Figures & data

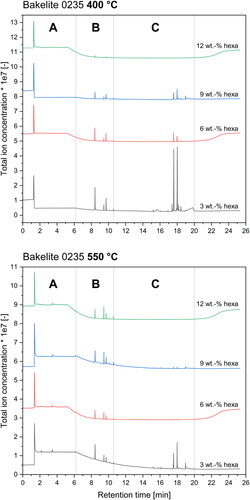

Figure 1. Microgel formation in thermoset polymers during curing, adapted from Vidil et al. [Citation43]. The large orange circles indicate the microgel islands in the phenolic resin melt.

![Figure 1. Microgel formation in thermoset polymers during curing, adapted from Vidil et al. [Citation43]. The large orange circles indicate the microgel islands in the phenolic resin melt.](/cms/asset/a323dd55-1e1e-48ff-97ed-7ea217e1a804/yadm_a_2187687_f0001_c.jpg)

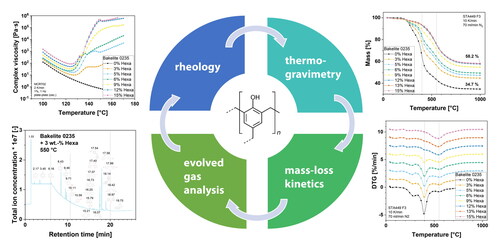

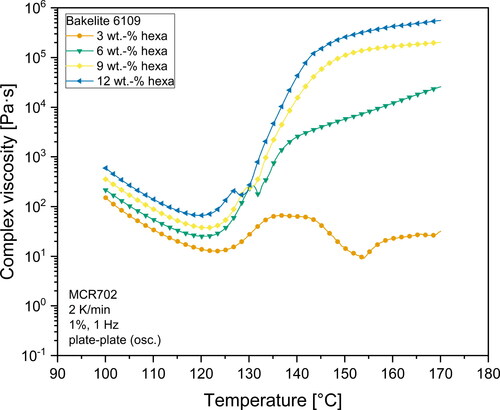

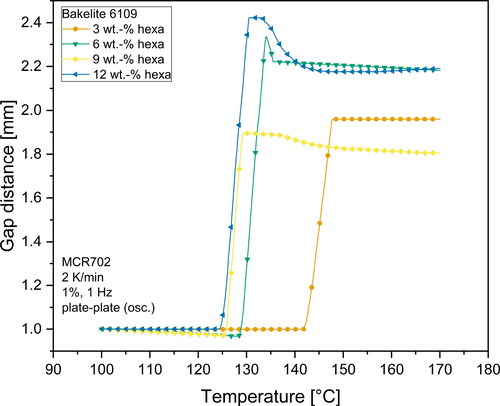

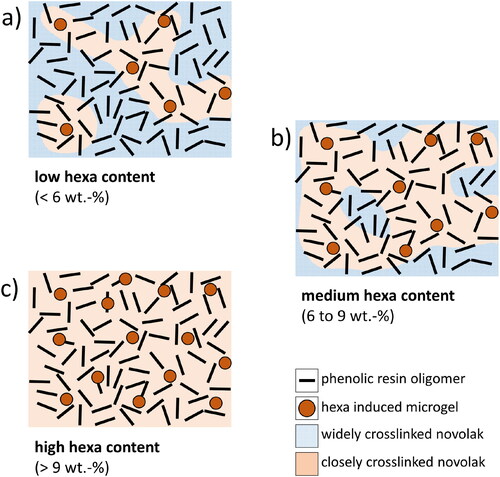

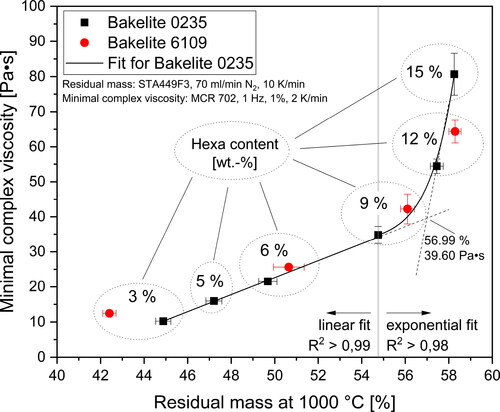

Figure 6. Influence of hexa content on the minimal complex viscosity for Bakelite 0235 and Bakelite 6109.

