?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.ABSTRACT

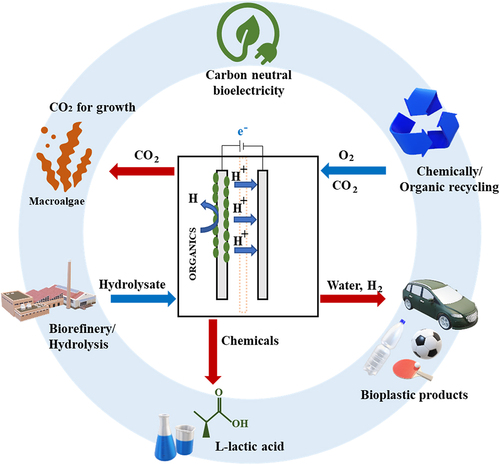

The imminent need for transition to a circular biorefinery using microbial fuel cells (MFC), based on the valorization of renewable resources, will ameliorate the carbon footprint induced by industrialization. MFC catalyzed by bioelectrochemical process drew significant attention initially for its exceptional potential for integrated production of biochemicals and bioenergy. Nonetheless, the associated costly bioproduct production and slow microbial kinetics have constrained its commercialization. This review encompasses the potential and development of macroalgal biomass as a substrate in the MFC system for L-lactic acid (L-LA) and bioelectricity generation. Besides, an insight into the state-of-the-art technological advancement in the MFC system is also deliberated in detail. Investigations in recent years have shown that MFC developed with different anolyte enhances power density from several µW/m2 up to 8160 mW/m2. Further, this review provides a plausible picture of macroalgal-based L-LA and bioelectricity circular biorefinery in the MFC system for future research directions.

Graphical Abstract

1. Introduction

Industrialization, the engine of urbanization and economic expansion, has accelerated the development of petrolic energy and polymer sectors in association with the growth of the global population and affluence [Citation1]. Meanwhile, due to the outbreak of the COVID-19 pandemic, a nearly 130-fold increment of plastic waste has been perceived over the past 10 years (2011–2020) and reached approximately 8.51 billion tons as an unprecedented increase in single-use plastics (SUPs), including protective medical suits and face masks [Citation2]. It is assessed that mismanaged plastic wastes are omnipresent and outweigh fish in the marine environment, with at least 7 million tons of plastic debris dumped into the ocean annually, which has caused catastrophic damage and deaths of marine animals [Citation3]. Such vivacious SUPs production results in well-established concerns that are deleterious to the environment, such as land pollution, air pollution, and marine pollution that causes anthropogenic CO2 emissions. The International Energy Agency (IEA) website shows that the rise in carbon footprint from 2005 to 2021 has reached an 18% increment [Citation1]. This linear economy has been heavily reliant on the overexploitation of fossil fuels and natural resources, which drastically impairs the life of future generations [Citation3]. Suppose the carbon footprint continuously rises at its current rate into the atmosphere. In that case, the dynamic equilibrium of the carbon cycle will diverge, resulting in irreversible changes in the climate system. Hence, sustainable practices and concerted efforts to minimize carbon footprint whilst simultaneously maintaining global economic growth have to be initiated through various technological interventions to meliorate the current linear economy toward a biobased bioeconomy.

In pursuing the United Nations’ 7th Sustainable Development Goal (SDG), the bioeconomy has to be designed to generate affordable, clean, and sustainable energy [Citation4]. From the point of view of sustainability, this concept covers three major points: (1) maximum utilization of organic resources; (2) minimum energy suffices the production processes; (3) the waste produced from one operation becomes the feedstock for another [Citation5]. Notably, the circular bioeconomy model has drawn significant attention to address the environmental burden and resource depletion caused by the linear economy model. In the circular bioeconomy model, the maximum energy potential and value of the biomass can be aroused, extracted, and retained to their maximum extent via the circular biorefinery approach. The circular biorefinery approach is a regenerative closed-loop method that conserves the longevous biomass resources to maximize economic productivity and minimize waste generation at the end of each service life, which helps mitigate the pressure on the environment [Citation6]. Recently, the concept of holistic zero-waste circular biorefinery has been successfully applied to the co-production of bioethanol and biogas (biomethane) from red macroalgae Eucheuma denticulatum residues by Loh et al. [Citation7]. They concluded that the developed macroalgae-based circular biorefinery system demonstrated an exergy efficiency of 73.74% with a functional exergy efficiency of 15.30% and the cascading approach allowing an almost complete conversion of the macroalgal biomass [Citation7]. A macroalgae-based circular biorefinery system for bioethanol and L-lactic acid (L-LA) was also established by Wong et al. [Citation8] using red macroalgae Eucheuma cottonii residues, manifesting the electricity generated from the combined heat and power plant of the system proficient at supplying up to 70% of the plant’s total electricity requirement. Further, Grasa et al. [Citation9] investigated the economic evaluation using brown macroalgae Laminaria sp. as biomass for large-scale L-LA production. They revealed that the minimum viable selling price is reduced by 34% compared with the current selling price (USD 3.83/kg), demonstrating an economic feasibility and sustainability biorefinery approach [Citation9]. To this extent, the macroalgae biomasses tally with the circular biorefinery concept compared to lignocellulosic biomass (LCB), a cornerstone of the biorefinery to date due to non-competitiveness with food supply and fast growth rate [Citation10,Citation11].

To achieve carbon neutrality and a sustainable circular biorefinery, durable biobased products need to be developed without sacrificing performance. Various strategic paths to produce carbon-neutral macroalgal bioenergy and bioplastics have been mapped out with expanding research outputs [Citation12,Citation13]. At the upshot of these efforts, one of the latterly proposed alternative bioenergy sources is microbial fuel cells (MFC) which generate renewable electricity using active microorganisms or bacteria as a biocatalyst in an anaerobic anode chamber [Citation13]. Gebreslassie et al. [Citation13] revealed that brown macroalgae Saccharina japonica was successfully metabolized by methanogenesis in a H-shape dual-chamber MFC for bioelectricity production with a maximum power density of 1820 mW/m2. Further, Okoroafor et al. [Citation14] detailly calculated the substitution potential of petrolic electricity with bioelectricity produced via MFC and evaluated global warming potential (GWP) impacts. Initially, the GWP was evaluated based on the United Kingdom’s electricity demand; further, GWP for bioelectricity MFC was evaluated for petrol-based electricity. It has been deduced from the calculations that 15.7–19.5 ktons of CO2 equivalents can be diminished by bioelectricity production of 10,030 GJ each year [Citation14]. Furthermore, using renewable carbon in bioelectricity helps curtail the dependency on fossil fuels, which can further control or reduce the carbon footprint throughout this life cycle [Citation15].

In addition to tremendous efforts to reverse global climate change, a valuable novel building block for poly-L-lactic acid (PLLA) bioplastic, notable L-LA, can also produce from macroalgal biomass via the biotechnological approach by using lactic acid bacteria (LAB) to valorize carbohydrate contents [Citation11]. PLLA is a biodegradable thermoplastic with properties similar to petrolic plastics (polypropylene, polyethylene, polystyrene, and polyamide) and offers added advantages due to generating a lesser carbon footprint on the environment with a feasible end-of-life strategy [Citation16]. By the biorefinery principle Task 42, the co-production of bioenergy and value-added biochemicals from biomass in an integrated system are advocated to advance the material wealth of human society in terms of materials and energy supply for a new sustainable industrial development [Citation17]. In an evaluation of the carbon footprint of biorefinery producing biochemicals and bioenergy from wastewater in an MFC model using an attributional life cycle assessment (LCA) assay, the authors revealed that the best scenario was the integration of the production chain compared to standalone production, resulting in a 112.18% diminution to the net system emission by attaining −2.2 global warming ratio compared to standalone processing [Citation18]. Thus, a cascading macroalgal biorefinery system in the MFC model is recommended for a zero-waste conversion technology to address the dilemma of bioelectricity and L-LA. Once fully optimized, the cascading macroalgal biorefinery system has the potential to transform the energy and polymer sector into a climate-neutral hub whilst helping the circular bioeconomy.

