?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.ABSTRACT

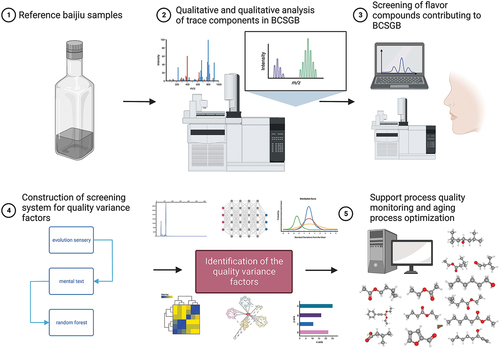

The aging process is crucial to improve the harmony and fullness of the flavor of baijiu. Nevertheless, the traditional aging process consumes space and times and significantly increased the loss of baijiu. Hence, how to shorten the aging time through manual intervention becomes the research hotspot. Thus, a new aging method of exposure to sunlight was established to accelerate the balance of flavor compounds in baijiu. It was still unclear about the quality variance factors and its influence on the flavor quality of BCSGB (banchengshaoguo baijiu) during the sun-exposure process. Hence, adsorption pen combined with GC–MS were utilized to identify trace components, and pH liquid–liquid extraction and GC–O–MS were employed to screen and assess flavor compounds. Afterward, based on the sensory evaluation of BCSGB, three assessment systems (sensory evaluation, mental test, and random forest) were created to screen the quality variance factors. Thus, the quality variance factors were responsive to changes in the flavor quality of BCSGB during the sun-exposure process, which support process quality monitoring and aging process optimization.

Introduction

Strong flavor baijiu is the mainstream of baijiu production and consumption in China, occupying more than 70% of baijiu market in China[Citation1]. Due to the different regions, raw materials and production technology, different styles of products have been sprung up, such as Chuan style (strong flavor baijiu produced in and around Sichuan province), Jianghuai style (strong flavor baijiu produced in the Yangtze River and Huaihe River basin), and Bei style (strong flavor baijiu produced in northern China) strong flavor baijiu.[Citation1] Of note, as the representatives of Bei style strong flavor baijiu (BSFB), Banchengshaoguo baijiu (BCSGB) is made of sorghum and wheat and is produced by the unique Laowuzeng production technique (Laowuzeng means that the Jiupei are removed from the Jiaochi, mixed with raw materials, then distilled and gelatinized at the same time in Zeng. Briefly, the Jiupei in Jiaochi are divided into four layers, namely covering layer, upper layer, middle layer, and base layer. After a round of fermentation, the covering layer is distilled and thrown away, and the upper layer is mixed with new raw materials and husks. Then the mixture is divided into a new upper layer and a middle layer in the next round of fermentation. The middle layer becomes the new base layer, and the base layer will become the new covering layer, which is abandoned after fermentation. This cyclical distillation technology is called Laowuzeng).[Citation2] Consequently, the flavor of BCSGB is characterized by elegant and clean. Whilst the freshly steamed baijiu (namely raw baijiu) is unfit for consumption. Because its flavor is full of spicy, stimulating, and incongruous. In practice, it is found that the flavor of the raw baijiu will be improved after a period of storage.[Citation3] Thus, the storage of raw baijiu is preserved and evolved into the baijiu aging process.[Citation4] During the aging process, physical and chemical changes such as oxidation, esterification, hydrolysis, and rearrangement continue to occur and make the flavor of raw baijiu become harmonious and mellow.[Citation5] Given the availability of materials and technology, pottery jars were widely applied to store the raw baijiu in ancient times (Sun). In contrast, with the improvement of production capacity and the guarantee of technique, the stainless-steel tank is more and more used to store raw baijiu.[Citation6] However, traditional aging process takes several years, occupies a large area, and results in significant loss of baijiu.[Citation7] Hence, how to shorten the aging time through manual intervention becomes the research hotspot.[Citation8,Citation9]

As is well known, 98% of baijiu is ethanol and water, with the remaining 2% consisting of trace components.[Citation1] The flavor quality of baijiu is mainly determined by the kind, proportion, and concentration of trace components.[Citation10] Up to now, there have been numerous studies focused on the trace components in strong flavor baijiu.[Citation11] Specifically, direct injection (DI),[Citation12] liquid–liquid extraction (LLE),[Citation13] liquid–liquid microextraction (LLME),[Citation14] and headspace solid-phase microextraction (HS-SPME),[Citation14] in combination with GC–MS,[Citation15] and GC–O–MS,[Citation16] were the common methods to analyze the trace components of strong flavor baijiu. Interestingly, the above-mentioned studies were focused on a few representative brands of strong flavor baijiu from Chuan style and Jianghuai style, such as Gujinggong (a brand of strong flavor baijiu),[Citation17] Wuliangye (a brand of strong flavor baijiu),[Citation18] Luzhou laojiao (a brand of strong flavor baijiu), and Yanghe (a brand of strong flavor baijiu).[Citation19] The trace components in Bei style strong flavor baijiu have received limited attention. Meanwhile, there have been many studies on the flavor profile of baijiu,[Citation16] but the study on the change of baijiu flavor during aging has not been systematic enough.[Citation20] Relevant research will serve as a foundation for the regulation of the baijiu aging process. Besides, the adsorption pens have also been gradually introduced into the analysis and research of flavor compounds, which offers several advantages, including high automation, a larger adsorption capacity, and mild treatment conditions. In addition, it is highly beneficial for the extraction, separation, and identification analysis of volatile components,[Citation21] thus, effectively improving the stability and sensitivity of the method. Hence, adsorption pen method has become popular in flavor analysis in recent years.[Citation22] It is also believed that this method can be utilized to verify the trace components in baijiu.

