid Hussain

Shahid Hussain is an Associate Professor of Biomedical Robotics at the University of Canberra. Previously a lecturer at the University of Wollongong, Australia, he earned his PhD in Mechanical Engineering from the University of Auckland in 2013. Specialising in assistive and rehabilitation robotics, his research covers human-robot interaction, biomechanical modelling, and MEMS, with over 74 published papers.

References

- Arnott, R. (2008). The RepRap project—open source meets 3D printing. Computer and Information Science Seminar Series.

- Assante, D., Cennamo, G. M., & Placidi, L. (2020, April 27-30). 3D printing in education: A European perspective. 2020 IEEE Global Engineering Education Conference (EDUCON), IEEE, Porto, Portugal.

- Besançon, L., Ynnerman, A., Keefe, D. F., Yu, L., & Isenberg, T. (2021). The state of the art of spatial interfaces for 3D visualization. Computer Graphics Forum, Wiley Online Library.

- Bhagia, S., Bornani, K., Agrawal, R., Satlewal, A., Ďurkovič, J., Lagaňa, R., Bhagia, M., Yoo, C. G., Zhao, X., Kunc, V., Pu, Y., Ozcan, S., & Ragauskas, A. J. (2021). Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Applied Materials Today, 24, 101078. https://doi.org/10.1016/j.apmt.2021.101078

- Bharti, N., & Singh, S. (2017). Three-dimensional (3D) printers in libraries: Perspective and preliminary safety analysis. Journal of Chemical Education, 94(7), 879–885. https://doi.org/10.1021/acs.jchemed.6b00745

- Biggs, J. B., & Collis, K. F. (2014). Evaluating the quality of learning: The SOLO taxonomy (structure of the observed learning Outcome). Academic Press.

- Bozkurt, Y., & Karayel, E. (2021). 3D printing technology; methods, biomedical applications, future opportunities and trends. Journal of Materials Research and Technology, 14, 1430–1450. https://doi.org/10.1016/j.jmrt.2021.07.050

- Branko, A., Šorgo, A., Helm, C., Weinhandl, R., & Lang, V. (2023). Exploring factors affecting elementary school teachers’ adoption of 3D printers in teaching. Tech Trends, 67(6), 990–1006. https://doi.org/10.1007/s11528-023-00909-y

- Capel, A. J., Rimington, R. P., Lewis, M. P., & Christie, S. D. (2018). 3D printing for chemical, pharmaceutical and biological applications. Nature Reviews Chemistry, 2(12), 422–436. https://doi.org/10.1038/s41570-018-0058-y

- Caulfield, S. L., & Caroline, H. P. (2006). Teaching social science reasoning and quantitative literacy: The role of collaborative groups. Teaching Sociology, 34(1), 39–53. https://doi.org/10.1177/0092055X0603400104

- Chen, J., Kolmos, A., & Du, X. (2021). Forms of implementation and challenges of PBL in engineering education: A review of literature. European Journal of Engineering Education, 46(1), 90–115. https://doi.org/10.1080/03043797.2020.1718615

- Chiou, H.-H. (2020). The impact of situated learning activities on technology university students’ learning outcome. Education+ Training, 63(3), 440–452. https://doi.org/10.1108/ET-04-2018-0092

- Choi, J.-I., & Hannafin, M. (1995). Situated cognition and learning environments: Roles, structures, and implications for design. Educational Technology Research & Development, 43(2), 53–69. https://doi.org/10.1007/BF02300472

- Fernando, S. Y., & Marikar, F. M. (2017). Constructivist teaching/learning theory and participatory teaching methods. Journal of Curriculum and Teaching, 6(1), 110–122. https://doi.org/10.5430/jct.v6n1p110

- Fry, R., & Kolb, D. (1979). Experiential learning theory and learning experiences in liberal arts education. New Directions for Experiential Learning, 6, 79.

- Garrick, B., Pendergast, D., Geelan, D., Garrick, B., Pendergast, D., & Geelan, D. (2017). Theorising Personalised Education: Electronically Mediated Higher Education (pp. 27–46). https://doi.org/10.1007/978-981-10-2700-0_3

- Gordon, M. (2009). Toward a pragmatic discourse of constructivism: Reflections on lessons from practice. Educational Studies, 45(1), 39–58. https://doi.org/10.1080/00131940802546894

- Hadgraft, R. G., & Kolmos, A. (2020). Emerging learning environments in engineering education. Australasian Journal of Engineering Education, 25(1), 3–16. https://doi.org/10.1080/22054952.2020.1713522

- Hernández de Menéndez, M., Vallejo Guevara, A., Tudón Martínez, J. C., Hernández Alcántara, D., & Morales-Menendez, R. (2019). Active learning in engineering education. A review of fundamentals, best practices and experiences. International Journal on Interactive Design & Manufacturing (IjideM), 13(3), 909–922. https://doi.org/10.1007/s12008-019-00557-8

- Hossain, M. A., Zhumabekova, A., Paul, S. C., & Kim, J. R. (2020). A review of 3D printing in construction and its impact on the labor market. Sustainability, 12(20), 8492. https://doi.org/10.3390/su12208492

- Huang, T.-C., & Lin, C.-Y. (2017). From 3D modeling to 3D printing: Development of a differentiated spatial ability teaching model. Telematics and Informatics, 34(2), 604–613. https://doi.org/10.1016/j.tele.2016.10.005

- Inoma, A. O., Ibhadode, O. O., & Ibhadode, A. A. (2020). The perception and deployment of 3D printing in the Nigerian educational sector for science and engineering programs. Scientific African, 10, e00641. https://doi.org/10.1016/j.sciaf.2020.e00641

- Kessler, A., Phillips, M., Koehler, M., Mishra, P., Rosenberg, J., Schmidt-Crawford, D., Wang, W., Harris, J., Mouza, C., & Mourlam, D. (2017, March 5). The technological pedagogical content knowledge (TPACK) framework: Lineages of the first ten years of research: Part 1. Society for Information Technology & Teacher Education International Conference, Association for the Advancement of Computing in Education (AACE), Austin, TX, USA.

