?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.ABSTRACT

High-performance engineered wood products (EWPs) and composite mass timber products (CMTPs) are being employed more frequently in residential projects with increasing interest in more sustainable systems that achieve long-spans. The relative performance of these systems is not readily apparent, with individual manufacturers offering proprietary products assembled from specific timber resources. In addition, the suitability of producing these long-span systems using plantation hardwoods is currently unknown. This research investigated the comparative performance of four typical EWPs and CMTPs; 1. solid slab, 2. thin-walled cassette, 3. T-sections, and 4. slab on beam. Key performance metrics of depth, mass, stiffness, vibration response, fire performance and global warming potential were assessed. The mechanical performance of two high-strength plantation hardwood varieties (Eucalyptus nitens and Eucalyptus globulus) were determined experimentally and subsequently used to re-calculate performance criteria for the previously assessed typologies. Substantial improvements over the typical softwood varieties were identified, particularly in structural efficiency, global warming potential and fire performance. This highlights the potential for value adding to plantation hardwoods by using them in high-performance long-span engineered floor products.

1. Introduction

1.1. Context

The buildings we live in, work in and use contribute between 25 and 30% of all global greenhouse gas emissions (GHGs) (Chow et al. Citation2022). The carbon footprint of our built systems can be categorised into two general groups, operating carbon emissions and embodied carbon (Akbarnezhad and Xiao Citation2017). The operating carbon emissions relate to the energy used to heat, cool, and light our buildings as well as operate the many appliances within them. Being intrinsically linked to the mode of energy production these operational emissions will naturally reduce as the grid becomes less reliant on fossil fuels and as buildings become more efficient at achieving and maintaining appropriate temperatures. As the operational energy use decreases the embodied carbon of the building materials themselves will become increasingly important. Timber is a well-established building material with sustainability credentials superior to other traditional construction materials such as concrete and steel.

How and from where the timber is sourced can have a substantial impact on the sustainability credentials of the finished building (Sikkema et al. Citation2014). Plantation timber is a renewable resource from trees that are planted, managed, and harvested in cycles similar to other agricultural products. There are approximately 11 million cubic metres of hardwood plantation timber logged each year in Australia, 95% of these are being exported as low-value fibre products such as pulp and wood chip (Downham et al. Citation2019). A better understanding of the structural performance of plantation hardwoods would allow for their greater uptake in renewable timber building products and encourage further plantations by value adding to the resource.

The traditional timber building approach is the predecessor of our current “stick-build” typology using stud wall framing and timber joists or trusses and is adopted worldwide in one – or two-storey buildings. With improvements in concrete and steel technologies, larger builders were made possible, with more floors and longer floor spans. The traditional timber “stick-build” typology cannot achieve these same building heights and floor spans. For timber to contribute to these larger and taller buildings requires another type of timber product to emerge, that is engineered wood products (EWPs) and composite mass timber products (CMTPs) such as CLT, LVL and GLT. These mass timber products perform more comparably to concrete and steel than their sawn-timber components due to greater dimensional stability, larger and more complex structural sections, reduced effect of natural features such as knots and strength reducing characteristics, and more homogenous mechanical properties (Asif Citation2009, Ramage et al. Citation2017). It is these features that can allow timber products to replace concrete and steel in our modern high-rise, long-span buildings.

From the above context, there is a clear need to identify how plantation hardwoods can be better utilised in structural-grade products, to both substantiate their inclusion in such structural products and to value add to a commodity that is being utilised for low-value fiber-products. It is also clear that building design teams need more options for structural products that can achieve long-span floors with smaller carbon footprints than conventional concrete and steel. Evaluating the existing long-span timber floor typologies and exploring the application of the most common plantation hardwoods Eucalyptus globulus (E. globulus) and Eucalyptus nitens (E. nitens) within those typologies will work towards achieving both goals.

1.2. Previous research

1.2.1. Material and mechanical properties of plantation hardwoods from the literature

Structural applications for plantation hardwoods have been investigated in past research (Nolan et al. Citation2005, Redman and McGavin Citation2010, Medhurst et al. Citation2012, Wentzel-Vietheer et al. Citation2013 Downes et al. Citation2014, Derikvand et al. Citation2017, Derikvand Citation2019, Derikvand et al. Citation2020, Vega et al. Citation2020, Opazo-Vega et al. Citation2021, Nero et al. Citation2022). The studies reported on the key mechanical properties for floor structures, including bending strength and stiffness, with a summary of their findings presented in and . presents the timber variety, age, location, moisture content, density, strength, and stiffness for hardwood timber from fibre-managed plantations, while presents the same data for solid wood plantations. Improved drying times for plantation grown eucalypts were considered by Redman and McGavin (Citation2010) who found that the plantation timbers could be dried using conventional techniques in 25% less time than the same species from native forest logging. Non-destructive test methods for determining modulus of elasticity and crack prediction have been successfully utilised in a various studies (Derikvand et al. Citation2020, Navaratnam et al. Citation2020, Opazo-Vega et al. Citation2021). Derikvand (Citation2017) discusses the drivers, opportunities and challenges associated with utilising fibre-managed plantation hardwoods for structural applications. The small log diameters and higher proportion of strength reducing characteristics found in fibre-managed plantation timber compared with pruned and thinned plantations preclude excessive docking or the exclusion of the lower-grade portions of the log in order to keep volume recovery at a reasonable level (Derikvand et al. Citation2017). EWPs or mass-timber products are therefore suggested as being appropriate structural applications for these low-grade boards since the combination effect can mitigate these disadvantages. Nolan (Citation2005) published a report for the Australian Forest and Wood Products Research and Development Corporation that explores the opportunity for plantation hardwood eucalypts to be utilised in solid timber products. Since softwood milling speeds are typically quicker and drying times are typically shorter than for hardwoods, solid structural timber products produced from these hardwood resources need to distinguish themselves though better structural performance or reduced feedstock requirements (Nolan et al. Citation2005).

