ABSTRACT

The construction industry is confronted by resource constraints. It affects the initial costs and environment that requires resource and method optimization. The objective of the research is to design a mathematical MCDM model that would enable to select economically and ecologically suitable building material. To achieve this, the researcher designed, evaluated, and selected the suitable concrete grade using a combined mathematical MCDM. The objective sampling technique is used in Addis Ababa to collect samples of high-rise structures and materials. The study used objective-weighed MCDM and fuzzy-AHP to create specific concrete grades. The amount of the objective was fitted by 95% sensitivity analysis cost and quantity of concrete using a combination of MCDM, linear programming, and Monte Carlo simulation. The result demonstrates that, although the unit cost of concrete increased as strength grew, the project’s overall cost was reduced by reducing the project quantities. It will also add more space with environmentally friendly, sustainable structures. In conclusion, the integrated mathematical MCDM model is a helpful tool for selecting urban structure cost-effective materials

1. Introduction

The fast-growing construction industry is experiencing rapid rise in urbanization has led to a peak in material consumption (Simon & Kalbe, Citation2022; Tarekegn et al., Citation2022). Concrete is one of the construction materials that has the biggest impact on the construction industry (Abebe, Citation2005). It is a mixture of cement, aggregate, water, and additives (Tarekegn et al., Citation2022). Rock is extracted as a raw material and processed in a facility to manufacture cement that negatively effects on the nation’s economy (Subiyanto, Citation2020). But these days, other ingredients known as admixtures have emerged to improve the qualities of concrete by lowering the amount of cement needed, which lessens the negative effects of massive cement manufacturing on the environment and the economy (Mansor et al., Citation2018). Super plasticizing additive, one type of admixture that reduces cement and has a major impact on the manufacturing of concrete (Alsadey & Omran, Citation2022; Che et al., Citation2020; Muhsen et al., Citation2016). It is a plant byproduct that is readily regenerated and improves eco-efficiency by consuming less energy and reducing greenhouse gases (Burgos et al., Citation2012). This research used this admixture design and analysis of concrete in the construction of Addis Ababa high raise building.

The quantity of main ingredients of concrete are determined using concrete mix design (De Larrard, Citation1999; Ken, Citation1999; Kosmatka et al., Citation2002) that needed to produce economically appropriate, workable, strong, and durable concrete (Abebe & Aydın, Citation2022; Kosmatka et al., Citation2002). Therefore, the primary objective of mix design is to attain compressive strength at a given workability and age (ACI manual of concrete practice 121R–08, Citation2009). Even if durability, water-to-cement ratio, maximum size of aggregates, grading and type of aggregate, cement content, quality control, air voids, and compaction (Amin et al., Citation2022) are also considered, the quality of the material and admixture (Musbah et al., Citation2019) are also considered to improve the concrete properties (Amin et al., Citation2022; Che et al., Citation2020).

Admixtures, made up of fly ash, blast furnace slag, silica fume, and met kaolin, are also added to concrete to lower costs and increase workability as well as the material’s resistance to sulphate attack, alkali-aggregate expansion, and thermal cracking (Ramachandran, Citation2002). It improves the economy of the concrete mixture, boost ingredient efficiency, and improve the qualities of concrete in its plastic and hardened forms. In this study, the characteristics of both fresh and cured concrete enhanced by varying the water content up to 5–35% (Gelardi et al., Citation2016) using a water-reducing additive. The effect of water reducing additive affected by temperature, cement type and quantity, w/c ratio, addition type, dosage, and timing (Hover, Citation1998; Ken, Citation1999; Kosmatka et al., Citation2002). It impacts slump loss, bleeding and segregation, air content, finishing, and fresh concrete by decreasing the water content and making it more workable (Hover, Citation1998). By extending the typical workability period to 30 to 60 minutes, it causes a slump loss (Kosmatka et al., Citation2002), a 20% decrease in the water content and degree of hydration in cured concrete, as well as a reduction in creep, shrinkage, and permeability. Concrete has a reduced compressive strength on the first day, but between the third and seventh days, the strength has increased above the 28-day mark (Alsadey & Omran, Citation2022; Ramachandran et al., Citation2002).

While it is difficult to quantify (Simon & Kalbe, Citation2022), the production, use, and end-of-life of all construction materials has polluted the environment by releasing 38% of polluting gas (Burdová & Vilčeková, Citation2012), solid waste, climate change, and human toxicity (Baglou et al., Citation2017). Furthermore, the choice of building materials directly affects the structure’s complexity, kind, shape, and cost (Baskova et al., Citation2023). Thus, the building industry’s performance has brought attention to the growing demand for more environmentally friendly building techniques that would raise value, cut waste, and boost output. This problem will be resolved by maximizing cost-benefit analyses of construction methods, materials and harmonizing the social, economic, technological, and environmental elements (Alam Bhuiyan & Hammad, Citation2023; Navaratnam, Citation2022). Thus, the choice of appropriate building material (in this case, concrete as a prototype) will be covered in this study through developing a model that includes the subjective and objective decision at a certain value in case of mathematical complex with limited information. To achieve this, the researcher first selects, study the material property and design concrete strength. Secondly, the appropriate material should be selected using fuzzy-AHP, CRITIC and entropy MCDM. Thirdly, the amount of the decision fixed by using statistical theory, Monte-Carlo simulation and linear programming. Finally, the real benefit of the model shall be validated using cost and scenario analysis.

An integrated model of Monte Carlo simulation with fuzzy-AHP, objective weighted MCDM, and integrated linear programming will select the best concrete for a high-rise construction in Addis Ababa. This model will select construction materials and methods under uncertain, mathematically complex, and constrained data by the applying Monte-Carlo simulation (Prabatha et al., Citation2022). By adding the opinion and aim, MCDM was further optimized to decrease environmental pollution, deliver projects faster and at a lower cost while maintaining asset quality (Banihashemi et al., Citation2023). To establish the ideal selection value, liner programming was employed (Anyaeche & Okwara, Citation2011; Tewodros, Citation2023). The researcher would validate the model by showing how the choice of concrete material minimizes total cost and environmental influence. Environmental impact quantified by IPAT formula (Ehrlich & Holdren, Citation1971), and life-cycle assessment (Gibberd, Citation2014; Malmqvist et al., Citation2011) but it is not objective of this study.

2. Literature review and procedure

2.1. Description of the study area

Ethiopia’s capital, Addis Ababa, is one of the continent’s major metropolises. It is located at 2355 meters above sea level, with coordinates of 9°1’48‘and 38°44’24’ for the north and south, respectively. In 2007, the population of 2,738,248 persons live 530.14 km2, grew at a rate of 3.8% (Tadesse, Citation2011; T. Tamene, Citation2019). The city, which is still under development, is plagued by pollution, traffic congestion, and a lack of construction materials (Tadesse, Citation2011). Due to the country’s increasing population, mass migration, resource scarcity, and economic vulnerability, resource optimization is mandatory (Tamene, Citation2019; Tamene & Yeserah, Citation2023; Ulutaş et al., Citation2023) for sustain able development (Ulutaş et al., Citation2023). Therefore, one of the main issues facing a metropolitan city like the capital of Ethiopia will be covered by this research.

