Abstract

In Ethiopia, investigation of fiber quality and commercialization is limited to conventional cotton and there is no fiber property analysis for Organic and genetically modified cotton. The objective of this study is to characterize organic and genetically modified cotton and compare them to conventional cotton varieties. Conventional varieties with chemically treated and untreated seed cotton; organic and genetically modified cotton samples were collected using random sampling methods from different regions of Ethiopia. Cotton fiber qualities are tested on High-Volume Instruments based on the ASTM standard. The tested data is experimentally designed and analyzed using SPSS software version 22. The model is significant for the effect of fiber quality parameters on the similar and different cotton varieties p < 0.05. The JKCH 1947 cotton has a maximum spinning consistency index, Uniformity index, and maturity ratio of 151, 86.6, and 0.83, respectively. The organic cotton cultivated MRC (270) has a maximum fiber strength of 29.29 g/tex and elongation of 7.44 mm, minimum short fiber content of 4, and maturity of 4. Deltapine (DP) 90 untreated seed Forgena cotton has a maximum micronaire value of 4.24 and a minimum fiber length of 27.17 mm. Acala SJ2 cotton variety has a maximum fiber length of 28.3 mm, minimum micronaire of 3.69, and elongation of 4.44 mm. It was revealed there is little improvement in qualities of the organic and genetically modified cotton. Chemical treatment has a significant effect on the quality of cotton. Cotton parameters have a significant effect on varieties with strong and weak correlations.

REVIEWING EDITOR:

1. Introduction

One of the most commercially viable crops in our country Ethiopia is cotton (Gossypium hirsutum L.), which is primarily grown for its output of lint. Cotton is a major industrial fiber crop that is extensively grown worldwide and has a big impact on the political and socioeconomic problems that many nations face (Gebregergis et al., Citation2020).

According to the Ethiopian Agricultural Research Institute, social-cultural, economic, technological, and environmental perspectives influence the production of Ethiopian cotton. From the technological point of view, the challenges faced are often the production of cotton seed depends on traditional practices leading to the low volume of production and poor productivity; Low efficiencies of the processing technologies contributing to poor quality of cotton lint, especially at the cottage level (handlooms) (Mengistu, Citation2017).

In the conventional method of developing varieties, there were no varieties developed for some specific desired traits (Mengistu, Citation2017) (e.g. long staple and fine cotton varieties, varieties without gossypol, pest resistant/tolerant varieties, etc. Ethiopian cotton production is deficient to meet the increasing demand of the textile industries and hence the country is importing cotton (including BT cotton) from various international suppliers (Gebretsadik and Kiflu Citation2018).

The method of farming and agricultural management is what makes organic cotton different from conventional cotton (Mageshwaran et al., Citation2019). Conventional cotton is a naturally occurring raw material that is harvested from cotton plants, most of which are grown in the summer (Mohamed, Citation2003).

The organic cotton plant is not genetically altered, it is grown without the use of chemical pesticides, the soil is rotated, and insect issues are resolved naturally and have no negative effects on either human health or the environment (Action, Citation2007). Genetically Modified Organisms (GMOs) are creatures that have undergone genetic modification through the use of recombinant DNA technology or genetic engineering, a process that modifies the genetic makeup of living things, such as BT cotton (Phillips, Citation2008). BT cotton is a type of cotton where a gene from that bacterium has been introduced to the cotton plant, which produces an insect toxic. In turn, since the plants produce their toxin, there is no need for the grower to apply pesticides (Baffes, Citation2005).

Organic cotton has potential for developing countries because of their low dependence on chemicals and fertilizer (Devrent & Palamutcu, Citation2017). According to the report (Baffes, Citation2005) despite a very major push, organic cotton has limited potential in Africa, In 2017/18 the first organic cotton cultivation began in the Gamogofa zone Arbaminch Zurya woreda started with a few farmers, and recently the production was expanded to more small-scale enterprises, the cultivation was limited to Southern Nations Nationalities and peoples Region, Gamo Zone.

In light of the environmental hotspots in cotton cultivation, Gamo Zone organic cotton producers are the first Ethiopian producers of certified organic cotton; however, the study of (Gebretsadik and Kiflu Citation2018), particularly in terms of the way pesticides are used, the pilot project for organic cotton certification in the Gamo zone of Ethiopia demonstrated extremely promising results.

While labor costs are similar in East Africa, the lower input costs and comparable yields to the conventional sector make organic cotton an economically viable and desirable option for farmers, with significant room for growth. The production of cotton needs to be evaluated in West Africa’s sub-humid regions because it is the primary source of cash income for the 6 million farmers and rural workers there. The slower rate of output growth in West Africa is due to the longer time it takes for yields to increase; nonetheless, lower input prices make organic cotton a possibility for many poorer farmers, with the majority of them motivated by lower health and debt costs (Simon Ferrigno et al., Citation2005).

The cotton crop has direct ties to several agro-processing businesses, including the textile, oil, and animal subsectors. It is a crucial industrial component for textile businesses. Currently, Ethiopia has 50 medium-sized to large garment producers and roughly 14 textile plants. The textile and apparel industries in Ethiopia are also largely labor-intensive. In 2015, the cotton industry employed roughly 52,754 smallholder farmers, 408 mechanized rain-fed farms, and 107 mechanized irrigated farms, according to the Ethiopian Development Research Institute (EDRI)). Additionally, state and private commercial farms that grow cotton create a significant amount of short-term employment opportunities (Zeleke et al., Citation2019). This present study comes with the expansion of cotton growers and analysis of various cotton varieties cultivated in Ethiopia.

Genetically Modified (GMO) cotton has the potential to reduce the cost of production and thus increase profitability for the early adopters of the technology (Baffes, Citation2005).

Focal work on genetically modified cotton is conducted. However, there is no monitoring or testing of BT and organic cotton throughout the production (Gebretsadik and Kiflu Citation2018; Jayant et al., Citation2011). Hence this highlights the challenges and opportunities of the development of genetically modified crops in Ethiopia.

Cotton producers in Ethiopia frequently claim that there are no research initiatives that help them (Mengistu, Citation2017). The study of (Genetically Modified) GMO cotton in Ethiopia is important to satisfy the demand. Although Ethiopia currently produces a significant amount of both conventional and organic cotton, there are still several issues with fiber quality.

The expansion of agricultural industrial parks is anticipated to drive to increase in the demand for cotton supply and production in Ethiopia. To meet the cotton demand, Ethiopia has planned to begin the commercialization of BT cotton following the implementation of a decree that granted research rights both in the laboratories and on farmland. Hence, confined experimental trials are underway and commercialization of BT cotton is expected within the next couple of years (Gebretsadik and Kiflu Citation2018).

Recently (Genetically Modified) GMO cotton has been introduced to improve some of the limitations of organic and conventional cotton fiber; however, the production, productivity, and fiber quality of Ethiopian organic and (Genetically Modified) GMO cotton were not studied. The adaptability of the hybrids to various cotton-growing conditions and their higher yield performance as a result of increased protection against bollworm damage to yield losses (Gudeta et al., Citation2023). In the current study, samples are collected from their origin for conventional, organic cotton, and the physical properties are investigated and tested by the HVI (High Volume Instrument). The comparison, variation, and correlation between the properties of cotton fiber quality are analysis is done based on SPSS software version 22.