This paper is systematically designed to critically review the successful development of bioelectricity and L-LA from macroalgal biomass for bioenergy and bioplastic applications. The prospects and state-of-the-art technological development of MFC for integrated bioprocesses as a strategy for carbon neutrality and sustainability were enclosed. In addition, the advantages of key bioprocesses that are employed for macroalgae valorization for L-LA and bioelectricity production were also discussed extensively. Based on the different technological employment, some recommendations were made for future research directions on the seamless integration of macroalgal-based L-LA and bioelectricity production. Hence, this review provides essential technical enlightenment on the contemporary status and future trends of MFC applications in pursuit of a sustainable circular biorefinery.

2. Marine macroalgae: the future of sustainable bioenergy and bioplastic

The research interest in utilizing marine and cultivated macroalgal biomass began to arise once hindrances associated with LCB emerged, mainly the harsh thermochemical pretreatment involved in removing the lignin complexes [Citation19]. Among 29,800 identified macroalgae strains, merely 230 strains have been studied for biorefinery, and their potential for miscellaneous applications is irrefutable [Citation20]. The cradle-to-gate delineation of the development of macroalgal bioelectricity and bioplastics is illustrated in . Macroalgae are aquatic photosynthesis and carbohydrate-rich multicellular eukaryotic organisms ubiquitously present in marine habitats, hence the acronym ‘marine plants’ or ‘seaweeds.’ Macroalgae are of three types based on the natural pigmentation type: red (Rhodophyta) taxonomical group colored by phycoerythrin, brown (Phaeophyta) taxonomical group colored by fucoxanthin, and finally green (Chlorophyta) taxonomical group colored by chlorophylls. All taxonomical groups contain specific cell wall polysaccharides such as cellulose and phycocolloids in varying compositions, which contribute to the diversity of macroalgal species. Floridean starch, laminarin and amylopectin are usually the storage polysaccharides for red, brown, and green macroalgae, respectively. Their lack of recalcitrant lignin complexes indicates that less energy-intensive bioprocesses can be employed to recover value-added bioproducts of commercial interest, favoring techno-economic and LCA analyses of any potential biorefinery processes that utilize macroalgae as feedstock [Citation8,Citation10]. Moreover, high and specialty easy-degradable polysaccharides (65–95 wt%) in each taxonomical group of macroalgae species offer extensive features for either platform compounds or direct use in the biorefinery [Citation21].

Figure 1. Schematic representation of macroalgal bioelectricity and bioplastics from cradle-to-gate perspectives for durable applications.

From the perspective of bioelectricity generation and L-LA fermentation, the significant disparity between the three macroalgae species relies upon their inherent sugar composition, and the conversion yield will be evaluated by the fermentation performance of the endowing lactic acid bacteria on the derived rare sugars. depicts the major macroalgae-derived rare sugars via hydrolysis, revealing that rare sugars in the form of D-glucose can be found in all macroalgae taxonomical groups representing the appearance of cellulose compounds in the macroalgal cell wall [Citation11]. Red macroalgae, with Gracilaria sp. and Eucheuma sp. as the representative species, possess agarose and carrageenan as the heterogeneous phycocolloids composed of agarobiose, D-galactose, and 3,6-anhydro-D-galactose, of which 3,6-anhydro-D-galactose is non-metabolize [Citation12,Citation22]. Brown macroalgae are copiously cultivated for the extraction of alginate, laminarin, mannitol, and fucoidan, which is widespread in food processing applications. L-fucose, D-mannose, D-galactose, mannuronic acid, and glucuronic acid are the major monosaccharides in brown macroalgae hydrolyzates [Citation23,Citation24]. In addition, green macroalgae mainly embrace ulvan as the sole heterogenous polysaccharide composed of L-iduronic acids and rare sugars, including L-rhamnose and D-tagatose [Citation25]. Thus, macroalgae are considered sustainable sources of rare sugars for biorefinery purposes. It also addresses the sustainability concerns related to food security and arable land suffered by the edible crops and LCBs, as macroalgae are abundant in supply and generally grow in marine habitats [Citation11].

Furthermore, macroalgae are considered a year-round available feedstock for biorefinery purposes due to their bioavailability properties with a short average growth period of 10–15 days [Citation26]. The global industry exploits 35.08 million tons of 230 macroalgae species cultivated worldwide in 2020, dominated by red macroalgae species, which seizes 18.84 million tons and corresponds to 53.70% of the total productivity [Citation27]. Besides, the global annual production of wild stock macroalgae in seashore without any farming techniques bestows a net primary production (NPP) of 1.32 Pg carbon per year, where this productivity is aligned with the Amazon rainforests. NPP is defined as the balance between photosynthetic CO2 sequestration and CO2 released by autotrophic respiration, in which the positive NPP value describes the environment possessing high initial biomass and higher biomass productivity [Citation28]. Alongside macroalgae propagation from aquaculture or wild stocks as the feedstock for biorefinery purposes, carbon offsetting can occur simultaneously by photosynthetic CO2 sequestration. This is mainly due to macroalgal habitats being the most extensive and productive of all coastal vegetated ecosystems. Raven [Citation29] revealed that strongly autotrophic macroalgae communities globally sequester approximately 1.6 gigatons of carbon/year through their net production. Regarding climate change, Seghetta et al. [Citation30] concluded that the net removal of CO2 from the atmosphere by macroalgae aquaculture and biorefinery is about 190 kg of CO2 equivalents per hectare of cultivation area. From the perspective of CO2 sequestration, the intense photosynthetic activity by macroalgal forests obviates ocean acidification, resulting in a balanced pH for marine ecosystems. In fact, ocean acidification represents a threat that negatively impacts the growth and survival of calcifying organisms, including coral reefs, oysters, shrimps, and clams by wresting the minerals used by these organisms to build their shells and skeletons [Citation31].

In addition, bioenergy and bioplastics produced from macroalgal biorefinery will be zero net addition of CO2 to the atmosphere; any CO2 emitted in combustion originated from that sequestered during recent photosynthesis and can potentially be recaptured in the same way [Citation1]. Moreover, Plastics Europe Association (PEA) conducted the LCA of macroalgal-based bioplastic and concluded that macroalgae biomass has substantial potential to produce value-added biochemicals such as L-LA for bioplastic production [Citation32]. In short, the round-of-the-year availability of macroalgal biomass, the ability for CO2 sequestration, and high carbohydrate content increase their potential for bioenergy and bioplastics production.

2.1. Bioenergy

Interest in biomass-to-energy (B2E) strategies has peaked in the quest for establishing a carbon neutral cycle by drawdown CO2 released, solving both energy and environmental crises simultaneously. Renowned for its reliable and developed technology, B2E is an eco-friendly approach that can generate green energy from biomass or post-consumer waste [Citation33,Citation34]. Among the available B2E technologies, MFC has demonstrated promising prospects in directly converting biomass to bioelectricity over exoelectrogens (anodophilic) microorganisms [Citation15]. In general, the bioconversion of organic matter for bioelectricity production from MFC could be depicted in . The MFC consists of two chambers, an anode chamber and a cathode chamber, separated by a proton exchange membrane (PEM). Further, the exoelectrogens are typically immobilized on the surface of the anode, resulting in a biofilm over the anode surface to debase the biomass, releasing electrons and protons, which later be used for bioelectricity production [Citation35]. The bioelectricity potential and vitality transformation of MFCs rely significantly on the efficiency level attained by both the biodegradation process and electron transfer [Citation36]. Compared to conventional anaerobic degradation, MFC manifests greater potential with its higher energy recovery efficiency from biomass [Citation13]. Typically, conventional anaerobic degradation produces biogas from biomass, which is susceptible to 20% entropy lost during its combustive conversion into useable bioelectricity [Citation8]. Contrarily, such combustive conversion is negligible for MFC as its mechanism involves coupling exoelectrogen metabolism and electrochemical reaction to convert the chemical energy present in the biomass into usable electrical energy. Moreover, MFC can also operate under ambient temperature, thus offering a higher safety index and exergy efficiency for bioelectricity generation [Citation37].

