Abstract

Through an ethnographic analysis of the Graphene Engineering Innovation Centre (GEIC) at the University of Manchester in the United Kingdom and drawing on a Science and Technology Studies (STS) inspired theoretical framework, this article explores architectural space as configured by sociotechnical infrastructures. In the context of the GEIC, by paying attention to the flows of University-employed engineers, prototyped technologies, gas pipes, cables and ventilation, the article illuminates how new spatial configurations emerge through the practices and processes of which the building becomes a part. Such an analysis, it will argue, allows attention to move away from a sole focus on visions of architects and clients or even the agency of users to modify their environment. Instead, the work proposes a fruitful area for future study, paying attention to the connections, components and flows which are modularly plugged into the building and the legacies of “knowledge” which they leave behind.

Handing Over

In late 2019, I accompanied Tom, a member of the management team at the University of Manchester’s recently opened Graphene Engineering Innovation Centre (GEIC) to a meeting with the building’s construction team.Footnote1 The building, designed by Rafael Viñoly Architects, is officially called the Masdar Building after the Emirati state-owned energy company from Abu Dhabi which provided half of the £60 million funding for the centre, but is more often referred to simply as “the GEIC.” It was designed for the scale-up of technologies which utilise the “wonder material” graphene, a 2D (one-atom-thick) material that had been first isolated at the University of Manchester in 2004.Footnote2 Graphene was considered to have an array of technological applications, and ushered in a new family of 2D materials. While the University had invested heavily into its academic expertise in this emerging field, and its image as “the home of graphene,” this new centre, the GEIC, aimed to be where the University’s academic expertise could be translated into the more profitable form of intellectual property.

Few participants were left to take part in a meeting at this stage of the project. Along with Tom and another GEIC management team member, Lloyd, were two others, one representing the contractors and the other the project management. For the two representatives, and for Rafael Viñoly Architects, who had long left the proceedings, the GEIC was almost a finished product. The architects already had the building listed on their website as one of many successful projects. The meeting represented the “handover” stage of the project, when the University as the client finally parted ways with the contractor.Footnote3 Despite having opened nine months earlier, in December 2018, a long period of fitting out the building’s laboratories had followed. This work was now almost complete and just a few issues remained.

This was a strange time for an architectural researcher to enter proceedings. While a number of ethnographies of architectural and engineering practice have detailed the dynamism and complexity of design as a process, involving a vast array of participants (from architects, engineers, acousticians, politicians, drawings, models and computer software),Footnote4 in the GEIC’s handover meeting the building was presented by all present as a relatively stable entity. Yet, cracks in this veneer of stability began to show. Referring to a problem with airflow in the first-floor laboratories, Tom asked the group if, “going forward,” the GEIC might encounter these problems again when other laboratories were retrofitted. Lloyd interjected: this would be “post-contract work,” and the issue would be the University’s responsibility to resolve. Though not currently an issue which could be resolved, for the management team it was essential to consider the possibility of problems emerging in the future. It was a small reminder that, for Tom and Lloyd, the building resisted the status of finished product. “Going forward,” they would be tasked with treating the building as an evolving and uncertain entity, which may need to be reconfigured throughout its life.

It is from this position that this article will proceed. Focusing on the processes of modularly plugging in (and removing) new infrastructure into the facility, the article will argue that space is produced and reproduced in practice throughout the course of a building’s life. It will draw upon a five-month ethnographic study at the GEIC undertaken in 2019, which included participant observation, 35 semi-structured and three walking interviews with 28 participants (including interviews conducted between 2018 and 2020 as part of a broader PhD research project), and shadowing of key actors. The research follows recent studies on the National Graphene Institute (NGI)—the GEIC’s sister building—by architectural theorist Albena Yaneva and her work with physicist Kostya Novoselov, one of the two scientists responsible for isolating graphene in Manchester.Footnote5 This work demonstrates how the academically oriented NGI, completed in 2015 and designed by Jestico + Whiles, acts as a machine for building connections between disciplines and groups in the emerging field of 2D materials research. While the NGI looked to build interdisciplinarity amongst academics, the task faced by the GEIC was to form connections between the academic expertise which Manchester had amassed, and a 2D materials industry that was very much still in its infancy at the time of the study.

The article will be divided into three parts. Firstly, a short review of recent writing will present several ways in which laboratory architectures can be viewed: as reflective or generative of stable scientific practices and identities; as containers of multiple, changing scientific practices, requiring adaptation and flexibility; and finally, as part of the sociomaterial “infrastructure” upon which technoscientific exploration and knowledge creation relies. The second part of the article will outline three scenes from the ethnographic study of the GEIC: the plugging in of a new piece of machinery into the energy laboratory, and the choreographing of various flows in which the machine would soon become entangled; a moment of reflection in which Tom describes the potential for the facility to become a “finished” entity; and finally, the plugging in of a machine that would only temporarily be present in the facility, and a discussion of the “legacy” of services that would be left behind after the machine was unplugged. The final section of the article will present broader conclusions about the theoretical lens developed, seeing buildings as shaped and reshaped by the infrastructures that are modularly plugged-in and unplugged from them. It will suggest, drawing on Stewart Brand’s famous proposition that buildings “learn,” that this process of successive reformulations leads to the embedding of “knowledge” into the facility.

