ABSTRACT

The Meat Factory Cell (MFC) concept restructures the slaughter line into cell stations and merges elements of the slaughter- and primal cutting processes. With the MFC approach, most of the primals are removed prior to evisceration. This study describes the effect of the MFC concept on carcass hygiene, carcass yield, meat quality traits, and sensory characteristics of selected MFC products from trials with the very first pig carcasses processed with the MFC approach. Results show that hygiene of MFC carcasses rivals conventionally slaughtered carcasses. For quality variables and sensory characteristics of selected MFC products, the study shows that the MFC approach will result in products that equal, and in some cases surpass, conventional products, provided that proper processing, packaging and chilling is applied.

Introduction

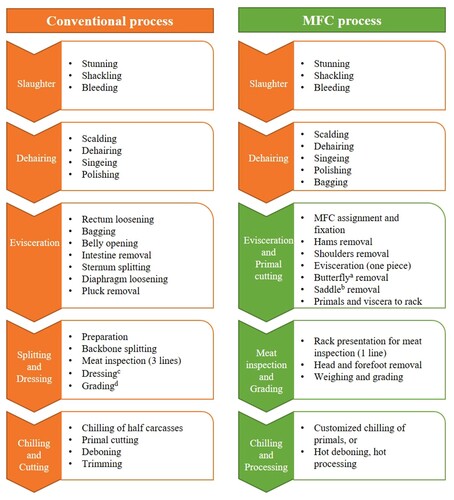

Meat Factory Cell (MFC) is a new, innovative approach to pig slaughtering and primal cutting, where the conventional slaughter line is restructured into a series of cell stations. The MFC concept has previously been described in detail (Alvseike et al., Citation2017, Citation2018, Citation2020), and a schematic comparison between the conventional line and MFC slaughter cells is given in . There are three key differences between the MFC approach and the conventional slaughter line: for the MFC approach, (1) work is partly organized into cells instead of lines, (2) elements of the ‘slaughter’ and ‘meat primal cutting’ processes, which are considered separate processes in the conventional line, will be combined and merged, and (3) the pig carcass will be ‘disassembled’ from the outside-in by removing most of the primal cuts prior to removal of internal organs.

Figure 1. Schematic overview comparing the conventional and MFC slaughter and primal cutting of pork. Orange arrows indicate traditional line-slaughtering, green arrows indicate MFC processing. a Bone-in belly with skirt and riblets attached. b Rind, spine and head attached. c Removal of fat, spinal cord, brain etc. d After polishing when using Autofom grading.

The MFC concept has been proposed to increase productivity in meat factories with small and medium-sized volumes. It is expected that the concept will ease automation due to the robustness and flexibility of the MFC concept, as compared to conventional production lines. When considering a new process as an alternative to conventional slaughter and primal cutting, it is relevant to compare the carcass hygiene, carcass yield, meat quality, and product quality between the two processes.

Since the MFC concept is organized into cells, where each carcass enters a cell directly after polishing and bagging, a natural consequence of the MFC approach is hot boning of the primals. It is a novel approach to hot boning in that most of the primals are removed from the hot carcass prior to removal of the internal organs. Primal cuts produced with the MFC approach are two pork shoulders, two hams, saddle with head, and a ‘butterfly cut’ (bone-in belly with skirt and riblets attached). These cuts, along with a complete set of internal organs (larynx, trachea, oesophagus, lungs, heart, diaphragm, liver, stomach and intestines, spleen, kidneys, urinary and reproductive organs, and flare fat), are immediately transferred to a rack for meat inspection. The practice of hot boning is well documented (Reagan, Citation1983; Pisula & Tyburcy, Citation1996; Troy, Citation2006). Advantages of hot boning are mainly associated with economic gains (reduced energy, building, labour, weight loss and transportation costs), better ergonomic conditions for operators/cutters, and superior functional properties of the meat; however, hot boning also has its disadvantages, including an increased risk of pathogenic bacteria on the meat when chilling, possible cut distortion of the meat, as well as potential detrimental changes with regards to tenderness and/or colour (Reagan, Citation1983; Pisula & Tyburcy, Citation1996; Waylan & Kastner, Citation2004; Troy, Citation2006).

An alternative slaughter and cutting process should result in carcass hygiene that at least meets established microbiological standards (U.S Food & Drug Administration, Citation1997; European Commission, Citation2005; Food Standards Australia New Zealand, Citation2018). Improved hygiene is expected from the MFC concept as the limbs, neck and loins are removed before evisceration and are thus less prone to faecal contamination.

The objective of this work was to describe the effect of the novel MFC concept on carcass hygiene, yield and meat quality traits, as well as evaluate sensory characteristics of a selected set of products collected from MFC-slaughtered pigs.

Materials and methods

Carcass selection and grading

Thirty finishing pigs of white crossbreeds (Duroc, Landrace and Yorkshire), live weight approximately 110 kg, were selected for MFC slaughtering and cutting at the Nortura Tønsberg abattoir, Norway. The study was performed in 6 trials, each trial carried out on a separate day with at least one week between trials. Since this exploratory study was conducted at an active abattoir, it was split into multiple smaller trials rather than one large trial in order to minimize disruption to the abattoir’s operations. Based on pre-trials held on a farm in Norway (described by Alvseike et al., Citation2020), it was concluded that a maximum of 5 pigs would be possible to process in one day. Thus, each trial had a total of 5 MFC pigs. Carcasses were selected based on a carcass length that best fitted the prototype MFC Carcass Holding Unit (CHU) (Tronrud Engineering AS, Norway) settings, that is ideally 176 cm from eye to lowest point of the slaughter hooks. The CHU is described in Alvseike et al. (Citation2020). For MFC-pigs, lean meat percentage (LMP) was measured in the saddle using a GP7 grading probe (Hennessy Grading Systems, New Zealand) at the standard measuring points (Causeur et al., Citation2003; Gangsei et al., Citation2018), while carcass weight was calculated as the total weight of the primal cuts (saddle without head and shoulder without foot). The MFC carcasses used in trials 1–6 had an average carcass weight of 83.2 ± 6.5 (mean ± standard deviation) kg and an average LMP of 61.7 ± 2.2%. The difference between trials was <1SD for both carcass weight and LMP. For the carcass hygiene tests, a corresponding number of control carcasses (n = 29) were randomly collected at the end of the conventional slaughter line, prior to chilling. The control carcasses had a mean carcass weight of 78.3 ± 7.7 kg, and a mean LMP of 61.6 ± 2.8%.

Slaughter and primal cutting

All pigs were lairaged, stunned with CO2, exsanguinated, scalded and dehaired at the same slaughter line at Nortura Tønsberg. Both conventional- and MFC-slaughter and cutting are illustrated and compared in .

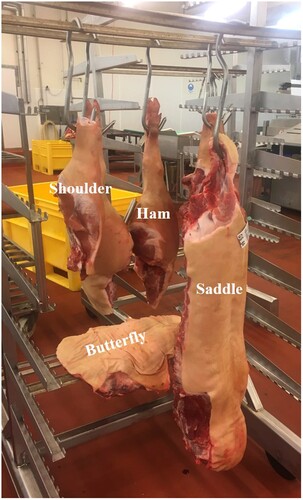

MFC slaughter and removal of primary cuts were performed as described by Alvseike et al. (Citation2018), with the exception that the head was kept attached to the saddle until meat inspection approval. For MFC-processing, right after polishing, the rectum of each pig was sealed by ‘bagging’ (Røssvoll et al., Citation2018) before the carcass was taken down from the conventional slaughter line and immediately affixed to the prototype CHU. The carcass was stretched by gravity in a hanging position and fixated in the CHU head down, using clamps and suction cups. Next, the carcass was brought into a horizontal position, belly up, before the shoulders and hams were removed, and then turned 180° around its longitudinal axis, belly down, for further processing. All MFC primal cuts were manually carried and hung on a rack (). The plucks were hung separately, and the abdominal viscera were collected in a trolley. All parts from the same carcass were presented together for meat inspection. Since the meat rack for the MFC concept was not constructed at the time of the trials, a sausage-hanging trolley with stainless steel smoking sticks served as a makeshift rack. This ‘meat rack’ was the starting point for hygienic and meat quality measurements.

