ABSTRACT

Before and aftermath of COVID-19 has created multiple waves of digital transformation adoption in supply chain management. The power of potential benefits is realised as a multitude however the transformation phases are not sustainable. This editorial special issue has edited papers of scholarly research contributions to the theory and practice of digital transformation aspects in the field of logistics and supply chain management. Based on the summary of each contribution and an extended literature review on the theme, this editorial paper proposes a novel framework that could facilitate the logistics industry at times of disruptive technologies when firms are struggling to cope with the challenges created due to the COVID-19 pandemic and the recovery.

1. Introduction

The increase in adoption of new digital technologies and the related intelligent transportation systems drive the logistics industry very much faster and better towards streamlined business processes and enhanced logistics security. At the same time, existing barriers to such digital transformation have become prevalent systemic blocks that need to be handled appropriately. In the growing domain of Logistics 4.0, like never before, an enormous amount of data is generated in smart transportation and logistics, which brings new opportunities and challenges (Sundarakani, Aneesh, and Gunasekaran Citation2021). While examining the upstream supply chain situations, Smart procurement (a.k.a procurement 4.0) needs the support of intelligent transportation in upstream logistics (Culot et al. Citation2020). Likewise, the middle stream activities such as digitalised manufacturing (be it 3D printing or additive manufacturing) would require unprecedented support of intelligent driven transportation systems as well. By taking full advantage of big data and digital twins, researchers can make informed decisions and thereby control costs (Čámská and Klečka Citation2020; Tao and Qi Citation2019), improving energy efficiency (Munsamy, Telukdarie, and Dhamija Citation2020), reducing the carbon emissions and achieving other operational goals (Ghadge et al. Citation2020) that are associated with 360-degree eco-system of logistics 4.0. Thus, the call would like to seek, should there be a need to challenge some of the existing technological adoption models and thus have a paradigm shift in the digital logistics business and or add the existing technological adoption domain body of knowledge, both are welcomed.

Existing research has revealed that there are many advantages brought by the new technologies and big data in intelligent transportation and logistics in manufacturing, however, there are also challenges that affect its performance (Barreto, Amaral, and Pereira Citation2017; da Silva, Kovaleski, and Pagani Citation2019; Winkelhaus and Grosse Citation2020). These include the fusion of multi-source data and transparent management in manufacturing with big data, the integration of intelligent logistics and transportation with smart manufacturing at different levels of design, planning and operational decisions, business intelligence and integration among the supply chain partners with cloud-based transportation and logistics. If these challenges and threats are appropriately assessed against the nature of sources, the entire logistics 4.0 ecosystem would emanate the next wave of competitive advantage for supply chain and logistics industries (Karia and Kays Citation2020). Having discussed there is limited research conducted in this space in terms of grounding theory on big data analytics (BDA), Prescriptive Analytics in logistics, Mixed Reality use in logistics, Machine learning application in theory and much more (Kostrzewski, Varjan, and Gnap Citation2020; Munsamy, Telukdarie, and Dhamija Citation2020). Therefore, this call paves the way for such novel research models that can be grounded on theory and be built on existing and new ideas around Logistics 4.0.

The purpose of this special issue is to publish the original academic applied logistics research that is related to intelligent transportation and logistics 4.0 revolving around the theme from procurement to manufacturing to distribution with a focus on big data, artificial intelligence, machine learning, 5G in transportation and logistics, data-driven modelling and solution methods, and innovative applications in downstream omni-channeling systems. The rise in technological developments in the last two decades has resulted in increased technology adoption in the business world. Today, business supply chains are increasingly undergoing digitisation to reduce their vulnerability to risks and improve business competitive advantage and performance. Marmolejo and Hartmann (Citation2018) define supply chain digitalisation as transitioning from analog supply chains to digital ones through the establishment of dedicated master data that aggregates data from the entire supply chain and information from other sources. Rogetzer, Nowak, and Jammernegg (Citation2019) hold that supply chain digitalisation involves changing how companies strategise and conduct their supply chain management practices by incorporating digital and technological advancements that promote interconnectedness and transparent flow of information among suppliers and organisations’ potential customers. Digitisation is critical in improving supply chain management as it enhances communication and automation of tasks, reducing errors.