Architectures and Infrastructures of Knowledge

The link between scientific practices and the places in which they are conducted have been explored in multiple fields, including architectural studies and history of science. Laboratory designs may have inscribed within them particular understandings and expectations of the needs and identities of future scientific users.Footnote6 Historical studies may analyse “venues” of science as a trace of these practices, assuming their design reflects underlying scientific values and norms.Footnote7 Other authors explore the aspirations of architects, clients and philanthropic donors in the design of buildings which may hope to produce new forms of behaviour in institutions and building users.Footnote8 Linking these various approaches is the notion that architecture, as an obdurate setting for scientific practices, plays a stabilising role. Authors have noted that, while change may be inevitable and expected, the architect’s original vision remains relatively fixed, a reality that must be negotiated by future users: “For laboratory architecture, however flexible in theory, necessarily stabilises scientific practice, since a philosophy of research is embedded in the very structure of the building and persists far longer than the initial vision and mission that gave it life.”Footnote9 In cases such as Louis Kahn’s Richards Laboratories (Philadelphia, 1957–64), this initial vision may be at odds with the needs of the scientist-users and thus require extensive retrofit. Kahn’s aspiration to instil a culture of openness through open-plan, studio-like laboratories was contrary to the eventual users’ desire for secrecy, and many of the laboratory spaces were quickly partitioned.Footnote10

This process of reconfiguring laboratories leads to a second approach to architectures of science: focusing not on the stabilisation of scientific practice but the inevitable evolution of the practices of scientists and their disciplines. Robert Venturi, describing his, John Rauch and Denise Scott Brown’s 1983 scheme (with Payette Associates) for the Lewis Thomas Laboratory at Princeton University, altered the maxim form follows function to argue that, for the design of the laboratory, “form accommodates functionS: functions that are inherently changing as they are complex and contradictory.”Footnote11 A design for any specific arrangement may quickly become outdated as the discipline for which it is designed progresses in perhaps-unpredictable ways.

It is no surprise, then, that Brand pointed to his experience with a research building as the cause of his initial interest in the subject of his book How Buildings Learn (1995). Brand criticised I.M. Pei’s Weisner Building, built for the Massachusetts Institute of Technology’s (MIT) Media Lab, in which he worked as a visiting scientist, for its “pretentiousness, ill-functionality, and non-adaptability” and its oversized and “sterile” atrium, which limited lab space and opportunity for growth, “exacerbating academic turf battles from the first day.”Footnote12 First opened in 1985, the building resisted change: “Getting new cabling through the interior concrete walls—a necessity in such a laboratory—requires bringing in jackhammers. You can’t even move office walls around, thanks to the overhead fluorescent lights being at a Pei-signature 45-degree angle to everything else.”Footnote13 Brand contrasts this lack of adaptability with the “low road” architecture of MIT’s Building 20 (first built in 1943), situated just metres from the Weisner building, which allowed it to respond to users’ needs.

Despite critique of his Richards Laboratories, Kahn has been praised for his creation of flexible, adaptable laboratory buildings. Most notably, his design for the Salk Institute (completed 1965) advanced those ideas of “served” flexible laboratory space and “servant” space dedicated to the building’s services that he had utilised in the Richards Laboratories project. Drawing on a comparison made by Jonas Salk, the head of the institute, Kiel Moe likens the “specifically generic” character of the service spaces of the building to mesenchyme cells (non-specific cells found within an embryo) capable of being transformed into specific cells for other bodily systems. “The building’s composition, systems, and details are most vitally understood as enablers of complex performances such as its capacity for mesenchyme-like adaptability, change, and growth rather than the stasis of its tectonic and visual appearances alone.”Footnote14 Although Moe’s interest focuses in large part on the intentions of the architect, Kahn, and Brand’s analysis of the ongoing adaption of buildings centres the agency of building users, both accounts allude to an approach to studying laboratory architecture that embeds these buildings in the ongoing practices and processes in which they become a part. Through this, the distinction between space and scientific practice (as an external force stabilising scientific practice, or as a container facilitating many functions) begins to be broken down. The unfolding and reformulation of laboratory spaces emerges through an ongoing engagement between the architecture of the laboratory, and the needs of human (scientists and technicians) and non-human (machines, pipework and equipment) participants.

Such attention to the multiple participants contributing to the “spacing” of laboratories relates to Yaneva’s work on the NGI, situated at the intersection of Science and Technology Studies (STS) and architectural theory. Yaneva urges scholars to pay greater attention to the interweaving of laboratory buildings and the practices they facilitate.Footnote15 Literature within STS analyses the sociomaterial practices of science, and while many of the classic laboratory ethnographies from the 1980s did not explicitly consider the architecture of laboratories (Latour and Woolgar’s famous study of the Salk Institute is notable for its lack of reflection on the institute’s architecture), literature in this field has paid close attention to the materiality of laboratories. Bruno Latour and Steve Woolgar, for instance, centre the “material setting” (the “configuration of machines specifically tailored for a particular task”) as constitutive of the phenomena under investigation in the laboratory, rather than simply a necessary background for the study of the phenomena.Footnote16 Drawing on Latour’s fieldwork in Roger Guillemin’s laboratory at the Salk, they argue that the “reality” being explored by the scientists would be profoundly altered should certain pieces of equipment be removed from the lab, something they say was clearly shown when equipment broke down or new equipment was brought in.Footnote17