Table 1. Bending characteristics of fibre-managed plantation hardwood in the literature.

Table 2. Bending characteristics of solid wood plantation hardwood in the literature.

Fibre-managed plantations do not typically undergo thinning or pruning procedures and have a larger number of stems per hectare than plantations managed for solid wood products. Recovery rate of sawn timber between pruned and thinned eucalyptus plantations versus un-pruned un-thinned ones was not found to be significantly different (Washusen et al. Citation2009). However, recovery rates from plantations managed for either fibre or solid wood have been found to offer greater recovery rates when using spindleless lathe technology to harvest timber veneers for EWPs such as LVL (McGavin et al. Citation2014).

1.2.2. Plantation hardwoods in EWPs and CMTPs in the literature

Some research has also been conducted on the feasibility of utilising plantation hardwoods in EWPs and CMTPs (Derikvand Citation2019, Pangh et al. Citation2019 Martins et al. Citation2020,). Derikvand (Citation2019) found that E. globulus and E. nitens nail-laminated timber (NLT) floor panels performed comparably to CLT panels of plantation eucalypts and Canadian hemlock (Liao et al. Citation2017 He et al. Citation2018,). Pangh et al. (Citation2019) studied the bending performance of CLT panels made from fibre-managed plantation Eucalyptus. They found that the E. globulus panels exhibited 17.7% more bending stiffness than their E. nitens counterparts, and those panels with high-grade boards in the top and bottom layers performed best. Martins et al. (Citation2020) explored non-destructive tests to predict the crucial bending performance properties of GLT made from plantation E. globulus. These papers showed that there is great potential for employing plantation hardwoods in EWPs and CMTPs. These mass timber build-ups were found to leverage the greater material stiffness and strength of plantation hardwoods as well as utilising the load redistribution characteristics of such systems to mitigate the effects of strength reducing characteristics (Brandner and Schickhofer Citation2006, Kandler et al. Citation2018).

While these studies do explore the application of plantation hardwoods to specific EWPs such as CLT, GLT or NLT, they do not consider the broader range of timber floor typologies and the application of plantation hardwoods within them.

Other studies have investigated EWPs from a material optimisation perspective (Mayencourt and Mueller Citation2019 de Vito et al. Citation2023, Harte et al. Citation2023,). However, this study will focus on quantifying and comparing the key performance metrics of products that have an established place in the construction industry.

1.3. Aim of this study

The aim of this paper is to identify, evaluate and compare the long-span timber floor typologies and identify the potential for valorisation of plantation hardwoods within these typologies.

The specific research objectives:

Identify typical EWP and CMTP floor system typologies commercially available and used in recent buildings.

Normalising each floor system to the fundamental long-span performance criteria of stiffness to evaluate and compare each typology.

Measure flexural stiffness and strength of plantation E. globulus and E. nitens.

Assess the potential for utilising these and other plantation hardwoods from the literature in the identified timber floor typologies.

2. Materials and method

2.1. Desktop study methodology

The overall performance of a floor system is fundamentally a product of its structural efficiency (span-to-depth ratio), mass, vibration response, fire response and global warming potential. These are the performance metrics by which each floor typology and system will be assessed and compared in the current study. Design for Manufacture and Assembly (DfMA) characteristics are also important, however, they are complex and can vary substantially for a given system. When considering differences in factory processes during manufacture as well as between sites with different construction approaches and designed connections to the rest of the structure, the DfMA credentials of the same system can vary substantially.

The desktop study was carried out by the following steps:

Identify EWP and CMTP floor systems being produced by manufacturers, and where possible being used in recent construction projects.

Categorise these timber floor systems into four primary typologies.

Calculate the performance of each typology normalised to the long-term deflection serviceability criteria.

Re-evaluate each typology with the material substituted for

a representative E. globulus feedstock, and

a representative E. nitens feedstock based on the material tests presented in this paper.

Compare the key performance metrics of each typology and system.

The vibration performance under footfall excitation was determined by calculating the natural frequency and response factor for each typology. These were determined by following the procedure for a one-way floor as set out in Abeysekera et al. (Citation2019) based on the velocity and acceleration approach from Willford et al. (Citation2006) and Eurocode 5, shown in Equations (2)–(12).

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

(11)

(11)

(12)

(12) where

is the natural frequency in Hz,

is the midspan deflection in mm under the self-weight (

) of the system.

is the span in mm, and

is the effective bending stiffness of the system.

is the effective impulse in Ns, based on a walking frequency of

= 1.5 Hz.

is the peak velocity response of the first mode, calculated based on an assumed modal mass

of 50% of the floor mass. The higher modes are accounted for in the calculation of

by the factor

. The root mean square velocity

is then calculated by factoring down the peak response by a factor

determined from parametric analysis. This

factor considers the natural frequency (

), the damping ratio (

), taken as 3.5% (mass timber floors with a floating layer) and the empirical factor

. Finally, the velocity response factor is calculated by dividing by the minimal perceptible velocity of 0.0001 m/s. A lower response factor is indicative of a better vibration performance. Ussher et al. (Citation2017) concluded that the dynamic response-based design employed by Eurocode 5 was the most appropriate approach for lightweight floors compared to other existing concepts and practices. The Eurocode approach is suitable for describing the motion of components in lightweight floors with natural frequencies less than 40 Hz.