During the production process of baijiu, several aging methods such as ultrasound, microwave, traditional aging, and ultraviolet are widely mentioned.[Citation23] However, due to limitations in materials, technology, and energy consumption, these methods mostly remain at the laboratory stage and have not been widely applied in practical production. While sun-exposure aging was a highly feasible method. It utilized sunlight exposure to accelerate the aging process of specific grades baijiu, aiming to improve quality and shorten aging time. Through sensory evaluation of the sun-exposed baijiu samples, it was observed that the exposed samples had a more advantageous taste compared to the non-aged samples. It was speculated that exposure to sunlight changes the composition of trace components in baijiu, thereby influencing on the sensory of raw baijiu.[Citation24] However, the correlation between this novel aging method and the sensory of baijiu is not yet clear. In detail, the dynamic changes in trace components in baijiu during exposure to sunlight need to be covered. Furthermore, the relationship and pattern between aroma compounds and flavor quality for raw baijiu needs to be confirmed.

In this study, different degrees of strong flavor baijiu (i.e., different sun-exposure times) were selected as object, the volatile trace components were confirmed by adsorption pen combined with GC–MS, afterward, molecular sensory omics were introduced to verify the potential aroma compounds and their dynamic changes during sun exposure process. Then, flavor matrix was established and combined with multivariate statistical analysis to investigate the correlation between aroma compounds and flavor quality for raw baijiu, and to screen the key aroma compounds for the sun exposure process. Finally, a random forest model was established to verify the relationship between flavor compounds and the sense of baijiu. The research will provide a theoretical foundation and scientific guidance for optimizing the sun exposure and aging processes.

Experimental methods

Chemicals and solvents

Analytical samples were obtained from the Chengde Qianlongzui Distillery Co., LTD (Hebei, China). Methylene chloride (analytical grade), sodium chloride (NaCl), ethanol (analytical grade), and sodium sulfate anhydrous (Na2SO4) were purchased from Sinopharm Chemical Reagent Co., Ltd (Beijing, China) in analytical grade, n-alkanes (C5−C29) were purchased from Beijing Chemical Reagent Co. Ltd (Beijing, China).

Sample information

Six raw BCSGB samples (labeled as BCSGB-1, BCSGB-2, BCSGB-3, BCSGB-4B, CSGB-5, and BCSGB-6) were obtained from Chengde Qianlongzui Distillery Co., Ltd. (Hebei, China). Samples were stored at 4°C until analysis and are detailed in and Table S1.

Table 1. Sample information for six raw BCSGB samples.

Identification of trace components in raw baijiu samples

Each sample of baijiu (2 mL) was diluted to 15% (v/v) ethanol with saturated salt solution and was added to a 20 mL glass headspace vial, which was sealed with a PTFE/silicone septum and a screw cap. The sample was extracted at 240 r/min for 20 min at 50°C. Each sample was analyzed in triplicate for GC–ΜS analysis.

After extraction, an Agilent 8890 gas chromatograph equipped with an Agilent 5977B mass spectrometer (Agilent Technologies, Palo Alto, CA, USA) was used to analyze the trace components in raw baijiu. Helium (≥99.999%) at a constant flow rate of 1 mL/min was used as carrier gas. The samples are analyzed using the DB-FFAP column (60 m × 0.25 mm i.d. and 0.25 μm) in splitless mode. The oven temperature program was held at 40°C, ramped at 10°C/min to 50°C, held for 10 min, ramped at 3°C/min to 80°C for 10 min, ramped at 5°C/min to 230°C for 10 min, and then held for 10 min.

For the GC–MS system, the temperature of the ionization source was 230°C. Electron impact mass spectra were recorded at 70 eV, and the acquisitions were performed over an m/z scan range of 50 − 450 amu. Spectral Library Retrieval, Standard Comparison Method and Retention Index Comparison were used to identify the trace components in raw baijiu samples. The retention index (RI) of each compound was calculated from the retention times of n-alkanes (C5–C29) according to Equation (1):

In Equation (1), tn and tn +1 are the retention times of n-alkanes with carbon number n and n + 1, respectively; ti is the retention time of the untargeted compound with the peak between n and n + 1.

Quantitative analysis of the trace components in raw baijiu samples

The internal standard method was used for quantitative analysis. A series of standard solutions were prepared by dissolving authentic standard compounds in 15% aqueous ethanol solution, which were added internal standard (4-octanol, 20 mg/L). The analyzed conditions for standard solutions were the same as 2.3. Selective ion monitoring (SIM) mass spectrometry was used to quantify the trace components. All the trace components detected were quantified by constructing standard curves, where y was the peak area ratio (peak area of volatile standard/peak area of internal standard) and x was the concentration ratio (concentration of volatile standard/concentration of internal standard). All the calibrations were performed in triplicate. The concentrations of the trace components were calculated based on the standard curves.

Verification for aroma compounds in raw baijiu samples

Each sample of Baijiu was diluted to 14% (v/v) ethanol with saturated salt solution and then extracted three times with 50 mL CH2Cl2, and the organic-phase extracts were merged to get the organic phase O1. Next, the organic phase O1 was washed three times with an alkaline solution (pH = 10.0, 50 mL each time), and separated to get the organic phase O2 and the merged water-phase extracts W2. Then the W2 was adjusted to pH = 2.0 with hydrochloric acid solution, the solution was saturated with NaCl. Moreover, the solution was extracted three times with CH2Cl2 (50 mL each time), and the combined organic phase named O3. Anhydrous Na2SO4 was added to O2 and O3 for dry (−20°C). Then filtered, after that the mixture was concentrated to about 1.5 mL by distillation on a rotary evaporation apparatus. The neutral/basic fraction (NBF) and acidic fraction (AF) of components in BCSGB were obtained. Finally, about 1.0 ml of each sample was injected for GC–O–MS analysis.