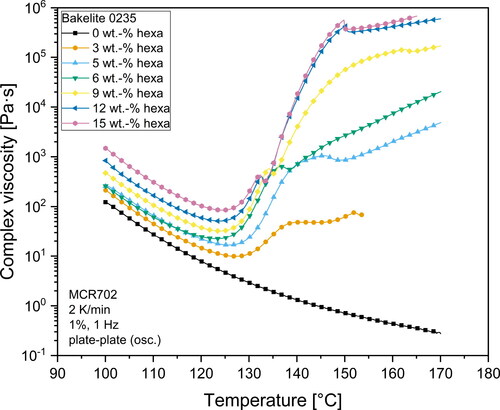

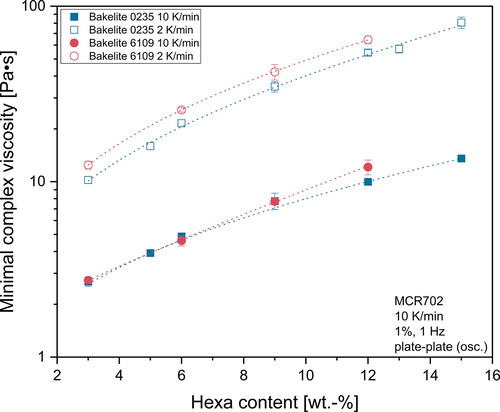

Figure 7. Influence of heating rate on curing behavior of Bakelite 0235 mixtures from 100 °C to 170 °C.

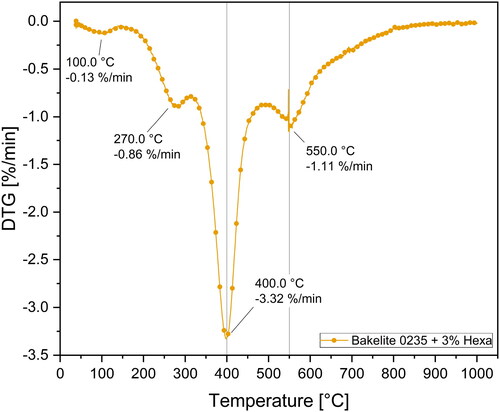

Figure 11. DTG curve for Bakelite 0235 mixture with 3 wt.-% hexa up to 1000 °C. Four kinetically important mass loss steps were detected at 100 °C, 270 °C and 400 °C and 550 °C.

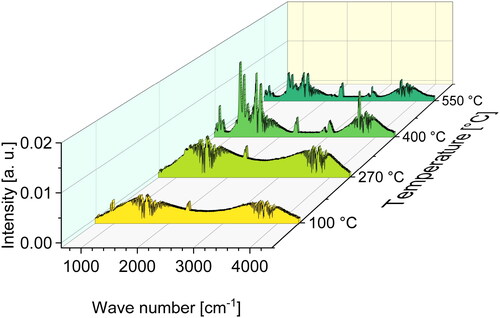

Figure 12. FTIR spectra of pyrolysis gas emitted by Bakelite 0235 mixture with 3 wt.-% hexa at 100 °C, 270 °C and 400 °C and 550 °C.

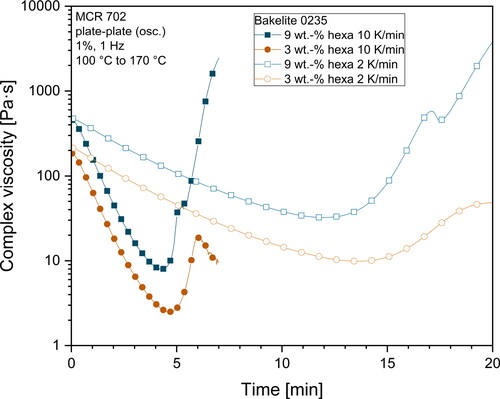

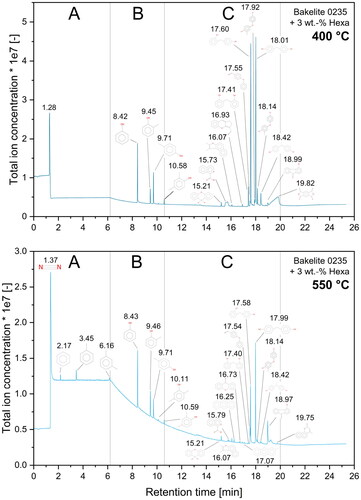

Figure 14. Total ion current chromatogram (TICC) for Bakelite 0235 + 3 wt.-% hexa at temperatures of 400 °C and 550 °C. Chemical substances were assigned to each peak by comparing measured mass spectra to chemical database spectra.

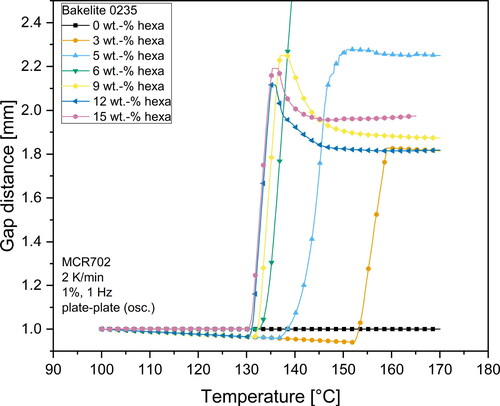

Figure 16. Minimal complex viscosity plotted over char yield for different hexa contents; A linear fit for hexa contents 9 wt.-% and an exponential fit for hexa contents

9 wt.-% was used to fit the data for Bakelite 0235 derived resins.

Supplemental Material

Download Zip (2.3 MB)Data availability statement

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.