2.2. Construction material selection

The decision-making of building materials and techniques is essential for optimizing time, money, safety, and quality. The decision makings’ methodical and procedural technique of process optimization are finding problems, preference manufacturing process, alternative evaluation, and best alternative selection. Qualitative and prescriptive analysis techniques of Multiple-criteria decision-making (MCDM) tools are applied to deal with the multi-criteria material selection problem (Thakkar, Citation2021). By optimizing complex charge and aggravate repercussions (Zarghami & Szidarovszky, Citation2011), this strategy makes the best choice possible on certain multiple attribute choice problems and design difficulties of multiple objective decision making (Vadivel et al., Citation2020; Zarghami & Szidarovszky, Citation2011).

The MCDM decision-making depends on the unique behaviour of the problem due to its unique strengths, weaknesses, and inconsistent weighting of the criteria, selection of the solution, objective scaling, and parameter handling. It also limited to the number of alternatives chosen, handling of viewpoints, result validation, sensitivity analysis, and structural hierarchy inefficiencies (Thakkar, Citation2021). The researcher has therefore suggested an integrated mathematical MCDM method that incorporates mathematical algorithm to circumvent one method’s shortcomings by utilizing the strengths of the other.

The integration of fuzzy-AHP, objective weight, and mathematical model will solve the difficulty. Objective MCDM (entropy and CIRITIC) will solve fuzzy-AHP constraints, subjective decision-making, and validation (Mardani et al., Citation2015; Sterna & Laumanns, Citation2020). This combination will address the validation of the result and the limitations of the decision maker, rather than the precise value in an uncertain environment and mathematical complexity. Hence, the combined MCDM approach offers a more practical and realistic approach than a single MCDM (Ho, Citation2008; Tewodros, Citation2023). Therefore, the researcher applied linear programming to ascertain the number of real-world difficulties (Tewodros, Citation2023). However, the combined MCDM model of fuzzy-AHP, objective weighting, and linear optimization will not solve the challenges of data shortage and mathematical complexity. So, the researcher once again added a Monte Carlo random number generator based on the properties of the data using @RISK (T. Tamene, Citation2019).

All in all, the researcher used fuzzy-AHP to include the opinion of the decision-maker, objective weighing to address the subjectivity of the decision-maker, and validation of fuzzy-AHP, combined linear programming, and Monte-Carlo simulation to address the shortcoming of uncertainty in the environment, data shortage, and mathematical complexity for the appropriate sustainable economic concrete strength selection of urban infrastructure of Addis Ababa.

2.3. Sampling and collecting of data

The researcher used Delphi, interviewing under fuzzy environment to collect qualitative data. In the first, the decision maker was given the questioner, and after considering the maximum output of the first questioner, the decision maker passed questionaries’ one again with the maximum result of the previous decision to the same decision maker. If the summary of the final question’s results is less than three-fourth, the researcher directly meets the decision-maker who disagreed to converge the divergence. The quantitative data were collected by objective sampling of Addis Ababa’s high-rise buildings and literature.

2.4. Data analysis and modelling

Resource shortages that need optimization is the common challenge of any industry due to imperfect match of demand and supply. Previous different MCDM have been applied to optimize this challenge based on various possibilities and criteria (Ho, Citation2008), such as cost assessment (Ibrahim & Elshwadfy, Citation2021), power plant (Khanlari & Alhuyi, Citation2022), risk factor (Rezakhani, Citation2022), transportation (Vadivel et al., Citation2020), resource planning (Shouzhen et al., Citation2019), healthcare (Zozaya et al., Citation2018), renewable energy (Shao et al., Citation2020), watershed prioritization (Jaiswal et al., Citation2015), water and environmental management (Zarghami & Szidarovszky, Citation2011), construction project (Salimian et al., Citation2023), concrete mixture (Moro, Citation2023), and formwork (Rane et al., Citation2023) selection. All of this decision-making based on the specific assumptions of each MCDM model.

The drawback of a single MCDM shall be addressed by combining different MCDM (Thakkar, Citation2021), For-example, integrated AHP, ANN, and COP were used to select contractors (Alzober & Yaakub, Citation2014), integrated DEMATEL-AHP (Thakkar, Citation2021), and a systematic, valid method of objective criteria specification was developed (Reza Afshari, Citation2015). However, this combined methods do not include the best representation of decision-makers opinions. Integrated TODIMVIKOR with Entropy weighted under picture fuzzy set (Arya & Kumar, Citation2021), combined fuzzy FEMA with VIKOR (Thakkar, Citation2021), integrated prospect theory with PROMETHEE (T. Chen et al., Citation2020), and combined TOPSIS with TODIM Methods based on entropy weight (Liu et al., Citation2020) under picture linguistic fuzzy set were developed to address uncertainty, vagueness, and subjectivity of decision-making. However, all of them do not solve the decision-making under mathematical complexity and a data shortage. The lack of information was addressed by integrating Grey AHP and TOPSIS (Thakkar, Citation2021). But it solves linguistic data, not the challenge of objective weight, and it is not applicable to complex mathematical problems. All in all, the above study lacks the subjectivity of decision-makers on objective criteria weight and result validation. All of them were developed for non-construction material selection, and they did not address the integrated decision-making of uncertain, vague, combined subject with objective, mathematical complex, and lack of information problem.

Appropriate material selection, which is a multicriteria problem (Zakeri et al., Citation2023), is required for sustainable (Abdelaal et al., Citation2023; Figueiredo et al., Citation2021; Lee et al., Citation2020; Ulutaş et al., Citation2023), with quality and safety (Lam et al., Citation2023), environmentally friendly and cost-effective construction (Alkan et al., Citation2022; Moro, Citation2023). Among all, concrete is a major contributor of pollution and cost (J. Chen et al., Citation2020), that shall be decided by hybrid MCDM method (Emovon & Oghenenyerovwho, Citation2020). Different researchers have developed different hybrid MCDM methods like an integrated PSI-MEREC-LOPCOW-MCRAT model (Ulutas et al., Citation2023), fuzzy logic (Obradović & Pamučar, Citation2020) was used to select fibre and construction material, respectively. The output of concrete and mix design factor was optimized by ILHWLAD-MCDM (J. Chen et al., Citation2020), and TOPSIS (Ahmed et al., Citation2020) under fuzzy environment, respectively. A hybrid MCDM was developed for green material selection without accommodating mathematical complexity or data shortages (Zhang et al., Citation2017). However, the above methods will not address uncertain, ambiguous, and low-information mathematically complex multi-criteria concrete grade selection problems that need output validation.

So, to achieve the best representation and eliminate the shortcomings of the above studies, the analysis of the Addis Ababa high-rise building infrastructure was carried out utilizing a combination of MCDM (fuzzy-AHP, objective weight CRITIC, and entropy), linear programming, and Monte-Carlo simulation, called the combined mathematical MCDM method. The shortcoming of fuzzy-AHP’s subjectivity should be addressed by integrating and cross-checking by objective-weighted MCDM decision-making. In addition, the uncertainty, mathematical complexity, and data shortage with known property data were addressed by combined Monte-Carlo simulation, linear programming, and statistical theory. Finally, the model should be validated by cost, environmental impact, and scenario analysis.