After extraction, an Agilent 7890B GC coupled with a 5977 mass spectrometer and an olfactometer system was used (Agilent Technologies, Santa Clara, CA) in this study. Moreover, baijiu samples were analyzed with a DB-Wax capillary column (60 m × 0.25 mm × 0.25 μm). The column temperature was initially 40°C, raised to 50°C at 10°C/min for 20 min, and raised to 70°C at 1°C/min for 10 min, and then raised to 250°C at 3°C/min for 15 min. Helium (>99.999%) at a constant flow rate of 1 mL/min was used as carrier gas. The temperature of the ionization source was 230°C, respectively. A 1 μL aliquot of the concentrated baijiu sample was injected into the splitless mode.

Three trained panelists from the Key Laboratory of Brewing Molecular Engineering of China Light Industry were chosen to perform the GC–O analysis, and each panelist should record the aroma description, expression intensity, and retention time for aroma compounds. Then the C8–C40 n-alkane mixture was injected under the same GC–MS with Baijiu samples to calculate RI. All analyses were repeated in triplicate by each panelist.

Odor active value calculation and taste active value calculation

All such experiments were performed in triplicate. The contribution of each aroma compound to the overall aroma profile of BCSGB was assessed by the OAV and TAV,[Citation25] which was calculated based on the ratio of the concentration of each compound to its odor and taste threshold value in ethanol solution.

Sensory evaluation

Sensory panel: An 18-member sensory evaluation panel was composed of well-trained graduate students (the students are at Beijing Technology and Business University). All of them had been previously trained by describing and recognizing the aroma descriptors and the aroma characteristics of baijiu through an oronasal route.

Flavor compounds sensory evaluation: The 18-member sensory evaluation panel was trained for an additional 3 h to identify and define the descriptive terms for BCSGB using the related aroma compounds or materials reported in the literature.[Citation26] Then they were requested to write down the aroma descriptors of BCSGB samples. The descriptors with higher frequencies were selected. The 18-member sensory evaluation panel was called together to discuss them until an agreement was reached. Ethyl hexanoate and ethyl butanoate (fruity), 2-phenylethanol (floral), ethanol (alcoholic), hexanoic acid (cellar), steamed sorghum (grain aroma), and 2,5-dimethyl pyrazine (roasted aroma) and were selected to evaluate the aroma profiles of the BCSGB samples (as shown in ). Finally, the panelists were asked to evaluate the odor intensities of the eight aforementioned aroma attributes represented by the above chemicals using a 6-point scale from 0 to 5 (0 = none, 1 = very weak, 2 = weak, 3 = moderate, 4 = strong, and 5 = very strong). All of the tests were performed in a sensory evaluation room at (25 ± 1) °C in three different sessions.

Table 2. The main sensory characteristic definitions.

Taste compounds sensory evaluation: The sensory evaluation of taste intensity of trace components in samples was based on the scoring test method of GB/T 33,404–2016 (Institute & Association, 2016). The 5-point scoring method was selected, and each taste attribute was provided to the panels, respectively (as shown in ). Then the panel tasted the sample. At the end of each taste, rinse the mouth with pure water before tasting the next sample. According to the difference between the taste intensities of the samples, score (5-point scale: no sensation − 0 points, slightly feel − 1 points, slightly − 2 points, − 3 points, strong − 4 points, very strong − 5 points).

Table 3. The main taste attributes.

Overall sensory attribute evaluation: The sensory evaluation of sensory attributes of BCSGB was based on the scoring test method of GB/T 33,404–2016 (Institute & Association, 2016). Each attribute (as shown in ) was a rating of the aforementioned attributes.

Table 4. Baijiu overall sensory attributes.

Statistical analysis

All independent experiments were performed at least in triplicate. The study was expressed as mean ±standard deviation (SD). One-way analysis of variance (ANOVA) and Turkey test at the α ≤ 0.05 level of significance were carried out to determine the significant differences between the concentration of trace components and sensory evaluation in samples with different sun exposure times. Flavor matrix was established and combined with multivariate statistical analysis to investigate the correlation between flavor compounds and flavor quality for raw baijiu using the R software package to screen the quality variance factors for the sun exposure process. The random forest analysis was performed using the R software package.

Results and discussion

Identification of trace components by the adsorption pen coupled with GC–MS

Qualitative analysis of trace components in BCSGB with six different sun-exposure times: The adsorption pen coupled with GC-MS was used for qualitative analysis of trace components in the baijiu samples to characterize the type of potential aroma compounds in six types of baijiu samples (BCSGB-1, BCSGB-2, BCSGB-3, BCSGB-4, BCSGB-5, and BCSGB-6). Consequently, 111 kinds of trace components were detected (as shown in ), including 43 esters, 9 acids, 20 alcohols, 7 aldehydes, 5 ketones, 6 acetals, 4 furans, 13 aromatics, 3 hydrocarbon alkyl, and 1 sulfur compound. A group of pictures were used to demonstrate the distribution and the dynamic change for the trace components during the sun-exposure process (). In general, esters, alcohols, and aromatics were the most abundant trace components and constituted above 50% in BCSGB samples, which was in congruence with the earlier reports on fermented beverages.[Citation27]

Figure 1. (a), the amount of various trace components in BCSGB. (b), the proportion of trace components in BCSGB. (c) ~ (d), the dynamic change for the trace components during sun-exposure process.