Fire design in buildings is a complex process that must account for a wide range of parameters including materials, fire-protection layers, location, architectural layouts, end-use, and active controls such as sprinkler systems, among others. The breadth of possible end-use applications for the timber floor typologies in question are beyond the scope of this study, however, the fundamental fire exposure behaviour is investigated. In the context of this study, the fire performance assessment will describe the char behaviour of the floor systems when exposed from below to an open fire. A duration before failure time will be calculated for each typology based on an ultimate strength limit state design approach with design load calculated as per AS 1170.0 clause 4.2.4. In lieu of experimental data for each of the timber varieties and floor typologies, the notional charring rate and charring depth will be determined according to AS 1720.4 clauses 2.5.2 and 2.6.1, shown in Equations (13) and (14).

(13)

(13)

(14)

(14) where

is the char rate in mm/min,

is the density of the timber at 12% moisture content, and

is the char depth in mm after time

in minutes.

The performance metric of global warming potential was measured for each floor typology and material by calculating both the GHG emissions associated with the production stage (raw material supply, transport, and manufacturing) and the biogenic carbon sequestered by the tree as it grows. The difference between these two values is also included to allow for comparison between the effective total global warming potential of each typology-material combination. These calculations were based on Environmental Product Declarations (EPDs) for dressed kiln-dried softwood, dressed kiln-dried hardwood, softwood GLT, hardwood GLT, and plywood within the Australian geographical context (Environmental Product Declarations | WoodSolutions Citation2022). It is assumed that sustainable forestry mandates replanting of harvested trees. In a worst-case scenario where trees are not replanted and biogenic carbon is released at the building’s end-of-life, timber structures have been found to have a more substantial long-term impact on global warming than concrete or steel (Hawkins et al. Citation2021). Where directly corresponding information was not available for a given product or material a factored estimate was made that accounted for the material type, density, and degree of manufacturing. This was the case for the CLT which was assumed to be similar to the GLT EPD, and the LVL which was assumed to be similar to the plywood EPD.

To isolate and compare the key performance metrics on a level platform several fundamental assumptions were made and applied consistently across all typologies considered. A span of 8 m is adopted as the design span for this study as it is a desirable architectural outcome for mid – and high-rise residential buildings which can be readily achieved by the conventional building materials of concrete and steel. All typologies are considered as primarily one-way spanning systems supported at both ends by pins. This assumption reflects the typical design case of a primary beam between columns or wall supports. The typical residential loading scenario of 1 kPa super-imposed dead load (SDL) and 1.5 kPa live load (LL) is adopted. The structural assessment of all systems is carried out without considering any additional mass from screed, since the design factors for vibration and acoustic performance which dictate the screed requirements are complex and very sensitive to site conditions (such as floor use, partition locations, partition types) and geographical locations (code requirements, user expectations). For this same reason, the footfall vibration performance criteria of natural frequency and velocity response factor will be included for direct comparison between typologies without considering whether they fall within or outside code requirements or guidelines. All floor typologies are designed to achieve a 100% utilisation of the Australian standard AS1170.0-1 long-term deflection criteria, which yields results equivalent to the European code. Full composite action is assumed for all typologies, which is in line with experimental studies on mass timber systems (Navaratnam et al. Citation2020).

2.2. Provenance and preparation

E. globulus boards were sourced from a 25-year-old plantation in Cathedral Ranges, Victoria, a state in the south-east of Australia. A total of 57 boards with dimensions of 1600 mm long x 60 mm wide x 20 mm thick were tested from this resource.

E. nitens boards were sourced from a 16-year-old plantation in North-East Tasmania, Australia. The fast-growing short-harvest rotation plantation timber was managed for structural and appearance grade sawn timber products. A total of 30 boards with dimensions of 1600 mm long x 92 mm wide x 26 mm thick were sourced for testing.

2.3. Measurement of material characteristics and testing

Each board was weighed at the time of testing to determine the average density. The average moisture content was established for each board from three readings taken with a Delmhorst J-2000 Moisture Meter. This method was adopted instead of the conventional over-dry method presented in AS 1080.1 due to limitations in equipment access at the time of testing.

The flexural stiffness and strength of the boards was determined in accordance with section 2.4 of timber test standard AS 4063.1:2010. The boards were tested in four-point-bending edgewise over a span of close to 18 times the depth with loads at third points. A consistent loading rate of 5 mm/min was applied to achieve failure in 2–5 minutes. The mid-span displacements were recorded with a laser transducer and the forces were recorded through the load cell in the universal testing machine. The apparent modulus of elasticity (MoE) and modulus of rupture (MoR) were then calculated from the force and displacement measurements using Equations (15) and (16).

(15)

(15)

(16)

(16) where

is the span (18 times depth),

is depth,

is the slope of the force-displacement curve in the 10%−40% zone, and

is the width. All dimensions are in mm, force is in N and moduli are in MPa.