2. Literature review

Digital transformation can be defined as the process of organisational shift towards digital technologies such as IOT, Cloud, Big data offerings, mobile and social media meta verse to provide products and services (AlNuaimi et al. Citation2022; Bresciani et al. Citation2021; Elgazzar et al. Citation2022; Nasiri et al. Citation2020). The digital transformation should be built on well-orchestrated strategies and execution for success. Many organisations fail miserably in this journey of transformation due to improper and misaligned execution (Facchini et al. Citation2020).

For supply chain digitalisation to meet its goals effectively, it must have a touch of sustainability. Apart from process automation, companies need to incorporate sustainability in their supply chains through environmentally friendly and financially viable practices from product design and development to manufacturing, packaging, and transportation (Sony Citation2019; Sundarakani et al. Citation2020). Sustainable digital supply chain management practices have a range of environmental, social, and economic benefits that cannot be underestimated.

Different environmental benefits are associated with digital supply chains aligned with sustainability. According to Junge and Straube (Citation2020), sustainable digital supply chains have various benefits that help reduce manufacturers’ environmental footprints. First, it drives efficient demand and supply planning, reducing overproduction and waste of resources. Lee (Citation2021) states that digital technologies such as artificial intelligence and machine learning can predict the likely demand for products, ensuring that only enough raw materials are used in the production process and reducing wastage. Secondly, sustainable digital supply chains promote transparency, providing that supplies engage in sustainable sourcing, thereby reducing the adverse environmental impacts of unsustainable sourcing (Zimon, Tyan, and Sroufe Citation2019). Thirdly, sustainable digital supply chains minimise energy consumption by optimising local, national, and international shipping routes through advanced analytics. Moreover, sustainability and digitisation of supply chains also help plan around the existing environmental risks and impacts (Mukhtar, Romli, and Abdullateef Citation2019). Currently, many supply chains have been affected by environmental risks such as climate change. Digitisation and sustainable practices are essential in the early prediction and mitigation of such risks using contingency plans.

Although digital supply chains provide several advantages to organisations, they are also associated with disadvantages. One of the problems related to digital supply chains is security threats. The efficacy of digital supply chains depends on the transmission of data over networks. This sharing of data over networks opens businesses in the supply chain to security breaches as they are prone to cyber-attacks (Dontigney Citation2021). These security threats and their increased sophistication weaken digital supply chain management.

Another problem of digital supply chains is the replacement of human labour with machines, resulting in unemployment. With the current technological advancements in the business sector following the fourth industrial revolution, supply chain managers are increasingly adopting technologies that require little labour to operate, reducing employment opportunities for many individuals (Miethlich et al. Citation2020).

As digitalisation and the use of technology become a business norm, firms are considering digital technologies in fostering sustainable supply chain management. Nonetheless, only a few firms have successfully deployed digitalisation in supply chain management to promote sustainability. Much of the supply chain management literature has not paid attention to the intersection of sustainability and emerging digital technologies in the supply chains (Büyüközkan and Göçer Citation2018). While sustainability and digitalisation have received considerable attention in the business and academic realms, less attention has been on how they are interconnected with supply chain management. Therefore, further research is necessary to understand the role of digital transformation in achieving sustainable supply chain management.