Many works have been done in this area, the present study focuses on a study of the fiber quality of Ethiopian Bt and organic cotton fibers, a comparative analysis of genetically modified (GMO), organic cotton, and conventional cotton properties based on standard test methods using cotton quality testing instruments is studied.

2. Materials and methods

2.1. Materials

Cotton seed fiber samples were collected from different areas of the country in January 2020. Samples of organic cotton were taken from smallholder farmers’ fields in the communities of Shella Mella in the Gamo Zone of the Southern Nations Nationalities and Peoples Region (SNNPR) of the southern Ethiopian Rift Valley, the genetically modified cotton was gathered in the Gambela region of Ethiopia; the Ethiopian Institute of Agricultural Research (EIAR) introduced JKCH-1947 samples that originated in India and one open pollinated variety (Sudan) that was collected from private owner commercial farmers under the leadership of Haile Adisu, while the seed cotton samples were taken from small and large farms in Forgena. The DP-90 cotton sample varieties that were earlier issued via the Ethiopian Institute of Agriculture Research’s National Cotton Research Program were collected from different cultivation techniques; Cotton seeds treated with pesticide chemicals before plantation and synthetic fertilizers used the cotton was not damaged by a pest; Cotton seeds that are not treated before cultivation and chemical pesticides are used after cultivation preventing the cotton plant from being attacked by pests and synthetic fertilizers are used for cultivation.

2.2. Methods

2.2.1. Study area

In the southern Ethiopian region, Arba Minch Zurya Woreda Shele Mela organic cotton producers were selected. The area is situated 275 and 505 km away from Addis Ababa, the capital of Ethiopia, and Hawassa, a regional metropolis. The district’s geographic coordinates are 5°42′ and 6°13′ North latitude and 37°19′ and 37°41′ East longitude. The Amhara regional states, Metema, (Forgena) were considered for conventional cotton. The Metema district is situated between 160 and 340 km west of the towns of Gondar and Bahir Dar, respectively, and 900 miles northwest of Addis Ababa. There are twenty kebeles in the district, of which eighteen are rural peasant administrations. The district is situated between 550 and 1608 m above sea level. BT cotton was collected from the Gambela region of Entag Woreda, Wanke Kebele cotton producers. Itang is a town in the Gambela Region of western Ethiopia (also written Etang; Ethiopic:). Itang is a part of the Itang woreda in Gambela, which is a unique woreda. Situated on Latitude: 8° 14′ 60.00″ N and Longitude: 34° 09′ 60.00″ E, on the Baro River (also called the or the).

2.2.2. Sampling methods and design

The sampling frame of the study was carried out in major smallholder rain feed for organic cotton and irrigation-cultivated conventional cotton-growing regional states in the North, Western, and Southern parts of Ethiopia that are currently under production. From each regional state, three main cotton-growing districts were selected which are called kebele (the lowest administrative unit in Ethiopia). A representative sample was collected by Cluster sampling by dividing the area into smaller sub-groups called clusters. Involves randomly selecting 10 groups of cotton growers from each cotton grower and 5 kg of each sample cotton variety was randomly collected from machine-picked cotton harvested tons of cotton from the farmland.

2.2.3. Experimental design and variables

The trial is with six cotton varieties Dp 90 seed treated from Forgena, Dp 90 untreated seed from Forgena, BT JKCH 1947, Organic (MRC 270), Acala SJ2, and Dp 90 from Shelle Mela, the samples were grouped into categories and coded as 1, 2, 3, 4, 5, and 6, respectively on SPSS version 22.0 software. Five tests were conducted for each type of cotton variety to analyze the cotton fiber quality, such as fiber length, moisture, fiber strength, micronaire, fiber elongation, short fiber index, spinning consistency index, upper half mean length, uniformity index, color investigated on a high-volume instrument USTER® HVI 1000.

2.2.4. Laboratory sample preparation

The laboratory samples to moisture equilibrium for testing in these test methods atmospheres for testing textiles. From each 5 kg sample cotton 1 kg fiber sample was taken from three plots from each site. The variety of cotton from different region cultivars for gin based on a small sampling technique is ginned in the laboratory ginning machine using mini ginning conditioned at standard laboratory atmospheric conditions, i.e. 20 °C temperature and 65% relative humidity, in the key state testing laboratory of Bahir Dar Textile Share Company. For acceptance testing, random materials were taken from each original sample from farmlands, such as loose fibers from one or more bolls, plants, or rows in a field mass of cotton; of any size or mass to yield the required test specimen(s). Based on individual test methods from the bulk sample, the laboratory samples were prepared and the test specimen was collected by zoning technique.

2.2.5. Data collection and analysis

Data were analyzed by using SPSS version 22.0 software, Descriptive and tested as categorical and numerical were employed to analyze the experimental result using frequency distribution, mean, percentage, standard deviation, standard errors, Mean, significance, F-value, comparison of the difference between and with the groups of cotton varieties, the correlation or the dependence of one variable over the other, the correlation between the types of fibers. Besides, the software analyses the data based on one-way ANOVA, and the pairwise comparison using paired t-test for multiple dependent variables was done using Tukey analysis, and the relationship between the fiber varieties and the fiber qualities was analyzed as (positive, negative) correlation. The data is presented by Creating descriptive statistics and graphs. Statistical analysis for the significance of the method was accepted when the p-value was <0.05%.

3. Results

3.1. Statistical parameters

The cotton fiber essential characteristics, such as micronaire, maturity, length, uniformity, short fiber index, strength, elongation, and color grade were evaluated as per standard using USTER® HVI 1000 and were tabulated in .

Table 1. HVI values of cotton bundle fiber properties.

As can be shown in , the maximum standard deviation of 1.78885 of the spinning consistency index is recorded by Organic (MRC 270), while that of JKCH 1947 is 1.64317, and the values for Dp 90 Arba Minch and Dp 90 treated Forgena are both low at 1.00000 and 1.14018, respectively. With improved standard deviation variance, the mean micronaire values for Acala SJ2 and Dp 90 treated Forgena were 0.15271 and 0.21829, respectively. The minimum distribution values were 0.01924 for Organic (MRC 270) and 0.12657 for Dp 90 treated Forgena. The maturity ratios for Dp 90 Arba Minch and Dp 90 untreated Forgena have maximum standard deviations of 1.0271 and 0.0681, respectively. These values are near the mean for JKCH-1947, with a standard deviation of 0.00837, and Organic (MRC 270), with a standard deviation of 0.02588. The fiber length distribution is lowest for Dp 90 treated Forgena and Organic (MRC 270) and highest for JKCH-1947 and Dp 90 Arba Minch, respectively. The JKCH-1947 uniformity index showed the maximum variance at 1.81659, followed by the Dp 90 Arba Minch at 0.53176, and the Dp 90-treated Forgena and Organic (MRC 270) at standard deviations of 0.13038 and 0.19494, respectively. The maximum distribution short fiber index of the standard deviation for Acala SJ2 is 0.34158, while Organic (MRC 270) has a value of 0.36469. The standard deviation of untreated Forgena, 0.11402, and JKCH-1947 is 0.71678; the highest and minimum spreads for Acala SJ2 are, respectively, 0.12759 and 0.14775. For Acala SJ2, JKCH-1947, the maximum standard deviation of fiber elongation is 0.4183, whereas Dp 90 treated Forgena and Dp 90 Arbaminch have the lowest standard deviations, 0.15811. The distribution of reflectance index (Rd+) for Dp 90 Arba Minch and Acala SJ2 is 1.46458 and 0.63555, respectively, while the distribution for Organic (MRC 270) is 0f 0.22804 and Dp 90 untreated Forgena is 0.27019. The maximum yellowness (+b) variation with mean of Dp 90 Arba Minch, Dp 90 untreated Forgena cotton has 0.49699 and 0.25884, respectively and minimum yellowness standard deviation for Dp 90 treated Forgena 0.13038, JKCH-1947 0.14832.