2.5. Research procedure and organization

The following procedures and methods can be used to accomplish the study’s goal of creating a suitable model for the selection of construction materials:

Problem identification, which determines the research’s importance by examining how material choice affects the development of the infrastructure.

Stating objective: this target is backed by objectives that direct the process of achieving the study goal by developing a framework that outlines the precise steps taken to accomplish the goal step-by-step.

Critical literature review: this stage of the study should provide a summary of the body of information that informs the goal of the investigation. It highlights the procedures, practices, and shortcomings of previous investigations and demonstrates how to integrate them into the present selection of materials model to comprehend the approach and content of the current study by using the proper material selection strategy.

A two-step process was used to collect data. The basic data was gathered in Addis Ababa by objective sampling of material and high-rise buildings, as well as questioning (i.e. subjective data). The objective MCDM analysis data was gathered from the analytical literature.

The @Risk software add-in for Excel, Monte Carlo simulation, and linear programming were used in tandem to optimize the uncertain data.

Data analysis and discussion was conducted to analyse the collected data, to determine the relative importance of the appropriate material selection model and recommend a useful supporting tool for researcher.

Validation: Using cost, scenario, and environmental analysis, the researcher confirmed the model. It was utilized to persuade decision-makers and end users of the model’s outcome by demonstrating real benefits.

Lastly, based on the model, analysis, and discussion of construction material selection and its benefit, the researcher will make conclusions and recommendations for researchers, infrastructure developers, contractors, consultants, and decision makers.

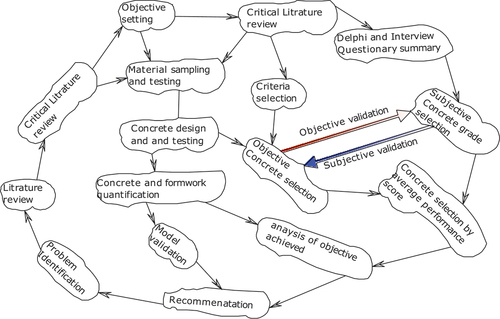

The shows the researcher’s identification of the problem to develop the general and specific objectives using primary and secondary data as well as a critical literature review. To gather secondary data, create research questions, and ultimately build a model using a combination of questioners and objective primary data collecting, a critical examination of the literature was employed. Following the development of the model, the study area was the subject of analysis and discussion to display the model’s prototype. After this model was verified, the overall goal for the issue found was used to inform the conclusion and recommendation that were provided. Eventually, the researcher will offer an efficient mathematical MCDM models for resolving the challenge of expense and environmental pollution by handling uncertainty, mathematical complexity at low information levels, validation using precise data properties, opinion, and objective weight.

3. Research methodology

This paper develops a combined mathematical MCDM model to select construction material for Addis Ababa infrastructure development through designing and producing high-strength concrete using ACI mix design techniques. The investigation began from collecting the physical characteristics of the components used in concrete using soil and concrete test. Then, contractors and consulting staff from different sectors was objectively chosen and finally, the researcher developed the following steps with a pictorail representation of to reach the objectives at a known degree.

Critical literature review of earlier work.

Materials are sampled and tested from Addis Ababa material site for concrete mix design.

Mix designed, tested and cost analysis is done with and without chemical.

Combined Delphi and interview method were used to summarize the decision.

The appropriate concrete strength was selected by Fuzzy-AHP and objective weighted CRITIC and entropy MCDM. The fuzzy-AHP used to include the opinion of decision maker whereas objective weight MCDM shall address shortage of opinion of decision maker.

The amount of concrete and formwork needed at a 95% confidence level was determined by using @RISK statistic software and linear Monte-Carlo Simulation.

Intergrade linear programming, Monte Carlo simulation and statistics theory is used to develop the amount of certainty of the selected material using the above MCDM method.

The validation of the model through evaluation of the adverse environmental effects and cost reduction was conducted.

Finally, the results of the combined mathematical model of Fuzzy-AHP, Objective weight MCDM, Linear Programming and Monte-Carlo Simulation are forwarded as a powerful tool to decide economic, environmentally friendly sustainable construction material on a certain degree on uncertain condition and the whole process is pictorially represented on .

All in all, the researcher solved the main objective of economical construction material selection for urban infrastructure development of Addis Ababa high-rise buildings through primary data collection using objective sampling and questioning. The secondary data were collected and analysed from the literature. These data were used to select concrete grades using fuzzy-AHP and objective-weighed MCDM. The uncertainty, complexity, and shortage of data for concrete and formwork quantification were analysed by combined Monte-Carlo simulation and linear programming under known properties of data from @RISK software. Finally, the output of the model was validated by cost and environmental analysis.

4. Material selection, analysis and discussion

4.1. Physical property aggregate and concrete design

Silt content is the quantity of dust, loam, and clay in sand (Solomon, Citation2014) that weakens the bond of concrete and mortar (Bashir & Science, Citation2018; Haque, Citation1980; Mathewos & Sida, Citation2022). To comply with Ethiopian standards, which allow for a maximum silt concentration of 6%, the researcher evaluated river sands using a sample taken for this study. The results were 4.5%. Then to fix the fineness, coarseness, and uniformity of aggregates, the fineness modulus index is determined using sieve analysis and grading tests (Chudley & Greeno, Citation2014; Solomon, Citation2014). A sieve was analysed in accordance with ACI standards to ascertain the coarse and fine aggregate particle size distribution of various sample sources. Since, the grading unsatisfied ACI criteria, the researcher blended and obtained 2.45 fines module.

According to a moisture content test, the water content of the aggregate is 10.90% for fine aggregate and 2.57% for course aggregate. The unit weights of compacted and loss fine aggregate are 1227.4 kg/m3 and 1360.2 kg/m3, respectively, and for compacted and loose course aggregates, they are 1449.6 kg/m3 and 1410.4 kg/m3, respectively. For coarse and fine aggregate, the average absorption capacity is 1.67% and 6.67%, respectively. The researcher adjusted the concrete mixture proportioning by employing Flow SP1 additive and the ACI −211 procedures to design the concrete at a 100 mm slump. All in all, the mix design data is summarized as follows. The column slump is 25–100 mm. the course aggregate nominal maximum size, dry-rode mass and absorption are 25 mm, 1450, and 1.67%, respectively. The fineness modules and absorption of fine aggregates are 2.45 and 6.67%, respectively. the specific gravity of cement used for this study is 3.15. So, using this material property, the researcher outlines design data for various concrete grades, concrete mix design and water content adjustment on .

Table 1. Mix design of concrete.

Following the preparation of this mix design, the concrete mix was created using a rotating drum mixer to yield the real test results. As seen in the first picture , the beginning of the concrete mixing process involved adding 1% of an additive and the mixture was highly segregated. Therefore, less water will be used overall for mixing, and the concrete mix was suitable.