3. Special issue theme

This special issue invited research on the following themes, but not limited to:

Pandemic-related challenges impacting the transport and logistics industry towards digitalisation

Last-mile delivery optimisation in multiple- and omni-channel businesses

Ubiquitous Sensing in autonomous transportation

Cloud Computing in transportation and logistics

Augmented Reality in warehousing and logistics

Descriptive, Predictive and Prescriptive Analytics in logistics

Edge Devices and their connections to non-proprietary networks

Artificial Intelligence and Machine Learning application in logistics

Block Chain technology implementation in BOL contracts

5G Technologies usage in mobility

Smart warehouse management and intelligence

Additive Manufacturing applications in logistics

Drone operations and drone system

Robotics and Dark Warehouses

Wearable Computing roles, impact and application in transportation

Big Data-driven logistics optimisation

Smart logistics and supply chains management in Industry 4.0

Procurement 4.0 and its impact on logistics 4.0

Internet of things and smart transportation

Cargo Monitoring and Digital Containerisation

Building a Digital Twin for supply chain

The call for paper was announced in Summer 2021 and the extensive review process was executed among the submitted manuscripts since then. In this editorial, we capture the review process adopted and summarise the final set of contributed papers that were accepted for publication as part of this special issue along with our proposed framework from thereof.

4. Contributed outcome

The following are the contributed articles that were successful based on the double blind peer review process and have been accepted for this special issue. The papers presented in this special issue on supply chain digital transformation cover a wide array of topics, providing valuable insights and analyses. The first paper by Zekhnini et al. (Citation2021) presented a holonic architecture for the supply chain performance in Industry 4.0. While Sindhwani et al. (Citation2022) addressed the state of the art of digital supply chain management to identify inhibitors for Logistics 4.0 adoption in micro, small, and medium enterprises, this paper offers a comprehensive understanding of the challenges and opportunities in the evolving landscape of supply chain technologies. Additionally, the exploration of new risks in Logistics 4.0, the impact of Industry 4.0 on last-mile urban logistics (Dixit and Verma Citation2022), and the potential of blockchain technology in combating drug counterfeiting showcase the intricate dynamics and pressing concerns within modern supply chains by Trautmann, Hübner, and Lasch (Citation2022). Furthermore, Çıkmak, Kantoğlu, and Kırbaç (Citation2023) delved into the transformative impact of Industry 4.0 on supply chain collaboration and design, as well as the evaluation of blockchain technology characteristics on SCOR model supply chain performance measurement attributes. Veile et al. (Citation2022) designed a supply chain collaboration framework in an Industry 4.0 environment, while Correia et al. (Citation2023) brought last-mile urban logistics to inventory fulfilment in a smart city environment. Overall, these seven papers not only contribute to the current body of knowledge but also offer significant implications for managerial practice and future research directions in supply chain digital transformation.

The findings and recommendations presented in these papers underscore the need for a strategic and holistic approach to leveraging digital technologies for supply chain optimisation. The identification of critical inhibitors for Logistics 4.0 adoption in MSMEs, the assessment of new risks in Logistics 4.0, and the proposed algorithm for addressing last-mile urban logistics challenges reflect the practical relevance of these research endeavours. Moreover, the emphasis on the potential of blockchain, IoT, and AI in enhancing supply chain visibility and combating drug counterfeiting demonstrates the growing importance of digital technologies in ensuring transparency and efficiency across pharmaceutical supply chains. Additionally, the insights into the implications of Industry 4.0 on supply chain collaboration, design, and performance measurement attributes highlight the evolving nature of inter-organisational relationships and the value of decentralised technologies. As such, these papers collectively shed light on the multifaceted nature of supply chain digital transformation and present avenues for organisations to enhance their competitive advantage and operational resilience in the digital age.

5. Proposed framework

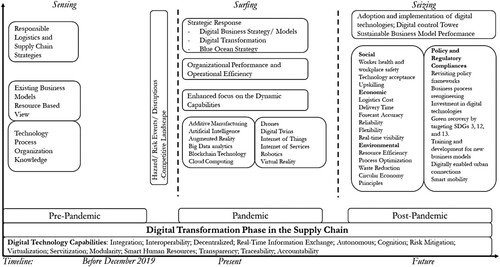

Based on the extant literature review, it can be said that pre-pandemic most of the organisations relied on tried and tested business models while focusing on their firm-level resources (Kor and Mahoney Citation2005) as depicted in . The organisations extensively deployed responsible logistics and supply chain strategies as the primary objective was to minimise costs, improve flexibility, and reduce carbon footprint (Tang et al. Citation2015). The business processes were defined by limited information technology resources, their adoption and implementation in the organisation, and the learnings associated with that technology. Digitalisation was a far cry for most organisations as there were only a few entrants in the digital transformation phase who were sensing the right opportunity (Ageron, Bentahar, and Gunasekaran Citation2020; Wamba and Queiroz Citation2022). The World Health Organization declared COVID a public health emergency of international concern (PHEIC) the highest level of alarm in global health regulations on 30 January 2020, as it jolted the various economies across the world and completely disrupted the supply chain and logistics globally creating a ripple effect with its repercussions still going on.