In his book Science in Action (1987), Latour further outlines the practices of “technoscience,” a term he uses to break down distinctions between science and technological development. He suggests that the construction and circulation of a fact or technology requires the production and maintenance of heterogenous networks both within and beyond the laboratory: “Forgetting the extension of the instruments [beyond the laboratory] when admiring the smooth running of facts and machines would be like admiring the road system, with all those fast trucks and cars, and overlooking civil engineering, the garages, the mechanics and the spare parts. Facts and machines have no inertia of their own […].”Footnote18 Several scholars have gone further, describing the networks of science in explicitly infrastructural terms.Footnote19 In Paul Edwards’s account of the “Vast Machine” of the science behind global warming, he uses the phrase “knowledge infrastructures” to detail the enduring sociotechnical networks of “people, artifacts, and institutions that generate, share, and maintain specific knowledge about the human and natural worlds.”Footnote20

Though few studies have considered architecture in any depth through this infrastructural approach to studies of science or technoscience, as a theoretical lens it could be particularly useful for considering the active role of architecture and space in technoscientific practices. Firstly, such a lens draws attention to the flows of people, ideas, technologies and materials that course through and configure laboratory buildings. Secondly, as described by Susan Leigh Star and Karen Ruhleder, infrastructure is a relational rather than inherent property.Footnote21 A machine, or a laboratory, could then be considered infrastructural once it becomes embedded and essential to patterns of use. Through considering the infrastructures of laboratory buildings, the singularity of the building and any overarching architectural vision becomes dissolved in the multiplicity of the overlapping processes with which the building becomes entangled. Finally, a consideration of infrastructure, and the ongoing work of care and maintenance within laboratories places focus on moments of stabilisation, breakdown and extension working at many scales in the laboratory’s day-to-day operation.Footnote22 Building upon this infrastructural lens and drawing particularly on the work of the building management team at the GEIC, this article now details the configuration and reconfiguration of the building as new components and new capacities become “plugged in,” and explore how these configurations are opened to future extension, adaption or redundancy.

Placing the GEIC

To use Latour’s term, the GEIC is explicitly a place of technoscience. It is a physical and organisational structure meant to bridge the gap between scientific enquiry and technological production. Having received much attention and funding after the isolation of graphene, the University of Manchester was keen to respond to the opportunity and pressure to become the place where the material was commercialised. Graphene is more electrically conductive than copper, highly thermally conductive, and the strongest material known. These properties, observed at the nanoscale, would require significant research and development before they could be harnessed in technological applications, and the GEIC was conceived as the location in which this could happen. While academic work may create small samples of technologies to study, the GEIC looks to produce these at a scale closer to what would be produced in a factory.

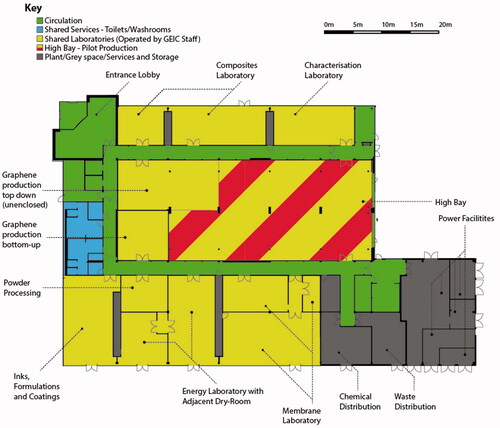

The GEIC is designed to accommodate collaborative projects between the University and external companies, with private laboratories on the first floor allowing some companies to permanently station employees in the building. Partnering companies collaborate with teams of specialist application engineers employed by the University, usually with experience in both academia and industry. These applications teams are located in laboratories on the ground floor, each with a different specialism associated with a potential area of graphene applications, including energy storage, inks, formulations and coatings, composite materials, membranes, and graphene production. These specialist laboratories are arranged in a horseshoe shape around a double height “high bay” (), a space intended for larger pieces of machinery and pilot production lines. Focusing primarily on these ground floor spaces, the following sections outline three scenes, experienced throughout my shadowing of Tom: plugging in a new piece of equipment, reflecting on the work undertaken so far and the possibility of a finished GEIC, and the processes of adaptation and reconfiguration that the building was already experiencing.

Coming Online

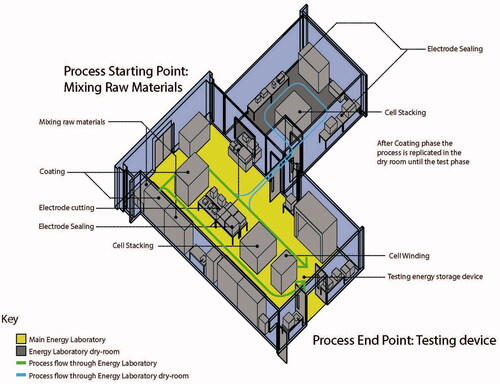

Walking briskly, Tom and I entered the GEIC’s energy laboratory. This shared laboratory on the ground floor of the building had remained stubbornly unfinished, even nine months after the building had opened. The applications team for the lab had spent the last few months working out of a temporary laboratory set up on the first floor, but had, in recent weeks, begun to move their work into their permanent home as equipment had started coming online. The spatial layout of the laboratory was intended to reflect a process flow which was well established in industry. Moving from one side of the laboratory to the other, the applications teams and the technologies they were developing would encounter the stages of mixing raw materials, coating electrodes, cutting, injecting and finally testing a completed device ().