Table 5. Concentrations of 111 trace components in six BCSGB samples.

Specifically, the total type of trace components decreased during the sun-exposure time. Ninety-two kinds of trace components were identified in the sample BCSGB-1, including 38 esters, 7 acids, 16 alcohols, 11 aromatics, 6 aldehydes 5 ketones, 5 acetals, 3 furans, and 1 sulfur compound. Among them, the types of trace components showed a trend of decreasing first and then increasing. The most trace components were identified in the sample BCSGB-1, and the fewest were found in the sample BCSGB-5. Among them, a phenomenon was found that the types of esters, ketones, and sulfur compounds decreased and the types of furans increased. For other types of trace components, no significant changes were found during the sun-exposure process. This corresponds to the variation in the concentration of esters in light, sauce and feng flavor of baijiu [28, 29]. In detail, four types of esters (3-methylbutyl hexanoate, ethyl nonanoate, ethyl decanoate, and 3-methylbutyl pentanoate) were not found after 12 days of solarization. Two types of alcohols (2,6-dimethyl-4-heptanol, 1-methyl-1-octanol) were hard to catch after 12 days solarization. A sulfur compound (dimethyl trisulfide) and three types of alkanes (1-ethoxy-1-pentoxyethane, 1-ethoxy-1-hexoxyethane, and 1-cyclopropylpentane) emerged gradually during the sun-exposure process. It was worth noting that 52 types of trace components were always present in the sun-exposure process; thus, these trace components were thought to be the main trace components of BCSGB.

Qualitative analysis of trace components in BCSGB with six different sun-exposure times: In order to further clarify the concentration distribution of trace components in the process of sun-exposure, six samples of BCSGB were subjected to the adsorbent pen combined with GC–MS to determine the concentrations of trace components. Roughly, it was consistent with the trend of type changes, the total concentration of trace components showed a general decreasing tendency with the length of sun-exposure time increased, as indicated in and . Obviously, the sample BCSGB-1 (1051456.38 μg/L) obtained the greatest total concentration of trace components, followed by the samples BCSGB-2 (1047420.27 μg/L), BCSGB-3 (1014404.49 μg/L), BCSGB-4 (851042.76 μg/L), BCSGB-5 (949190.27 μg/L), and BCSGB-6 (696786.31 μg/L). In detail, ethyl hexanoate (147255.38–338792.37 μg/L), ethyl butanoate (78252.24–88313.84 μg/L), ethyl acetate (52090.53–96633.77 μg/L), ethyl pentanoate (36689.75–61777.12 μg/L), hexanoic acid (47337.16–60794.08 μg/kg), and ethyl 2-hydroxypropanoate (23016.2–40177.58 μg/L) had relatively high concentrations in six BCSGB samples. Additionally, butyl 2-hydroxypropanoate (77.31–257.93 μg/L), 2-octenal (71.37–195.97 μg/L), and 2-ethyl hexanol (63.89–156.65 μg/L) presented low concentrations in such samples. In particular, esters have the highest concentration in BCSGB, followed by acids and alcohols. To further clarify the variation tendency in the concentrations for trace components during the sun-exposure process, the 111 trace components were standardized and exhibited in .

Figure 2. (a), The post-standardized concentration of various trace components in six BCSGB samples. (b) ~ (d), standardized results of esters in six BCSGB samples. (e), standardized results of alcohols in six BCSGB samples. (f), standardized results of aldehydes in six BCSGB samples. (g), standardized results of acids in six BCSGB samples. (h), standardized results of aromatics in six BCSGB samples. (i), standardized results of ketone in six BCSGB samples. (j), standardized results of acetals in six BCSGB samples. (k), standardized results of furans in six BCSGB samples. (l), standardized results of sulfur compounds in six BCSGB samples.

As a result, esters were the major trace components identified, with ethyl hexanoate, ethyl butanoate, ethyl acetate, and ethyl 2-hydroxypropanoate comprising more than 53% of the total esters collected from the BCSGB samples. Among them, ethyl hexanoate showed a significant downward trend, while others had no significant change (as shown in )). As reported, these trace components were predominant in many types of baijiu. Of note, their ratio of esters to corresponding acids could significantly affect the flavor of baijiu, which was found in literature reports and actual production. In detail, the ratio of ethyl acetate to acetic acid increased during the sun-exposure process, while the ratio of ethyl hexanoate to hexanoic acid decreased. A decreasing tendency for esters and an increasing tendency for acids were obviously observed, which was speculated to have an important effect on the flavor of baijiu. For acetic acid, its concentration was significantly higher than other kinds of acids, comprising at least 40% of the total acids, while the concentration of 3-methylbutanoic acid was observed to significantly change during the sun-exposure process (as shown in ). For alcohols, 3-methyl-1-butanol and 1-hexanol showed a higher concentration than others and exhibited a fluctuation decline during the sun-exposure process. Of note, only butyl pentanoate, 2-methyl-4-heptanol, and 2,3-dimethylcyclohexanol were found to be significantly different between these BCSGB samples. As a result, 12 kinds of aromatics were identified and a remarkable change was found in the concentration of ethyl benzoate, ethyl 3-phenylpropionate, and 2-phenylethanol (as shown in ). For sulfur compounds, only dimethyl trisulfide had a gradual reduction during the sun-exposure time (as shown in ). For other types of trace components, no significant variance was obtained during the sun-exposure process (as shown in ).

