Abstract

Various studies indicate that resources pose one of the primary challenges for SMEs in enhancing their performance. Existing theories and concepts are often impractical and too complex to be applied effectively in improving SME performance and feasibility due to resource limitations. This paper aims to design a model for strengthening the performance and feasibility of SMEs, particularly micro-industries, by integrating three crucial approaches: business model canvas, functional organization, and supply chain management. The resulting model, named ‘Feasibility Model for SMEs,’ can serve as a simple and practical solution by focusing on key variables resulting from the integration of these three approaches. The research methodology involves a literature review and conceptual research to design the SME performance enhancement model. Subsequently, the model is applied to SME cluster X. Quantitative research is conducted using smart PLS tools to confirm the theory and test hypotheses regarding the design model for 50 SMEs. The model testing results indicate that supply chain, production, value proposition, and marketing are significant variables for enhancing SME performance. The model designed in this study is novel and highly practical for enhancing SME feasibility focusing on five variables, namely supply chain, production, value proposition, marketing, and performance.

Reviewing Editor:

1. Introduction

The role of SMEs in enhancing the Indonesian economy is undeniable, even amidst the global economic downturn caused by the Covid-19 pandemic and the Ukraine war, triggering food and energy crises. Indonesia has 64.2 million SMEs, contributing 61.07% to the GDP, equivalent to 8,573.89 trillion Indonesian rupiahs. SMEs contribute to Indonesia’s economy by absorbing 97% of the total workforce and gathering 60.4% of total investments (Ministry of Economy, Citation2021). Literature suggests that SMEs contribute to GDP, act as engines for economic growth, absorb workforce, and facilitate socioeconomic transformation (Hatega, Citation2007; Kigozi, Citation2006; Okello, Citation2008). Besides their national economic contributions, SMEs are considered drivers of the global economy (Ardic et al., Citation2011). In addition to promoting economic growth, SMEs can enhance business competitiveness and foster innovation in product and service provision (Poole, Citation2018; Ratten, Citation2014).

However, SMEs face various global challenges in conducting their businesses, ranging from technology and financial constraints to human resource capabilities, production facilities, and managerial limitations. Common challenges include a lack of capital, leadership, and human resources (Achanga et al., Citation2004). Resources are generally acknowledged as one of the main challenges for SMEs in improving performance and growth (Amornkitvikai & Harvie, Citation2018; Taylor, Citation2013). A SWOT analysis of one SME cluster, focusing on knitwear production, indicated that the micro-industry is positioned in the WT (weakness-threat) quadrant, signifying weaknesses and facing threats (Chumaidiyah et al., Citation2018).

Various stakeholders, including the government, associations, academics, and independent institutions, are interested in aiding SMEs in enhancing performance through means such as facilitating capital loans, mentorship, takeovers, and skills training. Research on the government’s role in improving performance and inter-firm collaboration yields positive, negative, or non-impactful results (Doh & Kim, Citation2014; Guan & Yam, Citation2015; Hong et al., Citation2016). While good governance has been shown to affect products and services, it has not been proven to enhance SME performance (Dubey & Das, Citation2022). SMEs with limited resources may require external business mentoring or consultancy (Carey, Citation2015).

Other hindrances impacting SME performance and competitiveness include limited information about financing, inadequate and expensive raw material supply, and restricted access to business networks (Hatega, Citation2007; Kigozi, Citation2006). The supply chain is a critical indicator affecting SME performance, with issues such as delayed deliveries and inadequate supply chains impacting outcomes (Ntayi et al., Citation2010). The Covid-19 pandemic has exacerbated supply chain challenges, particularly in transportation due to regional restrictions, regulatory instability, strikes, floods, and heavy rain (Ali et al., Citation2021; Chowdhury et al., Citation2021; Laorden et al., Citation2022).

Given these challenges, opportunities, and obstacles, it is essential to reevaluate all business processes and activities comprehensively using a business model. The Business Model Canvas, consisting of nine elements, offers potential for capturing or creating added value (Morris et al., Citation2005; Osterwalder, Citation2004; Osterwalder & Pigneur, Citation2010). Each element in the Canvas has varying degrees of influence on a company’s success (T. Ladd, Citation2017).

Numerous overlapping and complex approaches, concepts, and theories make practical application challenging for SMEs. Researchers often face questions about the most suitable and practical concepts and approaches to improve SME performance considering their constraints and resources. This research designs a simpler yet comprehensive approach for enhancing SME performance.

SMEs in Indonesia generally share similar characteristics, facing challenges and resource limitations, making a single approach often ineffective in improving SME performance. This study uses a case study as confirmation and testing of the developed model, focusing on SME actors in the knitwear industry cluster X located in a single industrial center. The knitwear industry SME cluster X faces internal constraints such as low product quality, a lack of human resource skills, outdated machinery, narrow access roads, dense locations, and a shortage of knitwear raw materials (Chumaidiyah et al., Citation2018). Key factors influencing the success of the knitwear industry cluster are machining, creativity, marketing, and government policies (Chumaidiyah et al., Citation2020). These characteristics represent SMEs in general, making SME cluster X a case study in this research.

This paper aims to design a simple model for strengthening SME performance, particularly micro-industries, using a new integrated approach that aligns with SME capacities and resources. The conceptual framework integrates the BMC, functional organization, and supply chain management to enhance micro-industry SME performance, presenting a novel contribution. The research model design produces important variables from the integration of these three approaches that can be used as an effective framework for enhancing SME performance.

2. Literature review

2.1. Business model to capture value for SME

A series of activities within a company aimed at creating added value are mapped out as a business model, illustrating how the processes and business are executed. The business model portrays the entirety of the business, activities, and how the business operates to create value, revealing the business logic (Asadnezhad et al., Citation2017; Carter & Carter, Citation2020). Organizations capable of adapting and changing their business models have the potential to develop and increase its sustainability (Christensen et al., Citation2016). The significance of SMEs in raising awareness of the business model as a tool for mapping and developing enterprises, considering overall activities, is crucial, with one of the most popular being the Business Model Canvas (BMC) proposed by Osterwalder and Pigneur (Citation2010).

BMC is a simple business model that needs to be understood and considered in running a business to generate value and improve SME performance (Osterwalder & Pigneur, Citation2010). Research on informal sector women-led SMEs in India shows that the business canvas focuses on key partners, key resources, customer orientation, and sales promotion (S. Mukherjee, Citation2023). BMC is widely used with some empirical studies; a study on teams competing in an entrepreneur acceleration program indicates that teams using elements such as customer segment, value proposition, key activities, or key partnerships perform better in the competition (T. Ladd, Citation2017).