3. Identification and numerical analysis of floor typologies

3.1. Desktop study: identification of systems and categorisation of typologies

There are a significant number of EWP and CMTP manufacturers operating world-wide who output a large range of diverse products. These products can be employed as one part of a larger system, or as a standalone system by themselves. For example, mass timber CLT products that can be employed as floors, walls, for non-structural applications, or combined with other systems, are sold alongside CMTP products for specific design applications like the CLT deck + LVL ribs floor system produced by KLH, Storaenso and others. Attempts have been made in the literature to categorise EWPs, for example joist floor systems, stressed skin panels, and plate floor systems (Bazli et al. Citation2022). In this paper, categorisation of these products was tackled from the perspective of structural ideology. That is; how the floor system is designed to resist the out of plane bending action. This is visualised most clearly by considering the cross sections (see ). Following this categorisation by structural ideology, four main floor typologies were identified. First is the solid slab. That is, a solid mass timber product with flat finished surfaces on both the top and soffit of the floor system with no hollow sections within. These can be formed with all internal timber grains running in the same primary direction (such as DLT, or NLT), or alternating directions (such as CLT). Secondly, the closed rib-decks, or closed cassettes. These have flat finished surfaces on both the top and soffit of the floor system with hollow sections within. These can be arranged with continuous flanges (top and bottom plates) or continuous webs (internal ribs) with discontinuous flanges running between. These products were found to employ a mixture of solid timber, LVL or GLT for the ribs, and solid timber, LVL or CLT for the flanges. The third typology is the open rib-deck, or open cassette. The open rib-decks have a flat finished surface on the top of the floor system with open ribs projecting to the bottom of the assembly. Most often arranged with a continuous top flange and discretely projecting webs. The webs (or ribs) of these assemblies are typically spaced at 300–600 mm or less to maintain effective ‘T’ sections where the entire system is spanning in one primary direction, rather than having the top plate spanning transversely across the intermediate ribs. These products were found to have a similar mix of solid timber, LVL, CLT and GLT in their components. The fourth and last typology is the transverse slab on beams. This typology was not found to be commercially available as a single product, but was rather a common design solution that utilised the composite of two distinct mass timber products; CLT and GLT. These have a similar spatial build-up to the open-rib decks with a flat finished surface on the top of the composite floor system, but with large regularly spaced beams underneath. The top slab is typically CLT with the primary span direction aligned transversely to the primary span direction of the supporting beams. The assembly is often mechanically connected to ensure composite action between the plate and beam elements. This arrangement increases the effective depth of the beams while also allowing for them to be spaced further apart than in the open rib-deck typology. However, only the cross layers of the CLT contribute to the capacity in the primary direction of the system. The beams are spaced upwards of 3 m apart, which in turn allows greater spatial flexibility for services and architectural intent.

Recent construction projects have successfully employed these floor typologies. For example, the 4-storey office building 111 East Grand in Des Moines, Iowa, in North America utilised DLT floor slabs spanning between GLT beams on a 6.1 × 6.1 m grid (‘Neumann Monson’s 111 East Grand Brings Innovations in Mass Timber to Des Moines’ Citation2021). Closed LVL rib-deck floor cassettes were used in three office towers in Towcester, Northamptonshire in the UK, spanning 9 m (Finnforest’s Kerto-Ripa Citation2011). International House Sydney, in Australia is a 6-storey commercial office building with 9.5 m floor spans of GLT beams with composite transverse CLT slab above (Butler Citation2016).

shows a summary of the four long-span timber floor typologies identified by the desktop study along with example manufacturers and products.

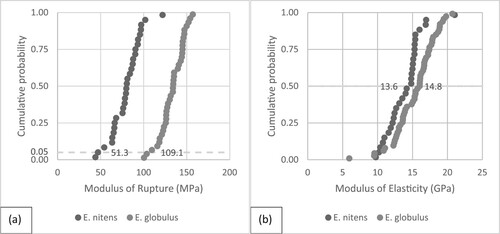

3.2. Plantation hardwood material characterisation

The mechanical characterisations of the plantation feedstocks E. globulus and E. nitens are presented in . The average modulus of elasticity of each variety was found to be 15.4 and 13.9 GPa respectively. Recent studies that reported the elastic modulus of plantation E. globulus ranged from 11.8 GPa up to 18.6 GPa (Wentzel-Vietheer et al. Citation2013 Downes et al. Citation2014, Derikvand et al. Citation2020,). Reported MoE values for plantation E. nitens in the literature varied from 10.4 GPa to 14.7 GPa (Medhurst et al. Citation2012, Derikvand Citation2019, Vega et al. Citation2020 Opazo-Vega et al. Citation2021,). The current findings agree with the past studies which collectively indicate a positive relationship between age, density and MoE.

Table 3. EWP and CMTP floor system typologies.

The modulus of rupture was found to average 133.4 and 79.8 MPa for the E. globulus and E. nitens tested in this study respectively. These strengths are substantially higher than the strength values reported in the literature of 47.8 and 53.0 MPa for the fibre-managed plantation E. globulus and E. nitens respectively (Derikvand Citation2019 Derikvand et al. Citation2020). This is to be expected when comparing the strength of essentially clear wood to timber from a fibre-managed plantation, with a much higher rate of strength reducing characteristics such as knots. This highlights the potential bending strength improvements to be made by thinning and pruning hardwood plantations to be a structural resource. The studies investigating the bending strength of fibre-managed plantation timber also reported a far greater number of flexural failures (43.4%) caused by knots (Derikvand et al. Citation2020).