Figure 3. (a) and (d), OAVs and TAVs are shown, with a color gradient denoting Spearman’s correlation coefficient. Aroma compounds and taste compounds was related to sensory attributes by partial (geographic distance-corrected) Mantel tests. Edge width corresponds to the Mantel’s r statistic for the corresponding distance correlations, and edge color denotes the statistical significance based on 9,999 permutations. (b) and (c), Aroma and taste descriptive profiles of BCSGB samples. The scores of selected descriptors were evaluated by 18 panelists on average. Significance was indicated at * p < .05 (significance), ** p<.01 (very significant), *** p < .001 (very highly significant).

Based on this, the change in type and concentration was deemed to be the result that affected the flavor of baijiu. However, the contribution of trace components has yet to be discovered. Hence, it was necessary to screen its flavor substances (aroma compounds and taste compounds) and evaluate their contribution to the flavor of baijiu.

Screening of flavor compounds contributing to BCSGB by pH liquid–liquid extraction/GC–O–MS

The study showed that not all the trace components had a direct contribution to the flavor of baijiu, and it was important to screen and evaluate the flavor compounds that made an important contribution to the flavor of Baijiu. Thus, pH liquid–liquid extraction/GC–O–MS was used to screen the dynamic change for aroma compounds during the sun-exposure process, and time intensity method was used to evaluate the aroma expression of the aroma compounds. As exhibited in , 35 kinds of flavor compounds were screened, including esters (15 types), acids (5 types), alcohols (4 types), aromatics (6 types), aldehyde (1 types), acetals (1 type), furans (2 types), fruity, floral, honey, and cheese-aroma were found to be the main aroma characteristic for flavor compounds. Thus, these aroma characteristics were considered as the basis of sensory evaluation in subsequent experiments. Of note, the aroma expression for hexanoic acid, butanoic acid, 2-phenylacetaldehyde, and ethyl hexanoate were higher than other aroma compounds.

Table 6. Osme for 34 flavor compounds in six BCSGB samples.

Esters, the most significant type of aroma compounds in strong flavor baijiu, were what gave baijiu its intense fruity fragrance.[Citation28] Based on this, higher aroma expression intensity for ethyl butanoate, 3-methylbutyl acetate, ethyl pentanoate, ethyl hexanoate, ethyl 2-hydroxypropanoate, and butyl hexanoate was observed by GC–O during the sun-exposure process. Ethyl hexanoate was a distinctive aroma compound of strong flavor baijiu with fruity aroma. Of note, due to hydrolysis and volatilization during the sun-exposure process, ethyl acetate, hexyl acetate, and ethyl heptanoate were hard to catch after 30 days of solarization. Acids appeared to be the most important contributors to the desirable aroma of vinegar and cheese-aroma. Moreover, alcoholics and furans contributed to alcoholic and malty, floral and honey, sweet and roasted aroma, respectively. Notably, the aroma expression of acetic acid, benzaldehyde, furan-2-carbaldehyde, 3-methyl-1-butanol, and furan-2-ylmethyl acetate changed greatly during the sun-exposure process. Thus, it was hypothesized that the concentration and aroma expression of aroma compounds changed during the sun-exposure process, resulting in different sensory characteristics of baijiu.

OAVs and TAVs of flavor compounds.

As described above, the contributions of aroma compounds in baijiu were not just determined by their concentration, the matrix effect should also be considered. Hence, in order to reveal the contributions of the flavor compounds in BCSGB, the odor and taste thresholds of flavor compounds from the literature were used to estimate the OAVs and TAVs. The results () showed that there were 35 (BCSGB-1), 34 (BCSGB-2), 35 (BCSGB-3), 26 (BCSGB-4), 26 (BCSGB-5), and 25 (BCSGB-6) aroma compounds with OAVs ≥ 1, respectively. Among them, ethyl hexanoate had the highest average OAVs (4566), followed by ethyl pentanoate (1850), ethyl octanoate (615), ethyl butanoate (985), dimethyl trisulfide (786), ethyl 3-methylbutanoate (399), 3-methylbutanal (372), 3-methylbutyl acetate (140), and ethyl 4-methylpentanoate (63). The result showed that these aroma compounds were thought to have substantial contributions to the aroma profiles of BCSGB. However, a significant difference for OAVs was found in 13 aroma compounds during the sun-exposure time (p < .05). Notably, a decreased trend was found in the OAVs of ethyl hexanoate, ethyl 3-phenylpropionate, dimethyl trisulfide and an increased trend was found in hexanoic acid during the sun-exposure process, which was responsible for the differences in the flavor characteristic of six BCSGB samples.

Table 7. OAVs of 35 flavor compounds in six BCSGB samples.

Considering the importance of baijiu’s taste quality and the fact that individuals predominantly choose baijiu based on their taste preferences, it is imperative to further investigate the contribution of flavor compounds to the taste of baijiu.[Citation25]aa Hence, the TAV value of flavor compounds was calculated as the ratio of the concentration determined in the BCSGB samples to its threshold value. As exhibited in , the TAVs for ethyl butanoate, 3-methylbutanal, and 3-methylbutyl acetate were higher than other taste compounds. Thus, these taste compounds were considered to have an important contribution in subsequent experiments. Based on this, a decreased trend was found in the TAVs of 2-phenylethanol, ethyl 3-phenylpropionate, and 3,4-dimethyl benzaldehyde and a fluctuate was found in hexyl hexanoate and 1-butanol.