Company competition is determined by the value offered and accepted by consumers, making it a competition between the values of products created by each company. Generally, there are four crucial components of the value proposition in a business model: value creation, value capture, value delivery, and value communication (Rayna & Striukova, Citation2014). The business model is a feedback circle creating values for customers, catching the values, and returning them to the environment (Abdelkafi & Täuscher, Citation2016). The innovation theory of business models encompasses seven components: value drive, value goal, value proposition, value creation, value transfer, value capture, and value evaluation, all of which have interconnections, logic, and theoretical foundations (Jin et al., Citation2021).

2.2. Supply chain for SME competitive advantage

Efficient supply chains are crucial in supporting the competitive advantage of SMEs, with at least five indicators influencing SME performance: sales volume, accurate cost determination, coordination among departments, coordination with suppliers, and coordination with customers (Koh et al., Citation2007). Supply Chain Management (SCM) is an approach that focuses on managing all interconnected activities from primary suppliers to end consumers (Cooper et al., Citation1997). SCM involves the integration of demand and supply management within and between companies (CSCMP., Citation2013; Danese et al., Citation2013).

Research on SCM related to SMEs generally reveals a relationship gap between SMEs and more dominant partners in the supply chain (Arend & Wisner, Citation2005; Kaminski et al., Citation2008). This gap arises due to the disproportionate capabilities of SMEs compared to upstream and downstream industries, typically because of their role as suppliers to large companies rather than leading companies themselves (T. Cragg & Y. McNamara, Citation2018; Bordonaba-Juste & Cambra-Fierro, Citation2009).

The supply chain of SMEs has also been disrupted by the COVID-19 pandemic, particularly as SMEs often lack sufficient knowledge and access to technology (Antonescu, Citation2020; Priyono et al., Citation2020). Supply chain sustainable in SMEs is crucial, influenced by culture and teamwork, competencies, information systems, and costs (Bak et al., Citation2020; Liu et al., Citation2021). The resilience of the supply chain in SMEs is an interesting area for study due to its broad application in recent decades (Mishra et al., Citation2022; Mishra & Singh, Citation2022).

2.3. Approach for SME performance

There are various approaches and theories serving as the foundation for measuring the performance of SMEs, including the functional approach, which assesses business performance from various functional aspects such as marketing, production, finance, and human resources. The performance of SMEs is also measured across four categories: subjective measures, accounting measures, stability measures, and cumulative abnormal returns (Christoffersen et al., Citation2014; Prabhudesai & Prasad, Citation2017). The business model is an approach that contributes to company performance through an attractive value proposition for consumers, generating revenue streams and impacting the competitive advantage of the product and service portfolio (Karimi & Walter, Citation2016; Teece, Citation2010).

Numerous studies indicate that the business model is crucial for the success of companies seeking growth (Terrenghi et al., Citation2017), achieving competitive advantage (Afuah & Tucci, Citation2000), and enhancing long-term company performance (Bock et al., Citation2012). Therefore, companies aiming to improve long-term performance must be innovative in developing their business models, especially when leveraging the potential of cutting-edge technology by creating new business models (Chesbrough & Rosenbloom, Citation2002) that can enhance company capabilities. The structured development of business models by connecting key elements as a method of adapting and innovating to market changes is referred to as Business Model Innovation (BMI) (Foss & Saebi, Citation2017; Hartmann et al., Citation2013). The correlation between BMI and company performance has been extensively studied, showing a significant contribution to enhancing corporate strategies (Hartmann et al., Citation2013; Lambert & Davidson, Citation2013; Latifi et al., Citation2021).

Financial performance is a critical component of SME performance, with accounting measures such as return on assets (ROA), return on equity (ROE), and return on sales (ROS) used to gauge financial performance indicating the level of company profitability (Parker, Citation2000). Although financial performance is crucial, it is not sufficient to measure the overall performance of a company (Murphy et al., Citation1996). Company performance is also determined by business scope, future company position, and market growth such as diversification, market share, and product development (Gray, Citation1997).

Performance management systems and processes (PMSP) are a topic that addresses management performance encompassing cross-functional aspects within an organization. PMSP is applied in organizations to determine where, how, and for whom PMSP creates value (Bisbe et al., Citation2019; De Leeuw & Van Den Berg, Citation2011). The functional areas of the organization include supply chain management and operations (De Leeuw & Van Den Berg, Citation2011; Forslund & Jonsson, Citation2009), marketing and sales (Bartol, Citation1999), human resources management (Aguinis, Citation2014; DeNisi & Smith, Citation2014), management accounting (Otley, Citation1999), and strategic management (O’Connell & O’Sullivan, Citation2014).

2.4. Research hypotheses

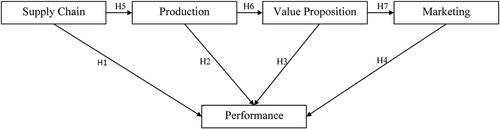

The research hypotheses proposed in this study consist of seven hypotheses:

H1: Supply chain influences performance.

H2: Production influences performance.

Production is a core activity in manufacturing companies, covering equipment suitability, production control, and production system integration. Continuous improvement processes and flexible equipment impact efficiency and productivity (Bayraktar et al., Citation2009). An efficient, productive, and high-quality production system will have a positive impact on SME performance. An efficient production process can reduce costs and improve the financial performance of SMEs (Bahri et al., Citation2017).

H3: Value proposition influences performance.

The value proposition indicates the characteristics of a company’s products and services that are valuable to customers and how they are offered (Clauss, Citation2017; Osterwalder & Pigneur, Citation2010). It explains how a particular company differentiates itself from its competitors and why customers choose to buy from that company instead of others. Previous research indicates that the value proposition has a positive impact on financial performance, where a company’s research and development capabilities have a positive effect on the value proposition (Ilyas & Osiyevskyy, Citation2022). Therefore, hypothesis H3 tests whether the value proposition influences SME performance.

H4: Marketing influences performance.

The success of a company is influenced by the success of marketing programs, with various studies showing how marketing contributes to company performance (Cao & Weerawardena, Citation2023; O’Sullivan & Abela, Citation2007). Marketing capabilities are initially related to marketing performance, then influences financial performance (Merrilees et al., Citation2011). Using big data analytics, marketing exploitation has a positive impact on both marketing and financial performance (Saeed et al., Citation2023). In this study, hypothesis H4 suggests that marketing influences performance.

H5: Supply chain influences production.