Table 2. Descriptive statistics.

According to the data result of standard deviation, a minimum standard deviation indicates that the values of a particular cotton variety tend to be close to the mean of the cotton fiber quality, which is the expected value of the test set; a maximum standard deviation indicates that the values are dispersed over a wider range.

3.1.1. Model

One-way ANOVA analysis and the F_test were used to examine the significance level, which was set at 5% (0.05). The model is significant for the effect of fiber quality parameters on similar and different cotton varieties p < 0.05. The study concludes that there is a significant difference between different varieties of cotton therefore it proceeds to posthock to know where the difference between cotton samples exists ().

Table 3. ANOVA table.

3.2. Properties of genetically modified and organic cotton fiber

The results in illustrate the fiber qualities obtained from HVI and its comparison. According to the annual Ethiopia cotton production report (Staffs, Citation2019), Ethiopian Textile Industry Development Institute (ETIDI) data on Ethiopian cotton quality grading is shown in which is useful to compare the current status of Ethiopian cotton and the newly emerged organic and BT cotton.

Table 4. BT JKCH-1947 and Organic (MRC 270).

Table 5. Cotton varieties grading (TIDI).

3.3. Cotton quality parameters using HVI

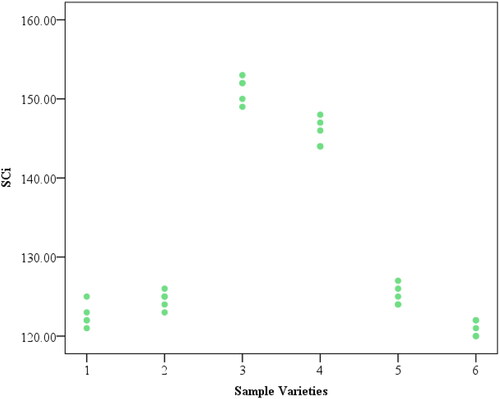

The spinning consistency index (SCI) (Mallick) is a formula for forecasting the cotton fiber’s overall quality and spinnability. It is determined by the length, fineness, and strength of the fiber (Majumdar et al., Citation2004). The mean SCI of all varieties is 131.7333. The maximum value was recorded by JKCH 1947 with 151 and a minimum of 121 for Dp 90 Arba Minch ().

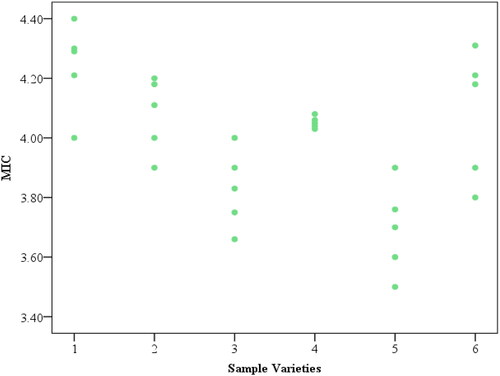

The lowest Micronaire value for Acala SJ2, which is fine fiber, was 3.69. The maximum Micronaire value for untreated Dp 90 cotton fiber from Forgena, which is less fine, was 4.24. This was followed by treated Dp 90 and untreated Dp 90 from Arba Minch cotton ().

The environment has a considerable impact on micronaire levels, which is consistent with earlier research by Pretorius et al. (Citation2015). A micronaire of <3.5 is typically regarded as weak and immature cotton lint.

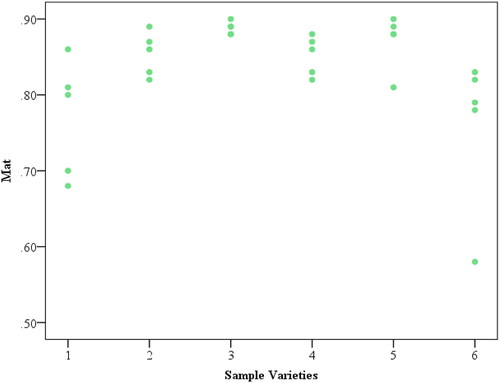

As shown in , the average maturity ratio for the studied varieties was 0.8327 under the grade of medium maturity fiber. The BT JKCH 1947 with 0.88 followed by Acala SJ2 with 0.87, with 0.85 DP 90 treated cotton, and organically cultivated with maximum maturity ratio, respectively. The untreated seed cultivated Dp 90 cotton from the northern part of Amhara region Metema Woreda (Forgena) maturity ratio of 0.77 and the untreated Dp 90 from southern Arba Minch Zurya Shelle Mela with less maturity ratio of 0.76.

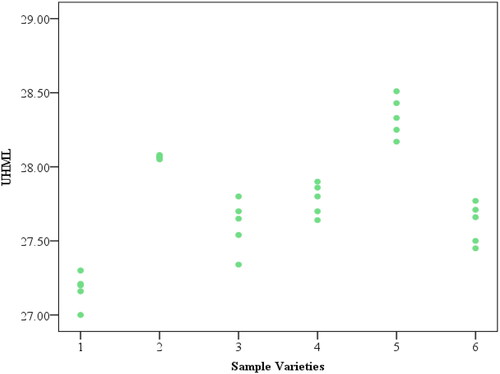

From the ANOVA table, it was observed that there is a significant difference in the fiber length distribution (i.e. p-value < 0.05) between the varieties. Based on the study the average fiber UHML is between 27.76 mm which is medium-length fibers. The BT cotton JKCH-1947 has a UHML of 27.6060 and Acala SJ2 with a maximum length of 28.3380.

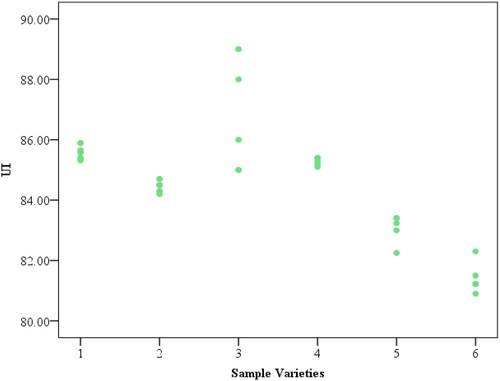

The uniformity index has a significant effect on the quality of cotton fiber. The average uniformity index of the tested samples is 84.39 where JKCH 1947 with maximum uniformity of 86.6 and a minimum uniformity index of 81.42 for DP 90 from the southern region Arba Minch Zurya Woreda Shele Mela (). In similar reports (Gudeta et al. Citation2023), significant differences (p < 0.05) of uniformity index for JKCH 1047 are achieved where low percentages were recorded for standard checks for DP-90.