While in an industry context these stages would be contained within a single production line, in the GEIC’s energy lab the black box of the production line was opened; its component parts mapped onto physical space for them to be reconfigured. As an engineer based in the lab had told me during an earlier visit, the users of the space were able to experiment with inserting new techniques into their production processes for their devices. The physical layout of the laboratory intended, therefore, to facilitate a “modularity” where “you don’t put material in one end and a battery comes out the other,” but instead the potential projects and outcomes of the work in the space could proliferate.Footnote23 Each step of the process would allow, through different machines, work at small batch scales and “pilot” scales, and some machines were duplicated in a moisture-controlled dry room to allow work with lithium. The laboratory became a space of intertwined flows, the physical movement through the lab of engineers, materials and prototyped technologies, the movement from raw materials to finished product, and, through this work, the flow (through translation) of scientific principles to production processes to be adopted in partnering companies’ production facilities.

Our reason for entering the laboratory lay at the far side of the room: a large roll-to-roll coating machine, currently disconnected from the building’s services (). The machine would allow production of 2D material-enabled electrode materials in a continuous fashion, rather than the small “batch” quantities experimented with in academic facilities. There had been some concerns over the safety of the machine, but Tom was keen to allow the users the freedom to use potentially dangerous materials without fear of contaminating the laboratory. It was decided that before the machine could become a functioning component of both the laboratory and the flows of technologies which would soon course through it, a casing should be commissioned and fitted, creating a barrier between any harmful chemicals inside and the users. Armed with the drawings for the machine, designed by a local firm, and along with an engineer who joined us in the lab, we were tasked with checking that the measurements on the drawings were correct, something made difficult since the drawings showed no indication of where the machine would sit inside the casing.

Tom and the application engineer began to collectively build a mental picture of the relationship between the planned structure of metal Rexroth structural framing and clear panels, and the machine in front of us. Realising that a sloped section on the casing drawings corresponded to the angled side of the machine, we began to use this as a useful point of reference. Tom quickly realised that the measurements in the drawing did not correspond to the machine we saw in front of us.

“That seems too close.”

“Good job we checked that!”

“Where the hell has he got that from?”

The printed drawings became adorned with scribbles denoting the correct measurements. Yet establishing the relationship between casing and machine was not the only consideration. Slowly, Tom and the engineer began to build up an understanding of the spatial practices which would emerge around the machine—acting out the future use of the space. Would it be possible to reach through the casing to insert and retrieve materials into the machine? Would the door need to be lowered? How would the machine be operated once enclosed by the casing? Would steps need to be provided to allow the engineer, who is struggling to reach through the imagined door of the casing, to access the machine?

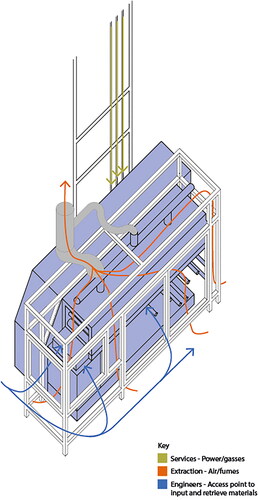

Flows of air and services must also be considered. Tom stopped to analyse the situation, pointing out that the “issue we’ve got is getting the pipework in.” Services flowing throughout the building must be connected with the machine without being impeded by the casing, but must simultaneously not compromise the casing’s integrity, which could cause the unwanted movement of contaminants from the machine into the laboratory. An important element of this would be the extraction system, currently hanging disconnected from the open ceiling above. Once connected to the casing, the systems would steadily draw air from the laboratory, underneath the casing and over the machine, picking up any potentially dangerous fumes before being drawn through pipes overhead and out of the building through filters.

Rather than a simple process of connection, plugging in this new component, vital for the laboratory’s ability to facilitate the translation of academic objects to industrial processes, required a complex choreographing of multiple flows—of people, air, technologies, materials, and services—each of which must be carefully managed so as not to compromise one another (). From a disconnected machine, sitting within a newly opened laboratory, a dynamic infrastructural component began to emerge, situated within a carefully orchestrated confluence of movements. Each new component situated on the journey taken through the laboratory, from raw materials to finished device, could similarly reshape the generic design of the laboratory. Following this slow process of bringing the laboratory online draws our attention to the multiple moments of design and choreographing on the micro-scale, mediating the relationships between the various bodies coalescing in the lab from engineers to machines and from gas lines to solvent fumes. This is an overlooked but essential process of producing the space of the laboratory, and indeed, transforming the laboratory into a functioning assemblage of infrastructural components.

All That Is Solid …

Outside the GEIC, with the roar of cars from the nearby “Mancunian Way” ring road, Tom lit a cigarette, the smoke disappearing into the grey sky. Tom had joked, when the prospect of shadowing him had first been raised, that I would need to bring my walking boots. “I do a lot of miles in a day!”Footnote24 The joke had been apt. In the months since the GEIC had opened, Tom had been busy setting up laboratories and equipment, training staff on machines, moving partners into the building as well as many other tasks. I asked Tom if he envisaged a shift. Would his role become one of maintenance, ensuring that the infrastructures of the GEIC resisted breakdown?Footnote25 Tom responded that, while there may be a shift in his role, change would be ever present in the GEIC.

This resonated with a comment in a previous interview, in which Tom had stated that the facility: “won’t be ‘done’ for another couple of years,” before quickly clarifying: “what I’m saying is I don’t foresee it reaching steady state for a couple of years.”Footnote26 The GEIC, sitting at the frontier of academia and industry, intending to bridge the two, was perhaps in an inherently unstable position. A “steady state,” not completion, was all that could be hoped for. The facility and its infrastructures would remain obdurate only so long as they remained relevant to the various companies associated with the facility, and to the broader shifts within the academic and industrial worlds.