The quality of the supply chain, such as raw materials and other components, affects production outcomes, where good supply leads to good production processes, resulting in quality products. Various studies repeatedly discuss the supply chain, production, operations, and manufacturing, highlighting the importance of supply chain in production for SMEs (Johnstone, Citation2020; Machado et al., Citation2020). Hypothesis H5 tests whether the supply chain influences production.

H6: Production influences value proposition.

The integration of capabilities, technology, and new processes leads to increased production flexibility in supporting the creation of value as a value proposition (Bock et al., Citation2012). Production flexibility strengthens SMEs’ ability to respond to changes in market demand and new opportunities (Rajala et al., Citation2012). Changes in market demand are a primary reference in creating a value proposition. Hypothesis H6 suggests that production influences the value proposition.

H7: Value proposition influences marketing.

The reputation of SMEs in offering products to customers is crucial for marketing efforts. The value proposition becomes a driving factor for customers to appreciate the company (Ilyas & Osiyevskyy, Citation2022), which impacts increased sales. Various studies examine the influence of the value proposition on marketing (Biloshapka & Osiyevskyy, Citation2018; Bocken et al., Citation2015; Du et al., Citation2010; Ma & Osiyevskyy, Citation2017).

3. Methodology

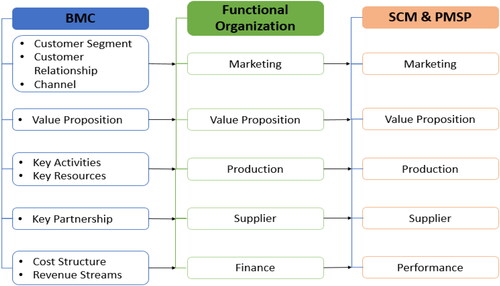

This study employs the BMC approach integrated with functional organization and SCM to measure the performance of micro-industry SMEs. All BMC components are mapped onto the functional organization based on the similarities among the elements in the business model and the functional organization using the Performance Management Systems and Processes (PMSP) approach. Subsequently, the functional organization is integrated into supply chain management, forming a process from upstream to downstream, where the performance of the supply chain system is measured from the financial performance perspective of micro-industry SMEs.

The mapping is adjusted to the characteristics of micro-industry SMEs, which have limited resources to perform activities in BMC elements. The mapping is detailed as follows:

Customer relationship, customer segment, and channel elements are transformed into marketing functions because these three elements are related to marketing activities in the SME organization, supported by various marketing theories (Kotler & Keller, Citation2021). Marketing is one of the functional areas and a primary activity in the organization (Bartol, Citation1999; Porter, Citation1998).

Value proposition represents the value offered by micro-industry SMEs for their products, which becomes a distinctive feature that is not easily imitated by competitors. In this case, the value proposition is manifested in product design and product quality offered by SMEs. The value proposition is related to design sensitivity to achieve organizational goals in producing value that influences organizational performance (Abdelkafi & Täuscher, Citation2016; Asadnezhad et al., Citation2017; Carter & Carter, Citation2020; Hansen, Citation2021; Jin et al., Citation2021; Rayna & Striukova, Citation2014; Zimmerman, Citation2020).

Key activities and key resources are resources and activities conducted to produce products; therefore, these two elements are related to activities in the production and operational processes that carry out production functions in micro-industry SMEs. Production activities are part of the manufacturing function, one of the primary activities in the organization (De Leeuw & Van Den Berg, Citation2011; Flapper et al., Citation1996; Forslund & Jonsson, Citation2009; Porter, Citation1998).

Key partnerships are entities directly related to micro-industry SMEs in supporting production activities, such as suppliers. Suppliers are associated with the supply of raw materials needed in production activities. SCM is part of the functional area in the organization that determines organizational performance (De Leeuw & Van Den Berg, Citation2011; Forslund & Jonsson, Citation2009).

Cost structure and revenue streams are related to the costs incurred and income generated in carrying out production activities. Both elements are integrated into the financial/financial functional area that manages the costs and income obtained by micro-industry SMEs. Management accounting is one of the functional areas in the organization (Euske et al., Citation1993; Murphy et al., Citation1996; Otley, Citation1999; Parker, Citation2000).

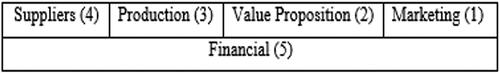

Thus, the nine elements of the BMC have been mapped into five functional areas in the organization to carry out processes and activities for micro-industry SMEs. In this functional organization of SMEs, there are at least five functions in its organizational structure. When associated with the process sequence in the value chain, the five functional areas in the micro-industry SME organization can be illustrated as follows ():

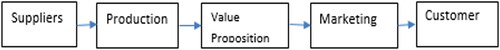

In these five organizational functions, they are then arranged according to the sequence of the value chain and business processes in SCM, starting from suppliers to consumers. SCM aims to maximize the value generated, where SCM is a logistics system that starts from raw materials processed into finished products distributed to end-users. SCM focuses on managing all interrelated activities from the main supplier to the end consumer (Cooper et al., Citation1997; CSCMP., Citation2013; Danese et al., Citation2013). SCM, as a transformation from the functional organization of SMEs, can be illustrated as shown in .

In this supply chain system, the financial functional area is transformed into financial performance, indicating the comparison between revenue and cost structure, as well as other financial ratios. Thus, financial performance is integrated into the supply chain system of SMEs, starting from suppliers, production, value proposition, marketing, and up to consumers. The elements in this supply chain system are the key variables influencing the performance of SMEs. Performance measurement is carried out using financial performance as part of the performance management systems and processes (PMSP) approach.

The entire framework of thought in this study can be illustrated in , showing how the elements of the nine blocks in the BMC are mapped to the functional organization and subsequently transformed within the SCM.

From the literature study and conceptual research conducted above, a design of a simple performance model for micro-industry SMEs is obtained through the integration process of BMC, functional organization, and SCM, as illustrated in . This model generates four variables that influence the enhancement of SME performance: supplier, production, value proposition, and marketing.

The design of the model resulting from the integration in this study is called the ‘Feasibility Model for SMEs.’ Subsequently, the model was tested for the first time with SME participants in the knitwear production center X. Data from the year 2023 indicate that there are total of 100 SMEs in that industrial center. Using the formula with a margin of error of 10%, the sample size is calculated with the formula n = N/(1 + Ne2). The calculation yields n = 100/(1 + 100*10%2) = 100/2 = 50. Based on this calculation, the number of samples used in this study to confirm the designed theory is 50 SMEs.

The design of the feasibility model for strengthening SMEs’ performance is tested with a sample of 50 active knitwear-producing SMEs to determine the influence of supplier, production, value proposition, and marketing on SME performance using Smart PLS. Smart PLS is utilized to predict relationships between constructs, confirm theories, and elucidate whether there is a relationship between latent variables.