The above illustrates the first mix of concrete with admixture without reducing the water content while the second mix of concrete with admixture by reducing 19% of the water. Workability test was conducted on selected C30 and C60 concrete. It was not significantly affected by adding admixture to the C30 concrete mix design at the required slump of 110 mm for 0% and 95 mm for 1% additional admixture, respectively. On the other hand, the 20 mm slump for C60 concrete, which has a 1% additive addition, greatly affects construction price. The mix proportion analysis revealed the slump loss occurring every 20 minutes. Thus, the working location is where the admixture will be placed. The researcher conducted concrete’s compressive strength according to the 15 cm cube test on 3rd, 7th and 28th days for selected concrete grade, which is as per the standard.

4.2. Unit cost analysis

The cost was analysed at material market price of 2023 by addition of 1% super plasticizer admixture. The labour and material breakdowns are taken from the 2013 Ethiopian Road Authority crew formation manual and the hourly indexing rate is taken from the hourly rate of labour released on 2merkato.com in 2022 (Concrete Work Material Prices in Addis Ababa, Citationn.d.). The inflation rate of 28.8% of material (Ethiopia Inflation Rate –September Citation2023 Data − Citation2006–2022, 2023) was used to forecast the hourly rate of the 2023 labour rate. So, the labour unit cost of reinforced concrete and formwork is 86.69 and 128.26 ETB, respectively. In addition, the unit cost formwork materials as per 2merkato.com of August 2023 is 918.71 ETB and the unit cost of C25, C30, C40, C50, and C60 is 6,421.24, 6,743.85, 7,546.00, 7,873.70 and 8,266.60 ETB corresponding. The study indicates, the unit cost of concrete increased by an average of 6.55% as the concrete grade increased.

4.3. Selection of concrete strength using MCDM and linear programming

Nine high-rises building ranging from 2B+G + 14 to 4B+G + 25 was selected from Addis Ababa. These structures are moderate to large that incorporated mezzanine floors and it featured distinct story sizes for every column. The study considered that to construct the column dimensions, every column up to half of the story would have the same size, and every other column would take up 75% of the basement column dimension. The design concrete strength was chosen in Addis Ababa using the material cost and the facts. In Ethiopia’s construction sector, column concrete grades ranging from C25 to C60 are available. Thus, the unit cost, the amount of concrete (m3) and formwork (m2) needed for the structure, the size of the columns (m2), astatic, and workmanship are all considered when choosing the right concrete strength. For the objective weightage, the value of astatic and workmanship is represented as Low (1), Below Average (2), Average (3), Good (4), and Excellent (5).

The above chart on shows the hierarchal structure of design concrete strength selection in the design office and their major criteria. The summary of decision made by five experienced engineers utilizing the direct interview and Delphi procedures illustrated below on .

Table 2. Pair-wise comparison matrix.

below show the associated Fuzzified Pair-wise comparison matrix, fuzzy weight, and performance score of the concrete mix design, respectively.

Table 3. Fuzzified Pair-wise comparison matrix.

Table 4. Fuzzy weight calculation.

Table 5. Performance score concrete mix design selection.

According to the above analysis’s FAHP performance score, the greatest concrete strength is the main concrete strength used in Addis Ababa’s high-rise construction design. However, the primary disadvantage of utilizing the FAHP approach for decision-making is that it is a complex fuzzy operation without established methods for evaluating fuzzy consistency and fuzzy priority vector (Rezakhani, Citation2022). Therefore, using the CRITIC and entropy methods, the researcher reselects the design concrete objectively to validate the FAHP result. The performances score of C25, C30, C40, C50 and C60 is 0.34, 0.43, 0.53, 0.68, and 0.94 correspondingly in Entropy Method and 0.61, 0.65, 0.69, 0.77 and 0.88 in CRITIC method and yet C60 is top in both objective MCDM. The average performance score of subjective and objective MCDM is 0.515, 0.569, 0.638, 0.737, and 0.894 for C25, C30, C40, C50 and C60, respectively, that have similar rank. So, the concrete grade ranked as C60 > C50 > C40 > C30 > C25 and the high-grade concrete is preferable in designing a high-rise structure.

To maximize overall advantages, linear programming is used in concrete grade selection based on average performance score to illustrates each concrete’s contribution in fulfilling the city design office’s suggestion. displays the MCRN cost of construction together with the average performance score of fuzzy-AHP, CRITIC, and entropy associated with each concrete grade.

Table 6. Column concrete linear optimization.

Cj: Binary decision variable for concrete j, j = 1 (if concrete j is selected, 0 otherwise), n: Number of Concrete grades, J: Concrete number, j = 1 - n, A = Total Benefits, Bj: Overall benefit on the ranking of concrete j from the performance score of Fuzzy-AHP, CRITIC and Entropy,aij: Average cost concrete and formwork of concrete i required when project designed by concrete j, and Di: Total capital available

Amax = 0.515C1 +0.569C2 +0.638C3 +0.737C4 +0.894C5

Constraint

Total cost, 19.44C1 +17.74C2 +15.51C3 +13.61C4 +12.77C5 ≤79.07

If the design concrete grade different at different level of building, C3+C4+C5 ≤1

The structure can be design by 3 concrete grades at different level, C1 + C2 + ⋯ + C5 ≤3

The decision variable; Cj ≥0 for Cj = 0 – 1; C1, C2, C3, C4 and C5 ≥0

Optimization of Linear Systems. The coefficient of concrete grade is 1 for C60 and 0 for C25, C30, C40, and C50, according to the Excel-Solver results. With a benefit of 0.894, concrete grade C60 is determined to be the best option. This suggests that to maximize their advantage to 89.4% in terms of the eight constraints, the city should direct the construction of high-rise buildings utilizing high concrete grade. Therefore, to successfully complete projects on schedule and within budget, the designer shall design by high-grade concrete. The cost of the concrete and formwork for the 3B+G + 22 building will ultimately come to 352,83 million ETB if the design office decides to design 50%, 30%, and 20% of the columns by C60, C50, and C40.

4.4. Validation and comparative analysis

4.4.1. Comparative study

Comparative analysis plays used to test, confirm, verifying the effectiveness and the reliability of a the existing and proposed decision-making method (Rane et al., Citation2023). The researcher selected three MCDM model that are too some extent comparable with the result the proposed model by considering subjective and objective decision without considering mathematical complexity, data limitation and how much the objective achieved. The selected classical fuzzy-TOPSIS, PROMETHEE II, TODIM, VIKOR. The order of concrete is C60 > C50 > C40 > C30 > C25. However, PROMETHEE II does not consider risk preferences, TOPSIS needs to determine the positive with negative ideal solutions of each criterion, VIKOR provides a compromising solution based on maximum utility of group with the minimum regret of individuals and TODIM is used to handle based on under uncertainty and risk (Arya & Kumar, Citation2021; T. Chen et al., Citation2020; Kumar et al., Citation2022). This indicated that material selection by combined Delphi, fuzzy-AHP, entropy, CRITIC linear programming, Monte-Carlo simulation and statistical theory are appropriate model that can solve the shortcoming of the above model on problem stated on Section 2.2.