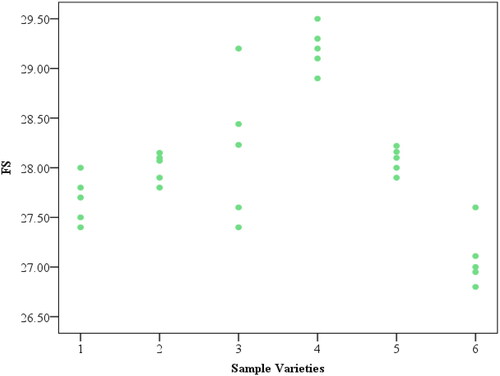

All cotton cultivars displayed significant differences (p < 0.05) in cotton fiber strength across all regions. The maximum mean strength of 29.2 g/tex was observed on Organic (MRC 270) minimum of 27.09 g/tex for DP 90 from Shele Mela. The treated DP 90 seed cotton shows higher fiber strength than untreated DP 90 cotton fiber from the same place Forgena and Arbaminch Zurya Woreda Shele Mela.

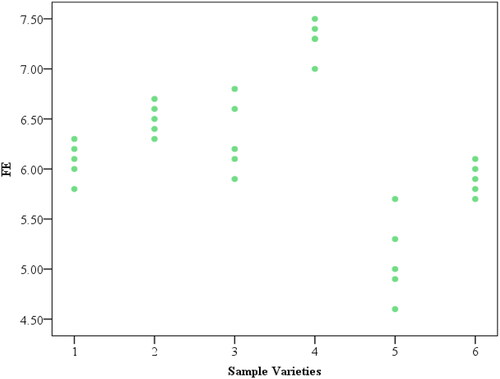

Maximum fiber elongation was observed on, Organic (MRC 270) 7.44 mm and a minimum elongation of 4.46 mm for Acala SJ2 ().

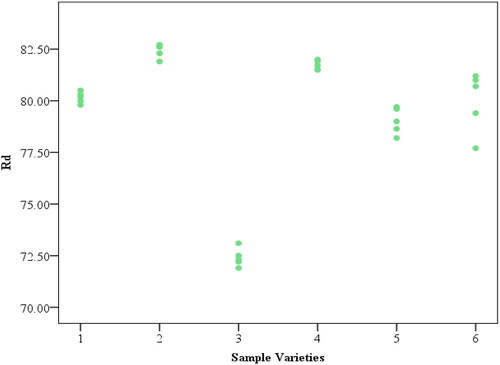

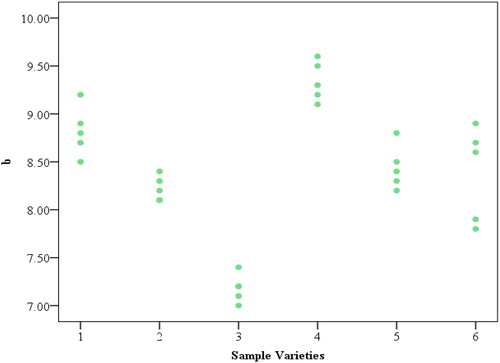

Color has a significant change in the qualities of cotton varieties. The mean reflectance of the varieties is 79.2913. The reflectance of the cotton of Dp 90 treated fiber has a maximum of 82.44 with a yellowness value of 8.22 and minimum and BT JKCH 1947 fiber has an inferior color of 72.4 with a yellowness of 7.18 ( and ).

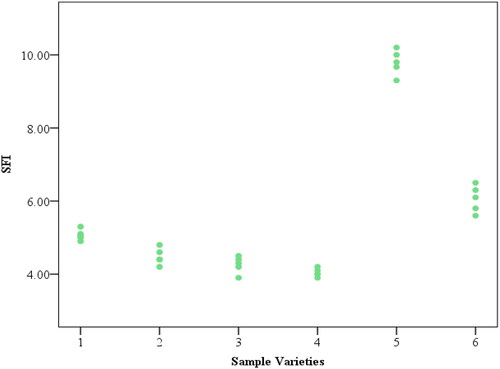

The SFI means of all varieties fall between 5.6173, the maximum SFI is 9.7940 for Dp 90 at Arba Minch, and a minimum of 4.04 for Organic (MRC 270) ().

Similar HVI result findings of Ethiopian DP-90, and Acala SJ2 cotton are reported by Tesema and Drieling (Citation2019) cotton parameters, such as fiber length, moisture, fiber strength, micronaire, fiber elongation, short fiber index, spinning consistency index, upper half mean length, uniformity index, color.

4. Discussion

The main purpose of BT cotton is not mainly for the cotton quality. It is noteworthy that under field conditions, biotic and biotic stresses are the major reasons for poor seed set which leads to both yield loss and lower fiber quality. Hence, it is important to understand the impact of these stresses on fiber development based on the molecular response of cotton concerning external environmental stresses documented (Manik & Ravikesavan, Citation2009). The quality of transgenic cotton fiber was not affected due to the presence of BT as compared with non-BT cotton (Rashid et al., Citation2009). It is reported (Nicolay et al., Citation2020) the EIAR/WARC site records the JKCH 1947 variety’s performance with micronaire, fiber length, and fiber strength of 4.06, 27.78 mm, and 27.75 g/tex, respectively ().

In comparison to the research conducted by (Gudeta et al. Citation2023), which reported staple lengths ranging from 27.78 to 28.44 mm and fiber strengths from 27.75 to 28.59 g/tex, the JKCH-1047 cotton fiber quality exhibited acceptable limits with a mean length of 27.8 and a strength of 28.17 g/tex. From an economic point of view, GM-type cotton (like all other GM products) serves as a hedge against insect pests, and weeds. Herbicide and insect-resistant cotton, better cotton cultivars, and the Boll Weevil Eradication Program are all recent advancements in cotton agriculture (Marra, Citation2007). Because of its reduced reliance on pesticides and fertilizers, organic cotton has great potential in developing countries.

Organic cotton crops are not susceptible to the rising salt levels caused by irrigation and changing climate conditions (Foolad & Crops, Citation2007) Pesticides hurt soil fertility as well as environmental factors strongly influence Cotton fiber length.

Organic Cotton crops are not subjected to elevated salt conditions that are rising due to irrigation and changing climatic conditions Pesticides reduce soil fertility. Environmental conditions largely influence cotton fiber length.

As observed from the result (), the difference between the quality of organic and BT cotton fiber qualities is narrow. It was reported that cotton quality is affected by cotton cultivars and growing conditions (Price et al., Citation2009).

The fiber quality is mainly affected by the genotype and environmental conditions, such as weather conditions, irrigation management, fertilization, and cultural practices (Hussain et al., Citation2022).

4.1. Spinning consistency index (SCI)

The SCI of the varieties fell between 131.7333 and the maximum SCI was observed by JKCH-1947 151 and a minimum of 121 for Dp 90 Arba Minch (). The spinning consistency index (SCI) is a calculation for predicting the overall quality and spinnability of the cotton fiber, the higher the index, the better the overall fiber spinnability (Majumdar et al., Citation2004).

Biotechnology in agriculture is generating tolerant crops to biotic and abiotic stress, as seen by the greater SCI of GM cotton (Askari-Khorasgani & Pessarakli, Citation2018), as a result, the fiber’s mechanical properties have improved.