Figure 3. Microbial fuel cells (MFC) for bioelectricity production from a variety of biomass and waste sources.

Gebreslassie et al. [Citation13] proved the feasibility of macroalgae for the co-production of bioelectricity and hydrogen by applying red macroalgae Saccharina japonica as substrate in MFC. The authors revealed that energy recovery of 17.3% was attained with an optimum power density and hydrogen production of 1.82 W/m2 and 110 mL/g, respectively [Citation13]. As a further illustration, S. japonica substrate in the anode chamber is oxidized by fermentative bacteria under dark fermentation operation to produce hydrogen; however, carboxylic acids, including acetic acid, butyric acid, propionic acid, and lactic acid (LA) were produced simultaneously as the by-products. The produced carboxylic acids are strongly hydrophilic; thereby, the recovery of carboxylic acids from fermentation broths requires a complicated separation process, which hinders their practical application [Citation13]. Hence, the produced carboxylic acid molecules [composition: R-COOH] participated in the anodic reaction and oxidized by exoelectrogens into a reduced form for electrons and protons production, which can be depicted in Eq. (1). The released electrons from the anodic reaction are then transferred to the anode through the exoelectrogen cell membrane, where anode acts as a terminal for the electron transfer process to the cathode chamber. At the cathode chamber, the electrons transported from the anode combine with the protons, which traverse the PEM, resulting in the creation of water molecules in the presence of oxygen [Citation38]. This reaction completes the electron flow in the circuit, balancing the charges caused by the anodic reaction and generating electric current.

Notably, CO2 is released as a biogenic by-product of microbial respiration and decomposition of biomass during the anodic reaction, in which the exoelectrogens and fermentative bacteria in the anode chamber of the MFC oxidize S. japonica substrate as their energy source. From Eq. (1), R-COOH compounds are broken down, releasing biogenic CO2 as an inherent metabolic by-product, considered a natural carbon cycle [Citation13]. Interestingly, the released biogenic CO2 can indirectly help mediate the pH shift between the two chambers by participating in the carbonate buffering reactions, shown in Eq. (3) [Citation35]. Okoroafor et al. [Citation14] concluded that adding buffer salts such as phosphates and carbonates to the anolyte and catholyte is not economically feasible for large-scale production and will contribute to an 80% increment of GWP compared to CO2 as a buffering agent. Furthermore, an integrated MFC system for bioelectricity and carbon capture was developed by Zhang et al. [Citation39] using an algal biocathode with a layer of biofilm consisting of photosynthetic algae Chlorella vulgaris. With this technique, the released biogenic CO2 will be supplied to promote better growth and photosynthesis of the algae biomass [composition: (CH2O)n], improving carbon fixation [Citation39]. Eq. (4) depicts that oxygen is generated as an electron acceptor by photosynthesis, which later is used in the cathodic reaction, creating a sustainable cycle loop. Thus, MFC aligns with green chemistry and provides a framework for contributing to achieve the carbon neutrality goal as they operate under mild conditions to convert the chemical energy of biomass to electrical energy through microbial metabolism. The detailed reaction for carbon capture and fixation is further discussed in Section 3.2.

Table

2.2. Bioplastic

Over the years, petrolic plastic consumption and production have grown significantly, owing to its adaptability and affordability, making it ideal for widespread applications [Citation3]. Global plastics production has reached over 360 million tons annually, dominated by petrolic plastics with seizes 276 million tons and up to 50% of that is for single-use purposes () [Citation40]. Jem and Tan [Citation41] reported that 82% of plastic waste from total plastic production was excluded from recycling, in which the majority of plastic waste was either heaped in landfills or cremated, with the remainder spewed into the ocean as litter. As for the plastic waste dumped into the oceans, the carbonyl group of petrolic plastic absorbs UV radiation below 280 nm, making the polymer susceptible to photo-oxidative degradation, breaking down into petrolic microplastics [Citation40]. Petrolic microplastic contamination has reached an alarming level as they are ubiquitous and available for ingestion by aquatic organisms. These aquatic organisms will suffer from entanglement and starvation as their stomachs become filled with plastic, leading to death. Moreover, petrolic microplastics can cause genotoxicity and immunotoxicity to marine life as they contain polycyclic aromatic hydrocarbons [Citation42]. Recent research has shown overwhelming evidence that microplastics are in tandem with other toxic chemicals (heavy metals and organic metals), serving as a vector for their transport in the environment, which then be enriched in the food chain to endanger not only marine life but also human beings [Citation43]. Besides, the accumulation of plastic waste in landfills is a growing environmental concern as petrolic plastics take around a century or more to degrade. During thermal-oxidation degradation of petrolic plastics, methane and ethylene will be produced and contribute to CO2 emission when exposed to sunlight and heat, impacting human health and climate [Citation3].

Figure 4. World production of synthetic plastics and bioplastics from 2011 to 2020. Adjusted from [Citation40].

![Figure 4. World production of synthetic plastics and bioplastics from 2011 to 2020. Adjusted from [Citation40].](/cms/asset/d9445ed4-97fa-4f3d-a9fb-bc2faf76db88/kbie_a_2236842_f0004_oc.jpg)

The awareness of the pressing environmental issue regarding plastic pollution has diverted attention toward the utilization of alternatives, such as biodegradable plastic (bioplastic) derived from a biopolymer. Unlike petrolic plastics for remaining unchanged for centuries, bioplastics can be degraded relatively quickly by the action of microorganisms, namely biodegradation, with a specific surface degradation rate of 21 µm/year under specific conditions [Citation44]. Bioplastics can be broken down into nutrient-rich biomass, CO2, and inorganic compounds, leaving no toxins and residue behind. The nutrient-rich biomass can be converted into fertilizer or utilized as feedstock for biorefinery purposes, while the CO2 released can be sequestrated for photosynthetic activity by Plantae [Citation45]. Thus, CO2 emissions are avoided as no carbon is involved in the manufacturing process of bioplastics. One of the most extensively researched biopolymers for bioplastics is polylactic acid (PLA). PLA is a biodegradable aliphatic thermoplastic polyester and has excellent market prospects, with a range of applications from industrial to civilian use [Citation46]. Briefly, PLA can be defined as a chain-formed oligomer of LA that polymerizes by either a Ring-Opening reaction of lactide or by a Direct Poly-Condensation of high-purity LA that can be derived from macroalgal biorefinery [Citation41,Citation47,Citation48].

Its monomer, LA, can be found in either D(-) or L(+) enantiomeric forms due to an asymmetric carbon atom, but L-LA is the dominant isomer for commercialized PLA. Compared to L-LA, D-LA usage in biomedical applications is skeptical due to its harmful to human health, especially will cause neurotoxicity in the human body [Citation49]. This is because L-LA is the primary endogenous agonist of hydroxycarboxylic acid receptor 1 (HCA1), which naturally occurs in living organisms and the human body has enzymes and metabolic pathways specifically designed to metabolize L-LA. Contrarily, D-LA is not naturally produced by the human body and the enzymes do not efficiently metabolize D-LA, leading to the accumulation of D-LA in the body, which can disrupt the normal physiological processes of human beings [Citation50]. Excessive accumulation of D-LA can result in acidosis, an abnormal decrease in blood pH, affecting detrimental effects on various bodily functions. Prolonged exposure to acidic conditions can be detrimental to cells and tissues. Further, heaping D-LA can induce inflammation and impede tissue healing and generation, making D-LA not suitable for biomedical applications [Citation49]. Hence, good biocompatibility is an important reason for the wide use of poly-L-lactic acid (PLLA) in the field of biomedicine.