The operational variables of the simple SME performance model in this study consist of one dependent variable and four independent variables. The dependent variable is financial performance, while the independent variables are supply chain, production, value proposition, and marketing.

4. Result and analysis

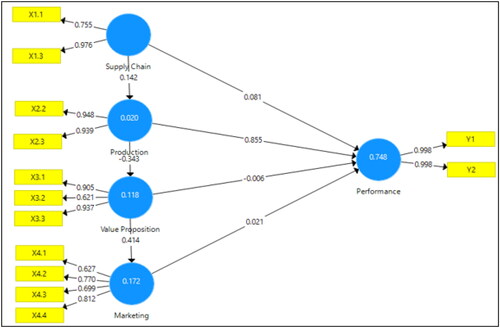

The confirmatory process on the model regarding the relationship between supplier (X1), production (X2), value proposition (X3), and marketing (X4) on financial performance (Y) is conducted through quantitative analysis using structural equation modeling with the alternative method of partial least squares, using Smart PLS 3.3 software. The data used are from a case study on SMEs in knitwear production center X, with a sample size of 50 SMEs. From the data processing of the outer model, the final path diagram results are obtained, as shown in .

In the discriminant validity analysis to test the measurement instrument externally, comparisons are made with indicators of other latent variables. The results of the discriminant validity analysis, tested through cross-loading and the Fornell-Larcker criterion, are presented below.

According to Hair et al. (Citation2014, p. 105) a cross loading which is bigger than the outer loading shows that there is a discriminant validity issue. shows that loading value of each construct factor (latent variable) has a higher indicator compared to the indicators in other latent variables. The data shows that the indicators have a stronger relation with their own construct compared to that with the other ones.

Table 1. Cross-loading between constructs.

Hair et al. (Citation2014, p. 105) also conveys that if the square root of average variance extracted is smaller than the correlation value of among latent variables, it shows that there is a discriminant validity issue. In , it can be seen that the square root of average variance extracted (diagonal line) of each latent variables are still bigger than their correlation with other latent variables. The data shows that latent variables have a stronger relation with their indicators than that with other latent variables. The discriminant validity test shows that there is not any discriminant validity issue among the five latent variables.

Table 2. Fornell-Larcker criterion.

Structural model is a model relating exogenous latent variables with endogenous latent variables. The data analysis leads to a structural model as can be seen in the following table ().

Table 3. Structural model of exogenous latent variable relationship with endogenous latent variables.

Based on the structural test results at the SME center X, it was found that the supply chain does not significantly influence performance, with a path coefficient value (β) of (β = 0.081; p = 0.230, p > 0.05). The test results indicate that hypothesis 1 is not supported. Therefore, it can be concluded that the supply chain does not significantly affect performance at the SME center X. This is due to the fact that currently, the participants in SME center X only have one supplier from the knitting yarn factory.

The testing of hypothesis 2 proved to be true with a path coefficient value (β) of 0.855 (p = 0.000, p < 0.005). This indicates that the production factor significantly affects performance at the SME center X and provides empirical evidence that increasing production will enhance performance. Production has an influence of (0.855)2 = 73.1% on performance at the SME center X.

In the testing of hypothesis 3, the path coefficient value (β) was -0.006 (p = 0.469; p > 0.05). This means that hypothesis 3 is not supported at the SME center X. Therefore, with a 5% error rate, the value proposition does not significantly affect performance at the SME center X. This is because the value proposition has not received much attention in SME center X, where craftsmen tend to imitate existing designs favored by consumers at the time.

The testing of hypothesis 4 resulted in a path coefficient value (β) of 0.021 (p = 0.405; p > 0.05). This indicates that hypothesis 4 is not supported. Thus, it is concluded that marketing does not significantly affect performance at SME center X. This is due to the current passive and suboptimal marketing practices by the SME participants.

In the testing of hypothesis 5, the path coefficient value (β) obtained was 0.142 (p = 0.192; p > 0.05). This means that hypothesis 5 is not supported and, therefore, rejected. It can be concluded that the supply chain does not significantly influence production at SME center X. The relationship with suppliers is not yet optimal, resulting in no significant impact.

The testing of hypothesis 6 resulted in a path coefficient value (β) of −0.343 (p = 0.001; p < 0.05). This indicates that hypothesis 6 is supported. Therefore, it can be concluded that production significantly influences the value proposition at the SME center X. The production factor has an influence of 11.8% on the value proposition at SME center X.

In the testing of hypothesis 7, the path coefficient value (β) was 0.414 (p = 0.003; p < 0.05). This means that hypothesis 7 is supported. It can be concluded that the value proposition significantly influences marketing at SME center X. The higher the value proposition, the greater the impact on marketing. The value proposition has an influence of 17.2% on marketing at SME center X.

Through the R-square values, it can be observed that the supply chain only contributes 2% to production, production contributes 11.8% to the value proposition, and the value proposition contributes 17.2% to marketing. Simultaneously, the supply chain, production, value proposition, and marketing collectively contribute 74.8% to performance at SME center X. The Q2 value represents predictive relevance, and since Q2 > 0, it indicates that the four obtained structural models have predictive relevance.

5. Discussion

The role of SMEs in improving the economy has been proven in various countries; however, numerous research findings reveal various constraints and obstacles faced by SMEs. Therefore, a comprehensive solution is needed to enhance SME competitiveness. Performance in SMEs has connotations of feasibility due to limited resources and constraint. This study develops a model to improve SME feasibility in a simple and comprehensive way, making it easy to implement in SME organizations by integrating BMC, functional organizations, and SCM.

The BMC is a business model that needs to be understood and considered in running a business to generate value and improve SME performance through its nine-block elements. Activities in each BMC element need to be transformed into the relatively simple functional areas of SME organizations with efficient functions due to the resource limitations of SMEs. The transformation results in the main functional areas of micro-industrial SMEs, namely the supply chain, production, value proposition, marketing, and finance.

An efficient supply chain is crucial in supporting the improvement of SME performance from upstream to downstream. Some of the obstacles faced by SMEs in their activities originate from an ineffective supply chain system. Through the integration of functional organizations and supply chain systems, a model for strengthening the performance of micro-industrial SMEs is obtained, with four independent variables: supply chain, production, value proposition, and marketing, and one dependent variable: financial performance.

From the results of the model design for strengthening SME performance, an initial testing process of the model was conducted by measuring the relationship between the dependent and independent variables. In a case study at the SME center X, it was found that simultaneously, the supply chain, production, value proposition, and marketing collectively contributed 74.8% to financial performance at SME center X. However, in the model test, only the production variable significantly affected SME performance. This is because the SME center X currently prioritizes production and has not yet focused on other factors such as value proposition, making other variables not significant.