Spinning consistency has a significant effect on the qualities of studied cotton fibers varieties, untreated Dp 90 and treated Dp 90 at Forgena have SCI mean variation with Organic (MRC 270) and Jkch-1947 (p = 0.00 and 0.009), however, there is a narrow change in the mean between untreated Dp 90 and Dp 90 at Arbaminch, and Acala SJ2 because the cultivation system was almost the same conventional production system. However, untreated Dp 90 at Forgena has a heterogeneous mean with untreated Dp 90 at Arba Minch.

The mean of Acala SJ2 is similarly the same with untreated Dp 90 and treated Dp 90 and the mean is varied for Dp 90 from Arba Minch, Organic (MRC 270), and Jkch-1947. However, Dp 90 Arba Minch has a significant mean difference with treated Dp 90 at Forgena, Dp 90 Arba Minch, Acala SJ2, Organic (MRC 270), and JKCH 1947.

4.2. Maturity

The degree (amount) of fiber cell wall thickening with the diameter or fineness of the fiber is known as fiber maturity (Perkins et al., Citation1984; Shaukat et al., Citation2013). It has a significant effect on cotton fiber qualities of the same varieties grown in different regions and different varieties of cotton result in a change in the maturity of the fiber. Growing conditions also affect the growth and maturity of the crop which ultimately affects fiber thickening and Micronaire (Rajput et al., Citation2017).

Cotton seed normally bears a heavy load of microorganisms in the fuzz in addition several kinds of bacteria and fungi find their way into the interior of the seed. From the result, it becomes found that the cotton seed loss from microorganisms (treated seed, genetically modified cotton) indicates a successive maturity ratio. The maturity index can vary depending on the variety, planting time, product management system, climatic conditions, and harvest time. It was reported that micronaire is low in immature cotton fibers due to the mechanical property of the fiber being affected (Yasar & Karademir, Citation2021). The mature fiber has good spinning quality as compared to immature fiber the higher maturity of BT cotton is attributed to the ability of this cultivar to produce medium-sized plants and hence, transfer more photosynthesis to developing bolls for rapid maturity (Aziz et al., Citation2011).

4.3. Micronaire value

The micronaire value has significantly affected the quality of different cotton varieties between and within groups. Fiber fineness is another important fiber character affecting yarn strength. It contributes to the number of fibers in the cross-section of yarn. The finer the cotton, the more fibers per cross-section there are, resulting in increased yarn strength (Ashokkumar et al., Citation2014). To avoid having the fiber grow excessively coarse for spinning, micronaire levels more than 4.9 are less desired (Guitchounts, Citation2003).

Micronaire value is an indirect measurement of fineness thus high micronaire value results in coarse fiber and low-value results in fine fiber (Addis et al., Citation2022). In this study Acala SJ2 () variety cotton results in fine fiber. Next to Acala SJ2, BT cotton JKCH 1947 is finer than the rest of the verities. It was also reported by Rajput et al. (Citation2017), that the micronaire value of transgenic varieties was slightly greater than conventional non-BT cotton varieties. Conversely, a high micronaire can be misinterpreted as too coarse (high Mtex) when the sample maturity is high wherein the lumen does not collapse and cell wall circularity is maintained (Addis et al., Citation2022). The micronaire value of untreated Dp 90 Forgena, treated Dp 90 Forgena, Dp 90 Arba Minch, and Organic (MRC 270) are slightly the same, however, their micronaire value is significantly different from JKCH 1947 and Acala SJ2. The micronaire value of treated Dp 90 at Forgena, JKCH 1947, is slightly the same. However, the value is significantly different from Acala SJ2.

The mean micronaire value of JKCH 1947 has an insignificant difference to other varieties however it shows significant variation with Dp 90 untreated Forgena. The micronaire value of Organic (MRC 270) cotton is no significant difference between different varieties of cotton. The Micronaire value of Acala SJ2 is different from the micronaire of all cotton varieties however JKCH 1947 BT cotton Is not affected. The micronaire value of Dp 90 Arbaminch is varied compared with Acala SJ2. However, the value is slightly the same compared with the rest of the cotton varieties. The variation in micronaire value is due to the varieties being collected from different regions of Ethiopia and varieties are not of the same kind. The study concluded that Cotton lint with a micronaire below 3.5 is usually considered immature and weak. Therefore the current cotton varieties in this study are mature fibers according to Chaudhry and Guitchounts (Citation2003).

4.4. Fiber length

The length of the fibers has a significant impact on the quality of cotton. Generally, four typical staple measures characterize the quality of the fibers in a way that the longer the staple, the better the quality. The length of the fibers is inherent, and it varies greatly among cotton species and types (McAlister et al., Citation2003). The lowest quality refers to ‘short’ fiber lengths <25 mm, followed by ‘medium’ lengths between 25 and 30 mm, ‘long’ fibers at 30–35 mm, and the so-called ‘extra-long’ fibers at >35 mm (also called Extra Long Staple, ELS) (Exchange, Citation2017).

The average length for DP 90, Acala SJ, and JKCH 1947 was 27.61, 28.3, and 27.6 mm, respectively which was reported in similar work (Lançon & Woldu, Citation2020) as 27.7 for DP 90, 28.6 for Acala SJ and 27.8 for JKCH 1947.

According to the observed results (), untreated Dp 90 from Forgena farms had a minimum fiber length of 27.17 mm and a maximum fiber length of 28.3 mm for Acala SJ2. It is advised to use Acala SJ2 for Ethiopian irrigation and rain-fed crops (Lançon & Woldu, Citation2020). Fiber length is largely upland cotton fiber length conversion affected by variety, the plants to risky extreme temperatures, water imbalance, or nutrient insufficiencies may result in short fibers. Fiber length depends on the variety of cotton, but also the plants’ exposure, very high temperatures, water stress, and nutrient deficiencies can shorten the length. The longer the Fibers, the stronger the fiber (Addis et al., Citation2022). The untreated Dp 90 produced in the northern part of Ethiopia around the Amhara region Metema Woreda Forgena cluster was compared with Dp 90 where the seed is treated before plantation results in a mean length of 28.06 mm was higher than untreated DP 90 with fiber length 27. 17 mm length of fiber is attributed to the treated seed the benefits of seed treatments are increased germination, uniform seedling emergence, protection of seeds or seedlings from early-season diseases and insect pests, and improved crop emergence and growth (Govindaraj et al., Citation2017). The mean length of untreated DP 90 Forgena and treated Dp 90 at Forgena compared with different types of fiber shows a significant difference with p < 0.05. The mean difference between JKCH-1947 and varieties of cotton is significant except for Organic (MRC 270) and Dp 90 Arba Minch.

In comparison to the other types and variations, the means of Organic (MRC 270), Acala SJ2, and untreated DP 90 at Forgena differ and are not statistically significant. For every cotton fiber, there is a considerable mean difference in Acala SJ2. There is a noteworthy average variation between Dp 90 Arbaminch, treated Dp 90 Forgena, and untreated Dp 90 Forgena in comparison to Acala SJ2. However, the change in mean fiber length with, JKCH 1947 and Organic (MRC 270) Dp 90 Arbaminch was not found different they have insignificant mean variation. From the results above Acala, SJ2 is the finest fiber, in a similar report by Ibrahim (Citation2018) and the tallest fiber is the finest and strongest. Moderate temperatures during the fiber elongation phase can result in the longest fiber length, but maximum temperatures, extreme water stress, and potassium deficiency can shorten the fiber.