4.4.2. Result validation

4.4.2.1. Quantification of concrete and formwork

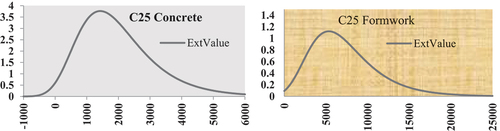

In Addis Ababa, the basic design of a high-rise building column that was objectively chosen is used to estimate how much concrete and formwork will be needed as the concrete strengthening increases. The researcher made the following assumptions: the concrete in the columns would be class I work; the load transmitted between the slab and higher structure would be a superimposed factored load; all stories of each building would utilize the basement floor design of the columns; and the gross ratio would be 0.01. The data’s properties utilizing @RISK probability are summed together, and the C25 concrete and formwork probability distribution is displayed below.

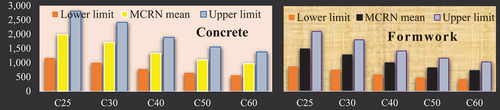

The above graph on shows the property of C25 concrete and formwork data, for the rest was conducted similarly. With a 95% confidence and in consideration of data property, a 100,000 randomly generated numbers, the average amount of concrete and formwork is determined. The result indicated that the average decrease in concrete and formwork as the concrete grade increases is 16.29 and 8.16%, respectively, and graphically represented as below.

at 95% confidence level, the chart displays the lower and upper bounds of the quantity of concrete and formwork that were determined by analyzing the probability distribution of each grade of concrete and formwork. The MCRN mean is the average of 100,000 randomly generated numbers that fall between the upper and lower bounds when the probability distribution is considered.

4.4.2.2. Environmental impact assessment

The influence of rising building material production on human toxicity, climate change, and solid waste is demonstrated in this study (Danso, Citation2018; Tegegne et al., Citation2023), with attention paid to CO2, fuel, power, water, raw materials, SO2, and NOx and the unit rates founded from previous study (Baglou et al., Citation2017). In this study as stated in , raising the concrete grade during the construction of a high-rise structure in Addis Ababa reduces the environmental effect of CO2, fuel, power, water, raw materials, SO2, NOx, and production costs by 8.18% for formwork production and 3.84% for concrete. Therefore, high concrete strength shall be used in the construction of the Addis Ababa high rise building in order encourage environmentally sustainable development. Additionally, high concrete strength design is one of the most promising treatment technologies that can be used to address construction-related environmental reduction problems as electrochemical degradation in textile industry wastewater treatment (Yehuala et al., Citation2022).

Table 7. The effect of improving concrete quality on the environment.

4.4.2.3. Cost scenario analysis

The purpose of the cost scenario study was to determine how much the initial investment cost of a high-rise structure in Addis Ababa is affected by the quality of concrete. It has three scenario analyses. The first case analyzes how changing the amount of concrete or the building’s size might affect the grade of the concrete. The second one examines the impact of material increases or decrees on the choice of concrete grade during the construction of a high-rise structure in Addis Ababa. The third one shows what happens when we change the grade section of the high-rise building in Addis Ababa in terms of both material and cost. The worst and best scenario is 100% reduction and increasing of the unit cost of concrete and size of the high raise building in Addis Ababa. The result indicates that as the concrete grade increase, the amount of the variation of building size and cost increase too. So, the high concrete grade shall be appropriate for high rise buildings depending on the building size and material cost since it will reduce the initial investment cost of buildings.

Overall, the study evaluated the use of admixtures to select the concrete grade for the high-rise building in Addis Ababa based on multiple criteria decision-making. The cost and scenario analysis also supported the requirement that high concrete strength be used in the design of the building. The inference is that, the concrete quantity will determine the building’s construction process than the unit cost. Thus, initial investment is more sensitive to the size of the building and less sensitive to the unit cost of concrete. While these findings are highly novel in terms of the selection of concrete strength in buildings, working methodology, space required and concrete finish.

4.4.2.4. Effectiveness of the model result based on previous studies

The combined mathematical MCDM model is the most effective model for the selection of concrete is the construction of high-rise building. The best concrete C60, which is the high performing concrete (Rolander, Citation2019) indicate that as the concrete grade increase the total cost of building, construction period, the column size and environmental impact will decrease (Jayasinghe et al., Citation1997; Samir et al., Citation2014; Santos, Citation2021; Sonawane & Gawali, Citation2022). This reduction will enhance the land utilization, concrete finish, environmental protection, freeze-thaw resistance, and construction of high-rise buildings (Kovačević & Džidić, Citation2018; Sinit, Citation2014). This study also shows the effectiveness of concrete grade selection based on size and purpose of building (Jayasinghe et al., Citation1997; Sinit, Citation2014) since as the concrete grade increase the unit cost of material also increase, the fire resistance decreases (Rolander, Citation2019).

5. Conclusion and recommendation

Material selection with the correct ingredient content can reduce cost and increase environmental protection, depending on the decision-maker and the method of decision-making. In this study, the researcher developed a new integrated mathematical MCDM model including the Delphi method, fuzzy-AHP, objective weighting MCDM (CRIRIC, entropy), linear programming, Monte-Carlo simulation, and statistical theory to select the best material under uncertainty, vagueness, subjectivity, limited information, and mathematically complex decision-making by including the opinion of the decision-maker.

The results indicated that high concrete strength is the appropriate concrete strength in the construction of the Addis Ababa high-rise building. The order of alternatives indicates that as concrete becomes more quality, its functionality increases. In addition, the total cost of concrete decreased as the grade increased, even if the unit cost of concrete increased as the grade increased. Further, the design of a building with high concrete strength minimizes the column size and increases working space, which decreases the quantity of concrete and formwork. The cost of concrete and formwork also decreased by 3.84% and 8.18% at 95% confidence, respectively, so that decreased the overhead costs by maximizing the advantage at 89.4% under the best alternative. Further, it minimizes the amount of concrete to handle and increases the early strength by minimizing construction time and investment capital to have an early return. Besides that, increasing the strength of concrete in building construction through admixture improves environmentally friendly and sustainable construction by decreasing the construction material required and pollutant emissions. All in all, the construction of a building with high concrete strength would decrease the initial investment and project duration. It increases the working space and encourages environmentally friendly, sustainable construction.

An integrated mathematical MCDM model is critical model that makes accurate and informed decision with dependable results. It can handle both subjective and objective data under uncertain, vague, subject, limited information, and mathematically complex decision-making condition. Its shortcomings are the data collection, material selection and outcome validation processes are complex. It provides an analytical framework to help policymakers and infrastructure developers choose the optimum concrete-grade material among commercially accessible. However, integrated mathematical MCDM model was employed for evaluating concrete grades, but it can be applied to any MCDM problem.

The researcher can recommend that the integrated mathematical models of fuzzy-AHP, objective weight MCDM, statistical theory, linear programming, linear Monte-Carlo simulation are significant and effective tools for determining, to some extent, the most cost-effective and environmentally friendly sustainable urban infrastructure construction materials in an uncertain environment.

Acknowledgments

The researcher would thank the AACRA for material testing laboratory.

Disclosure statement

No potential conflict of interest was reported by the author(s).