The limitations of this study include the limited indicators used for the research variables, necessitating the addition of other indicators that better represent the research variables. Additionally, the results of the test of the ‘feasibility model for SMEs’ on 50 SMEs in this study did not show maximal results because only 3 out of 7 proposed hypotheses were proven.

Ultimately, the ‘feasibility model for SMEs’ generated in this study needs further examination and testing on a larger and broader sample, replicating it in other micro-industrial SMEs. This is necessary to generalize the feasibility model for SMEs designed in this study. The feasibility model for SMEs developed in this study is specifically for micro-industrial SMEs. In future research, the test results on other micro-industrial SMEs can be used as an evaluation of the designed model.

6. Conclusion

The design model resulting from this research is named the ‘feasibility model for SMEs’ and is an integration of the BMC, functional organization, and SCM approaches. The model consists of one dependent variable, which is financial performance, with four independent variables: supply chain, production, value proposition, and marketing. This model is highly practical for enhancing SME performance, focusing solely on these four variables.

The testing of this research model was conducted at SME center X, and the test results of the seven hypotheses revealed that only three hypotheses were proven. The three proven and significant hypotheses are that production affects financial performance (H2), production influences value proposition (H6), and value proposition impacts marketing (H7).

Based on the R-square values from the test results at SME center X, it was found that the supply chain only contributes 2% to production. Furthermore, production influences value proposition by 11.8%, and value proposition affects marketing by 17.2%. Simultaneously, supply chain, production, value proposition, and marketing collectively contribute 74.8% to financial performance. The dominant variable influencing financial performance is production, accounting for 73.1%.

The limitations of this study include the accuracy of the indicators used for all research variables, the new model test conducted only at SME center X, and the research methodology employed. In future research, it is essential to add and examine indicators that more accurately represent the research variables. Additionally, the model design should be replicated on samples from other SME centers more extensively to generalize and validate the model for strengthening SME performance.

6.1. Theoretical contribution

Generally, various approaches are employed in enhancing SME performance, including (1) the BMC approach that maps all activities into 9 blocks of business activity elements, (2) the functional approach that emphasizes each function within the organization to carry out tasks maximally, (3) the supply chain approach that focuses on the flow from upstream to downstream. While each of these approaches has its merits, there is an intersection of activities among them. The theoretical contribution of this paper is the integration of these three approaches into a new but simpler concept that can be easily applied to SMEs. Functionally, there are five core functions in this model, namely supply chain, production, value proposition, marketing, and finance. In this model, finance is utilized as a performance metric, specifically financial performance. The design of the model in this study is termed the ‘Feasibility model for SMEs’.

6.2. Managerial implications

The limitations of resources owned by SMEs pose a unique challenge in empowering SME businesses. The new approach generated in this paper emphasizes strengthening four areas: supply chain, production, value proposition, and marketing, as variables influencing the empowerment of SME performance. With this approach, the managerial implication for SMEs is that it becomes easier and simpler to implement efforts to strengthen SME performance by focusing on improving these four research variables. Researchers and SME facilitators can utilize the ‘Feasibility Model for SMEs’ developed in this study, to enhance the performance for feasibility of SMEs.

Notes on contributors

Endang Chumaidiyah contributed on original idea, research design, and analysis.

Putri Maulani Fauzi contributed with data collecting and research secretary.

Anton Abdulbasah Kamil contributed on data analytic and data processing.

Disclosure statement

The authors declare there is no conflict of interest at this study.

Additional information

Notes on contributors

Endang Chumaidiyah

Endang Chumaidiyah is an Associated Professor of feasibility, risk, and technology management at Industrial Engineering Department on Telkom University, Indonesia.

Putri Maulani Fauzi

Putri Maulani Fauzi got bachelor degree majoring in Industrial Engineering of Telkom University.

Anton Abdulbasah Kamil

Anton Abdulbasah Kamil is a Professor of Econometrics at the department of Business Administration, Faculty of Economics, Administrative and Social Sciences, Istanbul Gelisim University, Turkiye.

References

- Abdelkafi, N., & Täuscher, K. (2016). Business models for sustainability from a system dynamics perspective. Organization & Environment, 29(1), 1–15. https://doi.org/10.1177/1086026615592930

- Achanga, P., Taratoukhine, V., Roy, R., & Nelder, G. (2004). The application of lean manufacturing within small and medium sized enterprises: What are the impediments? [Paper presentation].Paper Presented at the 2nd International Conference on Manufacturing Research (ICMR 2004), Sheffield Hallam University, Sheffield.

- Afuah, A., & Tucci, C. (2000). Internet business models and strategies: Text and cases. McGraw- Hill.

- Aguinis, H. (2014). Performance management. Pearson Education.

- Ali, S. M., Paul, S. K., Chowdhury, P., Agarwal, R., Fathollahi-Fard, A. M., Jabbour, C. J. C., & Luthra, S. (2021). Modelling of supply chain disruption analytics using an integrated approach: An emerging economy example. Expert Systems with Applications, 173, 114690. https://doi.org/10.1016/j.eswa.2021.114690

- Amoako, T., Sheng, Z. H., Dogbe, C. S. K., & Pomegbe, W. W. K. (2022). Assessing the moderation role of ICT in the relationship between supply chain integration and SME performance. Journal of Industrial Integration and Management, 07(02), 203–233. https://doi.org/10.1142/S2424862221500160

- Amornkitvikai, Y., & Harvie, C. (2018). Sources of finance and export performance: Evidence from Thai manufacturing SMEs. The Singapore Economic Review, 63(01), 83–109. https://doi.org/10.1142/S0217590817440027

- Antonescu, D. (2020). Supporting small and medium size enterprises through the Covid-19 crisis in Romania. Central European Journal of Geography and Sustainable Development, 2(1), 38–57. https://doi.org/10.47246/CEJGSD.2020.2.1.4

- Ardic, O. P., Mylenko, N., & Saltane, V. (2011). Small and medium enterprises: A cross-country analysis with a new data set. In World Bank policy research working paper series. No. 5538. The World Bank.

- Arend, R. J., & Wisner, J. D. (2005). Small business and supply chain management: Is there a fit? Journal of Business Venturing, 20(3), 403–436. https://doi.org/10.1016/j.jbusvent.2003.11.003

- Asadnezhad, M., Hejazi, R., Akbari, M., & Hadizadeh, E. (2017). Designing the business model of herbal pharmaceutical knowledge based companies. Journal of Entrepreneurship, Business and Economics, 8(2), 36–92.