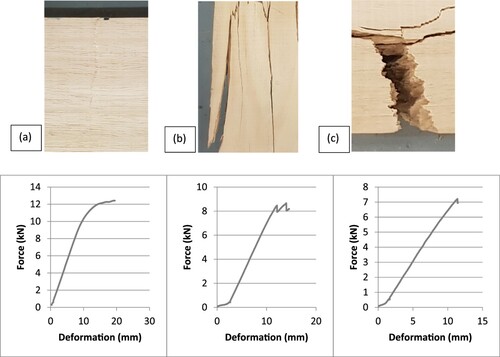

Failure modes observed from the 4-point bending tests were predominantly fibre crushing on the compression side or along-grain splitting on the tension side, see . Sudden tensile rupture of the fibres on the tension side were also observed, but far less frequently. The force-displacement behaviour of each of these failure modes is distinct. Compression failures were found to be very ductile, with a clear plateau in the force-displacement relationship. Along-grain tensile splitting failures were typified by a saw-tooth force-displacement curve as progressively more and more of the fibres in the tension face failed, leading to brittle failure. Sudden tensile fibre rupture presented a force-displacement graph with an immediate load drop after the ultimate tensile stress was reached, with all tension fibres breaking at once. The distribution of these failure mechanisms for each timber variety are presented in .

Figure 1. Failure mechanisms: (a) compression fibre crushing, (b) along-grain splitting on tension side, and (c) sudden tensile fibre rupture.

The cumulative density functions and characteristic values for MoE and MoR can be seen in .

Figure 2. Cumulative density functions of: (a) E. globulus and E. nitens MoR with characteristic 5th-percentile, (b) E. globulus and E. nitens MoE with characteristic 50th-percentile.

To apply these material measurements to a numerical analysis of the timber floor typologies identified, their characteristic properties were determined. For the bending stiffness of the material the 50th percentile value is used since this determines the deflection and vibration performance of the system, which are serviceability limit states. For the bending strength, the 5th percentile value – calculated following the approach from AS4063.2 – is used since the ramifications of exceeding the ultimate limit state are far more catastrophic. These characteristic values are shown for both E. globulus and E. nitens in .

3.3. System performance assessment and substitution for plantation hardwoods

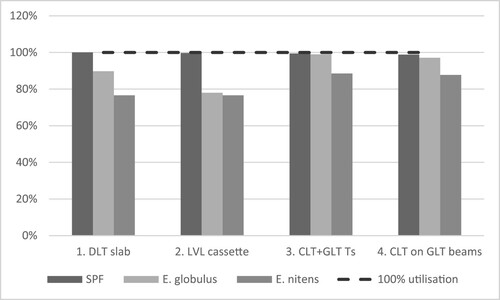

The results of the performance analysis of each of the floor typologies is shown in . The design of each of the systems was initially normalised to achieve 100% utilisation of the long-term deflection limit state.

Table 4. Material characteristics, MoE and MoR.

shows the relative long-term deflection results for each of the typologies normalised to 100% utilisation alongside the system behaviour when adjusted for E. globulus and E. nitens feedstock. All systems demonstrated an improved bending performance when adjusted for the plantation hardwood timbers. This indicates that from a simple stiffness-to-weight ratio perspective the E. globulus and E. nitens tested in the current study are suitable for long-span timber floor systems. However, the two open rib systems (numbers 3 and 4) did not exhibit as substantial an improvement as the others. This is because the improvements in effective bending stiffness of the systems were marginal compared to the original stiffness of the GLT ribs and beams, whereas the mass increase was more substantial. For the same reason, the DLT slab and LVL cassette typologies both exhibited greater improvements in bending performance (10–30%) when adjusted for the plantation hardwoods where the relative stiffness increases outpaced the increases in mass. When comparing between the performance of the two hardwoods, the E. nitens demonstrated greater improvements in effective bending stiffness than the E. globulus. This can be attributed to the relative elastic moduli and densities of the two species. The scoping assumption of a relatively low residential loading scenario rewards lighter systems and punishes heavier ones, since the self-weight of the system account for a larger proportion of the design loads. The trends shown here would need to be adjusted for applications with higher loads (such as office or retail spaces) where in general the heavier and stiffer E. globulus systems will perform better.

Table 5. Results.

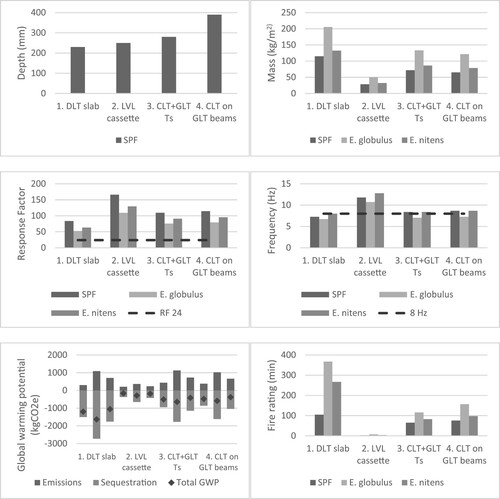

In addition to the bending stiffness comparison, the performance metrics of depth, mass, vibration response, fire response and global warming potential have also been analysed numerically. A graphical representation is shown in . The overall depths of the four timber floor typologies after being normalised for 100% utilisation of long-span deflection were 230 , 250 , 280, and 390 mm for the DLT slab, LVL cassette, CLT + GLT Ts, and CLT on GLT beams respectively. As expected, the solid timber DLT typology was able to achieve the 8 m span with the shallowest depth. This system has the greatest effective section modulus relative to its depth compared to the other systems since all its solid cross-section is aligned parallel to the span direction. The typology with the largest total depth was found to be the CLT on GLT beams. However, the total depth is measured to the underside of the supported beams which are spaced at 3 m centres. This means that the effective depth for most of the floor area is only the depth of the deck, a 110 mm thick 3-layer CLT slab.