Globally, a nearly 14-fold increment of PLLA has been produced compared to 2011, reaching circa 22.72 million tons in 2020 [Citation40]. The drastic growth in annual PLLA capacity (25% of bioplastic production, ) stems from its high mechanical strength and durability properties similar to petrolic plastics [Citation46]. The mechanical performance of PLLA is characteristic of glassy polymers with low deformation and high melting temperature (160–180°C), which is suitable for different processing means, including melt-extrusion molding, vacuum molding, foam molding, and injection molding. The good flexural strength (up to 140 MPa) and processing ability of PLLA yield various plastic products, such as bioplastics, filament for fused deposition modeling, and fabrics for industrial and civilian use [Citation46,Citation51]. With its biocompatibility properties and approval by the United State Food and Drug Administration (FDA) for biomedical applications, high molecular weight PLLA has been used to produce non-dismantling surgical sutures and bone screws, while low molecular weight PLLA as a slow-release drug-packaging agent [Citation45]. Casalini et al. [Citation52] manifested that the degradation of PLLA material by the enzymes produced by the human body can be used for drug release. By controlling the metabolism rate and composition of PLLA material in the capsules, the therapeutic drugs can quickly target the lesion site, improve its bioavailability, and reduce its toxic side effects and toxicity to other tissue types, leading to a benefit for drug delivery and as a material for implants structure [Citation52].

To comprehensively compare PLLA with petrolic plastics from the point of view of carbon footprint, a cradle-to-grave LCA along with Intergovernmental Panel on Climate Change method was performed by Morão and de Bie [Citation53]. The authors revealed that the production cycle of PLA-based plastic demonstrated lower environmental burdens than petrolic plastic by uptaking 1.8 tons of CO2 equivalents per ton of plastic produced [Citation53]. In addition, Abdul-Latif et al. [Citation54] revealed that the annual production of macroalgal-based PLLA should be more than 600 million tons to replace the petrolic plastics for achieving carbon neutrality, which is calculated by using carbon emission pinch analysis with total CO2 emission levels and plastic production in the view of the year 2016 as base study. Based on the current PLLA production data, there is an urgent need to accelerate our efforts to increase macroalgae-based L-LA production to meet the high demand for PLLA. Besides diminishing carbon footprint, Coppola et al. [Citation55] also reported that the production of PLLA saves circa two-thirds of the energy required for petrolic plastics production, which offers an energy-effective process. Thus, macroalgal-based PLLA is a promising solution to defossilize the economy.

In order to meet the global market demand, large amounts of macroalgal-based L-LA are essential for the industrial-scale production of PLLA. L-LA can be derived by chemo-catalytic or microbial fermentation processes. The chemo-catalytic process uses petrolic chemicals such as propionaldehyde and acetaldehyde as feedstock which may be subject to the potential supply problem of crude oil and its dramatic price variation. The drawback of the chemo-catalytic process is that it involves environmentally unfavorable chemicals (hydrogen cyanide, sulfuric acid, and sodium hydroxide) and produces only the racemic (50:50) mixture of L-LA and D-LA, which is not desirable for food and biomedical applications due to the metabolic issues that D-LA may cause. Further, the racemic mixture is not feasible for PLA production, typically requiring LA with high optical purity (e.g. ~99% L-LA or ~ 99% D-LA) [Citation56]. Then, the microbial fermentation process outcompetes the chemo-catalytic process for high optical purity L-LA production as particular microbes have a specificity of ldhL gene that secretes L-lactate dehydrogenase (L-LDH) enzymes, which can only convert pyruvate to L-LA. Typical microbes employed for L-LA production are low guanine and cytosine-content Gram-positive bacteria, namely, lactic acid bacteria (LAB) [Citation57]. LAB is a group of microorganisms that belong to the family Lactobacillaceae and is characterized by their ability to produce L-LA via carbohydrate metabolism. Being considered the macroalgal hydrolyzate composed of mixed rare sugars, which need to be completely metabolized for better L-LA conversion yield, the LAB offers an excellent regulatory mechanism known as carbon catabolite repression (CCR) for efficient carbohydrate metabolism [Citation58].

CCR is the central governing mechanism in LAB for the regulation of rare sugar uptake, which ensures cellular resource efficiency by selectively regulating the uptake and metabolism of favorable carbon sources in the presence of non-favorable carbon sources, leading to both the favorable and non-favorable carbon sources can be metabolized albeit in a different rate [Citation59]. In brief, CCR in LAB is regulated by different elements participating in rare sugar transport and metabolism, including sugar phosphotransferase system (PTS), enzyme I (EI), phosphocarrier histidine protein (HPr), and catabolite control protein A (CcpA) acts as the trans-acting repressor [Citation60]. PTS is a complex transport system responsible for the uptake and phosphorylation of various rare sugars in the macroalgal hydrolyzate to acquire energy and regulate carbohydrate metabolism. The PTS transporters are sugar specific and phosphorylate the incoming sugar at the expense of phosphoenolpyruvate (PEP), mirroring the most suitable carbon sources available in the hydrolyzate. Notably, the energy for sugar transport is derived from PEP by donating the phosphoryl group as an energy carrier through the phosphotransferase reaction. This reaction converts PEP to pyruvate and transfers the phosphoryl group to a histidine residue on EI. EI, in turn, transfers the phosphoryl group to HPr. From the HPr, the phosphoryl group is transferred to the permease complex of the LAB cell. Then, the phosphoryl group is further transferred from the permease complex to the incoming sugar molecules, resulting in sugar phosphorylation. This phosphorylation step enhances the diffusion of sugar into the LAB cell and contributes to its subsequent metabolism [Citation61]. Further, CcpA is a regulatory protein that acts as a transcriptional regulator facilitated in mediating CCR by controlling the expression of genes involved in metabolizing non-favorable carbon sources when the favorable carbon source is available. The CcpA will bind to specific DNA sequences called catabolite-responsive elements (cre), which are generally found in the promotor regions of target genes. The binding of CcpA to cre sequences modulates gene expression, leading to activation or repression of target genes involved in the utilization of non-favorable carbon sources, which further enhances carbohydrate metabolism [Citation60]. Along with this functionality, Ahorsu et al. [Citation62] revealed that the probiotic-based LAB Bacillus coagulans can simultaneously metabolize xylose in the presence of glucose for L-LA production. Besides, mesophilic LAB Lactobacillus plantarum also showed clear diauxic growth in a glucose-mannose-galactose mixture by attaining a L-LA conversion efficiency of approximately 65% [Citation47].