4.5. Uniformity index

Significant differences (p < 0.05) in the uniformity index between the cotton varieties were discovered.

The Uniformity Index expresses the ratio of the Mean Length to the upper half mean Length. Forgena with DP 90 untreated and Dp 90 treated Forgena and JKCH 1947, Acala SJ2, and Dp 90 Arbaminch exhibit a large mean difference. The means are not varied compared with Organic (MRC 270), and DP 90-treated Forgena.

The mean uniformity index of JKCH 1947 was observed inversely compared with all-cotton varieties studied. The uniformity index of Organic (MRC 270) is diverse with JKCH-1947, Acala SJ2, and Dp 90 Arbaminch and close to the uniformity means of DP 90 untreated Forgena and Dp 90 treated Forgena.

The mean uniformity index of Acala SJ2 has a significant difference from the rest of the cotton varieties and the difference was not significant with Dp 90 Arba Minch untreated. There is a significant variation of uniformity index between Dp 90 Arba Minch untreated, JKCH 1947, DP 90 untreated Forgena, and Dp 90 treated Forgena.

Fiber length and length uniformity are the primary factors in yarn uniformity and defect level (Braden, Citation2005). An unexpected proportion of short fibers is likely present in a fiber with a poor homogeneity index.

4.6. Fiber strength

Fiber strength and elongation have a significant effect on the types and variety of cotton. Stronger fibers tend to have higher elongation which results in better work-to-break (Tesema & Drieling, Citation2019).

The cotton cultivars range in strength from strong to average strong fibers, according to the study (). The transgenic cotton varieties showed a reduction in staple strength compared with conventional varieties (Wu et al., Citation2003). Fiber strength is largely determined by variety. However, it may be affected by plant nutrient deficiencies and weather (Osman, Citation2018). Dp 90 untreated Forgena and Dp 90 treated Forgena have mean differences with Organic (MRC 270) and Dp 90 Arba Minch and no significant mean difference with the rest of the cotton varieties. There is a strong difference between JKCH 1947, Organic (MRC 270), and Dp 90 Arba Minch, however, there is no change in fiber strength between JKCH 1947, Dp 90 treated Dp 90 untreated seed, and Acala SJ2. There is insignificant strength variation between Acala SJ2; Dp 90 treated Forgena, and Dp 90 untreated Forgena, JKCH1947. Fiber strength depends on many factors, with genotype being critical. However, cultural practices and environmental conditions also affect fiber quality, Low fiber strength values were attributed to dry growing conditions (Salah et al., Citation2015). The fiber strength of hybrid JKCH-1947 was 28.1740 which is in line with the study by (Gudeta et al. Citation2023) where the fiber strength for the hybrid is from 27.75 to 28.59 g/tex.

4.7. Fiber elongation

Elongation is the degree of stretching or lengthening of a fiber under a tensile force. Fiber elongation is commonly measured as ‘elongation-at-break’, which is the amount of stretch that can be endured by the fiber before it breaks. A fiber that will stretch or elongate more before breakage will show greater ‘toughness’, or durability, than a stiffer fiber that breaks at the same breaking load but with a lower elongation (Mathangadeera, Citation2014).

Fiber elongation has a significant effect on cotton fiber varieties and types. The DP 90 untreated, Dp 90 treated Forgena, and JKCH 1947 have fiber elongation mean difference with Organic (MRC 270), and Acala SJ2, However, there is a significant difference between Dp 90 treated and Dp 90 Arba Minch. There was a significant mean difference in the elongation of Organic (MRC 270), and Acala SJ2 with the rest of the varieties. The mean difference between Dp 90 Arba Minch Organic (MRC 270), and Acala SJ2 and There is a narrow change in elongation with other cotton types. The Elongation % difference between organic and conventional cotton is believed to be due to that the elongation process is considered to be unstable and sensitive to external factors (environment, nutrition, etc.) (Salah et al., Citation2015).

4.8. Color

Color change may be caused by several factors, such as foreign matter, exposure to rain and moisture, honeydew, exposure to UV particle radiation, heat, and bacterial degradation. Color is well defined in terms of its reflectance (Constable et al., Citation2015) and yellowness (+b) or color grade, which can be tested by a photoelectric cell (Addis et al., Citation2022). The color Reflectance (Rd) was greater in the conventional system, and the minimum yellowness (b+) minimum reflectance for organic, and BT cotton so the finding agrees with (Mohamed, Citation2003). Also similar findings by Rajput et al. (Citation2017), there was a minor enhancement in reflectance among different transgenic varieties.

With variation, Dp treated has insignificant reflectivity. The reflectance means of DP 90 untreated, Acala SJ2, and Dp 90 from Arba Minch are homogeneous. JKCH 1947 BT cotton differs significantly from all other types. Acala SJ2, Dp 90 untreated seed, Dp treated seed, and Dp 90 from Arbaminch had insignificant mean yellowness variation. Dp treated and Dp 90 from Arbaminch, on the other hand, have identical yellowness values. When compared to all cotton varieties, JKCH 1947 Bt cotton and organic cotton have a significant yellowness mean difference. The reflectance means of DP 90 untreated, Acala SJ2, and Dp 90 from Arba M inch are homogeneous. JKCH 1947 BT cotton differs significantly from all other types of short fiber.

Short fiber has a significant effect on the quality of cotton fiber. Dp 90 untreated Forgena has different means with all-cotton varieties except for Acala SJ2 with the approximate mean.

Dp 90 treated Forgena has a mean difference with Acala SJ2 and Dp 90 Arbaminch however the means of Organic (MRC 270), Dp 90 untreated Forgena, JKCH 1947, and Dp 90 treated Forgena has no change. JKCH-1947 shows a mean difference with Dp 90 untreated Forgena, Acala SJ2, and Dp 90 Arba Minch and no mean variation with Organic (MRC 270) and JKCH 1947. Organic (MRC 270 has to mean difference with Dp 90 untreated Forgena, Acala SJ2, and Dp 90 Arba Minch, narrow change in mean with JKCH 1947, Organic (MRC 270), and Dp 90 treated Forgena. The mean difference between Acala SJ2 and Dp 90 Arba Minch is significant with all the rest of the short fiber index (SFI) of cotton varieties.

Short fiber represents a loss in being combed out in spinning and contributes to a lack of uniformity (Constable et al., Citation2015)With variation, Dp treated has insignificant reflectivity.

4.9. Correlation between cotton quality parameters

As shown in below the correlation between different cotton types can be posited as follows: the Spinning consistency index has a strong relation with maturity, uniformity index, fiber strength, and elongation nevertheless micronaire has little relation with fiber length and short fiber index. Micronaire value has a positive relationship with the uniformity index. Maturity has a positive relationship with the Spinning consistency index, fiber length, short fiber index, uniformity index, fiber strength and elongation, and a weak relationship with micronaire. UHML has a positive relation with Maturity, uniformity index, and short fiber index. There is a weak relationship with fiber strength, elongation, and micronaire.

Table 6. Correlation between cotton fiber parameters.