In the context of what has been termed academic capitalism, in which market pressures and behaviours become embedded into the university, the centre is positioned at and simultaneously is tasked with reformulating the once sacred distinction between the pursuit of knowledge and the pursuit of profit.Footnote27 A connection to this incessant pace of renewal could be made to Karl Marx and Friedrich Engel’s famous observation that under capitalism, “All that is solid melts into air, all that is holy is profaned […].”Footnote28 Unpacking this quote, anthropologist Tim Choy elaborates that both social relations, but also the instruments of production, must constantly be renewed, replaced with “livelier” forms so as to prevent them becoming “fixed and ubiquitous.”Footnote29 Caught between a young and fast-evolving scientific field and a growing graphene industry, the latter in pursuit of new and novel applications and production processes, the GEIC was tasked with building connections between the two.Footnote30 However, neither “academia” nor “industry” could be considered singular points to be bridged, but are inherently multiple, containing an array of different academic disciplines on the one side and markets on the other.

Caught amongst these shifting landscapes, as the field of 2D materials research evolved, as new commercial applications were explored, and as new companies entered the facility, each with their own industry focuses, the GEIC could not stand still. But, in what follows, eschewing binaries between solidity and fluidity, I wish to avoid the conclusion that would place the GEIC as a space of pure change. I wish to not only conclude that the pressure to continuously develop new and novel modes of production for commercial graphene technologies precludes “solid” or “static” configurations, but also ask how new stable configurations of space in the GEIC are produced. What is left behind after this stability fails? What is the materiality of this fluidity?

Legacy

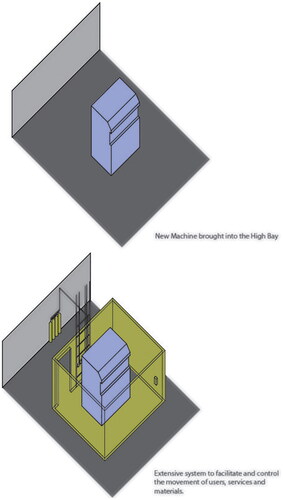

The high bay, a large ten-metre-high space punctuated by steel columns and with two cranes running overhead to lift equipment, sits at the centre of the GEIC’s ground floor (). During my study, this double-height space had been largely empty, initially being used for storage of new equipment and furniture before it slowly dissipated throughout the building. Some larger pieces of University equipment, such as an autoclave, had now been set up there. However, the high bay’s future use would be central to the GEIC’s program of scaling up 2D material technologies. Tom excitedly explained that it would be partitioned along its nine-meter grid and rented to partnering companies for them to set up production equipment. This equipment, which is often tall to limit floor space (and associated costs), would be able to rise into the generous interior.Footnote31

Pointing to the perimeter of the high bay, Tom started to detail its future arrangement:

This would essentially be a walkway—a corridor, if you like, that goes around the outside, and they can come out of their lab and they’ve got safety showers and everything outside […] this is, if you like, a service gantry down both sides, […] if you imagine this is your lab here, you can have a door here, and you can come out, use a hand sink, safety shower […]Footnote32

Services would have to be dropped from above to connect with the machine. Looking up into the high bay, a mass of pipework could be seen: the building’s “guts,” as Tom referred to it.Footnote33 The high bay acts as a central riser for the building, with services dropping down from the plant space above before being distributed around the building. The building, Tom said, was designed in a “fairly modular fashion,” by which he meant that it would be possible to add new connections, bringing power, process cooling water or a specific type of gas to a machine in the high bay or to one of the labs elsewhere in the building.

The SLM required a constant supply of argon gas to flood the chamber of the machine to prevent oxidation of the materials inside. Several bottles of this gas were lined up behind the machine, using a mechanism which would automatically switch bottles once one was empty, preventing any gap in the supply. Tom explained that they were considering erecting walls around the machine, which would prevent the metal powder that the machine used from dissipating across the open space. There would be no ceiling in this new room, so as not to limit the entry of services and allow cranes to be used to move items in and out of the space. The argon bottles, situated outside of this future wall, would be connected by pipes which looped over and entered from above (). However, this configuration could cause a problem. If a leak sprung in the machine, argon, which is heavier than air, could slowly and silently fill the room, potentially suffocating its users. To prevent this, sensors would be placed at a low level around the machine, providing users with an early warning of any leak.

Again, the act of plugging the machine into the GEIC was not a purely technical connection, but rather a process in which it, and the management team, configured necessary spatial arrangements—a process through which a new space emerged. It was therefore a surprise to me that this machine would be within the facility for only a matter of months. Was the time, materials and labour required to connect the machine worth it?

Perhaps sensing my confusion, Tom explained that the value of this machine and its supporting services to the facility would likely outlast the specific functions it was installed to accommodate. Tom spoke of the “legacy” of pipe-work and other services that would be left behind after the SLM was removed and which may then be connected to new machines and facilitate new functions. This could be witnessed months later when I revisited the GEIC, seeing a new machine soon to be connected to the services previously connected to the SLM (). Whilst it may not be possible to foresee the exact usage of these services or the precise flows that would course through the high bay in five, ten or fifteen years, as spaces and services were slowly configured, legacy services may simplify the installation of new machines in the future.