Data availability statement

The data will be obtained upon reasonable request

References

- Abdelaal, M. A., Seif, S. M., El-Tafesh, M. M., Bahnas, N., Elserafy, M. M., & Bakhoum, E. S. (2023). Sustainable assessment of concrete structures using BIM–LCA–AHP integrated approach. Environment, Development and Sustainability. https://doi.org/10.1007/s10668-023-03701-3

- Abebe, D., (2005). The need for standardization of aggregates for concrete production in Ethiopian construction industry. International Conference on African Development Archives. 90. https://scholarworks.wmich.edu/africancenter_icad_archive/90

- Abebe, D., & Aydın, A. C. (2022). Comparative analysis of selected concrete mix design methods based on cost-effectiveness. Advances in Civil Engineering, 2022, 1–22. https://doi.org/10.1155/2022/4240774

- ACI manual of concrete practice 121R-08. (2009). Guide for Concrete Construction Quality Systems in conformance with ISO 9001. American Concrete Institute.

- Ahmed, M., Mallick, J., Alqadhi, S., & Ben Kahla, N. B. (2020). Development of concrete mixture design process using MCDM approach for sustainable concrete quality management. ‘Sustainability’, 12(19), 8110. https://doi.org/10.3390/su12198110

- Alam Bhuiyan, M. M., & Hammad, A. (2023). A hybrid multi-criteria decision support system for selecting the most sustainable structural material for a multistory building construction. ‘Sustainability’, 15(4), 3128. https://doi.org/10.3390/su15043128

- Alkan, R., Yucesan, M., & Gul, M. (2022). A multi-attribute decision-making to sustainable construction material selection: A bayesian BWM-SAW hybrid Model. Advance in Best-Worst Method, 67–78. https://doi.org/10.1007/978-3-030-89795-6_6

- Alsadey, S., & Omran, A. (2022). Effect of superplasticizers to enhance the properties of concrete. Design, Construction, Maintenance, 2, 84–91. https://doi.org/10.37394/232022.2022.2.13

- Alzober, W., & Yaakub, A. R. (2014). Integrated Model for MCDM: Selection Contractor in Malaysian construction industry. Applied Mechanics & Materials, 548–549, 1587–1595. https://doi.org/10.4028/www.scientific.net/AMM.548-549.1587

- Amin, J., Acharjee, R., Hossain, M., Tahmid, A., & Chowdhury, S. R. (2022). Factors affecting mix design of concrete. Malaysian Journal of Civil Engineering, 34(2), 19–28. https://doi.org/10.11113/mjce.v34.18311

- Anyaeche, C. O., & Okwara, R. A. (2011). An integer linear programming model for project portfolio selection in a community. International Journal of Engineering Research in Africa, 4, 67–74. https://doi.org/10.4028/www.scientific.net/JERA.4.67

- Arya, V., & Kumar, S. (2021). A picture fuzzy multiple criteria DecisionMaking approach based on the combined TODIM-VIKOR and Entropy Weighted Method. Cognitive Computation, 13(5), 1172–1184. https://doi.org/10.1007/s12559-021-09892-z

- Baglou, M., Ghoddousi, P., Saeedi, M. (2017). Evaluation of building materials based on sustainable development indicators. Journal of Sustainable Development, 10(4), 143–154. https://doi.org/10.5539/jsd.v10n4p143

- Banihashemi, S. A., Khalilzadeh, M., Antucheviciene, J., & Edalatpanah, S. A. (2023). Identifying and prioritizing the challenges and obstacles of the Green Supply Chain Management in the construction industry using the fuzzy BWM method. ‘Buildings’, 13(1), 38. https://doi.org/10.3390/buildings13010038

- Bashir, T., & Science, M. K. (2018). Effect of silt content on the strength property of concrete-A case study. International Journal of Engineering Research & Technology (IJERT), 7(9), 1–10.

- Baskova, R., Tazikova, A., Strukova, Z., Kozlovska, M., & Cabala, J. (2023). A dynamic Model for effective and optimal planning of Formwork in construction projects. Buildings, 13(7), 1794. https://doi.org/10.3390/buildings13071794

- Burdová, E. K., & Vilčeková, S. (2012). Environmental assessment of building materials and constructions. Applied Mechanics and Materials, 174–177, 3161–3165. https://doi.org/10.4028/www.scientific.net/AMM.174-177.3161

- Burgos, M. O., Palacios, M., Rivilla, P., & Puertas, F. (2012). Compatibility between superplasticizer admixtures and cements with mineral additions. Construction and Building Materials, 31, 300–9. https://doi.org/10.1016/j.conbuildmat.2011.12.092

- Che, A. R., Ismail, K. N., Mohamad, I. N., Azmi, N. J. (2020). Influence of superplasticizer on performance of cement - bottom ash concrete. In IOP Conference Serious Earth Environ Science. Institute of Physics Publishing, vol. 476, https://doi.org/10.1088/1755-1315/476/1/012025.

- Chen, T., Wang, Y. T., Wang, J. Q., Li, L., & Cheng, P. F. (2020). Multistage decision framework for the selection of renewable energy sources based on prospect theory and PROMETHEE. International Journal of Fuzzy Systems, 22(5), 1535–1551. https://doi.org/10.1007/s40815-020-00858-1

- Chen, J., Zhang, C., Li, P., Xu, M., & Mahmood, T. (2020). The ILHWLAD-MCDM framework for the evaluation of concrete materials under an intuitionistic linguistic fuzzy environment. Journal of Mathematics, 2020, 1–11. https://doi.org/10.1155/2020/8852842

- Chudley, R., & Greeno, R. (2014). Building construction handbook. Routledge is an Imprint of the Taylor & Francis Group, an Informa Business.

- Concrete Work Material Prices in Addis Ababa. (n.d). Retrieved October 16, 2023 from https://con.2merkato.com/prices/cat/2.

- Danso, H. (2018). Identification of key indicators for sustainable construction materials. Advances in Materials Science and Engineering, 2018, 1–7. https://doi.org/10.1155/2018/6916258

- De Larrard, F. (1999). Concrete mixture proportioning: A scientific approach. ‘E & FN Spon, An Imprint of Routledge’.

- Ehrlich, P. R., & Holdren, J. P. (1971). Impact of population growth. Science, 171(3977), 1212–1217. https://doi.org/10.1126/science.171.3977.1212

- Emovon, I., & Oghenenyerovwho, O. S. (2020). Application of MCDM method in material selection for optimal design: A review. Results in Materials, 7, 100115. https://doi.org/10.1016/j.rinma.2020.100115

- Ethiopia Inflation Rate – September 2023 Data – 2006-2022. (2023) https://tradingeconomics.com/ethiopia/inflation-cpi.

- Figueiredo, K., Pierott, R., Hammad, A. W., & Haddad, A. (2021). Sustainable material choice for construction projects: A life cycle sustainability assessment framework based on BIM and fuzzy-AHP. Building and Environment, 198, 107805. https://doi.org/10.1016/j.buildenv.2021.107805

- Gelardi, G., Mantellato, S., Marchon, D., Palacios, M., Eberhardt, A. B., & Flatt, R. J. (2016). Chemistry of chemical admixtures. Science and Technology of Concrete Admixtures, 149–218. https://doi.org/10.1016/B978-0-08-100693-1.00009-6

- Gibberd, J. (2014). Sustainability impacts of building products: An assessment methodology for developing countries. African Journal, 21(2), 69–84.