Maturity, micronaire, spinning consistency index, fiber strength, and elongation all benefit from UI, while fiber length and short fiber index have a poor relationship. Short fiber index has a substantial effect on Maturity, fiber length, and negative relation with micronaire, spinning consistency index, fiber strength, and elongation. Spinning consistency index, Maturity, fiber elongation, and fiber length all have a good relationship with fiber strength, whereas micronaire and short fiber index have a poor relationship. Fiber elongation has a favorable relationship with the spinning consistency index, Maturity, fiber length, and uniformity, but it has a poor relationship with micronaire and the short fiber index.

5. Conclusion

Cotton of the same and different varieties is collected from different regions of the country. According to statistical results, it was concluded that the one-way ANOVA shows that essential cotton quality parameters of sample cotton varieties are significant. According to HVI results, the mean variation revealed that the properties of BT cotton are improved. However, genetic modification of BT cotton does not exceedingly improve fiber quality and the salient property is to resist insects, pests, and ball worms. The Lint quality characteristics of transgenic cotton varieties are not significantly affected compared with conventional varieties. Organically cultivated MRC 270 cotton is the new variety where strength and elongation were improved. Organic cultivation reduces the stress on fiber through water irrigation and chemicals.

There is significant mean variation between BT organic cotton; and conventional cotton varieties. The treated Dp 90 cotton is found to have good fiber properties compared to untreated seed cotton. The chemical-treated cotton fiber protects seeds or seedlings from early-season diseases, fungi, and insect pests. The essential fiber parameters, such as micronaire, length, strength, maturity and length uniformity ratio of studied cotton in Ethiopia are under the cotton grading of A and B. There is a strong and weak correlation between fiber parameters.

Based on the study, rain-fed and irrigated cotton from different regions of the country is collected, from the varieties, organic cotton variety resulted in acceptable quality and recommended to be cultivated in rain feed, and both conventional and genetically modified cotton varieties to be recommended for both irrigated and rain feed cultivation areas at different areas of Ethiopia.

Future perspectives

The single fiber property of new varieties of BT and organic cotton should be investigated on USTER® AFIS PRO2 and FAVIGRAPH in the future, as well as the impact of chemical seed treatment on cotton varieties from various regions. These tasks should be done in addition to ongoing annual research follow-ups on BT and organic cotton quality.

About the Author.docx

Download MS Word (13.4 KB)Supplmentary material.docx

Download MS Word (31 KB)Disclosure statement

No potential conflict of interest was reported by the author(s).

Data availability statement

The authors have annotated the entire data-building process, the empirical techniques presented in the paper, and the number of runs generated using SPSS 22 software for the characterization and analysis of the cotton parameters of different varieties. All data used to support the findings of this study are included in the paper.

Additional information

Funding

Notes on contributors

Chirato Godana Korra

Chirato Godana Korra was born in 1992 in the Karat ZuryaWoreda district of the Konso Zone, a Southern Nation Nationality. After completing preparatory school, I graduated from the Ethiopian Institute of Textile and Fashion Technology (EiTEX), Bahir Dar University, Ethiopia, with a BSc in Textile Engineering (July 2016) and an MSc in Textile Chemistry (July 2019). I am currently employed as a Lecturer at Wolkite University’s College of Engineering and Technology. I conduct research in the field of textiles, and my published works include studies on the surface roughness of textile fabric structures, modeling, flame retardant textiles, antifungal textiles, and starch for cotton sizing. The current research interests are in the field of Characterization of genetically modified, organic, and conventional cotton varieties which includes related fields of agriculture, biotechnology, engineering, and statistics.

Kura Alemayehu Beyene

Kura Alemayehu Beyene was born in August 1991 in Ambo Twon, West Oromia region. After completing preparatory school, I received a BSc. in Textile Engineering (July 2016) and an MSc. in Textile Manufacturing (July 2019) from the Ethiopian Institute of Textile and Fashion Technology (EiTEX), Bahir Dar University, Bahir Dar Ethiopia. I began working as a Lecturer and Researcher at the Ethiopian Institute of Textile and Fashion Technology (EiTEX), Bahir Dar University in July 2016 and have continued to do so. I have many published research and review papers in different indexed journals (e.g. WOS, SCOUPS, etc.) in the area of Cellulosic-based conductive hydrogels, Self-Responsive Electrospun Nanofibers Wound Dressings, effects of pretreatment on the surface roughness textile fabrics, studies on geometerical surface properties of textile fabrics, and statistical modeling for prediction and evaluation geometerical surface properties of textile fabrics, etc.

Tiliksew Addis Desta

Tiliksew Addis Desta was born in Dangila woreda, West Gojam Amhara regional state in June 1972. After completing high school in Dangila Secondary school, she joined Bahirdar polytechnic institute, the current Bahir Dar University after graduating with an advanced diploma in textile technology. I worked in Arbaminch textile factories as a physics laboratory head and process control experts from to 1997-2005. Since 2005 I have continued to work and study in the BahirDar University up to now. I have graduated from Ethiopian Textile and Fashion Technology institute with MSC degree in Textile Technology and currently I am working as a lecturer in the same university.

References

- Action, P. (2007). The deadly chemicals in cotton. Environmental Justice Foundation in Collaboration with Pesticide Action Network UK.

- Addis, T., Kachi, A., Akankwasa, N. T., & Wang, J. J. (2022). Analysis of the cotton varieties under production in Ethiopia. Journal of Natural Fibers, 19(4), 1–16. https://doi.org/10.1080/15440478.2020.1780181

- Ashokkumar, K., Kumar, K. S., & Ravikesavan, R. J. (2014). An update on conventional and molecular breeding approaches for improving fiber quality traits in cotton–A review. 13(10), African Journal of Biotechnology, 1097–1108.

- Askari-Khorasgani, O., & Pessarakli, M. (2018). Safety assessment of genetically modified crops for yield increase and resistance to both biotic and abiotic stresses and their impact on humans and the environment. Advances in Plants & Agriculture Research, 8(2), 109–112.

- Aziz, A., Akhtar, N., Afzal, M., Ashraf, M., Tanveer, A., Ahmad, R., Safdar, M. E., & Ahmad, S. (2011). Comparative performance of BT cotton with some elite conventional cotton cultivars under arid to semi-arid conditions. African Journal of Agricultural Research, 6(6), 1600–1606.

- Baffes, J. (2005). The “cotton problem”. The World Bank Research Observer, 20(1), 109–144. https://doi.org/10.1093/wbro/lki004

- Braden, C. A. (2005). Inheritance of cotton fiber length and distribution. Texas A&M University.

- Chaudhry, M. R., & Guitchounts, A. (2003). Cotton facts. International Cotton Advisory Committee.

- Constable, G., Llewellyn, D., Walford, S. A., & Clement, J. D. (2015). Cotton breeding for fiber quality improvement. In V. M. V. Cruz, , & D. A. Dierig, (Eds) Industrial Crops. Handbook of Plant Breeding, 9, 191–232.

- Devrent, N., & Palamutcu, S. (2017). Mini review on organic cotton. Journal of Textile Engineering & Fashion Technology, 3(2), 610–614.

- Exchange, T. (2017). The quick guide to organic cotton. Textile Exchange.

- Foolad,, M. R. J. (2007). Current status of breeding tomatoes for salt and drought tolerance. (Vol. 1, pp. 669–700). Dordrecht: Springer.