Table 8. TAVs of 35 flavor compounds in six BCSGB samples.

Above all, seven flavor compounds (ethyl butanoate, 3-methylbutanal, 3-methylbutyl acetate, aldehyde acetal, ethyl 4-methylpentanoate, ethyl 3-methylbutanoate, and ethyl acetate) were considered as the essential factors that were attributed to the fact that their OAVs and TAVs were both greater than 1. However, the correlation between flavor compounds and flavor characteristics was uncovered. Hence, it was necessary to establish the correlation between flavor compounds (aroma compounds and taste compounds) and various flavor characteristics (aroma characteristics and taste characteristics) of BCSGB and to explore the interaction between various flavor compounds.

Correlation analysis between flavor compounds and flavor characteristics for BCSGB

To evaluate the flavor profile of BCSGB, nine aroma attributes (fruity, floral, alcoholic, cellar, grain aroma, roasted aroma, zao-like aroma, fullness, and harmony) and seven taste attributes (acid, sweet, bitter, spicy, astringent, durability, and softness) were chosen. As shown in , sun-exposure had no significant effect on individual taste perception, but it did have a notable effect on overall taste perception (p < .001). Moreover, a remarkable difference was found in the aroma attribute of grain (p < .05) and the taste of softness (p < .01).

Although the OSME values from GC–O and calculated OAVs and TAVs could be used to evaluate the flavor (odor and taste) intensities and contributions of flavor compounds, the contribution of these flavor compounds to the corresponding flavor characteristics of BCSGB still needed further study. Hence, the relationship between flavor compounds and flavor characteristics of corresponding baijiu samples was established by mental test. As shown in , ethyl butanoate and 1-octen-3-ol had a strong positive correlation with grain aroma, ethyl 3-methylbutanoate exhibited a significant positive impact on roasted aroma, while zao-like aroma was found to be closely positive related to 1-octen-3-ol. As shown in , a positive correlation was found between 3-methylbutanoic acid and sweet taste, while furan-2-carbaldehyde and 1-hexanol had a positive impact on astringent taste. Interestingly, the aroma expression among esters had a positive correlation with each other, while there was a negative aroma expression between esters and acids. Thus, it was speculated that the perception of aroma compounds was also influenced by the presence of flavor compounds. Above all, ethyl butanoate, 1-octen-3-ol, ethyl 3-methylbutanoate, 3-methylbutanoic acid, furan-2-carbaldehyde, and 1-hexanol were thought to influence the sensory characteristics of baijiu, which were responsible for the quality change of BCSGB during the sun-exposure process.

To verify the relationship between flavor compounds and the sense profile of baijiu, a random forest model based on flavor compounds and overall sensory attribute evaluation (as shown in ) was established.[Citation31] Based on the importance analysis, it can be seen that the characteristics of the four trace components, ethyl hexanoate, 2,6-dimethyl-4-heptanol, butyl-2-hydroxypropanoate, and 2-phenylethanol, were of great importance for the flavor of baijiu. In consideration of three evaluation methods (OAVs and TAVs, mental test, and random forest), esters, acids and aromatics were regarded as the most important kinds of flavor compounds influencing the flavor of baijiu. It was discovered that ethyl butanoate, 3-methylbutanal, 3-methylbutyl acetate, aldehyde acetal, ethyl 4-methylpentanoate, ethyl 3-methylbutanoate, ethyl acetate, 1-octen-3-ol, 3-methylbutanoic acid, furan-2-carbaldehyde, 1-hexanol, ethyl hexanoate, and 2,6-dimethyl-4-heptanol were significant factors influencing the quality of baijiu, their modifications improve the harmonious aroma and soft taste of baijiu, as well as the aroma expression of grain note. In detail, the concentration of esters decreased, leading to a weakening of the fruit and roasted aromas, while acetal demonstrated a downward trend, resulting in the enhancement of the floral aroma. It was worth noting that lowering the esters to acids ratio results in more sensual harmony for baijiu. Furthermore, it was discovered the sweet taste faded with the concentration of aromatics and acids decreased. Esters and alcohols showed a positive relation to astringency and improved the fullness of baijiu. Above all, exposure to sunlight affected the distribution of esters, acids, and alcohols, resulting in corresponding changes in the fruity aroma, floral aroma, astringency, and harmony of the baijiu.

Figure 4. (a) Flavor profile analyses (post-standardized) of BCSGB samples. The scores of selected descriptors were evaluated by 18 panelists on average. Significance was indicated at * p < .05 (significance), ** p < .01 (very significant), *** p < .001 (very highly significant). (b), the error of random forest model. (c), Curve of significant influence factors.

Conclusion

In summary, a total of 111 trace components were identified. Further, 34 aroma compounds and 11 taste compounds were recognized as the important flavor compounds owing to their relatively high OAVs or TAVs, which were mainly esters, acids, and alcohols. Based on flavor expression, mental test, and random forest, it was indicated that 13 kinds of flavor compounds were verified as significant factors influencing the quality of baijiu, which can be used as a grapple to grade product quality and monitor the brewing process. This study provides strategies and ideas for optimizing directional processes and improving the quality of baijiu.

Supplemental Material

Download PDF (38.6 KB)Acknowledgments

This paper is supported by the Young Elite Scientist Sponsorship Program by Bast (No. BYESS2023055), the National Natural Science Foundation of China (32001826), the project of the National Key R&D Program of China (No. 2022YFD2101205), 2023 Beijing Technology and Business University Graduate Student Discipline Competition Project, and 2023 postgraduate research capability improvement program funding.

Disclosure statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability statement

Data will be made available on request.