During the pandemic, most of the LSCMOs did not know how to react to the external environment initially as most of their ‘tried and tested' business models had failed miserably (with global lockdowns in place and restriction of movement of goods and people) (Guan et al. Citation2020; Nandi et al. Citation2021). Based on the dynamic capabilities view, this was right after the sensing phase, and we define it as the surfing phase. Majority of the organisations are embracing the digital transformation phase with technologies such as blockchain, artificial intelligence, and additive manufacturing taking the forefront during the pandemic (Koshta, Devi, and Patra Citation2021; Sharma et al. Citation2020). Not only did the COVID-19 pandemic disrupt the global supply chains, but it also provided an opportunity for organisations globally to digitally transform in the competitive landscape. Therefore, organisations need to rethink their digital transformation strategy and exploit innovative digital business models (Seetharaman Citation2020). Organisations can also adopt the blue ocean strategy for triggering economic recovery in this phase of the pandemic (Caballero-Morales Citation2021).

Another major concern for the organisations to consider is recovery post-pandemic. This is the prime area wherein an organisation can unleash their digital potential (focusing on dynamic capabilities) for sustainable recovery while seizing the competitive digital landscape. Digital technology capabilities such as Integration; Interoperability; Decentralised; Real-Time Information Exchange; Autonomous; Cognition; Risk Mitigation; Virtualisation; Servitisation; Modularity; Smart Human Resources; Transparency; Traceability; and Accountability come into the picture and pave the way for effective digital business strategies (Longo, Nicoletti, and Padovano Citation2017; Sharma and Shishodia Citation2022; Zekhnini et al. Citation2021). Enhanced focus is to be given to investments in digital technologies for ushering in a green recovery and sustainable practices (Sharma et al. Citation2021). As highlighted by Sindhwani et al. (Citation2022), micro, small, and medium enterprises (MSMEs) can adopt logistics 4.0 for a successful digital transformation provided adequate investment in digital transformation and IT infrastructure is made. Of late, the resiliency of the supply chains is an important concern for a majority of the organisations as highlighted by the disruptions brought about by the recent pandemic. Organisations can therefore leverage real-time information capture through big data analytics for improving agility and supply chain preparedness (Manikas, Sundarakani, and Shehabeldin Citation2022). Moreover, organisations can focus on establishing digital control towers to ensure end-to-end visibility and transparency in the supply chains.

As there is a lot of data generated in the logistics operations, managing the organisational performance and sustainable performance (along the triple bottom line dimensions) of digital supply chains or data-driven supply chains will be of interest to the practitioners and the academia. organisations should target a green recovery by critically improving sustainable development goal (SDG) numbers 3 (good health and well-being), number 12 (responsible production and consumption), and number 13 (climate action) (Genc Citation2021). On the social performance front, the practitioners must focus on technology acceptance, worker health and workplace safety, and worker upskilling (training and development for new business models) (Sharma et al. Citation2020). On the economic performance front, the organisations must focus on reducing logistics costs, improving delivery time by ensuring better connectivity for last-mile delivery, improving reliability and visibility, and enhancing real-time end-to-end supply chain visibility (Ignat and Chankov Citation2020). On the environmental performance front, organisations must focus on transitioning towards circular economy principles and therefore embrace ReSOLVE (regenerate, share, optimise, loop, virtualise, and exchange) business model. This will reduce waste, optimise processes, and improve resource efficiency (Mastos et al. Citation2021).