Figure 2. A makeshift ‘MFC meat rack’ with the primals resulting from an MFC slaughter: Shoulder × 2, ham × 2, butterfly and saddle.

Hot boning is a consequence of the MFC approach; however, the abattoir at which these trials were completed is not a hot boning facility, therefore, proper processing, packing or chilling of the pre-rigour meat to the standard of true hot boning was not possible. gives an overview of traits addressed and analyses performed in each trial.

Table 1. An overview of the focus of each of the six MFC trials. DS = day of slaughter; ON = overnight after chilling; OA = analyses completed outside of abattoir.

Carcass hygiene sampling

The surface of the pre-rigour primal cuts hanging on the meat rack was sampled in the slaughter hall for microbial analysis. The whole skin surface of both MFC-carcasses and controls was swabbed (approximately 12,000 cm2). The results were presented as the log10 CFU per cm2 of swabbing area (carcass area). Results below the detection limit (CFU < 1) were set at 0.1 CFU per sample for statistical analysis. The Enterobacteriaceae samples for trials 1 and 2 were incubated at 42°C by mistake and had to be discarded, resulting in a total of 19 MFC- and 19 control samples. Swabbing was conducted using a sterile medical gauze cloth (10 × 10 cm) (Mesosoft, Mölnlycke Health Care AB, Sweden) to which 10 mL peptone salt broth was added (Tryptone sel boullion, France) as described by (Alvseike et al., Citation2019). For each carcass, four gauze cloth swabs were used, and all four swabs were pooled into a single sample in a stomacher bag (Laboratory blender, Stomacher 400, UK). All samples were kept refrigerated until microbial analyses were performed on the subsequent day at the in-house laboratory at Nortura Tønsberg.

Microbial analyses

The hygiene samples were homogenized for 30 s in 40 mL buffered peptone diluent (Buffered Peptone Water, Merck kGaA, Germany). One millilitre of the homogenates was added to individual petrifilms for Escherichia coli (E. coli) (3M™ Petrifilm™ Select E. coli Count Plates (6434 /6435), 3M Company, USA) and Enterobacteriaceae (3M™ Petrifilm™ Enterobacteriaceae Count Plates 6420, 3M Company, USA), and incubated at 42°C (E. coli) or 37°C (Enterobacteriaceae) for 24 h and read according to the manufacturer's instructions.

Post MFC processing and meat quality sampling

After meat inspection approval, the head and trotters were removed from the saddle and shoulders, respectively. The remaining primal cuts were weighed and returned to the meat rack, before being chilled in a designated chill room overnight. The primal cuts in trials 1 and 4 were used for registration of yield, while in trials 2, 3 and 6, selected cuts were used to produce consumer products: sliced wet-cured ham from the hams, pork loin from the left loin on the saddle, and pork bellies from the butterfly.

Temperature controls

Temperature loggers (Stainless Steel ThermaData Pro Data Loggers, Electronic Temperature Instruments Ltd, UK) were inserted into either primal cuts (between the 7th and 8th rib from the caudal end on the saddle; in the M. semimembranosus of the ham; under the rind on the pork skirt of the butterfly) or subprimal cuts (into the centre of a whole loin; in the intercostal muscles of the pork belly) prior to chilling. Furthermore, temperature loggers were hung on the meat rack to measure the temperature in the chill room overnight. Temperatures were recorded every two minutes for approximately 24 h. The average temperature of the chill room was 0.40 ± 1.14°C in trials 1, 2, 3 and 4. In trial 5, chilling of primal cuts failed due to a malfunction in the chill room. In this trial, the average temperature of the chill room was −1.11 ± 2.24°C, and it dipped below −5°C for longer periods of time. Due to the malfunction of the designated chill room in trial 5, trial 6 primals and subprimals were chilled in the abattoir’s main chill hall overnight. The average temperature of the chill hall used in trial 6 was 3.07 ± 0.77°C. Due to the chilling error in trial 5, only hygiene measurements and day of slaughter (DS) measurements were completed for this trial. An overview of measurements in each trial is presented in .

Primal and subprimal cuts

All pH and weight measurements were taken on day of slaughter as well as on the subsequent day. pH45 and pH24 were measured in the semimembranosus muscle of the ham and in the longissimus thoracis et lumborum muscle (pork loin) of the saddle using a digital portable pH-meter with a combined pH- and temperature electrode (WTW pH3310, Germany). pH in the hams was measured 45–52 min and 22–25 h after stunning, while pH in the saddles was measured 59–64 min and 23–25 h after stunning. The pH45 in the saddle was slightly delayed due to the saddle being the last primal to be removed from the CHU.

To register yield and overnight weight loss of MFC carcasses, primal cuts from 10 pigs were weighed on a Panther Plus PTHK terminal scale (Metteler Toledo, USA) on the day of slaughter, prior to overnight chilling. From each saddle primal, two pork loins were deboned and trimmed for visible connective tissue layers, and then vacuum packed (right loins n = 15, whole; left loins n = 15, cut into two parts) before overnight chilling. The butterfly primal was cut into two pork belly subprimals. One subprimal was weighed, vacuum packed, chilled overnight and measured for pH and weight loss on the day after slaughter. The other pork belly was cut into 4 pieces, each of which was vacuum packed, chilled and saved for sensory evaluations. Subprimal pork bellies from trial 2 were vacuum packed hot directly. In trial 3, the primal butterfly was hung in the chill room for 30–60 min before being cut into two subprimals, vacuum packed warm and chilled. The butterfly from trial 6 was hung on the meat rack in the chiller for 1 h before it was cut into two pork bellies and weighed. The pork bellies were not vacuum-packed, instead, they were placed on metal trays and chilled overnight on a rack.

Pork loin quality

Pork loin quality parameters pHu, purge loss, cooking loss, sarcomere length measurements and Warner–Bratzler shear force (WBSF) were measured in 15 MFC left loins and 15 control-loins collected directly from the cold cutting line at Nortura Tønsberg. Purge and cooking loss were recorded for each MFC and control loin-section prior to WBSF and sarcomere length analyses as previously described by Haug et al (Citation2018). Purge (drip, g juice expelled*100/g initial weight) during chilling was determined by weighing the vacuum-packed pork loin sample and the expelled juice in the vacuum bag two days post-mortem. Cooking loss (g juice lost*100/g initial weight) was determined by weighing the expelled juice in the sealed vacuum bags from the samples heated for WBSF analysis. The ultimate pH (pHu) was measured in the expelled juice of the pork loin 2 days post-mortem using a pH meter (Knick Portamess 911 pH, Knick Elektronische Messgeräte GmbH & Co., Germany) equipped with a combination pH puncture electrode (Hamilton double pore, VWR International, USA).

Sarcomere length measurements and WBSF

The caudal two-thirds of each left loin (1.45 ± 0.24 kg, n = 15) was used for WBSF and sarcomere length measurements. For Sarcomere length measurements, the thickest end of the caudal side of the loin was trimmed on day 2 post mortem, before a 1-cm cross-sectional slice was cut off, frozen in liquid nitrogen and stored at −80°C. This slice was chosen for sarcomere length measurement as it was closest to the cranial one-third of the loin used for sensory analysis. Four frozen muscle cubes with dimensions 1 × 1 × 1 cm were cut from each slice and processed according to Cross et al (Citation1981). From each cube, the sarcomere length of 45 fibre samples was determined (180 total measurements per pork loin sample) to ensure sufficient precision. Sarcomere lengths were measured using phase contrast microscopy on a Leitz biomed light microscope (type 020-507.010, Leica Mikroskopie & Systeme GmbH, Germany) with a 10x eyepiece and 40x air objective lens (Leitz 40x/0.65 EF 160/0.17 PHACO 2, Leica Mikroskopie & Systeme GmbH, Germany).