Supplementary material

Supplemental data for this article can be accessed online at https://doi.org/10.1080/10942912.2023.2281885

Additional information

Funding

References

- Baoguo, S.; Huilin, L. Current situation of healthy food industry and transformation and development of food industry. J. Food Sci. Technol, China. 2023, 41(2), 1–6.

- Wang, J.; Chen, H.; Wu, Y.; Zhao, D. Uncover the Flavor Code of Strong-Aroma Baijiu: Research Progress on the Revelation of Aroma Compounds in Strong-Aroma Baijiu by Means of Modern Separation Technology and Molecular Sensory Evaluation. J. Food Compost. Anal. 2022, 109(18), 104499–104517. DOI: 10.1016/j.jfca.2022.104499.

- Huang, H.; Wu, Y.; Chen, H.; Hou, Y.; Wang, J.; Hong, J.; Zhao, D.; Sun, J.; Huang, M.; Sun, B. Identification of Regionalmarkers Based on the Flavor Molecular Matrix Analysis of Sauce-Aroma Style Baijiu. J. Sci. Food Agric. 2023, 103(15), 7434–7444. DOI: 10.1002/jsfa.12823.

- Liu, H.; Sun, B. Effect of Fermentation Processing on the Flavor of Baijiu. J. Agric. Food. Chem. 2018, 66(22), 5425–5432. DOI: 10.1021/acs.jafc.8b00692.

- Zhao, K.; Liu, L.; Zheng, Q.; Gao, F.; Chen, X.; Yang, Z.; Yu, Y.; Yu, Y. Differentiating Between Ageing Times of Typical Chinese Liquors by Steady-State Microelectrode Voltammetry. Microchem. J. 2019, 15, 1104244–1104250. DOI: 10.1016/j.microc.2019.104244.

- Yajie, M.; Fuping, Z.; Mingquan, H.; Yuhang, Z.; Fuyan, Z.; Baoguo, S. Analysis of Volatiles in Laobaigan Base Baijiu Manufactured by Traditional Technology and Mechanized Technology Using Comprehensive Two-Dimensional Gas Chromatography/Time of Flight Mass Spectrometry. J. Chin. Inst. Food Sci. Technol. 2019, 19(3), 266–280. DOI: 10.16429/j.1009-7848.2019.03.034.

- Jia, W.; Fan, Z.; Du, A.; Shi, L. Untargeted Foodomics Reveals Molecular Mechanism of Magnetic Field Effect on Feng-Flavor Baijiu Ageing. Food Res. Int. 2021, 149, 110681–110694. DOI: 10.1016/j.foodres.2021.110681.

- Fang, C.; Lu, W.; Liu, Q.; Chen, Y.; Jia, W.; Xu, Y. Comparative Study Between the Effects of Aged and Fresh Chinese Baijiu on Gut Microbiota and Host Metabolism. Food Biosci. 2022, 49. DOI: 10.1016/j.fbio.2022.101859.

- Zhang, W.; Xiao, Y.; Deng, R.; Wang, Y.; Qiu, Y.; Sun, Q.; Luo, A. An Electric-Field Instrument for Accelerated Aging to Improve Flavor of Chinese Baijiu. LWT. 2023, 174, 114446–114454. DOI: 10.1016/j.lwt.2023.114446.

- Fan, Q.; Wang, X.; Zhao, Y.; Zheng, F.; Li, H.; Zhang, F.; Chen, F.; Chen, F. Characterization of Key Aroma Compounds in Laobaigan Chinese Baijiu by GC×GC-TOF/MS and Means of Molecular Sensory Science. Flavour Fragr. J. 2019, 34(6), 514–525. DOI: 10.1002/ffj.3533.

- Xu, Y.; Wu, M.; Zhao, D.; Zheng, J.; Dai, M.; Li, X.; Li, W.; Zhang, C.; Sun, B. Simulated Fermentation of Strong-Flavor Baijiu Through Functional Microbial Combination to Realize the Stable Synthesis of Important Flavor Chemicals. Foods. 2023, 12(3), 644–665. DOI: 10.3390/foods12030644.

- Hu, G.; Lu, J.; Cai, X.; Yin, J. Analysis and Study on Characteristic Components of Sesame Flavor Liquor. Liquor-Making Sci. & Tech. 1994, (4), 75–77.

- Fan, W.; C Qian, M. Identification of Aroma Compounds in Chinese ‘Yanghe Daqu’ Liquor by Normal Phase Chromatography Fractionation Followed by Gas Chromatography[sol]Olfactometry. Flavour Fragr. J. 2006, 21(2), 333–342. DOI: 10.1002/ffj.1621.

- Zhu, M.; Fan, W.; Xu, Y.; Zhou, Q. 1-Diethoxymethane and Methanethiol as Age Markers in Chinese Roasted-Sesame-Like Aroma and Flavour Type Liquor. Eur. Food Res. Technol. 2016, 1(11), 1985–1992. DOI: 10.1007/s00217-016-2697-x.

- Miller, J.; Puch-Solis, R.; Buchanan, H. A. S.; Nic Daeid, N. A Ground Truth Data Set of Gas Chromatography Mass Spectrometry (GCMS) Analysed Synthesised Methylenedioxymethylamphetamine (MDMA). Data Brief. 2023, 47, 108931–108941. DOI: 10.1016/j.dib.2023.108931.