Further, in the proposed framework, for the organisations to completely overhaul their existing business strategies and embrace digital business models, a lot has to be done. As regulatory compliance and tasks, the existing policy frameworks have to be revisited to incorporate the radical shifts during this transformation. Business process reengineering for most organisations has to be done for successfully riding this digital transformation wave.

6. Emerging research questions

Possible research questions (RQs)/ themes which future studies can take up based on this editorial review and the proposed framework are:

RQ1. Identification of barriers and critical success factors for digital transformation in LSCMOs.

RQ2. Interaction of barriers and critical success factors based upon digital maturity in different settings such as MSMEs and developed and developing economies.

RQ3. Sustainable performance measurement of supply chains in digital distribution and logistics management.

RQ4. Digital skills and strategies for green recovery post-pandemic in LSCMOs.

RQ5. Innovative business and servitisation models in LSCMOs post-pandemic.

RQ6. Effects of digital transformation on consumers of LSCMOs.

7. Conclusion

This paper forms part of a special issue titled ‘Digital transformation in Logistics: Logistics 4.0', guest edited by Balan Sundarakani, Ioannis Manikas and Angappa Gunasekaran. Review findings, new framework for digital transformation in logistics and supply chain and emerging research questions are major contributions of this editorial article that could set the stage for further research. The guest editors would like to thank all the reviewers who spent their invaluable time reviewing the articles on time, which enabled us to complete this special issue successfully. Additionally, the special issue editors would like to thank the support provided by Dr.Rohit Sharma. More importantly, the guest editors would like to thank the editor-in-chief of the International Journal of Logistics Research and Applications, Prof. Ming Lim and the journal's editorial office for providing feedback on the initial call for papers, offering support on the literature review process and towards all publication process.

Acknowledgements

The editors would like to thank all reviewers who have supported the peer review process with the fullest ethical involvement and Dr. Rohit Sharma for his in-kind support in the process.

Disclosure statement

No potential conflict of interest was reported by the author(s).

References

- Ageron, B., O. Bentahar, and A. Gunasekaran. 2020. “Digital Supply Chain: Challenges and Future Directions.” Supply Chain Forum: An International Journal 21 (3): 133–138. https://doi.org/10.1080/16258312.2020.1816361.

- AlNuaimi, B. K., S. K. Singh, S. Ren, P. Budhwar, and D. Vorobyev. 2022. “Mastering Digital Transformation: The Nexus between Leadership, Agility, and Digital Strategy.” Journal of Business Research 145:636–648. https://doi.org/10.1016/j.jbusres.2022.03.038.

- Barreto, L., A. Amaral, and T. Pereira. 2017. “Industry 4.0 Implications in Logistics: An Overview.” Procedia Manufacturing 13:1245–1252. https://doi.org/10.1016/j.promfg.2017.09.045.

- Bresciani, S., A. Ferraris, M. Romano, and G. Santoro. 2021. “Digital Leadership.” In Digital Transformation Management for Agile Organizations: A Compass to Sail the Digital World, 97–115. Bingley: Emerald. https://doi.org/10.1108/978-1-80043-171-320211006.

- Büyüközkan, G., and F. Göçer. 2018. “Digital Supply Chain: Literature Review and a Proposed Framework for Future Research.” Computers in Industry 97:157–177. https://doi.org/10.1016/j.compind.2018.02.010.

- Caballero-Morales, S. O. 2021. “Innovation as Recovery Strategy for SMEs in Emerging Economies During the COVID-19 Pandemic.” Research in International Business and Finance 57:101396. https://doi.org/10.1016/j.ribaf.2021.101396.

- Čámská, D., and J. Klečka. 2020. “Cost Development in Logistics Due to Industry 4.0.” LogForum 16 (2): 219–227. https://doi.org/10.17270/J.LOG.2020.415.

- Çıkmak, S., B. Kantoğlu, and G. Kırbaç. 2023. “Evaluation of the Effects of Blockchain Technology Characteristics on SCOR Model Supply Chain Performance Measurement Attributes Using an Integrated Fuzzy MCDM Methodology.” International Journal of Logistics Research and Applications, 1–31. https://doi.org/10.1080/13675567.2023.2193736.