For WBSF, four 4-cm thick cross-sectional slices were successively cut from the remaining loin and allocated into two pre-labelled bags for WBSF-measurement after wet-ageing at 4°C for 2 and 7 days post mortem. The vacuum-packed slices were cooked in a water bath to an internal temperature of 72°C after which the samples were transferred to an ice-bath and cooled to a core temperature of 40°C and stored in a 4°C chiller overnight. Five strips per slice were cut to dimensions 1 cm × 1 cm × 4 cm, the latter parallel to the muscle fibre direction. WB peak force was determined using a texture analyzer (HDP/BSK knife blade, 25 kg load cell, and 4 cm/min cross head speed; TA-HDi Texture Analyser; Stabile Micro Systems, UK).

Sensory characteristics

Production of consumer products

Wet-cured ham, roasted pork belly and pork loin were produced from MFC and conventional cold-boned pork for sensory evaluation. Both MFC and control wet-cured hams were made at Nortura Sarpsborg, Norway. Two MFC wet-cured hams were produced using the semimembranosus, semitendinosus, biceps femoris and part of the gluteus muscles from three carcasses per wet-cured ham, while two wet-cured ham controls were made with cold cut meat from the same muscles types, randomly selected from the conventional cold cutting line at Nortura Tønsberg. Both MFC and control ham cuts were injected with a 1.7% NaCl and nitrite brine solution held at 3°C, giving an 18% meat weight increase. The ham cuts for each of the wet-cured hams were tumbled using a pilot scale tumbler (Spicer meat tumbler, 50 L marinade tumbler, J. Navestad AS, Norway) with 20 cycles/min under vacuum for 3 h. Meat cuts were packed into vacuum bags and placed in ham press moulds to form wet-cured hams of approximately 4–5 kg each. The hams were steamed in an oven (Rational SCC 61, SelfCookingCenter®, RATIONAL AG, Germany) at 80°C for 3 h 15 min to obtain a core temperature of 73°C. After cooking, the hams were cooled at −18°C for 2 h, then stored at 4°C for 30 days for maturation, prior to slicing and consumer packaging.

The cranial one-third of each left loin (0.79 ± 0.14 kg, n = 15) was used for MFC pork loin sensory evaluation, while nine control sample loins were randomly selected from the conventional cold cutting line at Nortura Tønsberg. Each loin was cooked in an oven (Rational SCC 61, SelfCookingCenter®, RATIONAL AG, Germany) at 80°C for 1 h to give a core temperature of 72°C. Heat-treated loins from MFC- and control samples were cut in half lengthwise, and sliced into 1 cm thick samples shortly before serving. Samples were served warm, at approximately 60°C.

Fifteen MFC pork bellies (1.15 ± 0.15 kg) were collected for sensory evaluation. Two whole pork bellies were randomly selected from the conventional cold cutting line at Nortura Tønsberg to serve as controls. To produce roasted belly a quarter of each pork belly cut were steamed in an oven (Rational SCC 61, SelfCookingCenter®, RATIONAL AG, Germany) at 100°C for 40 min, then roasted at 180°C for 1 h 30 min. Shortly before serving warm (approximately 60°C), the bellies were cut into equal-sized pieces, regardless of whether bone was present or not; however, all samples contained meat, fat and crackling.

Sensory evaluation of consumer products

Sensory evaluations were performed on MFC and control samples of sliced wet-cured ham, roasted pork belly and heat-treated pork loin to compare these consumer products when made from MFC-pigs versus conventional cold cuts. The laboratory for sensory analysis at Nortura Løren, Norway was designed according to ISO 8589:2007. During the evaluation, water and cucumber were served to the assessors to cleanse their palate between samples. Every assessor evaluated all samples, but the sample order was randomized for each assessor. Both semi-trained and untrained assessors were used. Semi-trained assessors have passed a basic taste test and must be annually retested on quality assessment of products with quality defects. All assessors, both semi-trained and untrained, have a special interest for meat and sensory attributes. Untrained assessors were under training and were used when simple attributes were of interest. In addition, the untrained assessors were able to provide an insight from a consumer point of view.

Triangle test. Triangle tests were used to determine if assessors were able to differentiate between MFC- and conventionally processed pork loin and wet-cured ham (Sinkinson, Citation2017). Each test was performed twice. For pork loin, nine assessors (7 semi-trained, 2 untrained) were served three slices of cold pork loin at a time and asked to identify the sample that differed from the other two samples. MFC Pork loin samples were evaluated after 9 and 16 days of storage post hot-boning, while the control pork loin samples were evaluated after 8 days of storage after collection off the cold cutting line. For consumer-packaged wet-cured ham, eleven assessors (7 semi-trained, 4 untrained) were served three slices of ham at a time and asked to identify the sample that differed from the other samples. The wet-cured ham used in the two triangle tests was consumer-packed 29 days post production and stored for either 49 or 56 days post hot-boning.

Sensory shelf-life test. Sensory shelf-life tests were performed to evaluate off-odour and off-flavour during storage of sliced wet-cured ham (5 samples in 2 sessions) and raw and heat-treated pork loin (5 samples in 2 sessions) and pork belly (4 samples in 2 sessions). The samples were stored at 4°C for 2–46 days post mortem, then frozen at −20°C, before being thawed at 4°C for 28 h prior to evaluation. Sensory shelf-life evaluations were completed on days 14, 29, 35, 39 and 46 post mortem for wet-cured hams, on days 2, 17, 21, 23 and 24 post mortem for pork loin, and on days 2, 13, 16 and 20 post mortem for pork belly. 6–7 semi-trained assessors judged the presence of off-odour, off-flavour, and tenderness on a 9-point hedonic scale (Peryam & Pilgrim, Citation1957; Lawless & Heymann, Citation2010). The assessors used a scale from 1 (extreme off-flavour/odour) to 9 (no off-flavour/odour) to evaluate odour and flavour. A sensory score of 7–9 indicates a good product, a score of 4–6 indicates a product that will require some further improvements, while a sensory score of 1–3 indicates that the product is not good enough to reach the consumer market. The test was performed twice. Before performing the sensory analysis, each assessor smelled and tasted both fresh and stored control samples, collected from the conventional cold cutting line, to calibrate themselves to the sample type to be assessed, and a collective score for the control was agreed upon.

Sensory tenderness test. Sensory tenderness of five MFC pork loins (5 samples in 2 sessions) was evaluated using a 9-point hedonic scale. Nine semi-trained assessors were served one slice of pork loin each and asked to evaluate the sensory tenderness on a scale from 1 (extremely tough) to 9 (extremely tender). As for the shelf-life evaluations, a sensory tenderness score of 7–9 indicates a good and tender product, 4–6 indicates a product that will require some further improvements, while a score of 1–3 indicates that the product is too tough and not good enough to reach the consumer market.

Product quality discussion. Quality of MFC pork belly was evaluated using product quality discussion. Four semi-trained assessors were served one piece of heat-treated pork belly from the MFC samples and one control sample each. Approximately 15 s were given for individual assessment before a group discussion on the characteristics of the sample. Two discussions were performed. In the first product quality discussion, two MFC pork bellies from trial 2 and two bellies from trial 3, in addition to two control sample taken from the conventional cutting line at Nortura Tønsberg, were evaluated. In the second product quality discussion, five MFC pork bellies from trial 6 were evaluated. In this round, the assessors were served one piece of heat-treated pork belly from each of the five MFC samples. Approximately 15 s were given for individual assessment before a group discussion on the characteristics of the samples.

Statistical analysis

All results are expressed as mean values ± standard deviation (SD). Statistical tests used in comparing groups included the Welch two-sample t-test and one-way ANOVA. If significant results were obtained in the one-way ANOVA, Tukey’s HSD post hoc test was used. All comparisons were performed two-tailed with a significance level of 5%. All statistical tests were completed using the statistics software R, version 4.1.2 with the R commander package, version 2.7-2 (Fox & Bouchet-Valat, Citation2021; R Core Team, Citation2021).