- Bahri, M., St-Pierre, J., & Sakka, O. (2017). Performance measurement and management for manufacturing SMEs: A financial statement-based system. Measuring Business Excellence, 21(1), 17–36. https://doi.org/10.1108/MBE-06-2015-0034

- Bak, O., Shaw, S., Colicchia, C., & Kumar, V. (2020). A systematic literature review of supply chain resilience in small medium enterprises (SMEs): A call for further research. IEEE Transactions on Engineering Management, 1–14.

- Bartol, K. M. (1999). Reframing sales force compensation systems: An agency theory-based performance management perspective. Journal of Personal Selling and Sales Management, 19(3), 1–16.

- Bayraktar, E., Demirbag, M., Lenny Koh, S. C., Tatoglu, E., & Zaim, H. (2009). A causal analysis of the impact of information systems and supply chain management practices on operational performance: Evidence from manufacturing SMEs in Turkey. International Journal of Production Economics, 122(1), 133–149. https://doi.org/10.1016/j.ijpe.2009.05.011

- Bhatia, M. S., & Jakhar, S. K. (2012). The effect of environmental regulations, top management commitment, and organizational learning on green product innovation: Evidence from automobile industry. Business Strategy and the Environment, 30(8), 3907–3918. https://doi.org/10.1002/bse.2848

- Biloshapka, V., & Osiyevskyy, O. (2018). Value creation mechanisms of business models. The International Journal of Entrepreneurship and Innovation, 19(3), 166–176. https://doi.org/10.1177/1465750318782774

- Bisbe, J., Kruis, A. M., & Madini, P. (2019). Coercive, enabling, diagnostic, and interactive control: Untangling the threads of their connections. Journal of Accounting Literature, 43(1), 124–144. https://doi.org/10.1016/j.acclit.2019.10.001

- Bock, A. J., Opsahl, T., George, G., & Gann, D. M. (2012). The effects of culture and structure on strategic flexibility during business model innovation. Journal of Management Studies, 49(2), 279–305. https://doi.org/10.1111/j.1467-6486.2011.01030.x

- Bocken, N. M. P., Rana, P., & Short, S. W. (2015). Value mapping for sustainable business thinking. Journal of Industrial and Production Engineering, 32(1), 67–81. https://doi.org/10.1080/21681015.2014.1000399

- Bordonaba-Juste, V., & Cambra-Fierro, J. (2009). Managing supply chain in the context of SME’s: A collaborative and customized partnership with the suppliers as the key for success. Supply Chain Management: An International Journal, 14(5), 393–402. https://doi.org/10.1108/13598540910980305

- Cao, G., & Weerawardena, J. (2023). Strategic use of social media in marketing and financial performance: The B2B SME context. Industrial Marketing Management, 111, 41–54. https://doi.org/10.1016/j.indmarman.2023.03.007

- Carey, P. J. (2015). External accountants’ business advice and SME performance. Pacific Accounting Review, 27(2), 166–188. https://doi.org/10.1108/PAR-04-2013-0020

- Carter, M., & Carter, C. (2020). The creative business model canvas. Social Enterprise Journal, 16(2), 141–158. Available at: https://doi.org/10.1108/SEJ-03-2019-0018

- Chen, H., Amoako, T., Quansah, C. E., Danso, S. A., & Jidda, D. J. (2023). Assessment of the impact of management commitment and supply chain integration on SMEs’ innovation performance: Moderation role of government support. Heliyon, 9(5), e15914. https://doi.org/10.1016/j.heliyon.2023.e15914

- Chesbrough, H., & Rosenbloom, R. S. (2002). The role of the business model in capturing value from innovation: Evidence from Xerox Corporation’s technology spin-off companies. Industrial and Corporate Change, 11(3), 529–555. https://doi.org/10.1093/icc/11.3.529

- Chowdhury, P., Paul, S. K., Kaisar, S., & Moktadir, M. A. (2021). COVID-19 pandemic related supply chain studies: A systematic review. Transportation Research Part E: Logistics and Transportation Review, 148, 102271. https://doi.org/10.1016/j.tre.2021.102271

- Christensen, C. M., Bartman, T., & Van Bever, D. (2016). The hard truth about business model innovation. MIT Sloan Management Review, 58(1), 31–40. Available at: http://mitsmr.com/2cBmhTk

- Christoffersen, J., Plenborg, T., & Robson, M. J. (2014). Measures of strategic alliance performance, classified and assessed. International Business Review, 23(3), 479–489. https://doi.org/10.1016/j.ibusrev.2013.07.001

- Chumaidiyah, E., Aurachman, R., & Sagita, B. H. (2018 Strategy for Capability Development of Knitting Small Medium Enterprises Using SWOT Analysis [Paper presentation]. Proceedings of the International Conference on Industrial Engineering and Operations Management (IEOM), Bandung, Indonesia.

- Chumaidiyah, E., Kamil, A. A., & Amani, H. (2020). The success factors of knitting small medium enterprises: A case study on SME centre. International Journal of Supply Chain Management, 9(5), 1–7.

- Clauss, T. (2017). Measuring business model innovation: Conceptualization, scale development, and proof of performance. R&D Management, 47(3), 385–403. https://doi.org/10.1111/radm.12186

- Cooper, M. C., Douglas, M. L., & Janus, D. P. (1997). Supply chain management: More than a new name for logistics. The International Journal of Logistics Management, 8(1), 1–14. https://doi.org/10.1108/09574099710805556

- Cragg, T., & McNamara, T. (2018). An ICT-based framework to improve global supply chain integration for final assembly SMES. Journal of Enterprise Information Management, 31(5), 634–657. https://doi.org/10.1108/JEIM-04-2014-0038

- CSCMP. (2013). “Definitions of supply chain management”, Council of Supply Chain Management Professionals, available at: www.cscmp.org/about-us/supply-chain-management-definitions.