- Correia, D., C. Vagos, J. L. Marques, and L. Teixeira. 2023. “Fulfilment of Last-Mile Urban Logistics for Sustainable and Inclusive Smart Cities: A Case Study Conducted in Portugal.” International Journal of Logistics Research and Applications, 1–28.

- Culot, G., G. Nassimbeni, G. Orzes, and M. Sartor. 2020. “Behind the Definition of Industry 4.0: Analysis and Open Questions.” International Journal of Production Economics, 107617. https://doi.org/10.1016/j.ijpe.2020.107617.

- da Silva, V. L., J. L. Kovaleski, and R. N. Pagani. 2019. “Technology Transfer in the Supply Chain Oriented to Industry 4.0: A Literature Review.” Technology Analysis & Strategic Management 31 (5): 546–562. https://doi.org/10.1080/09537325.2018.1524135.

- Dixit, V., and P. Verma. 2022. “Identification, Assessment, and Quantification of new Risks for Logistics 4.0.” International Journal of Logistics Research and Applications, 1–25. https://doi.org/10.1080/13675567.2022.2100331.

- Dontigney, E. 2021. “The Methodology of Supply Chain Management in E-Manufacturing.” Accessed November 18, 2021. https://smallbusiness.chron.com/methodology-supply-chain-management-emanufacturing-81065.html.

- Elgazzar, Y., R. El-Shahawy, and Y. Senousy. 2022. “The Role of Digital Transformation in Enhancing Business Resilience with Pandemic of COVID-19.” In Digital Transformation Technology: Proceedings of ITAF 2020, 323–333. Singapore: Springer.

- Facchini, F., J. Oleśków-Szłapka, L. Ranieri, and A. Urbinati. 2020. “A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research.” Sustainability 12 (1): 86. https://doi.org/10.3390/su12010086.

- Genc, T. S. 2021. “Implementing the United Nations Sustainable Development Goals to Supply Chains with Behavioral Consumers.” Annals of Operations Research, 1–32. https://doi.org/10.1007/s10479-021-04037-9.

- Ghadge, A., M. E. Kara, H. Moradlou, and M. Goswami. 2020. “The Impact of Industry 4.0 Implementation on Supply Chains.” Journal of Manufacturing Technology Management, in-print.

- Guan, D., D. Wang, S. Hallegatte, S. J. Davis, J. Huo, S. Li, Y. Bai, et al. 2020. “Global Supply-Chain Effects of COVID-19 Control Measures.” Nature Human Behaviour 4 (6): 577–587. https://doi.org/10.1038/s41562-020-0896-8.

- Ignat, B., and S. Chankov. 2020. “Do E-Commerce Customers Change Their Preferred Last-Mile Delivery Based on its Sustainability Impact?” The International Journal of Logistics Management 31 (3): 521–548. https://doi.org/10.1108/IJLM-11-2019-0305.

- Junge, A. L., and F. Straube. 2020. “Sustainable Supply Chains – Digital Transformation Technologies’ Impact on the Social and Environmental Dimension.” Procedia Manufacturing 43:736–742. https://doi.org/10.1016/j.promfg.2020.02.110.

- Karia, N., and H. E. Kays. 2020. “Resource-Based Logistics (RBL) and Competitive Advantage: Logistics 4.0 Ps Model.” In Handbook of Research on the Applications of International Transportation and Logistics for World Trade, 181–194. IGI Global.

- Kor, Y. Y., and J. T. Mahoney. 2005. “How Dynamics, Management, and Governance of Resource Deployments Influence Firm-Level Performance.” Strategic Management Journal 26 (5): 489–496. https://doi.org/10.1002/smj.459.

- Koshta, N., Y. Devi, and S. Patra. 2021. “Aerial Bots in the Supply Chain: A New Ally to Combat COVID-19.” Technology in Society 66:101646. https://doi.org/10.1016/j.techsoc.2021.101646.