Depending on the particular LAB strain and the specificity of aldolase, the L-LA fermentation pathway can be divided into homolactic fermentation and heterolactic fermentation process. LAB possesses the aldolase enzyme is considered the homofermentative LAB, which can convert the carbohydrate-rich hydrolyzate exclusively into L-LA. Homofermentative LAB includes the strain from Lactococcus, Streptococcus, Pediococcus, Lactobacillus, and Enterococcus sp [Citation57,Citation63]. Due to the high energy yield characteristic that is beneficial for cell anabolism and cellular growth, the glucose molecule is the favorable carbon source for most of the LAB strains. In this perspective, glucose molecules will be metabolized via the Embden-Meyerhof glycolytic pathway by the homofermentative bacteria. For an insightful understanding of the Embden-Meyerhof glycolytic pathway, the glucose metabolism by homofermentative LAB, Lactobacillus delbrueckii subsp. Bulgaricus is illustrated in . Glucose molecules are phosphorylated to glucose-6-phosphate (G6P) and transported into the cell by facilitated diffusion through PTS at the expense of one adenosine triphosphate (ATP) molecule. The ATP yield per glucose molecule diffused inside the cell is 2. Then, the G6P will convert to pyruvate by glycolysis yielding two molecules of ATP and one molecule of reduced nicotinamide adenine dinucleotide (NADH) per pyruvate [Citation63]. The overview of the main steps and reactions involved in the glycolysis pathway is depicted in . During the homolactic fermentation process, the G6P is phosphorylated by the enzyme phosphofructokinase-1, consuming one ATP molecule, forming fructose-1,6-diphosphate (FDP). The FDP is then cleaved into three-carbon molecules: dihydroxyacetone phosphate (DHAP) and glyceraldehyde-3-phosphate (G3P). DHAP is an isomer for G3P, but only G3P can directly continue through the next steps of glycolysis. Although both three-carbon molecules exist in equilibrium, but the equilibrium is ‘pulled’ strongly downward as G3P is depleted. Thereby, DHAP will convert into G3P by the enzyme triose phosphate isomerase, ensuring full utilization of both molecules. The G3P molecules undergo oxidation by the enzyme glyceraldehyde-3-phosphate dehydrogenase, resulting in the production of NADH and the formation of 1,3-diphosphoglycerate (1,3-DPG). NADH carries high-energy electrons that will later be used in ATP synthesis. Subsequently, 1,3-DPG donates one phosphate group to the adenosine diphosphate (ADP) molecule for producing an ATP molecule, forming 3-phosphoglycerate (3-PG). For further reaction, the 3-PG is converted into its isomer, 2-phosphoglycerate (2-PG). Then, 2-PG loses a molecule of water via a dehydration reaction catalyzed by enolase, becoming PEP. PEP is an unstable molecule, poised to transfer its phosphate group to ADP molecules for ATP generation. As it loses its phosphate, PEP is converted to pyruvate, the end product of glycolysis. This reaction is catalyzed by the enzyme phosphoglycerate kinase [Citation64]. Consequently, L-LA is produced by the action of L-LDH on the pyruvate. On a molecular level, the metabolization of pyruvate by L-LDH is an additional means of NADH recycling. NADH plays a crucial role in the recycling of NAD+ to maintain glycolysis and the production of ATP through the L-LA fermentation, allowing the continuous breakdown of glucose and energy production under anaerobic conditions. The recycling pathway for NADH can be described as follows: (1) During glycolysis, the NAD+ is reduced to NADH when G3P is converted to 1,3-DPG; (2) During L-LA fermentation, a hydride ion (H−) from NADH is transferred to pyruvate for the formation of L-LA, resulting the regeneration of NAD+. By regenerating NAD+ from NADH, L-LDH ensures the availability of NAD+ for the continuation of glycolysis [Citation65]. However, the produced L-LA has to be actively transported out of the cell at the expense of an ATP molecule. This is because of the fact that at high intracellular pH, L-LA dissociates into lactate and a proton. By maintaining the intracellular pH and proton motive force, this proton has to be exported via the plasma membrane proton ATPase at the expense of one ATP per proton. Once exported, at a low extracellular pH, the L-LA is again present in its protonated form. In theory, one molecule of glucose can produce two molecules of L-LA through homolactic fermentation [Citation66].

Figure 5. Simplified illustration of the cellular mechanisms involved in lactic acid production under homolactic fermentation and self-inhibition in the cytoplasm of Lactobacillus delbrueckii subsp. bulgaricus in anaerobic wort fermentation.

In contrast to homofermentative LAB, heterofermentative LAB can decompose carbon sources into a variety of biochemicals, including L-LA, acetic acid, bioethanol, and CO2. Whereas CO2 gas detection is a diagnostic test for heterofermentative from homofermentative fermentation. Heterofermentative LAB includes the strain from Leuconostoc, Oenococcus, and Weissella sp [Citation57,Citation63]. The typical reaction pathways of heterofermentative fermentation include the phosphogluconate pathway, pentose phosphate pathway, and phosphoketolase pathway (). During the phosphogluconate pathway, the glucose molecules are initially phosphorylated into G6P through the process of PTS and participate in the glycolysis process, which occurs in the cytoplasm of the LAB cell. The G6P is further oxidized by the enzyme glucose-6-phosphate dehydrogenase, resulting in the production of one molecule of NADH and 6-phosphogluconic acid. Through the pentose phosphate pathway, two half-reactions occur simultaneously: (1) 6-phosphogluconic acid is oxidatively decarboxylated by the enzyme 6-phosphogluconate dehydrogenase; (2) NAD+ is reduced to NADH. The overall reaction is exergonic, releasing energy that is then used to decarboxylate the 6-phosphogluconic acid, generating CO2 and ribulose 5-phosphate (Ru5P). The Ru5P molecule is then converted into other pentose phosphate sugar, ribose-5-phosphate (R5P) or xylulose-5-phosphate (X5P), which is catalyzed by the enzyme phosphopentose isomerase. The interconversion of Ru5P and R5P allows the synthesis of essential cellular components, including nucleotides and coenzymes for cell propagation. Subsequently, the X5P molecule is subjected to the phosphoketolase reaction and cleaved by the enzyme phosphoketolase, resulting in the production of two molecules including G3P and acetyl phosphate (AcP). Then, the G3P generated from the phosphoketolase reaction is further metabolized through the usual glycolytic pathway, similar to the steps in the conventional Embden-Meyerhof glycolysis pathway. Whereas G3P will enter the downstream steps of glycolysis, leading to the production of ATP and L-LA. While the other product of the phosphoketolase reaction, AcP is decarboxylated by the enzyme pyruvate decarboxylase, resulting in the release of CO2 and the formation of acetaldehyde. Lastly, acetaldehyde is reduced by the enzyme alcohol dehydrogenase, utilizing NADH as a cofactor. This step converts acetaldehyde into bioethanol [Citation64]. In theory, one molecule of glucose can produce one molecule of L-LA and one molecule of bioethanol through heterolactic fermentation process [Citation66]. However, the CO2 release and co-production of L-LA and other organic acids, which required additional separation and purification processes also hindered the employment of heterofermentative LAB for microbial fermentation [Citation57]. Therefore, the utilization of homofermentative LAB is preferred over heterofermentative LAB for L-LA and PLLA commercial production due to it offering the high yield, productivity, and optical purity of L-LA.

3. Microbial fuel cell (MFC)

Contingent upon several cathodic reactions, MFC diversification has been developed to explore the particularity in the mechanism of distinct processes while enhancing the product output. Multi-faced applications based on the eventual anticipated product reorientated the nomenclature of MFC as microbial electrosynthesis system (MES), microbial desalination cell (MDC), electro-fermentation (EF), and microbial electrolysis cell (MEC). However, EF is explicitly applied for the production of a broad range of bioenergy and biochemicals, potentially achieving higher conversion efficiency (88%) than other MFC systems (44%) and conventional anaerobic fermentation (28%) [Citation67]. Thereby, the mechanisms of EF will be further discussed in the section below.

3.1. Electro-fermentation (EF) – Enhanced L-lactic acid and bioelectricity production

EF is an electrochemically induced technique that regulates electron flux in both working electrodes (anode/cathode) and microbial augmentation, directing redox reactions toward specific products at a higher rate [Citation67,Citation68]. In this context, the bioelectricity generated by polarized working electrodes is not the main energy source but is instead a product of interest and triggers the fermentation process driving toward an imbalanced intracellular oxidation-reduction potential (ORP) condition [Citation69]. The intracellular ORP is particularly important as it controls enzyme synthesis and gene expression in the electroactive bacteria, thus impacting the whole metabolic process and pathway. It can be estimated from the reduced/oxidized nicotinamide adenine dinucleotide (NADH/NAD+) ratio due to intracellular redox homeostasis [Citation70]. Variations in the NADH/NAD+ ratio of the system influence the direction of electron flux, which will be bidirectional and thereby help resolve the shortcomings of conventional fermentation for desirable product yields. Electron dispersion at the anode tends to reduce the NADH/NAD+ ratio, resulting in compensatory cellular regulation favoring pathways for NADH replenishment. Subsequently, this mechanism further elongated the oxidative and reductive conditions in the EF system and promoted the formation of ATP molecules for cell division and anabolism, which results in a higher yield of products. Choi and Sang [Citation71] revealed increased biochemical production yield in response to the additional NADH through cellular regulation.