Results

Carcass cutting quality

The professional meat cutters emphasized that the MFC butterfly primal was more difficult to cut when warm, and that it was nearly impossible to score the rind. Furthermore, the meat cutters pointed out that when the pork belly was vacuum-packed hot immediately after cutting, the suction from the vacuum caused any residual blood left in the carcass post exsanguination to be sucked out and pooled in the vacuum bag. In trial 2, a large amount of blood was observed in the vacuum-packed samples; therefore, in trial 3, the butterfly cut was hung on the meat rack and chilled for 30–60 min before it was cut into two pork bellies and vacuum-packed. This reduced the presence of blood but not sufficiently. The pork bellies in trial 6 were therefore not vacuum-packed, instead, the butterfly primal was hung for 60 min before pork bellies were cut out, placed on metal trays and chilled overnight on a rack. The bellies were weighed again after 24 h.

For the MFC saddle primal, the meat cutters found it to be rather large and heavy to work with (see ). When trimming the MFC hot-boned pork loin, the meat cutters predicted that using a derinding skinning machine, which is used on cold-boned loin to remove the silver skin, would produce a high-quality product, likely with a higher yield than the cold-boned counterpart as the silver skin is expected to separate from hot meat more cleanly than from meat that has been chilled.

When trimming the shoulder, the professional meat cutters stated that this primal would likely produce a higher yield than a cold-boned shoulder, as the meat was more easily cleaned off the hot MFC shoulder blade bone. For the ham primals, the meat cutters reported that following the natural muscle seams in the hot ham made deboning very easy and allowed for a higher yield than cold-boned ham. This was evident during the trials where meat from the ham primal was used to produce wet-cured-ham. Removing the skin was also easier on the MFC hot-boned ham than on a ham that has been chilled. Furthermore, taking HSE into consideration, MFC primals are easier and better to debone than cold primals as there is less resistance for the knife in the hot muscle.

Weight loss and yield

Of the MFC primals, only the trimmed shoulder has a cutting pattern that is comparable to that of a conventionally cold-boned primal and is thus the only primal that can be compared when considering yield. When compared to conventionally cold boned pigs with similar carcass weight and lean meat percentage, no significant differences in yield, measured as percentage of carcass weight, were found between conventional and MFC trimmed shoulder (Conventional 8.77 ± 0.21%, n = 10; MFC 8.69 ± 0.25%, n = 10; t (17.5) = −0.801, p = 0.434). To calculate yield for conventional carcasses, hanging weight was used. Yields of the MFC primal cuts are presented in .

Table 2. Average initial weight and weight loss of primal cuts during chilling of MFC-hot boned samples in trials 1 and 4, and subprimals in trials 2, 3 and 6. All values are mean ± SD.

Mean weight loss for primal cuts of MFC pig carcasses during chilling (24 h) was 2.04 ± 0.22% as presented in . The average chilling weight loss for the subprimals was lower than the average weight loss measured for the primals (t (38.4) = 14.965, p < 0.001). There was a significant difference between the weight loss for pork bellies in trials 2 and 3 when compared to trial 6 (p < 0.001), but no significant difference was observed for weight loss between trials 2 and 3 (p = 0.345). No significant differences were seen for pork loin overnight weight loss in the three different trials (p = 0.356).

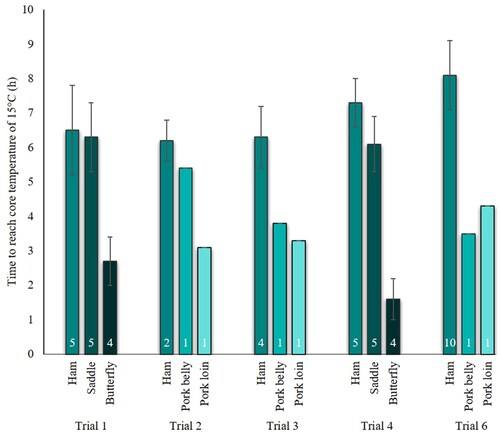

Temperature and pH

The time needed for the core temperature measured in MFC primals (ham, saddle and butterfly) and subprimals (pork belly and pork loin) to reach 15°C are presented in . The ham primals chilled in the abattoir’s main chill hall reached 15°C later than the hams chilled in the chill room, although the difference was non-significant. For the saddle and butterfly primals, no significant difference in time needed to reach 15°C was observed between trials (saddle: t (7.5) = 0.273, p = 0.792; butterfly: t (5.6) = 2.238, p = 0.070). For the subprimals, the pork loin chilled in the chill hall needed more time to reach a core temperature of 15°C than the pork loins chilled at a lower temperature, while the opposite was observed for the pork belly subprimals where the pork belly chilled in the chill hall reached 15°C faster than the other pork bellies. For the MFC primals ham and saddle, pH was measured approximately 1 h post mortem (pH45) and 22–25 h post mortem (pH24). In ham/semimembranosus the pH45 was 6.54 ± 0.23 (n = 30 hams) and pH24 was 5.47 ± 0.06 (n = 28 hams). For the saddle/longissimus pH45 was 6.45 ± 0.23 while pH24 was 5.49 ± 0.06 (n = 10 saddles). For the MFC subprimals loin and belly, pH24 was measured approximately 23–25 h post mortem. The average pH24 of pork loins was 5.44 ± 0.12 (n = 10 loins), while pork bellies had an average pH24 of 5.71 ± 0.08 (n = 5 pork bellies).

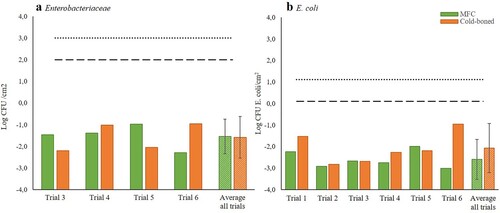

Carcass hygiene

Enterobacteriaceae were detected in 95% (18/19) of the MFC-hot boned carcasses and 89% (17/19) of the control carcasses. E. coli was detected in 52% (15/29) of the MFC-hot boned carcasses and 69% (20/29) of the control carcasses. For the MFC-hot boned carcasses in total, the Enterobacteriaceae mean value was log −1.54 ± 0.80 log CFU/cm2 (n = 19) and the E. coli mean value was −2.60 ± 0.93 log CFU/cm2 (n = 29). Results are given in . For the control carcasses in total, the Enterobacteriaceae mean value was −1.58 ± 0.96 log CFU/cm2 (n = 19) and the E. coli mean value was −2.07 ± 1.14 log CFU/cm2 (n = 29).

Figure 4. (a) Enterobacteriaceae and (b) E. coli mean values for MFC and cold-boned carcasses per trial. For the Enterobacteriaceae samples (a) trials 1 and 2 are not included as they were incubated at 42°C by mistake and had to be discarded. Patterned bars show mean and ±SD for all trials combined. The dashed line shows the lower limit (m) for each indicator, below which all values are considered acceptable. The dotted line shows the upper limit (M) for each indicator, above which all values are considered non-acceptable (European Commission, Citation2005; Animalia et al., Citation2016).

Pork loin quality

Air temperature recordings for the designated chill room used in trials 2 and 3 showed that nearly 90% of all recordings were below 1°C, and only 6% of the recordings showed temperatures above 2°C. In contrast, the temperature never dropped below 1°C in the abattoir’s main chill hall in trial 6, and 76% of all temperature recordings for that trial were between 2°C and 4°C. Based on the substantially different temperature profiles of the chill room and the main chill hall in the three loin quality trials, quality data collected from MFC loins from trials 2 and 3 were pooled together (Trial2 + 3).

When comparing pHu of MFC loins to control loins, the average pHu for the control loins was lower than that of the MFC pork loins, but the difference was only significant in loins chilled in the designated chill room ((a)). No significant difference in pHu were observed when comparing MFC pork loins chilled at different overnight temperatures (p = 0.493).