- Kostrzewski, M., P. Varjan, and J. Gnap. 2020. “Solutions Dedicated to Internal Logistics 4.0.” In Sustainable Logistics and Production in Industry 4.0, 243–262. Cham: Springer.

- Lee, S. 2021. “Sustainable Supply Chain Management, Digital-Based Supply Chain Integration, and Firm Performance: A Cross-Country Empirical Comparison between South Korea and Vietnam.” Sustainability 13 (7315): 2–13. https://doi.org/10.3390/su13137315.

- Longo, F., L. Nicoletti, and A. Padovano. 2017. “Smart Operators in Industry 4.0: A Human-Centered Approach to Enhance Operators’ Capabilities and Competencies Within the New Smart Factory Context.” Computers & Industrial Engineering 113:144–159. https://doi.org/10.1016/j.cie.2017.09.016.

- Manikas, I., B. Sundarakani, and M. Shehabeldin. 2022. “Big Data Utilisation and its Effect on Supply Chain Resilience in Emirati Companies.” International Journal of Logistics Research and Applications, 1–25.

- Marmolejo, J. A., and S. Hartmann. 2018. “Trends in Digitization of the Supply Chain: A Brief Literature Review.” EAI Endorsed Transactions on Energy Web 7 (29): 164113. https://doi.org/10.4108/eai.13-7-2018.164113.

- Mastos, T. D., A. Nizamis, S. Terzi, D. Gkortzis, A. Papadopoulos, N. Tsagkalidis, D. Ioannidis, K. Votis, and D. Tzovaras. 2021. “Introducing an Application of an Industry 4.0 Solution for Circular Supply Chain Management.” Journal of Cleaner Production 300:126886. https://doi.org/10.1016/j.jclepro.2021.126886.

- Miethlich, B., D. Belotserkovich, E. Zatsarinnaya, and O. Veselitsky. 2020. “Digital Supply Chain Management – New Competitiveness Imperative for Economic Development.” https://www.researchgate.net/publication/344495391_Digital_Supply_Chain_Management_-_New_Competitiveness_Imperative_for_Economic_Development.

- Mukhtar, A., A. Romli, and M. Abdullateef. 2019. “Environmental Risks in Supply Chain: Recommendations and Directions for Future Research.” IOP Conference Series: Materials Science and Engineering 551 (1): 012034. https://doi.org/10.1088/1757-899X/551/1/012034.

- Munsamy, M., A. Telukdarie, and P. Dhamija. 2020. “Logistics 4.0 Energy Modelling.” International Journal of Business Analytics 7 (1): 98–121. https://doi.org/10.4018/IJBAN.2020010106.

- Nandi, S., J. Sarkis, A. A. Hervani, and M. M. Helms. 2021. “Redesigning Supply Chains Using Blockchain-Enabled Circular Economy and COVID-19 Experiences.” Sustainable Production and Consumption 27:10–22. https://doi.org/10.1016/j.spc.2020.10.019.

- Nasiri, M., J. Ukko, M. Saunila, and T. Rantala. 2020. “Managing the Digital Supply Chain: The Role of Smart Technologies.” Technovation 96:102121. https://doi.org/10.1016/j.technovation.2020.102121.

- Rogetzer, P., T. Nowak, W. Jammernegg, and T. Wakolbinger. 2019. “ Impact of digitalization on sustainable supply chains. Chancen und Grenzen der Nachhaltigkeitstransformation: Ökonomische und soziologische Perspektiven.” 131–144.

- Seetharaman, P. 2020. “Business Models Shifts: Impact of Covid-19.” International Journal of Information Management 54:102173. https://doi.org/10.1016/j.ijinfomgt.2020.102173.

- Sharma, R., A. B. L. de Sousa Jabbour, V. Jain, and A. Shishodia. 2021. “The Role of Digital Technologies to Unleash a Green Recovery: Pathways and Pitfalls to Achieve the European Green Deal.” Journal of Enterprise Information Management 35 (1): 266–294. https://doi.org/10.1108/JEIM-07-2021-0293.