Literature related to the virtues for the co-production of biochemicals and bioelectricity using EF system showed an increasing trend with expanding research outputs, leading EF technology a potential methodology for biorefinery [Citation72,Citation73]. An overview of the basic components comprising an EF system is mandatory to understand the significant role played by biofilm-producing microbes in the EF system. The typical EF system is assembled in a dual-chamber design consisting of an anodic and cathodic chamber divided by a PEM (). Other designs, including single-chamber and stacked EFs, are also retrievable from the literature [Citation74,Citation75]. depicts the tenable materials that can be employed in the fabrication of the EF system. The anodic chamber is made up of one of the two primary components of EFs, which is referred to as an anaerobic chamber, signifying the critical role of exoelectrogens and electron mediators in it. When subjected to an appropriate anaerobic condition, exoelectrogens in the anode function as biocatalysts, oxidatively decompose organic substrate or hydrolyzate into simple molecules or biochemicals. This results in the generation of electron-proton pairs, which are later transferred to the cathodic chamber through the external circuit and PEM, respectively. As the electrons travel along the external circuit, inducing the current flow in the connecting wire, thereby producing bioelectricity [Citation76]. Generally, aerating the anodic chamber is prohibitive, as it could retard the anaerobic performance of exoelectrogens in the EF system. This is because the presence of oxygen can result in the stripping of dissolved CO2 from the anode chamber, elevating the pH and inducing alkaline conditions. The pH shift may detrimentally affect the microbial community and electrochemical reactions, hurdling EF performance. Moreover, excessive aeration can lead to mechanical agitation and disruption of biofilm formation on the anode surface, reducing microbial activity and hindering electron transfer processes [Citation77].

Figure 7. Basic components of microbial fuel cells and the materials used for structure [Citation36].

![Figure 7. Basic components of microbial fuel cells and the materials used for structure [Citation36].](/cms/asset/e9a8ec64-5d92-4e92-8cc9-383443045d8d/kbie_a_2236842_f0007_oc.jpg)

Contrarily, the cathodic chamber is referred to as an abiotic chamber, comprising electron acceptors for the electron reduction process [Citation36]. Potassium ferricyanide (K3[Fe(CN)6]) is widely accepted as the electron acceptor, which attracts and dissipates the electron generated in an anode by reducing its Fe (III) ion to Fe (II) ion before reacting with the proton migrated from PEM. In terms of power generation, K3[Fe(CN)6] is an excellent electron shuttle, facilitating the transfer of electrons from the anode to the cathode, which enhances the electrochemical activity and performance of the EF system. This electron transfer stimulates the metabolic activity of exoelectrogens by balancing the redox reactions in the system [Citation78]. Farah et al. [Citation79] revealed that the power output attained are 8.33 W/m3 and 0.06 W/m3 for K3[Fe(CN)6] and phosphate buffer as catholyte, respectively, highlighting potassium ferricyanide possess superb catalytic activity. However, the utilization of K3[Fe(CN)6] is limited to large-scale applications due to poor reoxidation, which demands the catholyte to be frequently replaced. Further, the long-standing function of the system can be affected by the diffusion of ferricyanide ions across the PEM into the anodic chamber, resulting in aeration anodic chamber, which retard the metabolic activity of exoelectrogens [Citation80]. Then, oxygen is employed as an electron acceptor owing to its availability. Such a process only yields water as the final product, signifying its positive environmental benefit, but oxygen possesses limitations of limited diffusivity (~2 × 10−5 cm2/s) and low solubility (2–4 mM) in water [Citation81]. Considering the trend of miniaturization and integration for future EF systems, potassium permanganate (KMnO4) is one possible candidate oxidant due to its characteristics, including high oxidation ability, large redox potential, and high regenerability. KMnO4 is a potent oxidizing agent with a high standard reduction potential that can readily accept electrons from the anode, which enhances the electron transfer efficiency in the EF systems and promotes higher power generation [Citation82]. KMnO4 has been applied successfully to yield an output voltage of 3003 mV, which conveniently powers low-voltage appliances [Citation83]. In addition to the type of electron acceptor, catalyst activity is also a crucial factor in the performance of the EF cathode [Citation84]. Giordano et al. [Citation85] further boosted the power output of the EF system from 70 mW/cm2 to 115 mW/cm2 by applying 0.1 M sulfuric acid (H2SO4) as a supporting catholyte. This result underlined the positive effect of adding H2SO4 as a supporting catholyte in the EF cathodic chamber on the catalyst activity and electrochemical output [Citation85]. The addition of H2SO4 as a supporting electrolyte improves the overall ionic conductivity of the system for electron transfer between cathode and anode as H2SO4 dissociates in water to release hydrogen ions (protons) and sulfate ions. The presence of hydrogen ions in the catholyte facilitates proton conduction from the cathode to the anode through the electrolyte, enhancing the electrical conductivity and open-circuit voltage. In fact, proton transfer is essential to the overall electrochemical reaction occurring in the EF system [Citation82]. Besides, the sulfate ions generated from the dissociation of H2SO4 can act as the ion exchange sites of PEM due to sulfate ions approaching the behavior of sulfonic groups in Nafion®, increasing the mobility of protons through the membrane [Citation85].

Regarding electrode material selection, chemical stability, biocompatibility, and conductivity are desired properties for optimizing EF performance [Citation86]. Although benchmarked with its conductivity and arc erosion resistance, copper is not an ideal electrode material due to its antibacterial features. During anodic reactions, copper ions released from the anode will participate in redox reactions with the protons and generate reactive oxygen species (ROS), such as superoxide ions and hydroxyl radicals. The generated ROS can cause oxidative stress within exoelectrogen cells, damaging cellular components and disrupting the microbe cell membrane, leading to leakage of cell contents and ultimately cell death. Consequently, high copper concentrations can result in oxidative damage and impede microbial growth [Citation87]. Thereby, non-corrosive and less harmful stainless steel and molybdenum steel mesh provide an excellent alternative to copper for electrode purposes in the EF system. Similarly, carbon-based materials, including graphite, carbon cloth, carbon felt, and carbon nanotubes, are among the most widely used electrode materials with high adaptability and excellent electrical conductivity [Citation88]. Other than conductivity, the choice of electrode materials significantly influences the biofilm formation process and direct electron transfer performance of exoelectrogens to the anode. In EF, the exoelectrogens or bacterial attachment to and biofilm formation on the anode surface is crucial for the efficient biological transfer of electrons between the exoelectrogens and anode [Citation89]. Biofilm is an extracellular polymeric substance (EPS) encased, surface-adhering microbial community. EPS is a self-produced matrix of exoelectrogens comprised polysaccharides, proteins, nucleic acids, and other biomolecules that surround the biofilm to provide structural support and protection to the biofilm community, which is an advantage for exoelectrogens’ survival. In theory, the formation of biofilm on the anode involves several steps: (1) exoelectrogens present in the anodic chamber initially come into contact with the anode surface as anode possess conductive properties and availability of electron donors, which is suitable for microbial attachment; (2) exoelectrogens begin to adhere to the anode surface via weak and reversible interactions which facilitated by factors such as van der Waals interactions, hydrophobic interactions, and electrostatic forces; (3) Upon exoelectrogens adhere to the anode, they will secrete EPS that holds the microbial cells together and provides structural stability to the biofilm; (4) When biofilm developed, exoelectrogen cells within the biofilm proliferate and undergo cell division, resulting in an increment in the population within the biofilm; (5) Within the biofilm, synergistic relationship develop between exoelectrogens, allowing for the electron transfer, exchange of metabolites, and enhanced biofilm functionality; (6) Over time, channels and void spaces may form within the biofilm as additional EPS and exoelectrogen cells are produced, stimulating the movement of metabolic by-products, nutrients, and electron transfer [Citation90]. In this respect, the preferred characteristics of anode materials for efficient biofilm formation and development include good surface charge, rougher surface, hydrophilicity, and affinity for EPS components [Citation89]. Among electrode materials, carbon felt and carbon nanotubes are the preferred material owing to the presence of microscopic irregularities, such as cervices and pores, aggrandizing structural integrity and biofilm stability. Furthermore, complementary charge characteristics of carbon nanotubes offer an excellent electrostatic interaction between the charged surface of the anode and exoelectrogens, facilitating microbial adhesion and subsequent biofilm development [Citation88]. Nonetheless, the influences of electrode materials and arrangement on the power output will be discussed in Section 4.2.