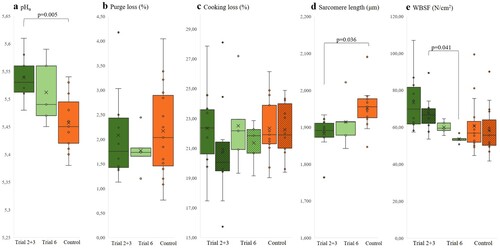

Figure 5. Pork loin quality measurements for MFC loins from trials 2 and 3 combined, MFC pork loins from trial 6, and cold boned control loins. (a) pHu; (b) purge loss; (c) cooking loss; (d) sarcomere length; (e) Warner–Bratzler shear force. For (c) and (e) solid boxes represent measurements taken 2 days post mortem while patterned boxes refer to measurements taken 7 days post mortem. Box plots show the smallest and largest sample values, the 25th and 75th percentiles, and the median. The group mean is indicated by an ‘X’ in the box plot, and dots show data points. Quartiles are calculated inclusive median. Horizontal bars indicate significant difference between groups.

Purge for MFC loins ranged from 1% to 4%, with an average purge of 1.7% for loins that underwent milder chilling and 2.1% for loins chilled at lower temperatures ((b)). Control loins experienced an average purge loss of 2.2%. The observed difference in purge from MFC pork loins when compared to control loins was, however, non-significant (Trial 2 + 3, p = 0.978; trial 6, p = 0.639). No purge differences were observed in loins from MFC carcasses chilled at different temperatures (p = 0.759). When evaluating cooking loss of MFC and control pork loins ((c)), no significant differences were found on either 2 days or 7 days post mortem (p = 0.990 and p = 0.352, respectively).

The average sarcomere length of MFC pork loins chilled at lower temperatures was measured to be 1.88 ± 0.05 µm ((d)), which was significantly shorter than the sarcomere length of control loins (control 1.95 ± 0.05 µm; p = 0.036). The sarcomere lengths of MFC samples from trial 6 were slightly longer than those of loins in the Trial 2 + 3-group however, the difference was non-significant (1.91 ± 0.07 µm, p = 0.466).

MFC samples chilled in the abattoir’s chill hall had lower shear force values than MFC samples that underwent colder overnight chilling, both 2 and 7 days post mortem ((e)); however, a significant difference was only evident 7 days post mortem (p = 0.041). Of the MFC pork loins chilled in the abattoir’s chill hall, three loins had WBSF values that were lower than the average WBSF for control loins 2 days post mortem, while for 7 days post mortem, all five MFC loins had lower WBSF values. In contrast, only two of ten MFC loins chilled in the chill room had lower WBSF values than the controls 2 and 7 days post mortem. Only MFC loins chilled at 3°C overnight had significantly decreased WBSF values from 2 to 7 days post mortem (t (6.7) = 3.462, p = 0.011).

Sensory characteristics

Sensory evaluation of consumer products

Triangle test. Results from the triangle tests for pork loin showed that 9 of 9 assessors in test 1, and 8 of 9 assessors in test 2 correctly identified the sample that differed in the MFC vs cold-boned pork loin test, indicating a significant difference between MFC pork loin and conventionally cold-boned pork loin (Carpenter et al., Citation2000). The assessors described the MFC pork loin samples as dry, tough, hard and acidulous. For wet-cured ham, the triangle test revealed that only 4 of 11 assessors in test 1 and 3 of 11 assessors in test 2 correctly identified the sample that differed, indicating that any difference between MFC and conventional wet-cured ham was not detectable.

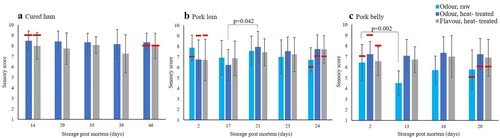

Sensory shelf-life test. In the sensory shelf-life tests, the presence and intensity of off-flavour and -odour for wet-cured ham, pork loin and pork belly produced from MFC-hot boned samples stored for 2–46 days after production was evaluated (). The scores for the MFC wet-cured ham sample stored for 14 and 46 days did not differ greatly from the collective scores given to the control samples ((a)). For the MFC samples, neither off-odour nor off-flavour changed significantly with storage times (odour p = 0.952; flavour p = 0.559). For MFC pork loin, the results indicate that some off-odour is present in the raw samples, especially those stored for 17 and 24 days ((b)); however, there was no significant change detected in off-odour for raw samples from 2 to 24 days (p = 0.259). Also, none of the raw MFC samples exhibit more off-odour than the control samples. For the heat-treated MFC pork-loin samples, off-odour was especially noted for the samples stored for 2 and 17 days, while the samples stored for 21–24 days had less off-odour and corresponded well with the stored control sample. There were no significant differences in the observed off-flavour for pork loin (p = 0.420), but higher intensities of off-flavour were noted for the samples stored for 2 and 17 days compared to the samples stored for 21–24 days. Raw MFC pork belly stored for 13 days had a stronger off-odour than any other samples with a score of 4.5 ((c)), but a significant difference was only seen between samples stored for 2 and 13 days (p = 0.002). Heat-treated MFC pork belly samples stored for 20 days had less off-odour and -flavour than the stored control samples.

Figure 6. Sensory shelf-life evaluation of (a) MFC wet-cured ham; (b) MFC pork loin; (c) MFC pork belly. Assessors judged the presence of off-odour and off-flavour on a scale from 1 (extreme off-flavour/odour) to 9 (no off-flavour/odour). Values represent the mean of off-flavour and off-odour at different storage times, error bars show ± SD. Horizontal bars indicate significant difference between groups. For comparison, the red lines show the collective score given to control samples for the corresponding trait.

Sensory tenderness test. Heat-treated MFC pork loin samples stored for 23 days received a tenderness score of 6.2 in the sensory panel tenderness test. Control samples received a tenderness score of 4.0 after 2 days of storage and a score of 6.0 after 24 days of storage.

Product quality discussion. In the first pork belly product quality discussion, the MFC pork bellies were described as slightly more acidulous than a conventional cold-boned pork belly. One of the MFC pork belly samples was described as lacking in flavour when compared to a control sample, while for two other MFC samples the taste was described as metallic, sulphur-like, and reminiscent of blood. The fourth MFC pork belly was described as acidulous and weak flavoured. The pork bellies were also described as having a barn-like odour. In the second product quality discussion, only two of five MFC pork bellies were described as having a very slight metallic flavour or after-taste. Of the two pork bellies described as slightly metallic, one was also described as having good umami flavours and a typical pork belly taste. Three MFC samples were described as somewhat sweet tasting.

Discussion

The paper presents the main effects on hygiene and meat quality traits of the novel MFC-concept. All results in the present screening study were based on a small set of samples, thus caution when interpreting the data must be exercised.

Carcass hygiene

Although not statistically significant, there was a tendency of lower Enterobacteriaceae and E. coli values for MFC compared to control. Both MFC and controls obtained excellent results as the means were well below the accepted lower limit (m) for both Enterobacteriaceae and E. Coli. Additionally, the qualitatively postulated hygienic advantage of MFC was supported (Alvseike et al., Citation2018). Usually, E. coli is used as an indicator variable on cold carcasses 24 h post mortem, and therefore the results may be considered conservative. The described trials were of the very first carcasses slaughtered in-doors with the MFC approach. The process included considerable improvisation and manual holding and carrying, compared to the conventional controls’ well-established procedures, hygienically optimized line and experienced operators.

Avoiding contamination of carcasses and meat by bacterial pathogens and spoilage flora, is the most important hygienic challenge in the meat industry. Evisceration has a high risk of faecal contamination of carcasses, due to knife cuts and punctures resulting in leakage of the intestinal content. Good Hygiene Practice (GHP) for evisceration includes ensuring that the risk of puncturing the viscera, gastrointestinal tract, uterus, urinary bladder, and gall bladder is minimized during separation cuts (Røssvoll et al., Citation2018). In addition, and regardless of knife wounds, the two ends of the gastrointestinal tract are of concern as potential sources of contamination of the carcasses (Røssvoll et al., Citation2018). Alvseike et al (Citation2020) have previously demonstrated that the intact gastrointestinal tract can be safely removed after the MFC shoulders, hams and saddle primals are cut off. During these trials, several different procedures including removal of bowels and plucks separately, bowels and plucks removed without larynges and tongues, and removal of the entire set in one piece.