- Danese, P., Romano, P., & Formentini, M. (2013). The impact of supply chain integration on responsiveness: The moderating effect of using an international supplier network. Transportation Research Part E: Logistics and Transportation Review, 49(1), 125–140. https://doi.org/10.1016/j.tre.2012.08.002

- De Leeuw, S., & Van Den Berg, J. P. (2011). Improving operational performance by influencing shopfloor behavior via performance management practices. Journal of Operations Management, 29(3), 224–235. https://doi.org/10.1016/j.jom.2010.12.009

- DeNisi, A. S., & Smith, C. E. (2014). Performance appraisal, performance management, and firm-level performance: A review, a proposed model, and new directions for future research. Academy of Management Annals, 8(1), 127–179. https://doi.org/10.5465/19416520.2014.873178

- Doh, S., & Kim, B. (2014). Government support for SME innovations in the regional industries: The case of government financial support program in South Korea. Research Policy, 43(9), 1557–1569. https://doi.org/10.1016/j.respol.2014.05.001

- Du, S., Bhattacharya, C. B., & Sen, S. (2010). Maximizing business returns to corporate social responsibility (CSR): The role of CSR communication. International Journal of Management Reviews, 12(1), 8–19. https://doi.org/10.1111/j.1468-2370.2009.00276.x

- Dubey, V. K., & Das, A. (2022). Role of governance on SME exports and performance. Journal of Research in Marketing and Entrepreneurship, 24(1), 39–74. https://doi.org/10.1108/JRME-08-2020-0109

- Euske, K. J., Lebas, M. J., & McNair, C. J. (1993). Performance management in an international setting. Management Accounting Research, 4(4), 275–299. https://doi.org/10.1006/mare.1993.1016

- Flapper, S. D. P., Fortuin, L., & Stoop, P. P. M. (1996). Towards consistent performance management systems. International Journal of Operations & Production Management, 16(7), 27–37. https://doi.org/10.1108/01443579610119144

- Forslund, H., & Jonsson, P. (2009). Obstacles to supply chain integration of the performance management process in buyer-supplier dyads. International Journal of Operations & Production Management, 29(1), 77–95. https://doi.org/10.1108/01443570910925370

- Foss, N. J., & Saebi, T. (2017). Fifteen years of research on business model innovation: How far have we come, and where should we go? Journal of Management, 43(1), 200–227. https://doi.org/10.1177/0149206316675927

- Gray, J. H. (1997). Small business strategy in Australia. Academic of Enterpreneurship, Journal, 2(2), 44–58.

- Guan, J., & Yam, R. C. (2015). Effects of government financial incentives on firms’ innovation performance in China: Evidences from Beijing in the 1990s. Research Policy, 44(1), 273–282. https://doi.org/10.1016/j.respol.2014.09.001

- Hair, J. F., Hult, G. T M., Ringle, C. M., & Sarstedt, M. (2014). A Primer on Partial Least Squares Structural Equation Modeling. SAGE Publications, Inc.

- Hansen, A. (2021). The purposes of performance management systems and processes: A cross-functional typology. International Journal of Operations & Production Management, 41(8), 1249–1271. https://doi.org/10.1108/IJOPM-04-2021-0245

- Hartmann, M., Oriani, R., & Bateman, H. (2013 The Performance Effect of Business Model Innovation: An Empirical Analysis of Pension Funds [Paper presentation].35th DRUID Celebration Conference, Barcelona, Spain.

- Hatega, G. (2007). “SME development in Uganda”, Private Sector Foundation Uganda, Available at www.uiri.org/sites/uiri.org/myzms/content/e773/e813/SMEDevelopment.pdf 3

- Hong, J., Feng, B., Wu, Y., & Wang, L. (2016). Do government grants promote innovation efficiency in china’s high-tech industries? Technovation, 57-58, 4–13. https://doi.org/10.1016/j.technovation.2016.06.001

- Hooshangi, M., Sadaghian, J. S., Astaneh, M. R., & Afshar, Z. A. (2017). The mediation role of supply chain integration in relationship between employee commitment with organisational performance. International Journal of Business Information Systems, 24(2), 210–226. https://doi.org/10.1504/IJBIS.2017.081447

- Ilyas, I. M., & Osiyevskyy, O. (2022). Exploring the impact of sustainable value proposition on firm performance. European Management Journal, 40(5), 729–740. https://doi.org/10.1016/j.emj.2021.09.009

- Jin, Y., Ji, S., Liu, L., & Wang, W. (2021). Business model innovation canvas: A visual business model innovation model. European Journal of Innovation Management, 25(5), 1469–1493. https://doi.org/10.1108/EJIM-02-2021-0079

- Johnstone, L. (2020). A systematic analysis of environmental management systems in SMEs: Possible research directions from a management accounting and control stance. Journal of Cleaner Production, 244, 118802. https://doi.org/10.1016/j.jclepro.2019.118802

- Kaminski, P. C., Oliveira, A. C., & Lopes, T. M. (2008). Knowledge transfer in product development processes: A case study in small and medium enterprises (SME’s) of the metal mechanic sector from Sao Paolo, Brazil. Technovation, 28(1-2), 29–36. https://doi.org/10.1016/j.technovation.2007.07.001

- Karimi, J., & Walter, Z. (2016). Corporate entrepreneurship, disruptive business model innovation adoption, and its performance: The case of the newspaper industry. Long Range Planning, 49(3), 342–360. https://doi.org/10.1016/j.lrp.2015.09.004

- Kigozi, D. (2006). “Business Linkage News”. A publication of the UIA-Enterprise Uganda Business Limited. Retrieved from http://www.ugandainvest.com/Business_linkagenews.pdf

- Koh, S. C. L., Demirbag, M., Bayraktar, E., Tatoglu, E., & Zaim, S. (2007). The impact of supply chain management practices on performance of SMEs. Industrial Management & Data Systems, 107(1), 103–124. https://doi.org/10.1108/02635570710719089

- Kotler, P., & Keller, K. L. (2021). Marketing management (16th ed.). Pearson Education.

- Ladd, T. (2017). Does the business model canvas drive venture success? Journal of Research in Marketing and Entrepreneurship, 20(1), 57–69. https://doi.org/10.1108/JRME-11-2016-0046

- Lambert, S. C., & Davidson, R. A. (2013). Applications of the business model in studies of enterprise success, innovation and classification: An analysis of empirical research from 1996 to 2010. European Management Journal, 31(6), 668–681. https://doi.org/10.1016/j.emj.2012.07.007

- Laorden, N. L., Sarmiento, J. M. P., Romo, G. D. A., Acuña, T. R., & Acopiado, I. M. A. (2022). Impact of supply chain disruptions during the COVID-19 pandemic to micro, small and medium enterprises in Davao Region, Philippines. Journal of Asia Business Studies, 16(3), 568–586. https://doi.org/10.1108/JABS-05-2021-0216

- Latifi, M. A., Nikou, S., & Bouwman, H. (2021). Business model innovation and firm performance: Exploring causal mechanisms in SMEs. Technovation, 107(1), 102274. https://doi.org/10.1016/j.technovation.2021.102274