- Haque, M. N. (1980). Some effects of silt contents on the strength of all-in-aggregate concrete. Cement and Concrete Research, 10(1), 13–22. https://doi.org/10.1016/0008-8846(80)90047-2

- Ho, W. (2008). Integrated analytic hierarchy process and its applications – a literature review. European Journal of Operational Research, 186(1), 211–228. https://doi.org/10.1016/j.ejor.2007.01.004

- Hover, K. C. (1998). Concrete mixture proportioning with Water-reducing Admixtures to enhance durability: A quantitative Model. Cement and Concrete Composites, 20(2–3), 113–119. https://doi.org/10.1016/S0958-9465(98)00002-X

- Ibrahim, A. H., & Elshwadfy, L. M. (2021). Assessment of construction project cost estimating accuracy in Egypt. The Open Civil Engineering Journal, 15(1), 290–298. https://doi.org/10.2174/1874149502115010290

- Jaiswal, R. K., Ghosh, N. C., Galkate, R. V., Thomas, T. (2015). Multi criteria decision analysis (MCDM) for watershed prioritization, International Conference on Water Resources, Coastal and Ocean Engineering (ICWRCOE 2015), Surathkal, Mangalore, India (Vol. 4, pp. 1553–1560). Aquatic Procedia.

- Jayasinghe, M. T. R., Jayanandana, A. D. C., Alwis, K. G. N. C. (1997). Applications of high strength concrete in high-rise buildings. Department of Civil Engineering, University of Moratuwa.

- Ken, W. D. (1999). Concrete mix design, quality control and specification. 2nd Edu. ‘E & FN Spon is an imprint of the Taylor & Francis Group, New Fetter Lane, London EC4P 4EE and Routledge.

- Khanlari, A., & Alhuyi, N. M. (2022). A review on the applications of multi-criteria decision-making approaches for power plant site selection. Journal of Thermal Analysis and Calorimetry, 147(7), 4473–4489. https://doi.org/10.1007/s10973-021-10877-1

- Kosmatka, S. H., Kerkhoff, B., & Panarese, W. C. (2002). Design and control of concrete mixtures (4th ed.). ‘Portland Cement Association’.

- Kovačević, I., Džidić, S. (2018). “High-strength concrete (HSC) material for high-rise buildings.” 12th Scientific/Research Symposium with International Participation, Metallic and non-metallic materials, Bosnia and Herzegovina.

- Kumar, S., Arya, V., Kumar, S., & Dahiya, A. (2022). A new picture fuzzy entropy and its application based on combined picture fuzzy methodology with partial weight information. International Journal of Fuzzy Systems, 24(7), 3208–3225. https://doi.org/10.1007/s40815-022-01332-w

- Lam, W. H., Liew, K. F., Lam, W. S., “Selection of materials in construction industry with multi-criteria decision-making models.” (2023). E3S Web of Conferences, vol. 405. https://doi.org/10.1051/e3sconf/202340504015.

- Lee, D., Lee, D., Lee, M., Kim, M., & Kim, T. (2020). Analytic hierarchy process-based construction material selection for performance improvement of building construction: The case of a concrete system form. ‘Materials’, 13(7), 1738. https://doi.org/10.3390/ma13071738

- Liu, D., Luo, Y., & Liu, Z. (2020). The linguistic picture fuzzy set and its application in multi-criteria decision-making: An illustration to the TOPSIS and TODIM methods based on entropy weight. ‘Symmetry’, 12(7), 1170. https://doi.org/10.3390/sym12071170

- Malmqvist, T., Glaumann, M., Scarpellini, S., Zabalza, I., Aranda, A., Llera, E., & Díaz, S. (2011). Life cycle assessment in buildings: The ENSLIC simplified method and guidelines. ‘Energy, 36(4), 1900–1907. https://doi.org/10.1016/j.energy.2010.03.026

- Mansor, A. M., Borg, R. P., Hamed, A. M., Gadeem, M. M., Saeed, M. M., “The effects of water-cement ratio and chemical admixtures on the workability of concrete.” (2018). In IOP Conference serious material science engineering, Institute of Physics Publishing, vol. 442. https://doi.org/10.1088/1757-899X/442/1/012017.

- Mardani, A., Jusoh, A., Nor, K. M. D., Khalifah, Z., Zakwan, N., & Valipour, A. (2015). Multiple criteria decision-making techniques and their applications – a review of the literature from 2000 to 2014. Economic Research-Ekonomska Istraživanja, 28(1), 516–571. https://doi.org/10.1080/1331677X.2015.1075139

- Mathewos, L. M., & Sida, A. (2022). The impact of aggregate washing and blending on concrete compressive. Ethiopian Journal of Engineering and Technology. 2(2–22), 43–53. http://www.journals.hu.edu.et/hu-journals/index.php/ejet/index

- Moro, C. (2023). Comparative Analysis of Multi-Criteria decision making and life cycle assessment methods for sustainable evaluation of concrete mixtures. ‘Sustainability’, 15(17), 12746. https://doi.org/10.3390/su151712746

- Muhsen, S. M., Salahaldein, A. M., & Megat, A. M. J. (2016). Influence of superplasticizer compatibility on the Setting Time, strength and stiffening characteristics of concrete. Advances in Applied Sciences, 1(2), 30–36. https://doi.org/10.11648/j.aas.20160102.12

- Musbah, M. G., Allam, A. M., Saleh, H. A., & Ateeg, I. M. (2019). Effects of super plasticizing admixtures on the compressive strength of concrete. Universal Journal of Engineering Science, 7(2), 39–45. https://doi.org/10.13189/ujes.2019.070203

- Navaratnam, S. (2022). Selecting a suitable sustainable construction method for Australian high-rise building: A multi-criteria analysis. ‘Sustainability’, 14(12), 7435. https://doi.org/10.3390/su14127435

- Obradović, R., & Pamučar, D. (2020). Multi-criteria Model for the selection of construction materials: An Approach Based on Fuzzy Logic. Technical gazette, 5, 1531–1543. https://doi.org/10.17559/TV-20190426123437

- Prabatha, T., Hewage, K., & Sadiq, R. (2022). An Energy Performance Contract Optimization Approach to meet the competing stakeholder expectations under uncertainty: A Canadian case study. ‘Sustainability’, 14(7), 4334. https://doi.org/10.3390/su14074334

- Ramachandran, V. S. (2002). “Concrete admixture handbook.” (2nd ed.). Noyes Publications.

- Ramachandran, V. S., Ralph, M. P., James, J. B., & Ana, H. D. (2002). “Handbook of thermal analysis of construction materials. Noyes Publications; William Andrew publishing Norwich.