- Sharma, R., and A. Shishodia. 2022. “Blockchain Technology Enablers in Physical Distribution and Logistics Management.” In Big Data and Blockchain for Service Operations Management, 329–344. Cham: Springer.

- Sharma, R., A. Shishodia, S. Kamble, A. Gunasekaran, and A. Belhadi. 2020. “Agriculture Supply Chain Risks and COVID-19: Mitigation Strategies and Implications for the Practitioners.” International Journal of Logistics Research and Applications, 1–27. https://doi.org/10.1080/13675567.2020.1830049.

- Sindhwani, R., A. Behl, A. Sharma, and J. Gaur. 2022. “What Makes Micro, Small, and Medium Enterprises Not Adopt Logistics 4.0? A Systematic and Structured Approach Using Modified-Total Interpretive Structural Modelling.” International Journal of Logistics Research and Applications, 1–26. https://doi.org/10.1080/13675567.2022.2081672.

- Sony, M. 2019. “Green Supply Chain Management Practices and Digital Technology.” Technology Optimization and Change Management for Successful Digital Supply Chains, 233–254. https://doi.org/10.4018/978-1-5225-7700-3.ch012.

- Sundarakani, B., V. Aneesh, and A. Gunasekaran. 2021. “Big Data Driven Supply Chain Architecture Design and Application for Block Chain in Industry 4.0.” Omega: The International Journal of Management Science, 102452. https://doi.org/10.1016/j.omega.2021.102452.

- Sundarakani, B., R. Kamran, P. Maheshwari, and V. Jain. 2020. “Designing a Hybrid Cloud for a Supply Chain Network of Industry 4.0: A Theoretical Framework.” Benchmarking: An International Journal, ahead of print online. https://doi.org/10.1108/BIJ-04-2018-0109.

- Tang, S., W. Wang, H. Yan, and G. Hao. 2015. “Low Carbon Logistics: Reducing Shipment Frequency to Cut Carbon Emissions.” International Journal of Production Economics 164:339–350. https://doi.org/10.1016/j.ijpe.2014.12.008.

- Tao, F., and Q. L. Qi. 2019. “Make More Digital Twins.” Nature 573 (7775): 490–491. https://doi.org/10.1038/d41586-019-02849-1.

- Trautmann, L., T. Hübner, and R. Lasch. 2022. “Blockchain Concept to Combat Drug Counterfeiting by Increasing Supply Chain Visibility.” International Journal of Logistics Research and Applications, 1–27. https://doi.org/10.1080/13675567.2022.2141214.

- Veile, J. W., M. C. Schmidt, J. M. Müller, and K. I. Voigt. 2022. “The Transformation of Supply Chain Collaboration and Design Through Industry 4.0.” International Journal of Logistics Research and Applications, 1–29. https://doi.org/10.1080/13675567.2022.2148638.

- Wamba, S. F., and M. M. Queiroz. 2022. “Industry 4.0 and the Supply Chain Digitalisation: A Blockchain Diffusion Perspective.” Production Planning & Control 33 (2-3): 193–210. https://doi.org/10.1080/09537287.2020.1810756.

- Winkelhaus, S., and E. H. Grosse. 2020. “Logistics 4.0: A Systematic Review Towards a New Logistics System.” International Journal of Production Research 58 (1): 18–43. https://doi.org/10.1080/00207543.2019.1612964.

- Zekhnini, K., A. Cherrafi, I. Bouhaddou, A. C. Benabdellah, and R. Raut. 2021. “A Holonic Architecture for the Supply Chain Performance in Industry 4.0 Context.” International Journal of Logistics Research and Applications, 1–28. https://doi.org/10.1080/13675567.2021.1999912.

- Zimon, D., J. Tyan, and R. Sroufe. 2019. “Implementing Sustainable Supply Chain Management: Reactive, Cooperative, and Dynamic Models.” Sustainability 11 (7227): 1–20. https://doi.org/10.3390/su11247227.