- Gebregergis, Z., Baraki, F., & Teame, G. J. (2020). Planting geometry of cotton under rain-fed conditions in the dry land areas of western Tigray. Cogent Food & Agriculture, 6(1), 1771113. https://doi.org/10.1080/23311932.2020.1771113

- Gebretsadik, K., & Kiflu, A. (2018). Challenges and opportunities of genetically modified crops production; Future perspectives in Ethiopia, review. The Open Agriculture Journal, 12(1), 240–250. https://doi.org/10.2174/1874331501819010240

- Govindaraj, M., Masilamani, P., Albert, V. A., & Bhaskaran, M. J. (2017). Effect of physical seed treatment on yield and quality of crops: A review. Agricultural Reviews, 38(1), 1–14.

- Gudeta, B., Kedisso, E. G., Gurmessa, D., Tesfaye, D., Damtew, S., Taye, W., Gebre-Egziabher, A., Balcha, M., Daba, T., Workie, A., & Maredia, K. (2023). Adaptability of genetically engineered BT cotton varieties in different growing regions of Ethiopia. Advances in Agriculture, 2023, 1–16. https://doi.org/10.1155/2023/8224053

- Guitchounts, M. R. C. A. A. (2003). “Cotton Facts,” Common Fund for Commodities, International Cotton Advisory Committee.

- Hussain, A., Sajid, M., Iqbal, D., Sarwar, M. I., Farooq, A., Siddique, A., Khan, M. Q., & Kim, I.-S. (2022). Impact of novel varietal and regional differences on cotton fiber quality characteristics. Materials, 15(9), 3242. https://doi.org/10.3390/ma15093242

- Ibrahim, I. (2018). Effect of fiber length and short fiber percent in cotton on fiber and yarn quality. Alexandria Science Exchange Journal, 39(October–December), 663–668. https://doi.org/10.21608/asejaiqjsae.2018.20692

- Jayant, M., Rashmi, J., Shailendra, M., & Deepesh, Y. (2011). Production of cellulase by different co-culture of Aspergillus niger and Penicillium chrysogenum from waste paper, cotton waste and bagasse. Journal of Yeast and Fungal Research, 2(2), 24–27.

- Lançon, J., & Woldu, B. (2020). The Ethiopian cottonseed system–Description, analysis and recommendations. 20–21.

- Mageshwaran, V., Satankar, V., Shukla, S., & Kairon, M. (2019). Current status of organic cotton production. Indian Farming 69(2), 09–14.

- Majumdar, A., Majumdar, P. K., & Sarkar, B. (2004). Selecting cotton bales by spinning consistency index and micronaire using artificial neural networks. AUTEX Research Journal, 4(1), 1–8. https://doi.org/10.1515/aut-2004-040101

- Mallick, S. (2017). Scientific perspective on sustainable development goals for Pakistan. A Scientific Journal of COMSATS, 21(1), 52–62.

- Manik, N., & Ravikesavan, R. (2009). Emerging trends in enhancement of cotton fiber productivity and quality using functional genomics tools. Biotechnology and Molecular Biology Reviews, 4(1), 11–28.

- Marra, M. M. (2007). Assessment by US cotton growers and other cotton experts of important innovations in cotton production in the last decade (1996–2006). Journal of Cotton Science, 11(4), 259–265.

- Mathangadeera, R. (2014). Evaluating the impact of fiber processing on cotton fiber tensile properties.

- McAlister, D. D.III, Foulk, J. A., & Harrison, R. E. (2003). Advanced fiber information system length measurement of kinds of cotton hand-sorted by length group. Journal of Cotton Science, 7(4), 259–266.

- Mengistu, F. (2017). Cotton research strategy 2016–2030.

- Mohamed, A. S. (2003). Differences in fiber contents of the major chemical constituents due to the variety and grade of some Egyptian kinds of cotton. Egyptian Journal of Agricultural Research, 81(2), 659–670. https://doi.org/10.21608/ejar.2003.276597

- Nicolay, G. E. G., Walsh, C., & Desalegn, P. (2020). Cotton value chain analysis in Ethiopia. Report for the European Union, DG-DEVCO. Value chain analysis for development project. European Union, 1, 43–44.

- Osman, K. (2018). Management of soil problems. Springer.

- Perkins, H., Ethridge, D., & Bragg, C. (1984). Fiber. In R. J. Kohel & C. F. Lewis (Eds.), Cotton Agronomy Monographs 24 (pp. 437–509). ASA, CSSA, and SSSA.

- Phillips, T. (2008). Genetically modified organisms (GMOs): Transgenic crops and recombinant DNA technology. Nature Education, 1(1), 213.

- Pretorius, M. M., Allemann, J., & Smith, M. F. (2015). Use of the AMMI model to analyse cultivar-environment interaction in cotton under irrigation in South Africa. African Journal of Agriculture, 2(2), 76–80.

- Price, C., Senter, H., Foulk, J., Gamble, G., & Meredith, W. (2009). Relationship of fiber properties to vortex yarn quality via partial least squares. Journal of Engineered Fibers and Fabrics, 4(4), 155892500900400412. https://doi.org/10.1177/155892500900400412

- Rajput, L. B., Cui, J., Zhang, S., Luo, J., Wang, C., & Lv, L. (2017). The effect of the different transgenic BT cotton technology on the fiber quality. Journal of Basic and Applied Sciences, 13, 166–170.

- Rashid, B., Khan, G. A., Husnain, T., & Riazuddin, S. (2009). Field evaluation and fiber analysis of transgenic cotton. Journal of Crop Science and Biotechnology, 12(3), 135–141. https://doi.org/10.1007/s12892-009-0112-x

- Salah, M. S., Abdel-Rahim, E. A. 2., Ahmed, S. H. 3., & Abdel-Baset, Y. (2015). Quality impact of conventional and organic cotton of Egyptian seed and fiber of Giza 86 variety. International Journal of Advanced Science and Engineering, 2(1), 26–31.

- Shaukat, S., Khan, T. M., Shakeel, A., & Ijaz, S. (2013). Estimation of best parents and superior cross combinations for yield and fiber quality-related traits in upland cotton (Gossypium hirsutum L.). Science, Technology and Development Journal, 32, 281–284.

- Simon Ferrigno, S. G. R., Ton, P., Davo Simplice Vodouhê, S., & Wilson, W. A. J. (2005). Organic cotton: A new development path for African smallholders? International Institute for Environment and Development, 25,1–25.

- Staffs, F. (2019). Ethiopia cotton production annual (No. ET1906).

- Tesema, G. B., & Drieling, A. (2019). Statistical analysis and instrumental characterization of commercial Ethiopian cotton varieties. Journal of Textile and Apparel, Technology and Management, 11(1), 1–16.

- Wu, K., Guo, Y., Lv, N., Greenplate, J. T., & Deaton, R. (2003). Efficacy of transgenic cotton containing a cry1Ac gene from Bacillus thuringiensis against Helicoverpa armigera (Lepidoptera: Noctuidae) in northern China. Journal of Economic Entomology, 96(4), 1322–1328. https://doi.org/10.1603/0022-0493-96.4.1322

- Yasar, S., & Karademir, E. (2021). Determination of the factors limiting cotton fiber quality in Turkey.

- Zeleke, M., Adem, M., Aynalem, M., & Mossie, H. (2019). Cotton production and marketing trend in Ethiopia: A review. Cogent Food and Agriculture, 5(1), 1691812.