MFC primals and subprimals

When examining the MFC approach from a professional meat cutter perspective, both advantages and disadvantages were identified. Feedback from the meat cutters indicated that the MFC approach, although differing from typical hot-boning will benefit from improved EHS and likely reduced risk of occupational injuries, both known advantages of hot-boning (Food Science Australia, Citation2001; Meat & Livestock Australia, Citation2004). Of the six primals from MFC, the saddle and the butterfly were considered by the professional meat cutters to pose a slight challenge, first and foremost due to shape and size.

The stick wounds were noted as being relatively small (approximately 3 cm wide), and this may have resulted in incomplete exsanguination of the carcass, which in turn may result in residual blood left in the carcass or natural cavities. The process was identical from stunning to polishing and therefore the bleeding was comparable between MFC and conventional slaughtered carcasses. Insufficient bleeding of the MFC carcasses posed a specific challenge for the butterfly primal when the pork belly subprimals were vacuum packed hot as residual blood left in the carcass post exsanguination pooled in the vacuum bag, staining the rind and potentially flavouring the meat. Hanging the butterfly primal for a period of time prior to sectioning and vacuum packing the pork belly subprimals warm did reduce, but not eliminate, residual blood in the vacuum bags. Hanging the butterfly primal for a period of time before chilling the MFC pork belly subprimals on trays overnight prior to vacuum packing did, however, eliminate the problem of residual blood. Assuring proper bleeding of all MFC carcasses prior to placing them in the CHU, is thus considered to reduce this particular problem. Nevertheless, it must be noted that allowing the pork belly to cool completely before vacuum-packing did significantly increase the overnight weight loss of this primal when compared to pork belly vacuum-packed whilst hot.

Another significant problem with the butterfly primal was that scoring the MFC pork belly prior to vacuum-packing was not possible while the pork rind was still hot. For the Norwegian meat industry, not being able to score the pork belly is likely of major concern since the traditional Norwegian Christmas dish ‘Ribbe’ requires scored pork belly skin. Although not explored in the present study, rapid chilling of the pork rind followed by scoring will likely fix this issue as the skin becomes more rigid when chilled. This suggest that, with the proper equipment, the issues observed with the hot pork belly will be of no hinderance to the meat industry. Both concerns facing the MFC butterfly primal can be simultaneously addressed by passing hanging pork belly subprimals through a rapid chilling tunnel immediately followed by scoring of the rind with a rind scoring machine and vacuum-packing.

Chilling weight loss

When measuring chilling weight loss, MFC primal cuts did not show a higher overnight weight loss than the standard assumed 2% chilling weight loss for conventionally cold boned pig carcasses during the first 24 h of chilling (van der Wal et al., Citation1995). An approximate reduced weight loss of 1.5% during chilling has been reported as one of the main economic advantages of hot boning (Pisula & Tyburcy, Citation1996; Ockerman & Basu, Citation2004; Troy, Citation2006); however, since the hot-boned MFC primals in this study were not vacuum-packed prior to chilling, the increased surface area subjected to evaporation may have resulted in an MFC chilling weight loss similar to that of a cold-boned carcass. For the MFC pork loin and belly subprimals, on the other hand, the advantage of reduced chilling weight loss was evident when compared to MFC primals. This is likely attributed to the subprimals being vacuum-packed whilst still hot, which was further supported by the significantly lower chilling weight loss observed for vacuum-packed MFC pork bellies from trials 2 and 3, versus the non-vacuum packed MFC pork bellies from trial 6. The pork belly vacuum-packed hot immediately after removal from the MFC carcass also experienced the slowest temperature decline.

Yield of MFC-cut carcasses cannot be directly compared to conventional cold boning since the MFC approach utilizes a different cutting pattern, nevertheless, the results from the present study provide an indication that no major differences in the yield from MFC and conventional slaughter line occur. It is important to note that in this study, only the weight of the intact primal on day of slaughter and after overnight chilling was used to calculate yield. For future MFC studies, each primal should be fully deboned and the edible product weight should be calculated to give a better indication of the yield of each MFC primal. A yield improvement of 1.5–2% is possible when hot-boning, attributed to reduced chilling weight loss as well as hot meat being easier to clean off bone (Food Science Australia, Citation2001). This hot-boning yield benefit will also be relevant for the MFC approach. Even small differences in yield may have considerable economic effects in large scale production and needs further studies.

Effects of temperature on pork loin quality

The unintentional changes in overnight chilling location and temperatures allowed for a highly valuable comparison of MFC subprimals chilled at very different temperatures. This was particularly relevant for certain quality parameters that may be affected by temperature, such as purge, shear force and sarcomere length.

For pork, onset of rigour usually occurs 15–60 min post mortem, and is completed after approximately 6 h (Savell et al., Citation2005). Too severe chilling before onset of rigour will cause cold shortening and tough pork. Cold shortening is rare in conventionally cold-boned pork as normal post mortem metabolism in pork happens rapidly (Ockerman & Basu, Citation2004). However, it may be a concern for hot boned pork as muscles removed from a hot carcass are no longer naturally stretched by the carcass-skeleton, nor benefitting from the insulating effects of both fat and carcass volume, and are thus more likely to contract (Marsh, Citation1981; Huff-Lonergan & Page, Citation2001; Troy, Citation2006). Cold shortening in hot boned cuts may be prevented by a chilling regime that maintains the internal temperature above 15°C while a significant amount of ATP is still present in the muscle and the pH is higher than 6.2 (Huff-Lonergan & Page, Citation2001; Lawrie & Ledward, Citation2006). This would in turn have a beneficial effect on energy consumption and sustainability (Valente et al., Citation2020).

In normal muscle, significant ATP is present for the first 3–4 h post mortem (Huff-Lonergan & Page, Citation2001). For MFC pork loins, only loins from the abattoir’s chill hall had core temperatures above 15°C 4 h post mortem. These loins differed from MFC loins chilled at colder temperatures in that they exhibited lower shear force and slightly longer sarcomeres, potentially explained by the slower decline in core temperature, which in turn may have prevented cold shortening (Ertbjerg & Puolanne, Citation2017). Although MFC loins chilled at 3°C had sarcomeres that were longer than those of loins chilled at below 1°C, both MFC groups had, on average, longer sarcomeres than previously reported average sarcomere lengths for pork loin (1.64–1.82 µm Meinert et al., Citation2008; 1.78 µm, Wheeler et al., Citation2000; 1.83 µm, DeVol et al., Citation1988; 1.85 µm, Feldhusen & Kühne, Citation1992). Sarcomere length has a significant effect on tenderness and water-holding capacity (WHC), two highly important quality parameters for meat, both of which are influenced by rate of pH- and temperature decline (Kim et al., Citation2014; Ertbjerg & Puolanne, Citation2017). A rapid pH decline can result in higher purge and cooking loss, while a rapid temperature decline may lead to tougher meat as sarcomeres shorten (Andersen, Citation1999; Ertbjerg & Puolanne, Citation2017). The pH decline of MFC loins was not measured in the present study, but no significant differences were observed for cooking loss or purge when comparing MFC and control loins. Cooking loss for MFC loins was within the normal range for pork, albeit in the upper segment of the range (Tower, Citation2016). The MFC loins in trial 6 had lower purge loss than loins chilled at a lower temperature, although purge for both groups was well within the normal range (Tower, Citation2016). MFC pork loins chilled below 1°C and at 3°C had on average 0.1% and 0.4% lower purge than controls, respectively. Although non-significant, it may indicate that the MFC approach can benefit from a purge reduction of 0.1% to 0.6% that has been reported for vacuum-packed hot-boned meat (Pisula & Tyburcy, Citation1996). It should be noted that reduced purge is a known, and expected, result of vacuum packing, but also that vacuum packaging itself may causes some purge as a result of the physical compression and negative pressure applied during packaging (Hermansen, Citation1983; Stella et al., Citation2019).