- Kolb, D. A. (1976). Management and the learning process. California Management Review, 18(3), 21–31. https://doi.org/10.2307/41164649

- Liaw, C.-Y., & Guvendiren, M. (2017). Current and emerging applications of 3D printing in medicine. Biofabrication, 9(2), 024102. https://doi.org/10.1088/1758-5090/aa7279

- Long, R. L., II, & Davis, S. S. (2017). Using STEAM to increase engagement and literacy across disciplines. The STEAM Journal, 3(1), 7. https://doi.org/10.5642/steam.20170301.07

- Love, T., Attaluri, A., Tunks, R., Cysyk, J., & Harter, K. (2022). Examining changes in high school teachers’ perceptions of utilizing 3D printing to teach biomedical engineering concepts: Results from an integrated STEM professional development experience. Journal of STEM Education: Innovations & Research, 23(2).

- Manoj, A., Bhuyan, M., Banik, S. R., & Sankar, M. R. (2021). Review on particle emissions during fused deposition modeling of acrylonitrile butadiene styrene and polylactic acid polymers. Materials Today: Proceedings, 44, 1375–1383. https://doi.org/10.1016/j.matpr.2020.11.521

- Maynard, C., Garcia, J., Lucietto, A., Hutzel, W., & Newell, B. (2021). Experiential learning in the energy based classroom. International Journal of Engineering Pedagogy (iJEP), 11(6), 4–26. https://doi.org/10.3991/ijep.v11i6.16539

- Mikula, K., Skrzypczak, D., Izydorczyk, G., Warchoł, J., Moustakas, K., Chojnacka, K., & Witek-Krowiak, A. (2021). 3D printing filament as a second life of waste plastics—A review. Environmental Science and Pollution Research, 28(10), 12321–12333. https://doi.org/10.1007/s11356-020-10657-8

- Munir, M. T., Baroutian, S., Young, B. R., & Carter, S. (2018). Flipped classroom with cooperative learning as a cornerstone. Education for Chemical Engineers, 23, 25–33. https://doi.org/10.1016/j.ece.2018.05.001

- Ngo, T. D., Kashani, A., Imbalzano, G., Nguyen, K. T., & Hui, D. (2018). Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B: Engineering, 143, 172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

- Novak, E., Brannon, M., Librea‐Carden, M. R., & Haas, A. L. (2021). A systematic review of empirical research on learning with 3D printing technology. Journal of Computer Assisted Learning, 37(5), 1455–1478. https://doi.org/10.1111/jcal.12585

- Pearson, H. A., & Dubé, A. K. (2022). 3D printing as an educational technology: Theoretical perspectives, learning outcomes, and recommendations for practice. Education and Information Technologies, 27(3), 1–28. https://doi.org/10.1007/s10639-021-10733-7

- Pehlivan, A. U., Sergi, F., & O’Malley, M. K. (2014). A subject-adaptive controller for wrist robotic rehabilitation. IEEE/ASME Transactions on Mechatronics, 20(3), 1338–1350. https://doi.org/10.1109/TMECH.2014.2340697

- Randolph, S. A. (2018). 3D printing: What are the hazards? Workplace Health & Safety, 66(3), 164–164. https://doi.org/10.1177/2165079917750408

- Seaman, J. (2008). Experience, reflect, critique: The end of the “learning cycles” era. Journal of Experiential Education, 31(1), 3–18. https://doi.org/10.5193/JEE.31.1.3

- Şen, C., Ay, Z. S., & Kiray, S. A. (2020). A design-oriented STEM activity for students’ using and improving their engineering skills: The balance model with 3D printer. Science Activities, 57(2), 88–101. https://doi.org/10.1080/00368121.2020.1805581

- Shahrubudin, N., Koshy, P., Alipal, J., Kadir, M., & Lee, T. (2020). Challenges of 3D printing technology for manufacturing biomedical products: A case study of Malaysian manufacturing firms. Heliyon, 6(4), e03734. https://doi.org/10.1016/j.heliyon.2020.e03734

- Sharpe, D. (2015). Chi-square test is statistically significant: Now what? Practical Assessment, Research & Evaluation, 20(1), 8.

- Song, M. J. (2018). Learning to teach 3D printing in schools: How do teachers in Korea prepare to integrate 3D printing technology into classrooms? Educational Media International, 55(3), 183–198. https://doi.org/10.1080/09523987.2018.1512448

- Szymanski, A. (2018). Prototype problem solving activities increasing creative learning opportunities using computer modeling and 3D printing. Creativity and Technology in Mathematics Education, 10, 323–344. https://doi.org/10.1007/978-3-319-72381-5_13

- Tallarida, R. J., Murray, R. B., Tallarida, R. J., & Murray, R. B. (1987). Chi-square test. Manual of Pharmacologic Calculations: With Computer Programs, 140–142.

- Trust, T., & Maloy, R. W. (2017). Why 3D print? The 21st-century skills students develop while engaging in 3D printing projects. Computers in the Schools, 34(4), 253–266. https://doi.org/10.1080/07380569.2017.1384684

- Zhou, D., Gomez, R., Wright, N., Rittenbruch, M., & Davis, J. (2022). A design-led conceptual framework for developing school integrated STEM programs: The Australian context. International Journal of Technology and Design Education, 32(1), 383–411. https://doi.org/10.1007/s10798-020-09619-5