The mass per square metre of each system was found to exhibit substantial differences. Comparing between the typologies utilising their original component timbers, typologies 1 and 2 are shown to have structural mass of 115 and 29 kg/m2 respectively: a difference of 77.4%. Since the component SPF timber in these systems has similar density, the relationship is indicative of a substantial difference in overall volume. Which, as well as effecting the other performance metrics, could have significant cost implications. When considering the mass of the typologies adjusted for plantation timbers, the E. globulus appears to have a clear weight premium. Although the contribution of the mass of the floor system to the column, wall and foundation sizes will vary according to the proportion of superimposed loads, the heavier systems will need more support from the rest of the structure. Over taller structures with more floors, the cumulative contribution of each floor’s self-weight could be substantial.

The two vibration performance criteria of Velocity Response Factor and natural frequency help to identify which typologies and timber varieties are best suited to long-span floor applications. A low Response Factor indicates a less perceptible footfall vibration response. Abeysekera et al. (Citation2019) identify six levels of floor vibration performance with corresponding Response Factors which vary from 4 at the highest quality up to 24 at the lowest quality performance. Although according to those design criteria all four typologies considered in the current study would require additional vibration control measures to be deemed suitable, the magnitude of the difference for each system is informative. The system with the best vibration performance corresponding to this metric was type 1 with E. globulus feedstock, with a Response Factor of 53. This system had the highest density and stiffness. The Response Factor of typology 3 with E. globulus was lower than that of typology 2 with SPF, 76 and 84 respectively. This highlights the importance of high effective stiffness and high mass when considering the vibration performance. The floor typology was not as critical as the density and elastic modulus of the component timber. Analysis of the different natural frequencies of each system offers another insight into the relative vibration performance. Vibration with frequency between 4 and 8 Hz is considered the most perceptible to people, and so floors are usually designed to have frequencies greater than 8 Hz. Within each of the typologies the systems with E. nitens performed best when considering natural frequency. They were the only systems to exceed the 8 Hz design limit state across all four typologies. Both vibration performance criteria indicate the necessity for further vibration mitigation measures to be employed to all floor typologies. This indicates that when considering long-span EWP and CMTP floor performance the serviceability deflection criteria is less critical than the vibration response.

From the analysis it was found that all typologies had a larger equivalent mass of sequestered CO2 than the CO2 emitted from the processes required to produce them. That is, they were all found to be net carbon negative. This highlights one of the crucial advantages of a timber structural system over a traditional steel or concrete one. When comparing the effective GWP between typologies, the solid DLT typology 1 exhibits the lowest potential with – 1199 kgCO2eq GHG emissions per metre strip. This is due to the large volume of timber in the system combined with the relatively low carbon emissions during manufacture. A larger volume of material is only beneficial to reducing the GWP of a system when the biogenic carbon outweighs the carbon emission relating to its production. When neglecting the contribution of biogenic carbon (as would be the case for a known end-of-life scenario such as combustion for energy recovery) the LVL cassette typology 2 performed best despite the relatively high emissions during production. This was due to the overall minimal volume of typology 2 compared to the high-volume DLT typology 1, 0.45 and 1.84 m3 per metre strip respectively. The effect of the material change on GWP from SPF in the original systems to E. globulus and E. nitens is also shown in . Across all four typologies the change from the softwood SPFs to the eucalyptus hardwoods increased the level of biogenic carbon sequestered by each system. This was likely due to the higher densities from the slower growing times of the plantation eucalypts. However, the change also resulted in increased emissions relating to manufacture. This was due to the greater energy required to fell, transport, kiln-dry, and process the hardwood timbers. When considering GWP the E. globulus outperformed the E. nitens. All E. globulus systems also exhibited greater levels of negative GWP than the base SPF systems. The solid DLT typology 2 showed the most extreme results with – 2727 kgCO2eq GHG emissions per metre strip for the E. globulus system, more than two times the original SPF system. Although the change to E. nitens did result in greater levels of carbon sequestration across all four typologies, these benefits were outweighed by the increased emissions from production, except for typology 2, the LVL cassette.

The fire performance metric of time before ultimate limit state flexural failure under fire loading conditions and charring scenario shows substantial differences between each system. When considering only the original systems typologies 1, 3 and 4 all exceeded a 1-hour duration, while type 2 suffered almost immediate failure. Although the two open rib typologies (3 and 4) allow the fire access to a larger surface area than typologies 1 and 2, the thin flange sections of the LVL cassette offer little fire protection and once gone the thin webs cannot sustain much volume loss before the entire system fails. The DLT slab typology exhibited the best fire response of the original systems, with a calculated 105 minutes before failure. This indicates that the DLT typology is most suited to a self-extinction approach to fire protection which provides opportunity for exposed timber, while the other typologies would likely require additional protective measures in the form of cladding. The most impressive results for fire performance however were seen when considering the inclusion of the plantation hardwoods. Aside from type 2 which still suffered almost immediate burnout, the hardwoods increased the time until section failure for each of the other three typologies by 250%, 78%, 107% (E. globulus) and 154%, 28%, 29% (E. nitens). The DLT slab typology showed the greatest improvement with E. nitens lasting almost 5 hours and E. globulus lasting over 6 hours before failure.

4. Conclusions

This study identified, evaluated, and compared commercial long-span timber floor typologies across a range of fundamental performance criteria. The four floor typologies identified were 1. DLT slab, 2. LVL cassette, 3. CLT + LVL Ts, and 4. CLT on GLT beams. Examples of these typologies and adjacent systems were shown to have been employed on recent construction projects. Experimental data was also collected from 57 E. globulus and 30 E. nitens bending specimens. Those test results informed a detailed evaluation of the potential to add value to the plantation hardwoods within the identified floor typologies.