Throughout the facility, this accumulation of “legacies” was expected and relied upon. Rentable laboratories on the first floor had been designed with minimal services, as little was known at the time of the design about the eventual shape of a graphene industry. As a member of the estates team explained, “industry couldn’t tell us at that stage what they wanted.”Footnote34 And with the University without the funds to design for every eventual outcome, the decision was made to bring primary services into each lab at a high level but cap them. They would then await future connection with whatever equipment partnering companies brought into the space. “We didn’t need to bring them down to the equipment because we didn’t know what equipment was going to come in, we didn’t know if it was ever going to come in.”Footnote35 Companies renting space may pay to be provided with additional services, such as particular gases which could be brought in from the high bay. These companies, who would usually sign two-year contracts with the University (although with the option to extend), would eventually leave the facility, leaving behind these new material connections. The result would be an accumulation of legacies—a palimpsest of pipework which may then become connected to uses and configurations not originally intended. These legacies, however, may also limit new arrangements. While in one of the laboratories, Tom commented that “where we bring the services down to a bench, like this one, that’s fixed.”Footnote36 The decisions as to where to place services such as gas lines, exhaust lines, and water cooling could then become, as one application engineer described, “the limiting factors” for future placement of machinery in laboratories, being too difficult and costly to move.Footnote37

The GEIC is thus not a space of limitless flexibility: throughout its life it would engage in a negotiation between fluidity and stasis. New capacities would be built into the facility, extending or embedding new sociotechnical networks and producing new configurations of space. But as what once were stable infrastructures are unplugged from the facility, traces may be left behind which can be drawn upon or limit future use.

Plugging In/Plugging Out

Much architectural literature has explored the role of users in the design and operation of buildings, looking to complicate the often-assumed autonomy of designers.Footnote38 However, by centring not only the “user,” but use as a process, this article has looked to demonstrate the ongoing production and reproduction of architectural space through a series of short scenes. The dynamics of negotiation, uncertainty and heterogeneity, so central to ethnographies of architectural design, are seen here as continuing throughout the life of the building as the facility looks to establish, maintain and adapt the infrastructure necessary to remain relevant to the fast-moving worlds of academia and the emerging 2D materials industry.

To study what he calls “science-in-the-making,” Latour argues that researchers must follow not the fact or technology after it has become “black-boxed” but the practices through which the fact or technology is constructed, or otherwise, the controversies which reopen previously sealed black-boxes.Footnote39 My research, occurring after the design and construction teams had left, months after the building had officially opened, but before the GEIC had reached a “steady state,” could be seen as following infrastructure-in-the-making. The GEIC as a building and as an organisation was described by the architects, client and local news media as a structure necessary to accelerate the scale-up of 2D material technologies. If described by a researcher in some years’ time, when in a “steady state,” the design of the GEIC may appear to be inherently capable of achieving this goal. Yet in the months after the building opened I could witness the slow, cumulative process of modularly plugging in necessary components, building the networks needed to connect knowledge in the academic laboratory with the industrial factory.

Infrastructure, understood as the networks of components necessary for technoscientific practices to occur and for knowledge and technologies to circulate, could be seen as multiple and evolving in the GEIC. Through the modular plugging in of components and users, the centre was able to maintain relevance to a diverse array of industry partners and a rapidly shifting scientific field. While modularity in architecture is often related to standardised modules or proportions, the “plugging in” of a new capacity at the GEIC, as seen in the plugging in of the SLM, could configure quite specific material arrangements of pipes, cables, sensors and walls.Footnote40

Neither conforming to the famous maxim form follows function, nor following Venturi’s modification of the phrase, form accommodates functions, the GEIC instead could be seen to simultaneously facilitate but also be reshaped by the various processes with which it became entangled.Footnote41 New functions had to be built through pipework, cables and plasterboard. This article has been situated alongside the work of Moe and Brand in their attention to the ways that research buildings are reshaped throughout their lives. Yet it also expands on their work. The GEIC certainly contains many of the qualities identified by Moe in his analysis of the performance of the Salk Institute, but the notion of its spaces as akin to mesenchyme cells, capable of transforming into an array of uses, perhaps raises the question of what becomes of these “nonspecific” spaces once they have become specialised. What is left behind once a particular use becomes obsolete? The work of Brand, on the other hand, proposes that buildings learn through the multiple modifications of its users. But how do we think about the knowledge they accrue?

In this article I have detailed the notion of legacy: the traces left behind, enabling and limiting new uses. This legacy becomes embedded in the building as knowledge. For the GEIC’s management team, knowledge, if defined as familiarity or accumulation of information through experience, becomes amassed over time (there was perhaps no one with a more intimate knowledge of the workings of every part of the facility than Tom). Based on this experience, the team collectively gained an increased ability to adapt to new circumstances and changes in the landscapes of graphene research and development. However, the building, too, through a palimpsest of multiple infrastructures tailored for an array of different tasks—the traces of past configurations—also gains this accumulation of experience which becomes embedded into the building, increasing its capacity to react to new functions. The legacies of services and previous material arrangements left behind after they become obsolete, coupled with the ongoing work and know-how of the management team, provide opportunity for future capacities of the building.

Acknowledgements

I would like to thank the GEIC for allowing me to conduct my research in the facility and their generosity throughout the research. I would also like to thank Albena Yaneva for her comments on the article, and Leandro Minuchin and Albena Yaneva for their supervision during the research. Ethical Approval for this project is through the Environment, Education and Development School Panel PGR at the University of Manchester, reference: 2019-7372-10776.