Employing a dual- or single-chamber EF system relies heavily on the proportion and compatibility of the final products formed at the counter electrode. Precisely, owing to good scalability and irreplaceable simplistic design, single-chamber systems depict greater up-scaling convenience [Citation91]. In most wastewater remediation cases, only an anodic chamber is mandatory, with the cathode exposed directly to the air. Hence, the inclusion of PEM can be excluded from this design, lowering the manufacturing cost [Citation92]. As shown in (A), the anode and cathode are positioned at each end of the tube, with only the former covered by a flat plate, indicating the simplest design for a single-chamber system. Operationally, the anodic chamber houses the organic substrate and exoelectrogens, while oxygen from the air is constantly supplied to the cathode through diffusion, which yielded a maximum power density of 1320 ± 50 mW/m2 by using sodium acetate as the substrate [Citation93]. Lee et al. [Citation92] came up with an air-cathode MFC design having the carbon felt anode inside a cylindrical chamber, while the wet-proof platinum-coated carbon cloth air-cathode is positioned on the exterior of the device for wastewater remediation (). The authors revealed that 82.79% of methylene blue dye in the wastewater was successfully degraded while simultaneously generating bioelectricity with a current density of 4571.43 mA/m2 over 3.5 h of operation under simulated solar light illumination [Citation92]. In another study, a cubic structure single-chamber air-cathode MFC was developed by applying six acrylic-based graphite-coated stainless-steel mesh as anode and six activated carbon-coated stainless-steel mesh as cathode, which is illustrated in [Citation94]. This study indicated the importance of surface modification on stainless steel mesh to increase the overall power output of the system by 50.22%, yielding a maximum power and current density of 463.88 mW/m3 and 1991 mA/m3, respectively [Citation94]. Nevertheless, besides the aforementioned merits of the air-cathode single-chamber system, the application of this system is still hindered by some setbacks. Complexity for air-cathode manufacturing is considered a significant setback as diffusion layer or noble metal catalysts, including platinum and argentum, are required to enhance the reduction performance. The increased complexity and associated costs can pose challenges for large-scale applications. Additionally, air-cathode can be degraded due to several factors, such as biofouling, chemical reactions, or mechanical stress. Regularly exposed to oxygen-rich environments, chemical reactions will take place at the cathode surface to produce ROS, leading to the degradation of the cathode surface and reducing the cathode’s lifespan [Citation82].

Figure 8. (a) Single-chamber air-cathode microbial fuel cell reactor [Citation93], (b) single-chamber membraneless microbial fuel cells operating on the open-air cathode [Citation92], and (c) single-chamber microbial fuel cells operating on stainless steel mesh painted by acrylic-based graphite [Citation94].

![Figure 8. (a) Single-chamber air-cathode microbial fuel cell reactor [Citation93], (b) single-chamber membraneless microbial fuel cells operating on the open-air cathode [Citation92], and (c) single-chamber microbial fuel cells operating on stainless steel mesh painted by acrylic-based graphite [Citation94].](/cms/asset/3820d321-2c7d-4b3e-bc09-00e522ae3d29/kbie_a_2236842_f0008_oc.jpg)

Recently, multi-chamber, also known as stacked EF systems, have been explored as a potential design configuration for enhanced efficiency in biochemical production and electrical power capacity. Notably, the power capacity can be increased by connecting multiple individual unit chambers in either parallel or series configurations. Halim et al. [Citation86] reported an 87% chemical oxygen demand removal efficiency with an optimal power density of 115.94 mW/m2 was attained in a parallel-wired stacked EF system. In a different study, a serially stacked EF system comprising graphite felt as the primary material for working electrodes was proposed by Kim et al. [Citation95], which yielded 3.3 V as the maximum voltage, realizing higher efficiency up to 16.5 times (boosted voltage from 0.2 V to 3.3 V) compared to single EF system. Coincidentally, a declination in power output was discerned over time in both configurations. This was mainly attributed to ionic short-circuiting and voltage reversal. With only a single anolyte and catholyte input, organic overloading could occur due to inefficient flow distribution. Accumulation of organic substrate or deposition of non-conductive materials on the electrode surfaces can increase internal resistance of the EF system, leading to electrode fouling and voltage reversal. This further results in biofilm decay and reduced the electron transfer efficiency [Citation96]. In view of this, the conventional configuration, the dual-chamber EF system is preferred for co-production of biochemicals and bioelectricity. Dual-chambered systems with membranes are applied when the optical purity of the bioproducts, such as L-LA and succinic acid is emphasized [Citation97]. Similar to the previous genre, dual-chamber EF systems also come in diverse designs after years of development. From (D), the anodic and cathodic chambers of the dual-compartment EF system are assembled in a flat-plate design, in which the electrodes are stacked into a single layer divided by a PEM. Such design impelled an enhanced proton transfer with the closely packed electrodes, yielding a maximum open circuit voltage and power density of 637 mV and 232 mW/m3, respectively [Citation99]. In addition, Gebreslassie et al. [Citation13] proposed a H-shape dual-chamber EF system with Nafion® 117 PEM salt bridge completing the circuit and sustaining the electrical neutrality of the device (). The authors revealed that the dual-chamber EF system can be a promising integrated reactor process for the co-production of hydrogen and bioelectricity by achieving a hydrogen yield of 110 mL/g and a power density of 182 mW/m2 [Citation13].

Figure 9. Diverse configurations for membrane-based microbial fuel cells. (a) Cuboid double-chamber MFC, (b) cylindrical double-chamber MFC. (c) spherical double-chamber MFC, (d) flat-plate double-chamber MFC, and (E) H-shape double-chamber MFC. In all designs, the “A” and “C” indicate anode and cathode, respectively [Citation98].