The key long-span floor performance metrics of bending stiffness, depth, mass, vibration response, fire response and global warming potential were numerically determined for each typology and system based on robust assumptions from past studies as well as product information from manufacturers and suppliers. While all four typologies were sized to satisfy the long-term deflection serviceability criteria with 100% utilisation, they differed substantially on many of the other performance criteria. The DLT slab typology was the shallowest, with a depth of 230 mm. This typology also exhibited the best vibration performance, fire response, and global warming potential (when considering the benefits of biogenic carbon). However, it was the heaviest of all the systems considered and had the greatest total volume of material. The LVL cassette typology was the lightest and had the smallest volume of material, however, it suffered from a high velocity response factor (poor vibration performance), had the lowest level of carbon sequestration, and required additional fire protection measures. The 3rd and 4th typologies (CLT + LVL Ts, and CLT on GLT beams) were both open rib sections and exhibited the most similar behaviours. They performed in the middle of the pack, with relatively high stiffness, vibration response, global warming potential and fire performance in proportion to their mass. This indicates that both typologies make efficient use of their materials. However, they both had substantially deeper total floor depths than typologies 1 and 2.

Each project will have specific requirements and contexts that will affect the relative importance of each of the performance metrics considered in this study. What is clear is the aspects of the floor performance which are most strongly and positively affected by the inclusion of hardwood plantation eucalypts. The vibration and fire performance metrics show a substantial improvement when utilising the denser and stiffer E. globulus and E. nitens hardwoods over the conventional SPF feedstock. This is especially important when considering that for long-span EWP and CMTP floor systems the vibration response is the most crucial performance criteria. The potential improvements to fire performance are also worth further investigation as the potential for exposed structural finishes is often architecturally desirable from both a spatial and aesthetic perspective.

Both plantation E. globulus and E. nitens timber have shown themselves to be suitable for use in the typical commercial long-span timber floor typologies utilised in recent construction projects.

Acknowledgements

This research was supported by funding from the Australian Government Research Training Program Scholarship (RTP). The authors would also like to acknowledge Mundroola Farms for supplying the timber feedstock.

Disclosure statement

No potential conflict of interest was reported by the author(s).

Additional information

Funding

References

- Abeysekera, I.K., et al., 2019. Development of a floor vibration design method for Eurocode 5. New Zealand Timber Design, 27 (1), 9.

- Akbarnezhad, A., and Xiao, J., 2017. Estimation and minimization of embodied carbon of buildings: a review. Buildings, 7 (1), 5. https://doi.org/10.3390/buildings7010005.

- Asif, M., 2009. 2—Sustainability of timber, wood and bamboo in construction. In: J. M. Khatib, ed., Sustainability of construction materials. Cambridge, Woodhead Publishing, 31–54.

- Bazli, M., Heitzmann, M., and Ashrafi, H., 2022. Long-span timber flooring systems: a systematic review from structural performance and design considerations to constructability and sustainability aspects. Journal of Building Engineering, 48, 103981. https://doi.org/10.1016/j.jobe.2021.103981.

- Brandner, R. and Schickhofer, G., 2006. System effects of structural elements—determined for bending and tension. In: 9th world Conference on Timber Engineering 2006, WCTE 2006, Vol. 2.

- Butler, T. and Design Make Lendlease., 2016. International house Sydney. In: Proceedings (Part II) 22nd. Wood Construction Forum (IHF 2016), pp. 35–45.

- Chow, W., et al., 2022. IPCC Sixth Assessment Report (AR6): Climate Change 2022 - Impacts, Adaptation and Vulnerability: Factsheet Human Settlements. https://policycommons.net/artifacts/2264360/ipcc_ar6_wgii_factsheet_humansettlements/3023414/.

- Derikvand, M., et al., 2017. What to do with structurally low-grade wood from Australia’s plantation eucalyptus; building application? BioResources, 12 (1), Article 1.

- Derikvand, M., et al., 2019a. Bending performance of nail-laminated timber constructed of fast-grown plantation eucalypt. European Journal of Wood and Wood Products, 77 (3), 421–437. https://doi.org/10.1007/s00107-019-01408-9.

- Derikvand, M., et al., 2019b. Characterisation of physical and mechanical properties of unthinned and unpruned plantation-grown Eucalyptus nitens H. Deane & Maiden lumber. Forests, 10 (2), Article 2. https://doi.org/10.3390/f10020194

- Derikvand, M., et al., 2020. Flexural and visual characteristics of fibre-managed plantation Eucalyptus globulus timber. Wood Material Science & Engineering, 15 (3), 172–181. https://doi.org/10.1080/17480272.2018.1542618.

- de Vito, A.F., Vicente, W.M., and Xie, Y.M., 2023. Topology optimization applied to the core of structural engineered wood product. Structures, 48, 1567–1575. https://doi.org/10.1016/j.istruc.2023.01.036.

- Downes, G., et al., 2014. Wood properties of Eucalyptus globulus at three sites in western Australia: effects of fertiliser and plantation stocking. Australian Forestry, 77 (3–4), 179–188. https://doi.org/10.1080/00049158.2014.970742.

- Downham, R., Gavran, M., and Frakes, I., 2019. ABARES National Wood Processing Survey 2016-17: Research Report 19.3. https://doi.org/10.25814/5CF8EBADB377F.

- Environmental Product Declarations | WoodSolutions, 2022, January 1. https://www.woodsolutions.com.au/environmental-product-declarations

- Finnforest’s Kerto-Ripa, 2011, January 17. https://www.metsawood.com/global/news-media/News/uk-news-archive/Pages/Finnforest27sKerto-Ripa.aspx.