A higher pHu has been suggested to result in lower shear force (Eikelenboom & Hoving-Bolink, Citation1994), however, this was not supported in the present study. Pork tenderness increases with aging (Channon et al., Citation2004), and it has been predicted that 90% of the tenderization happens at 6.1 days post mortem (Rees et al., Citation2002). In agreement with this, the shear force or MFC loins chilled overnight at 3°C decreased significantly from 2 to 7 days post mortem. While only a small decrease (about 6.5 N), this still indicates an improvement in tenderness in the loins. A significant WBSF decrease was not observed for MFC loins chilled below 1°C, nor for control loins.

Sensory evaluations of MFC products

Pork products such as wet-cured ham (cold cuts on bread), pork loin (roasted/grilled for dinner) and pork belly (roasted; traditional Christmas dish), are important products on the Norwegian consumer market. An alternative processing method like the MFC approach should therefore yield either equal or superior product quality for these products, when compared to products produced with today’s conventional slaughter line approach. Sensory evaluations of MFC wet-cured ham, roasted pork belly and heat-treated pork loin revealed that theses product, in general, are equally as good as their cold-boned equivalents, provided proper handling. The sensory panel could easily distinguish MFC loins from control samples in the triangle test; however, only MFC loins chilled at a low overnight temperature were included in this evaluation. The panel description of the overall juiciness, toughness and texture of the MFC loins coincide with potential cold shortening, which was observed in the sarcomere length and WBSF measurements. Li et al (Citation2009) reported that the shear force of hot-boned pork loin was significantly higher than that of cold-boned loin. This was not supported in the present study, where MFC loins chilled in the main chill hall had the same shear force values as cold-boned loin. This result was supported by the sensory panel tenderness score for the same MFC loins, which was equivalent to the score given to cold-boned pork loin. Similar sensory tenderness results have previously been reported for pork loins hot boned 45 min post mortem when compared to loins cold boned 24 h post mortem (Li et al., Citation2009).

In the loin tenderness test, the five MFC pork loins from trial 6 were given an average tenderness score of 6.2. Of these five MFC loins, the loin that received the highest sensory tenderness score (6.4) also received the highest WBSF value (56.8 N); however, this value was still lower than 40% of WBSF values for control loins. A weak relationship between instrumental measurements and sensory panel evaluation is largely accepted, and may be explained by e.g. lack of sensory panel precision or cooking method and -temperature (Choe et al., Citation2016).

Pork belly usually has a shelf-life of 14 days (Gilde Ribbe, https://www.norturaproff.no/produkter/000000005000005589), and the results from sensory shelf life tests showed that MFC pork bellies will have an equivalent or even longer shelf-life when based on sensory perception of flavour and odour. The MFC pork belly did, however, not perform as well in the pork belly quality discussions according to the assessors, where most of the descriptions of flavour and odour were unfavourable. This, in combination with the aforementioned issues of blood pooling in the vacuum-bag and difficulty scoring the pork belly rind, emphasizes the need for improved procedures and additional testing for this particular subprimal before the MFC approach is implemented. As for pork belly, wet-cured ham made from MFC meat was found to rival wet-cured ham from conventional cold-boned cuts in terms of shelf life. Conventional wet-cured ham has a shelf-life of 35 days (Gilde kokt skinke, https://www.norturaproff.no/produkter/000000005000000513). MFC wet-cured ham was given both odour and flavour scores at 46 days that correspond to a product that is fit for the consumer market. This, in turn, suggests that the MFC approach will not have a negative effect on one of the top sellers for the Norwegian pork industry.

The observed sensory shelf-life results for MFC loin, belly and wet-cured ham show the MFC approach will result in products that are comparable to their conventionally cold-boned counterparts. It is also likely that these MFC products are representative for other parts of a carcass slaughtered with the MFC approach, thus the information gathered here may be extrapolated to other products and cuts.

Conclusion

The present study highlights that even though hot boning is essentially just a natural consequence of the MFC concept, controlling the potential disadvantages of hot boning is crucial to the realization of MFC. With appropriate processing, packing and chilling of pre-rigour MFC meat to the standard of true hot boning, quality and sensory characteristics of pork produced with the MFC concept will be equivalent to, or in some cases surpass, today’s cold boned products. Furthermore, the study has identified potential concerns such as the importance of proper bleeding of MFC carcasses prior to cutting and vacuum packing, as well as the significance of correct chilling to avoid cold shortening of MFC meat. Lastly, the hygiene of MFC carcasses rivals that of carcasses on a conventional slaughter line. Removing most primals before they can be contaminated by the intestinal content is beneficial, and removal of an intact intestinal tract contributed to the excellent results. The hygiene is expected to further improve when the system is optimized. Taken together, implementation of the MFC approach to pig slaughter and cutting improves general hygiene and maintains meat quality.

Acknowledgements

Meat 2.0 was co-funded by Nortura SA. MeaTable was co-funded by Nortura SA, RobotNorge AS, Tronrud Engineering AS and Animalia AS. We also thank Tronrud Engineering AS for making the Carcass Holding Unit used in the study and Nortura for allowing access to their facilities.

Disclosure statement

No potential conflict of interest was reported by the author(s).

Additional information

Funding

References

- Alvseike, O., Prieto, M., Bjørnstad, P. H. & Mason, A. (2020). Intact gastro-intestinal tract removal from pig carcasses in a novel meat factory cell approach. Acta Veterinaria Scandinavica, 62(47). doi:10.1186/s13028-020-00546-y.

- Alvseike, O., Prieto, M., Torkveen, K., Ruud, C. & Nesbakken, T. (2018). Meat inspection and hygiene in a meat factory cell – an alternative concept. Food Control, 90, 32–39. doi:10.1016/j.foodcont.2018.02.014.

- Alvseike, O., Røssvoll, E., Røtterud, O. J., Nesbakken, T., Skjerve, E., Prieto, M., Sandberg, M., Johannessen, G., Økland, M., Urdahl, A. M. & Hauge, S. J. (2019). Slaughter hygiene in European cattle and sheep abattoirs assessed by microbiological testing and hygiene performance rating. Food Control, 101, 233–240. doi:10.1016/j.foodcont.2019.01.033.

- Alvseike, O., Sverdvik, H., O’Farrell, M. & Berg, P. (2017). Meat factory cell – a concept for the future? In D. J. Troy, C. McDonell, L. Hinds & J. Kerry (eds.) 63rd International Congress of Meat Science and Technology (Cork: Wageningen Academic Publishers), p. 494–495.

- Andersen, H. J. (1999). What is pork Quality? 50th Annual Meeting of the European Association for Animal Production, August 22–26. Zurich. pp. 19–26.

- Animalia, KLF & Nortura. (2016). Den norske kjøttbransjes retningslinje av 14.06.2012 for sikring av hygienisk råvarekvalitet ved slakting av storfe, sau og gris (Oslo).

- Carpenter, R., Lyon, D. & Hasdell, T. A. (2000). Appendix A – some useful tables for sensory tests. In R. Carpenter, D. Lyon, & T. A Hasdell (Eds.), Guidelines for Sensory Analysis in Food Product Development and Quality Control. 2nd ed. (Gaithersburg, MD: Aspen Publishers), p. 177–180.

- Causeur, D., Daumas, G., Dhorne, T., Engel, B., Font, I., Furnols, M. & Højsgaard, S. (2003). Statistical Handbook for Assessing Pig Classification Methods: Recommendations from the EUPIGCLASS Project Group. 132.

- Channon, H. A., Kerr, M. G. & Walker, P. J. (2004). Effect of Duroc content, sex and ageing period on meat and eating quality attributes of pork loin. Meat Science, 66(4), 881–888.

- Choe, J. H., Choi, M. H., Rhee, M. S. & Kim, B. C. (2016). Estimation of sensory pork loin tenderness using Warner-Bratzler shear force and texture profile analysis measurements. Asian-Australasian Journal of Animal Sciences, 29(7), 1029–1036. doi:10.5713/ajas.15.0482.