Disclosure Statement

No potential conflict of interest was reported by the author(s).

Additional information

Funding

Notes on contributors

Benjamin Blackwell

Benjamin Blackwell is a lecturer in architecture at the University of Manchester. His research is situated between architectural theory and science and technology studies (STS). He completed his PhD in 2022, exploring the architectures of laboratory buildings. More recently, his research has explored other buildings of knowledge creation and dissemination, including the design of “smart” secondary school buildings.

Notes

1 All individuals described in the study will be pseudonymised. Individuals described in participant observation will be given names, while interviewees will be identified through their job role.

2 K.S. (Kostya) Novoselov, A.K. (Andre) Geim, S.V. Morozov, D. Jiang, Y. Zhang, S.V. Dubonos, I.V. Grigorieva and A.A. Firsov, “Electric Field Effect in Atomically Thin Carbon Films,” Science 306, no. 5696 (2004): 666–69; Andre K. Geim and Konstantin. S. Novoselov, “The Rise of Graphene,” Nature Materials 6 (2007): 183–91; K.S. Novoselov, “Nobel Lecture: Graphene: Materials in the Flatland,” Reviews of Modern Physics 83, no. 3 (August 3, 2011): 837–49; Andre K. Geim, “Nobel Lecture: Random Walk to Graphene,” Reviews of Modern Physics 83, no. 3 (2011): 851–62. Though not the “discovery” of graphene (studies on what is now known as graphene arguably go back to the nineteenth century), the material, named in the 1980s, had been thought too unstable to exist in isolation. The work of Professors Andre Geim and Kostya Novoselov, which famously used scotch-tape to separate layers of carbon from graphene, was the first to isolate the material. Their work rediscovered graphene as a wonder material and ignited a frenzy of scientific activity as an array of different disciplines began to work with the material. The pair were awarded the Nobel Prize in Physics in 2010.

3 RIBA, “Plan of Work 2020 Overview” (London: RIBA, 2020), 68. The “handover” stage of a project is described in the 2020 Royal Institute of British Architects (RIBA) plan of work as stage 6, proceeded by stage 7 “use.”

4 Thomas Yarrow, Architects: Portraits of a Practice (Ithaca, NY: Cornell University Press, 2019); Brett Mommersteeg, “Approximations: On Some Ways to Listen to a Building ‘in the Making’,” Science, Technology, & Human Values 49, no. 2 (2022): 238–62; Sophie Houdart, “How (Far) Does Culture Go? Kengo Kuma and His Architecture,” Perspecta 44 (2011): 22–32, 195–96; Dana Cuff, Architecture: The Story of Practice (Cambridge, MA: MIT Press, 1991); Albena Yaneva, Made by the Office for Metropolitan Architecture: An Ethnography of Design (Rotterdam: 010 Publishers, 2009).

5 Albena Yaneva, “The Architecture of the Hybrid Lab: Spacing Graphene Research,” Social Studies of Science 52, no. 5 (2022): 733–57; Konstantin. S. Novoselov and Albena Yaneva, The New Architecture of Science: Learning from Graphene (Singapore: World Scientific, 2020).

6 T.F. Gieryn, “Two Faces on Science: Building Identities for Molecular Biology and Biotechnology,” in The Architecture of Science, ed. Peter Galison and E. Thompson (Cambridge, MA: MIT Press, 1999), 423–55.

7 D.N. Livingstone, Putting Science in Its Place (Chicago: University of Chicago Press, 2003).

8 K. Brandt and B. Lonsway, “Beanbags and Microscopes at Xerox PARC,” in Laboratory Lifestyles: The Construction of Scientific Fictions, ed. Sandra Kaji-O’Grady, Chris L. Smith, and Russell Hughes (Cambridge, MA: MIT Press, 2018), 29–48; William J. Rankin, “Laboratory Modules and the Subjectivity of the Knowledge Worker,” in Use Matters: An Alternative History of Architecture, ed. Kenny Cupers (London: Routledge, 2013), 51–68; Sandra Kaji-O’Grady and Chris L. Smith, LabOratory: Speaking of Science and Its Architecture (Cambridge, MA: MIT Press, 2019); Sandra Kaji-O’Grady, “Donor-Driven Designs on the University,” Architecture and Culture 9, no. 1 (2020): 45–68.

9 Stuart W. Leslie, “‘A Different Kind of Beauty’: Scientific and Architectural Style in I. M. Pei’s Mesa Laboratory and Louis Kahn’s Salk Institute,” Historical Studies in the Natural Sciences 38, no. 2 (2008): 173. Leslie also argues that, despite the philosophies built into laboratory designs, even in the well-known cases of Kahn’s Salk institute and I. M. Pei’s Mesa Laboratory, the buildings and institutions were forced to “adapt to new disciplinary configurations, funding opportunities, and research priorities, or risk becoming mere architectural icons” (173).

10 Robert Gutman, “Human Nature in Architectural Theory: The Example of Louis Kahn,” in Architects’ People, ed. Russell Ellis and Dana Cuff (Oxford: Oxford University Press, 1989), 113.

11 Robert Venturi, “Thoughts on the Architecture of the Scientific Workplace,” in The Architecture of Science, ed. Peter Galison and Emily Thompson (Cambridge, MA: MIT Press, 1999), 390 (emphasis in original).