- Li, J.; Xu, Y.; Du, W.; Jin, L.; Ren, P.; Ren, F.; Xie, J. C. Comparative Analysis of Aroma Compounds in Chinese Traditional Dry-Rendered Fat by HS/GC-IMS, SPME/GC-MS, and SPME/GC-O. J. Food Compost. Anal. 2022, 107, 104378. DOI: 10.1016/j.jfca.2021.104378.

- Zhao, D.; Shi, D.; Sun, J.; Li, A.; Sun, B.; Zhao, M.; Zheng, F.; Sun, X.; Li, H.; Huang, M. Characterization of Key Aroma Compounds in Gujinggong Chinese Baijiu by Gas Chromatography–Olfactometry, Quantitative Measurements, and Sensory Evaluation. Food Res. Int. 2018, 105, 616–627. DOI: 10.1016/j.foodres.2017.11.074.

- Niu, Y.; Kong, J.; Xiao, Z.; Chen, F.; Ma, N.; Zhu, J. Characterization of Odor-Active Compounds of Various Chinese “Wuliangye” Liquors by Gas Chromatography–Olfactometry, Gas Chromatography–Mass Spectrometry and Sensory Evaluation. Int. J. Food Prop. 2017, 20(sup1), S735–S745. DOI: 10.1080/10942912.2017.1309549.

- QIAN, W. F. M. C.; Qian, M. C. Headspace Solid Phase Microextraction and Gas Chromatography−olfactometry Dilution Analysis of Young and Aged Chinese “Yanghe Daqu” Liquors. J. Agric. Food. Chem. 2006, 7931−7938(20), 7931–7938. DOI: 10.1021/jf051011k.

- Xu, J.; Chen, M.; Liu, X. Changes in Main Trace Components of Different Alcoholic Crude Chinese Spirits During Storage. Int. J. Food Eng. 2018, 14(4). DOI: 10.1515/ijfe-2017-0083.

- Psillakis, E.; Yiantzi, E.; Sanchez-Prado, L.; Kalogerakis, N. Vacuum-Assisted Headspace Solid Phase Microextraction: Improved Extraction of Semivolatiles by Non-Equilibrium Headspace Sampling Under Reduced Pressure Conditions. Analytica Chimica Acta. 2012, 742, 30–36. DOI: 10.1016/j.aca.2012.01.019.

- Chen, L.; Wang, Z.; Liao, P.; Li, A.; Zhang, Y.; Li, H.; Sun, J. The Effect of Saliva on the Aroma Release of Esters in Simulated Baijiu Under the Impact of High Ethanol Concentration. J. Food Compost. Anal. 2021, 104, 104134–104144. DOI: 10.1016/j.jfca.2021.104134.

- Hong, J.; Huang, H.; Zhao, D.; Sun, J.; Huang, M.; Sun, X.; Sun, B. Investigation on the Key Factors Associated with Flavor Quality in Northern Strong Aroma Type of Baijiu by Flavor Matrix [Article]. Food Chem. 2023, 426(136576), 136576. DOI: 10.1016/j.foodchem.2023.136576.

- Qu, L.; Haiyue, X.; Yougui, Y.; Qing, Z. Why Does Distilled Liquor Has a Soft and Harmonious Flavor After Long-Time Ageing? A Thermodynamic Analysis. J. Food Compos. Anal. 2023, 123, 105609–105609. DOI: 10.1016/j.jfca.2023.105609.

- Wang, L.; Zhu, L.; Zheng, F.; Zhang, F.; Shen, C.; Gao, X.; Sun, B.; Huang, M.; Li, H.; Chen, F. Determination and Comparison of Flavor (Retronasal) Threshold Values of 19 Flavor Compounds in Baijiu. J. Food Sci. 2021, 86(5), 2061–2074. DOI: 10.1111/1750-3841.15718.

- Dong, W.; Guo, R.; Liu, M.; Shen, C.; Sun, X.; Zhao, M.; Wu, J.; Li, H.; Zheng, F.; Huang, M. Characterization of Key Odorants Causing the Roasted and Mud-Like Aromas in Strong-Aroma Types of Base Baijiu. Food Res. Int. 2019, 125, 108546–108559. DOI: 10.1016/j.foodres.2019.108546.

- Qiu, L.; Zhang, M.; Chang, L. Effects of Lactic Acid Bacteria Fermentation on the Phytochemicals Content, Taste and Aroma of Blended Edible Rose and Shiitake Beverage. Food Chem. 2023, 405, 134722–134734. DOI: 10.1016/j.foodchem.2022.134722.

- Hong, J.; Tian, W.; Zhao, D. Research Progress of Trace Components in Sesame-Aroma Type of Baijiu. Food Res. Int. 2020, 137, 109695–109704. DOI: 10.1016/j.foodres.2020.109695.

- Sha, S.; Shuang, C.; Michael, Q.; Chengcheng, W.; Yan, X. Characterization of the Typical Potent Odorants in Chinese Roasted Sesame-Like Flavor Type Liquor by Headspace Solid Phase Microextraction-Aroma Extract Dilution Analysis, with Special Emphasis on Sulfur-Containing Odorants. J. Agric. Food Chem. 2017, 65(1), 123–131. DOI: 10.1021/acs.jafc.6b04242.

- Zheng, Y. Characterization of the Key Odorants in Chinese Zhima Aroma-Type Baijiu Studies; [SCUT(South China University of Technology)]: Guangzhou, 2017.

- Lee, S.; Kim, J. Prediction of Nanofiltration and Reverse-Osmosis-Membrane Rejection of Organic Compounds Using Random Forest Model. J. Environ. Eng. 2020, 146(11), 146(11. DOI: 10.1061/(asce)ee.1943-7870.0001806.