- Cross, H. R., West, R. L. & Dutson, T. R. (1981). Comparison of methods for measuring sarcomere length in beef semitendinosus muscle. Meat Science, 5(4), 261–266. doi:10.1016/0309-1740(81)90016-4.

- DeVol, D. L., McKeith, F. K., Bechtel, P. J., Novakofski, J., Shanks, R. D. & Carr, T. R. (1988). Variation in composition and palatability traits and relationships between muscle characteristics and palatability in a random sample of pork carcasses. Journal of Animal Science, 66(2), 385–395. doi:10.2527/jas1988.662385x.

- Eikelenboom, G. & Hoving-Bolink, A. H. H. (1994). The effects of ultimate pH on eating quality of pork. In 40th International Congress of Meat Science and Technology: Meat 40-Fies. Vol. 29 (The Hague: Scientific Secretariart 40th ICoMST), p. 1–3.

- Ertbjerg, P. & Puolanne, E. (2017). Muscle structure, sarcomere length and influences on meat quality: A review. Meat Science, 132, 139–152. doi:10.1016/j.meatsci.2017.04.261.

- European Commission. (2005). Commission regulation (EC) No 2073/2005 of 15 November 2005 on microbiological criteria for foodstuffs. Official Journal of the European Union. L 338/1:26.

- Feldhusen, F. & Kühne, M. (1992). Effects of ultrarapid chilling and ageing on length of sarcomeres, and tenderness of pork. Meat Science, 32(2), 161–171. doi:10.1016/0309-1740(92)90103-B.

- Food Science Australia. (2001). Effect of hot boning on meat quality. Meat Technology Update: 6.

- Food Standards Australia New Zealand. (2018). Compendium of Microbiological Criteria for Food (Kingston). 978-0-642-34594-3.

- Fox, J. & Bouchet-Valat, M. (2021). Rcmdr: R Commander.

- Gangsei, L. E., Bjerke, F., Røe, M. & Alvseike, O. (2018). Monitoring lean meat percentage predictions from optical grading probes by a commercial cutting pattern. Meat Science, 137, 98–105. doi:10.1016/j.meatsci.2017.11.010.

- Haug, A., Vhile, S. G., Berg, J., Hove, K. & Egelandsdal, B. (2018). Feeding potentially health promoting nutrients to finishing bulls changes meat composition and allow for product health claims. Meat Science, 145, 461–468. doi:10.1016/j.meatsci.2018.07.015.

- Hermansen, P. (1983). Comparison of modified atmosphere versus vacuum packaging to extend the shelf life of retail fresh meat cuts. Proceedings of the Annual Reciprocal Meat Conference, 35, 60–64.

- Huff-Lonergan, E. & Page, J. (2001). The Role of Carcass Chilling in the Development of Pork Quality (National Pork Board, American Meat Science Association Fact Sheet), pp. 1–7.

- Kim, Y. H. B., Warner, R. D. & Rosenvold, K. (2014). Influence of high pre-rigor temperature and fast pH fall on muscle proteins and meat quality: A review. Animal Production Science, 54, 375–395. doi:10.1071/AN13329.

- Lawless, H. T. & Heymann, H. (2010). Sensory Evaluation of Food. 2nd ed. (New York: Springer). doi:10.1007/978-1-4419-6488-5.

- Lawrie, R. A. & Ledward, D. A. (2006). Lawrie’s Meat Science. 7th ed. (Place Unknown: Woodhead Publishing Limited and CRC Press).

- Li, C., Wu, J., Zhang, N., Zhang, S., Liu, J., Li, J., Li, H., Feng, X., Han, Y., Zhu, Z., Xu, X. (2009). Effects of boning method and postmortem aging on meat quality characteristics of pork loin. Animal Science Journal, 80(5), 591–596. doi:10.1111/j.1740-0929.2009.00677.x.

- Marsh, B. B. (1981). Properties and behavior of prerigor meat. In Reciprocal Meat Conference Proceedings. Vol. 34 (Champaign, IL: American Meat Science Association), pp. 75–80.

- Meat & Livestock Australia. (2004). Validation of the Chilling of Hot Boned Manufacturing Meat and Primals (North Sydney).

- Meinert, L., Christiansen, S. C., Kristensen, L., Bjergegaard, C. & Aaslyng, M. D. (2008). Eating quality of pork from pure breeds and DLY studied by focus group research and meat quality analyses. Meat Science, 80(2), 304–314.

- Ockerman, H. W. & Basu, L. (2004). Carcass chilling and boning. In Werner Klint Jensen, Carrick Devine, & Michael Dikeman (Eds.), Encyclopedia of Meat Sciences (Oxford: Elsevier), p. 144–149.

- Peryam, D. R. & Pilgrim, F. J. (1957). Hedonic scale method of measuring food preferences. Food Technology, 11, 9–14.

- Pisula, A. & Tyburcy, A. (1996). Hot processing of meat. Meat Science, 43(S), 125–134.

- R Core Team. (2021). R: A language and environment for statistical computing.

- Reagan, J. O. (1983). Hot processing of pork whole muscle cuts. Reciprocal Meat Conference Proceedings, Vol. 36, Champaign, IL. p. 71–73.

- Rees, M. P., Trout, G. R. & Warner, R. D. (2002). Tenderness, ageing rate and meat quality of pork M. longissimus thoracis et lumborum after acelerated boning. Meat Science, 60, 113–124.

- Røssvoll, E., Røtterud, O. J., Hauge, S. J. & Alvseike, O. (2018). A comparison of two evisceration methods on hygienic quality in the pelvic area of sheep carcasses. Meat Science, 137, 134–138. doi:10.1016/j.meatsci.2017.11.025.

- Savell, J. W., Mueller, S. L. & Baird, B. E. (2005). The chilling of carcasses. Meat Science, 70, 449–459. doi:10.1016/j.meatsci.2004.06.027.

- Sinkinson, C. (2017). Triangle test. In L. Rogers (ed.) Discrimination Testing in Sensory Science: A Practical Handbook (Place Unknown: Woodhead Publishing), p. 153–170. doi:10.1016/B978-0-08-101009-9.00007-1.

- Stella, S., Garavaglia, D., Francini, G., Viganò, V., Bernardi, C. & Tirloni, E. (2019). Evaluation of the weight loss of raw beef cuts vacuum-packaged with two different techniques. Italian Journal of Food Safety, 8(4), 184–187. doi:10.4081/ijfs.2019.8111.

- Tower, L. (2016). Pork Meat Quality: Understanding Industry Measurements and Guidelines. PIC Technology Update.

- Troy, D. J. (2006). Hot-boning of meat: A new perspective. In L. M. L. Nollet & F. Toldrá (eds.) Advanced Technologies for Meat Processing (Boca Raton, FL: Taylor & Francis), p. 73–85.

- U.S Food & Drug Administration. (1997). HACCP Principles & Application Guidelines.

- Valente, C., Møller, H., Johnsen, F. M., Saxegård, S., Brunsdon, E. R. & Alvseike, O. (2020). Life cycle sustainability assessment of a novel slaughter concept. Journal of Cleaner Production, 272, 122651. doi:10.1016/j.jclepro.2020.122651.

- van der Wal, P. G., Engel, B., van Beek, G. & Veerkamp, C. H. (1995). Chilling pig carcasses: Effects on temperature, weight loss and ultimate meat quality. Meat Science, 40(2), 193–202. doi:10.1016/0309-1740(94)00029-7.

- Waylan, A. & Kastner, C. (2004). Hot boning and chilling. In W. K. Jensen, C. Devine & M. Dikeman (eds.) Encyclopedia of meat sciences (New York: Elsevier), pp. 606–613.

- Wheeler, T. L., Shackelford, S. D. & Koohmaraie, M. (2000). Variation in proteolysis, sarcomere length, collagen content, and tenderness among major pork muscles. Journal of Animal Science, 78(4), 958–965. doi:10.2527/2000.784958x.