- Rane, N. L., Achari, A., & Kadam, D. (2023). Evaluating the selection criteria of formwork system (FS) for RCC building construction. International Journal of Engineering Trends and Technology, 71(3), 197–205. https://doi.org/10.14445/22315381/IJETT-V71I3P220

- Reza Afshari, A. R. (2015). Selection of construction project manager by using Delphi and fuzzy linguistic decision making. Journal of Intelligent and Fuzzy Systems, 28(6), 2827–2838. https://doi.org/10.3233/IFS-151562

- Rezakhani, P. (2022). Fuzzy MCDM Model for risk factor selection in construction projects. Engineering Journal, 16(5), 79–93. https://doi.org/10.4186/ej.2012.16.5.79

- Rolander, H. (2019). Potential applications for high-strength concrete in cast in-situ structures. Aalto University School of Engineering.

- Salimian, S., Seyed Meysam, M. S., Tupenaite, L., & Antucheviciene, J. (2023). An integrated multi-criteria decision Model to select sustainable construction projects under intuitionistic fuzzy conditions. ‘Buildings’, 13(4), 848. https://doi.org/10.3390/buildings13040848

- Samir, B., Boualem, K., & Ahmed, B. (2014). Optimized cost of high-performance concrete in the build. Advanced Materials Research, 911, 479–483. https://doi.org/10.4028/www.scientific.net/AMR.911.479

- Santos, L. B. S. (2021). Cost-benefit analysis between conventional concrete and high-performance concrete: Case study of a residential building. International Journal of Advanced Engineering Research and Science, 8(6), 090–100. https://doi.org/10.22161/ijaers.86.10

- Shao, M., Han, Z., Sun, J., Xiao, C., Zhang, S., & Zhao, Y. (2020). A review of multi-criteria decision-making applications for renewable energy site selection. Renewable Energy, 157, 377–403. https://doi.org/10.1016/j.renene.2020.04.137

- Shouzhen, Z., Muhammad, Q., Muhammad, A., & Tariq, M. (2019). Extended version of linguistic picture fuzzy TOPSIS method and its applications in enterprise resource planning systems. Mathematical Problems in Engineering, 2019, 1–8. https://doi.org/10.1155/2019/8594938

- Simon, F. G., & Kalbe, U. (2022). Measurement of the environmental impact of materials. ‘Materials, 15(6), 1–3. https://doi.org/10.3390/ma15062208

- Sinit, T. (2014). The Advantage of High-Strength Concrete (HSC) in High-Rise Buildings: From Area Saving Aspect. Master’s thesis, School of civil and environmental engineering, Addis Ababa Institute of Technology, Addis Ababa University.

- Solomon, H. (2014). “Effect of clayey silt content on concrete strength”, University intuitional repository. http://etd.aau.edu.et/handle/123456789/10516

- Sonawane, B. D., & Gawali, B. N. (2022). Cost effectiveness of high-performance concrete. International Research Journal of Engineering and Technology, 9(6), 836–841.

- Sterna, M., & Laumanns, M. (2020). “Advanced studies in multi-criteria decision-making series in operations research”. ‘Taylor & Francis Group’.

- Subiyanto, E. (2020). The relationship of cement consumption and economic growth: An updated approach. European Research Studies Journal, XXIII(Issue 3), 280–295. https://doi.org/10.35808/ersj/1638

- Tadesse, W. G. (2011). “Assessing & Quantifying the Level of Traffic Congestion at Major Intersections in Addis Ababa: A Case for East-West Corridor”, Master’s thesis, Department of civil engineering, Addis Ababa University.

- Tamene, T. (2019). “Improving Addis Ababa Light Railway Transit Service using queue theory and monte-carlo simulation models: Case of Torhailoch and lideta stations”, University intuitional repository. http://etd.aau.edu.et/handle/123456789/21889

- Tamene, T. W., & Yeserah, G. A. (2023). Analysis and optimization of Addis Ababa light railway ticketing window. Urban and Regional Planning, 8(3), 52–58. https://doi.org/10.11648/j.urp.20230803.14

- Tarekegn, M., Getachew, K., Kenea, G., & Putra Jaya, R. (2022). Experimental investigation of concrete characteristics strength with partial replacement of cement by Hybrid Coffee Husk and sugarcane bagasse ash. Advances in Materials Science and Engineering, 2022, 1–12. https://doi.org/10.1155/2022/5363766

- Tegegne, D., Abera, M., Alemayehu, E., & González-Fonteboa, B. (2023). Selection of sustainable building material using multi criteria decision-making Model: A case of masonry work in Lideta Sub city, Addis Ababa. Advances in Civil Engineering, 2023, 1–8. https://doi.org/10.1155/2023/9729169

- Tewodros, A. A. (2023). Application of multi-criteria decision-making based on combined analytic hierarchy process and linear programming as an alternative for project selection: The case of Ethiopian road authority road projects. Addis Ababa University intuitional repository.

- Thakkar, J. J. (2021). “Studies in systems, decision and control 336 multi-criteria decision making” (Vol. 336). Springer Nature Singapore Pte Ltd. https://doi.org/10.1007/978-981-33-4745-8

- Ulutaş, A., Balo, F., Mirković, K., Stević, Ž., & Mostafa, M. M. H. (2023). MCDM model for critical selection of building and insulation materials for optimising energy usage and environmental effect in production focus. Journal of Civil Engineering and Management, 29(7), 587–603. https://doi.org/10.3846/jcem.2023.19569

- Ulutas, A., Balo, F., & Topal, A. (2023). Identifying the most efficient natural fibre for common commercial building insulation materials with an Integrated PSI, MEREC, LOPCOW and MCRAT Model. Polymers, 5(6), 1500. https://doi.org/10.3390/polym15061500

- Vadivel, M. S., Sequeira, H. A., Jauhar, K. S., Baskaran, R., & Rajkumar, R. S. (2020). Application of multi-criteria decision-making method for the evaluation of tamilnadu privet bus companies. ‘Soft Computing: Theories and Applications, 209–222. https://doi.org/10.1007/978-981-4032-5_21

- Yehuala, G., Worku, Z., Angassa, K., Nkambule, T. T., & Fito, J. (2022). Electrochemical degradation of chemical oxygen demand in the textile industrial wastewater through the modified electrodes. Arabian Journal of Science and Engineering, 47(5), 5911–5922. https://doi.org/10.1007/s13369-021-05776-4

- Zakeri, S., Chatterjee, P., Konstantas, D., & Ecer, F. (2023). A decision analysis model for material selection using simple ranking process. Scientific Reports, 13(1). https://doi.org/10.1038/s41598-023-35405-z

- Zarghami, M., & Szidarovszky, F. (2011). Introduction to Multicriteria Decision Analysis. Multicriteria Analysis, 1–12. https://doi.org/10.1007/978-3-642-17937-2_1

- Zhang, H., Peng, Y., Tian, G., Wang, D., & Xie, P. (2017). Green material selection for sustainability: A hybrid MCDM approach. PloS ONE, 12(5), e0177578. https://doi.org/10.1371/journal.pone.0177578

- Zozaya, N., Moreno, J. O., & Vega, Á. H. (2018). Multi-Criteria Decision Analysis in Healthcare; its usefulness and limitations for decision making. Ana Moreno & Robin White.