- Harte, A.M., Baylor, G., and O’Ceallaigh, C., 2023. Web geometry optimisation of novel latticed LVL-webbed timber I-joists. Structures, 47, 748–759. https://doi.org/10.1016/j.istruc.2022.11.059.

- Hawkins, W., et al., 2021. Embodied carbon assessment using a dynamic climate model: case-study comparison of a concrete, steel and timber building structure. Structures, 33, 90–98. https://doi.org/10.1016/j.istruc.2020.12.013.

- He, M., Sun, X., and Li, Z., 2018. Bending and compressive properties of cross-laminated timber (CLT) panels made from Canadian hemlock. Construction and Building Materials, 185, 175–183. https://doi.org/10.1016/j.conbuildmat.2018.07.072.

- Kandler, G., Lukacevic, M., and Füssl, J., 2018. Experimental study on glued laminated timber beams with well-known knot morphology. European Journal of Wood and Wood Products, 76 (5), 1435–1452. https://doi.org/10.1007/s00107-018-1328-6.

- Liao, Y., et al., 2017. Feasibility of manufacturing cross-laminated timber using fast-grown small diameter eucalyptus lumbers. Construction and Building Materials, 132, 508–515. https://doi.org/10.1016/j.conbuildmat.2016.12.027.

- Martins, C., Dias, A.M.P.G., and Cruz, H., 2020. Blue gum: assessment of its potential for glued laminated timber beams. European Journal of Wood and Wood Products, 78 (5), 905–913. https://doi.org/10.1007/s00107-020-01567-0.

- Mayencourt, P., and Mueller, C., 2019. Structural optimization of cross-laminated timber panels in One-way bending. Structures, 18, 48–59. https://doi.org/10.1016/j.istruc.2018.12.009.

- McGavin, R.L., et al., 2014. Veneer recovery analysis of plantation eucalypt species using spindleless lathe technology. BioResources, 9 (1), Article 1.

- Medhurst, J., et al., 2012. Intra-specific competition and the radial development of wood density, microfibril angle and modulus of elasticity in plantation-grown Eucalyptus nitens. Trees, 26 (6), 1771–1780. https://doi.org/10.1007/s00468-012-0746-z.

- Navaratnam, S., et al., 2020. The use of digital image correlation for identifying failure characteristics of cross-laminated timber under transverse loading. Measurement, 154, 107502. https://doi.org/10.1016/j.measurement.2020.107502.

- Nero, R., Christopher, P., and Ngo, T., 2022. Investigation of rolling shear properties of cross-laminated timber (CLT) and comparison of experimental approaches. Construction and Building Materials, 316, 125897. https://doi.org/10.1016/j.conbuildmat.2021.125897.

- Neumann Monson’s 111 East Grand brings innovations in mass timber to Des Moines, 2021, April 12. The Architect’s Newspaper. https://www.archpaper.com/2021/04/111-east-grand-brings-innovations-in-mass-timber-to-des-moines/.

- Nolan, G.B., et al., 2005. Eucalypt Plantations for Solid Wood Products in Australia—A Review ‘If you don’t prune it, we can’t use it’ (Report). Forest Wood Products Research and Develoment Corporation. http://www.fwpa.com.au/content/pdfs/PN04.3002.pdf.

- Opazo-Vega, A., Rosales-Garcés, V., and Oyarzo-Vera, C., 2021. Non-destructive assessment of the dynamic elasticity modulus of Eucalyptus nitens timber boards. Materials, 14 (2), Article 2. https://doi.org/10.3390/ma14020269

- Pangh, H., et al., 2019. Flexural performance of cross-laminated timber constructed from fibre-managed plantation eucalyptus. Construction and Building Materials, 208, 535–542. https://doi.org/10.1016/j.conbuildmat.2019.03.010.

- Ramage, M.H., et al., 2017. The wood from the trees: the use of timber in construction. Renewable and Sustainable Energy Reviews, 68, 333–359. https://doi.org/10.1016/j.rser.2016.09.107.

- Redman, A., and McGavin, R., 2010. Accelerated drying of plantation grown eucalyptus cloeziana and eucalyptus pellita sawn timber. Forest Products Journal, 60, 339–345. https://doi.org/10.13073/0015-7473-60.4.339.

- Sikkema, R., et al., 2014. Legal harvesting. Sustainable Sourcing and Cascaded Use of Wood for Bioenergy: Their Coverage Through Existing Certification Frameworks for Sustainable Forest Management. Forests, 5 (9), Article 9. https://doi.org/10.3390/f5092163

- Ussher, E., et al., 2017. Prediction of motion responses of cross-laminated-timber slabs. Structures, 11, 49–61. https://doi.org/10.1016/j.istruc.2017.04.007.

- Vega, M., et al., 2020. Radial variation in modulus of elasticity, microfibril angle and wood density of veneer logs from plantation-grown Eucalyptus nitens. Annals of Forest Science, 77 (3), 65. https://doi.org/10.1007/s13595-020-00961-1.

- Washusen, R., et al., 2009. Pruned plantation-grown Eucalyptus nitens: effect of thinning and conventional processing practices on sawn board quality and recovery. New Zealand Journal of Forestry Science, 39 (1), 39–55.

- Wentzel-Vietheer, M., et al., 2013. Prediction of non-recoverable collapse in Eucalyptus globulus from near infrared scanning of radial wood samples. European Journal of Wood and Wood Products, 71 (6), 755–768. https://doi.org/10.1007/s00107-013-0735-y.

- Willford, M.R., Young, P., and CEng, M., 2006. A design guide for footfall induced vibration of structures. (London, Concrete Society for The Concrete Centre).