12 Stewart Brand, How Buildings Learn: What Happens After They’re Built (London: Penguin Books, 1995), 52–53.

13 Brand, How Buildings Learn, 53.

14 Kiel Moe, “Extraordinary Performances at the Salk Institute for Biological Studies,” Journal of Architectural Education 61, no. 4 (2008), 23.

15 Yaneva, “The Architecture of the Hybrid Lab,” 753.

16 Bruno Latour and Steve Woolgar, Laboratory Life: The Construction of Scientific Facts, 2nd ed. (Princeton, NJ: Princeton University Press, 1986), 64–65.

17 Latour and Woolgar, Laboratory Life, 64.

18 Bruno Latour, Science in Action (Cambridge, MA: Harvard University Press, 1987), 250.

19 Stephen C. Slota and Geoffrey C. Bowker, “How Infrastructures Matter,” in The Handbook of Science and Technology Studies, ed. Ulrike Felt, Rayvon Fouché, Clark A. Miller, and Laurel Smith-Doerr, 4th ed. (Cambridge, MA: MIT Press, 2017), 529–54; Geoffrey C. Bowker, “Sustainable Knowledge Infrastructures,” in The Promise of Infrastructure, ed. Nikhil Anand, Akhil Gupta, and Hannah Appel (Durham, NC: Duke University Press, 2018), 203–22; Paul N. Edwards, A Vast Machine: Computer Models, Climate Data, and the Politics of Global Warming (Cambridge, MA: MIT Press, 2010).

20 Edwards, A Vast Machine, 17.

21 Susan Leigh Star and Karen Ruhleder, “Steps Toward an Ecology of Infrastructure: Design and Access for Large Information Spaces,” Information Systems Research 7, no. 1 (1996): 111–34.

22 Stephen Graham and Nigel Thrift, “Out of Order: Understanding Repair and Maintenance,” Theory, Culture & Society 24, no. 3 (2007): 1–25; Ignaz Strebel, Alain Bovet, and Philippe Sormani, eds., Repair Work Ethnographies: Revisiting Breakdown, Relocating Materiality (Singapore: Palgrave Macmillan, 2019); Ignaz Strebel, “The Living Building: Towards a Geography of Maintenance Work,” Social & Cultural Geography 12, no. 3 (2011): 243–62.

23 Walking interview with Application Engineer 8, July 11, 2019.

24 Interview with Tom, May 31, 2019.

25 Alain Bovet and Ignaz Strebel, “Job Done: What Repair Does to Caretakers, Tenants and Their Flats,” 89–125; and Jérôme Denis and David Pontille, “The Dance of Maintenance and the Dynamics of Urban Assemblages: The Daily (Re)Assemblage of Paris Subway Signs,” 161–85; both in Repair Work Ethnographies, ed. Strebel, Bovet, and Sormani; Ignaz Strebel, “The Living Building,” 244. Much work has detailed the ongoing practices of maintenance, the regimes of visibility which allow for broken components to be identified, and the potential fragility of infrastructures.

26 Interview with Tom and Lloyd, April 3, 2019.

27 Sheila Slaughter and Larry L. Leslie, Academic Capitalism: Politics, Policies, and the Entrepreneurial University (Baltimore, MD: John Hopkins University Press, 1997); Sheila Slaughter and Gary Rhoades, Academic Capitalism and the New Economy: Markets, State, and Higher Education (Baltimore, MD: John Hopkins University Press, 2004); Edward J. Hackett, “Science as a Vocation in the 1990s: The Changing Organizational Culture of Academic Science,” Journal of Higher Education 61, no. 3 (1990): 241–79.

28 Karl Marx and Friedrich Engels, The Communist Manifesto, trans. Samuel Moore (Milton Keynes: Penguin Books, 2015 [1848]), 6.

29 Tim Choy, Ecologies of Comparison: An Ethnography of Endangerment in Hong Kong (Durham, NC: Duke University Press, 2011), 143–44. Choy’s analysis is useful here in theorising “air,” both literal and metaphorical, beyond “solidity’s opposite.”

30 Academics were now able to produce 2D materials in quantities that were previously unheard of or conduct experiments that they “couldn’t even dream of doing […] five or ten years ago.” Interview with communications officer, August 8, 2018.

31 Walking interview with Tom, July 15, 2019.

32 Walking interview with Tom, July 15, 2019.

33 Walking interview with Tom, July 15, 2019.

34 Interview with University of Manchester estates team member, June 3, 2019.

35 Interview with University of Manchester estates team member, June 3, 2019.

36 Walking interview with Tom, July 15, 2019.

37 Walking interview with GEIC application engineer 4, August 16, 2019.

38 Kenny Cupers, ed., Use Matters: An Alternative History of Architecture (New York: Routledge, 2013); Jonathan Hill, Actions of Architecture (New York: Routledge, 2003). This includes, for instance, Jonathan Hill’s categorisation of three types of user: “passive,” “reactive” and “creative.”

39 Latour, Science in Action, 258.

40 Le Corbusier, The Modulor: A Harmonious Measure to the Human Scale, Universally Applicable to Architecture and Mechanics, vol. 1 (Basel: Birkhäuser, 2000 [1958]); Rankin, “Laboratory Modules and the Subjectivity of the Knowledge Worker,” 62–66. The notion of repeatable laboratory modules, described by Rankin and utilised in the GEIC, does intersect with the account of modularity described here as such designs are deployed for their flexibility and adaptability. The specific processes through which modification takes place, detailed here, has been less thoroughly explored.

41 Venturi, “Thoughts on the Architecture of the Scientific Workplace,” 390.