- Liu, F., Fang, M., Park, K., & Chen, X. (2021). Supply chain finance, performance, and risk: How SMEs adjust their buyer-supplier relationship for competitiveness? Corporate finance: Governance. Journal of Competitiveness, 13(4), 78–95. https://doi.org/10.7441/joc.2021.04.05

- Ma, Q. A., & Osiyevskyy, O. (2017). Maximizing the strategic value of corporate reputation: A business model perspective. Strategy & Leadership, 45(4), 24–32. https://doi.org/10.1108/SL-05-2017-0043

- Machado, M. C., Vivaldini, M., & Oliveira, O. J. (2020). Production and supply-chain as the basis for SMEs’ environmental management development: A systematic literature review. Journal of Cleaner Production, 273, 123141. https://doi.org/10.1016/j.jclepro.2020.123141

- Merrilees, B., Rundle-Thiele, S., & Lye, A. (2011). Marketing capabilities: Antecedents and implications for B2B SME performance. Industrial Marketing Management, 40(3), 368–375. https://doi.org/10.1016/j.indmarman.2010.08.005

- Ministry of economy. (2021). MSMEs are an important pillar of Indonesia’s economy. https://ekon.go.id/publikasi/detail/2969/umkm-menjadi-pilar-penting-dalam-perekonomian-indonesia.

- Mishra, R., & Singh, R. K. (2022). A systematic literature review on supply chain resilience in SMEs: Learnings from COVID-19 pandemic. International Journal of Quality & Reliability Management, 40(5), 1172–1202. https://doi.org/10.1108/IJQRM-03-2022-0108

- Mishra, R., Singh, R. K., & Subramanian, N. (2022). Impact of disruptions in agri-food supply chain due to COVID-19 pandemic: Contextualised resilience framework to achieve operational excellence. The International Journal of Logistics Management, 33(3), 926–954. https://doi.org/10.1108/IJLM-01-2021-0043

- Morris, M., Schindehutte, M., & Allen, J. (2005). The entrepreneur’s business model: Toward a unified perspective. Journal of Business Research, 58(6), 726–735. https://doi.org/10.1016/j.jbusres.2003.11.001

- Mukherjee, S. (2023). The business model canvas of women owned micro enterprises in the urban informal sector. Journal of Enterprising Communities: People and Places in the Global Economy, 17(2), 398–418. https://doi.org/10.1108/JEC-05-2021-0068

- Murphy, G. B., Trailer, J. W., & Hill, R. C. (1996). Measuring performance in entrepreneurship research. Journal of Business Research, 36(1), 15–23. https://doi.org/10.1016/0148-2963(95)00159-X

- Ntayi, J. M., Gerrit, R., Eyaa, S., & Zeija, F. (2010). Contract and conflict in the supply chain: The case of Ugandan small and medium sized enterprises. Working Paper. Faculty of Computing and Management Science, Makerere University.

- O’Connell, V., & O’Sullivan, D. (2014). The influence of lead indicator strength on the use of nonfinancial measures in performance management: Evidence from CEO compensation schemes. Strategic Management Journal, 35(6), 826–844.

- O’Sullivan, D., & Abela, A. V. (2007). Marketing performance measurement ability and firm performance. Journal of Marketing, 71(2), 79–93. https://doi.org/10.1509/jmkg.71.2.079

- Okello, O. (2008). Business activities and information needs of SMEs in northern Uganda. Library Management, 29(4/5), 367–391.

- Osterwalder, A. (2004). The business model ontology: A proposition in a design science approach, Institut d’Informatique et Organisation. Ecole des Hautes Etudes Commerciales HEC (pp. 173). University of Lausanne.

- Osterwalder, A., & Pigneur, Y. (2010). Business model generation: A handbook for visionaries, game changers, and challengers. John Wiley & Sons.

- Otley, D. T. (1999). Performance management: A framework for management control systems research. Management Accounting Research, 10(4), 363–382. https://doi.org/10.1006/mare.1999.0115

- Parker, C. (2000). Performance measurement. Work Study, 49(2), 63–66. https://doi.org/10.1108/00438020010311197

- Poole, D. L. (2018). Entrepreneurs, entrepreneurship and SMEs in developing economies: How subverting terminology sustains flawed policy. World Development Perspectives, 9, 35–42. https://doi.org/10.1016/j.wdp.2018.04.003

- Porter, M. E. (1998). Competitive advantage: Creating and sustaining superior performance. Kindle Edition, Free Press.

- Prabhudesai, R., & Prasad, C. V. (2017). Antecedents of SME alliance performance: A multilevel review. Management Research Review, 40(12), 1261–1279. https://doi.org/10.1108/MRR-12-2016-0286

- Priyono, A., Moin, A., & Putri, V. N. A. O. (2020). Identifying digital transformation paths in the business model of SMEs during the Covid-19 pandemic. Journal of Open Innovation: Technology, Market, and Complexity, 6(4), 104. https://doi.org/10.3390/joitmc6040104

- Rajala, R., Westerlund, M., & Möller, K. (2012). Strategic flexibility in open innovation—designing business models for open source software. European Journal of Marketing, 46(10), 1368–1388. https://doi.org/10.1108/03090561211248071

- Ratten, V. (2014). Future research directions for collective entrepreneurship in developing countries: A small and medium-sized enterprise perspective. International Journal of Entrepreneurship and Small Business, 22(2), 266–274. https://doi.org/10.1504/IJESB.2014.062505

- Rayna, T., & Striukova, L. (2014). The impact of 3D printing technologies on business model innovation. In Benghozi, P.J., Krob, D., Lonjon, A. and Panetto, H. (Eds.), Digital enterprise design & management (pp. 119–132). Springer International Publishing AG.

- Saeed, M., Adiguzel, Z., Shafique, I., Kalyar, M. N., & Abrudan, D. B. (2023). Big data analytics-enabled dynamic capabilities and firm performance: Examining the roles of marketing ambidexterity and environmental dynamism. Business Process Management Journal, 29(4), 1204–1226. https://doi.org/10.1108/BPMJ-01-2023-0015

- Taylor, P. (2013). The effect of entrepreneurial orientation on the internationalization of SMEs in developing countries. African Journal of Business Management, 17(19), 1927–1937.

- Teece, D. J. (2010). Business models, business strategy and innovation. Long Range Planning, 43(2–3), 172–194. https://doi.org/10.1016/j.lrp.2009.07.003

- Terrenghi, N., Schwarz, J., Legner, C., & Eisert, U. (2017). Business model management: Current practices, required activities and IT support. At 13th International Conference on Wirtschaftsinformatik (pp. 972–986).

- Zimmerman, J. L. (2020). Accounting for decision making and control (10th ed.). McGraw-Hill.