![Figure 9. Diverse configurations for membrane-based microbial fuel cells. (a) Cuboid double-chamber MFC, (b) cylindrical double-chamber MFC. (c) spherical double-chamber MFC, (d) flat-plate double-chamber MFC, and (E) H-shape double-chamber MFC. In all designs, the “A” and “C” indicate anode and cathode, respectively [Citation98].](/cms/asset/51fd9919-47b8-496a-bab2-b985d2706c2c/kbie_a_2236842_f0009_oc.jpg)

Aside from the physical design parameters, the biocatalyst inoculated to the anode surface also imparts a significant impact on the bioelectricity generation potential and biochemical conversion efficiency of the EF systems. The endowment of pure or mixed microbial communities for bioelectricity production depends on the system’s architectural and physiochemical environment, including electrode size, electrode materials, internal resistance, and acidity of the system [Citation100]. Thus, the bioelectricity generation potential of a microbial culture cannot be compared with each other unless all physical and chemical parameters are similar. In the EF system, the capacity of microbes to decompose the organic substrates is primarily governed by the composition of the microbial community and its adaption [Citation101]. The use of exoelectrogens as biocatalysts is favorable for generating electricity by organic substrate degradation [Citation68]. Among exoelectrogen genera and species, the strain isolated from Clostridiaceae, Shewanellaceaae, Geobacteraceae, and Pseudomonadaceae genus, is of great interest phylum because of their capacity for extracellular electron transfer (EET) by direct electron transfer to the working electrode [Citation102–104]. These exoelectrogens are usually negatively charged and generally known as Gram-negative microbes due to the presence of uronic acids and ketal-linked pyruvates in the cell plasma membrane, thereby supplying the anode with positive potential and divalent cations, including calcium and magnesium, which maximizes the scope of biofilm formation on the anode surface by involving electrostatic interactions [Citation105]. Then, a negative potential is generated at the cathode to expedite the reductive reaction with the oxidizing agent by increased electronegativity in the system [Citation68]. In terms of direct electron transfer, Clostridium sp. can catalyze EET to the working electrode by excreting ferredoxin as endogenous mediators, while gram-negative proteobacterium belonging to the Geobacteraceae genus uses pili as conductive filament for EET [Citation103]. In addition, Shewanella sp. possesses both EET mechanisms, which use nanowires as conductive filaments and excrete riboflavin as endogenous mediators to catalyze bioelectricity production [Citation106]. Mechanistically, the metabolism of the organic substrate by exoelectrogen drives the production of NADH within the cell. For the cell to retain reducing power, NADH will re-oxidize to NAD+ by abstracting electrons and biochemicals, such as L-LA, by using dehydrogenase enzyme and the cytochrome system comprising menaquinone/quinone pool, periplasmic proteins, MacA, outer membrane OmcE protein, and outer membrane OmcS protein. These cytochrome proteins facilitate the electron transports by a series of redox reactions spanning the inner cytoplasmic membrane across the periplasmic space until the electrons are conducted across the outer membrane to the anode through outer membrane cytochromes OmcE and OmcS. Further, the direct electron transfer also occurs within multilayers of cells through a dense network of appendages with metal-like conductivity known as bacterial pili/nanowires. The transfer is manipulated cell by cell until electrons are donated to the electrodes [Citation107].

The details of pure microbial cultures used in the EF systems are provided in . Through pure microbial cultures, an insightful alteration in the process taking place during electron transfer and the complex behavior of individual species in mixed microbial cultures can be explored and studied. To date, exoelectrogenic Geobacter sulfurreducens have been gaining attention in the scientific community for their capacity to generate high power density [Citation104]. Applying Geobacter strains in EF systems manifests a significant advantage, whereby the generated electrons are directly transferred to the electrode through pili while vying for the limited surface area on the anode, which yielded a power density of 325 mW/m2. Theoretically, electrons were transferred to the anode via the membrane-bound redox proteins, with the direct EET controlling the overall shuttling rate [Citation120]. Furthermore, pure culture with exoelectrogenic G. sulfurreducens was also applied successfully to metabolize carboxymethyl cellulose for the generation of acetic acid with a concentration of 77 mg/L and bioelectricity with a maximum power density of 1146 ± 28 mW/m2 in a dual-chamber EF system by Jiang et al. [Citation115]. In contrast, Shewanella strains are relatively weaker in the aspect of generating electricity from the organic substrate. Evidently, only partial oxidation of sodium lactate into acetate can be provoked by Shewanella oneidensis, resulting in a lower overall amount of generated bioelectricity with a power density of 89.40 mW/m2 after 6 operation days. This can be attributed to the anaerobic nature of organic substrate metabolism and the non-central extracellular feature of the intermediates [Citation111]. However, Dai et al. [Citation112] revealed that a higher power density of 578 mW/m2 was attained using exoelectrogenic S. oneidensis in a dual-chamber EF system with bamboo fermentation effluent as the substrate for 8 operation days. The increment of the power capacity is significantly affected by the operation period as S. oneidensis will secrete flavins, including flavin mononucleotide (FMN), flavin adenine dinucleotide (FAD), and riboflavin in the concentration of 100–500 nM after 1 week of operation [Citation98]. The excreted flavins will then act as redox mediators to promote electron transfer from microbial cells to the electrode surface. The FAD and FMN are mainly involved in intercellular metabolism by mediating the oxidation of NADH and reduction of NAD+ to maintain the imbalanced intracellular ORP. At the same time, riboflavin is proposed to interact directly with outer membrane c-type cytochromes as a bridge between the working electrode and the cell for EET [Citation121]. The redox mediators can be reduced or oxidized by the exoelectrogens and then be recycled electrochemically at the working electrode [Citation122]. Indeed, García-Mayagoitia et al. [Citation108] concluded that the flavins excreted by the Bacillus subtilis strain and work as redox mediators were shown to enhance the bioelectricity production in the MFC system up to 105 mW/m2.

Table 1. A comparison study of pure culture and co-culture for electrofermentation system on L-lactic acid and bioelectricity production.

In addition to the self-secreted (endogenous) mediators by the exoelectrogens, Shirkosh et al. [Citation102] explored bioelectricity production through EF from a glucose medium by using S. oneidensis with exogenetic riboflavin. Such endowment prompted an enhanced bioelectricity capacity and lifespan of the system, which yielded a maximum current density of 138,181 mA/m2 with a prolonged operating duration of 50 days. These results are nearly 445% better than the values obtained without exogenetic riboflavin, indicating that the exogenetic riboflavin is essential for the survival of S. oneidensis in anaerobic conditions by offering the ability to access insoluble electron acceptors [Citation102]. This is attributed to the relatively slow production rate of endogenous mediators by S. oneidensis and will only produce limited concentrations in the stationary phase when the microbial cells are lysing [Citation98]. Thus, the endowment of exogenic riboflavin in the culture medium can boost the electron transfer process by undergoing reversible redox reactions, shuttling between its reduced (riboflavin semiquinone) and oxidized (riboflavin) forms. The riboflavin present in the extracellular environment will interact and bind with the outer membrane c-type cytochromes of exoelectrogens, forming a complex called riboflavin semiquinone with an electron attached to it. Then the riboflavin semiquinone diffuses from the exoelectrogen cells to the electrode surface. Once at the electrode surface, the riboflavin semiquinone transfers the electron to the electrode, completing the electron transfer pathway and shifting back to its oxidized form. This transfer is considered a direct electron transfer through the interactions of the mediator with the electrode, facilitating electron exchange [Citation123]. Another study reported bioelectricity production from activated sludge via EF using Bacillus megaterium with exogenic flavins. The optimum power density of bioelectricity was enhanced by 4.6-fold and reached approximately 170 mW/m2 compared to that without flavins addition under similar operating conditions [Citation110]. Similar results were also found in the study of Schwab et al. [Citation103] that the bioelectricity with a maximum current density of 5300 mA/m2 could be generated from glucose by Clostridium cochlearium isolated from the mouse gut after 5.2 h of operation duration with the addition of exogenic thiamine and riboflavin.

To date, most species studied for bioelectricity generation in EF systems are Gram-negative microbes. Interestingly, few Gram-positive LAB strains from Lactobacillus, Lactococcus, Lactiplantibacillus, and Bacillus genus are recognized to be both electroactive and able to metabolize a broad range of carbohydrates to valuable L-LA [Citation73,Citation97,Citation108,Citation109]. The LAB strains isolated from the abovementioned genus are considered excellent producers of high-purity L-LA as they contain only the ldhL gene that secretes L-LDH enzymes, which induces the formation of pure L-LA [Citation124]. In this regard, Tejedor-Sanz et al. [Citation97] demonstrated that both rare sugar (xylose and glucose) in the kale hydrolyzates can be fermented simultaneously to obtain a L-LA yield of 1.13 g/L and bioelectricity with a maximum current density of 752.14 mA/m2 by using Lactiplantibacillus plantarum at optical density (OD600) of 1.0 in a H-shape dual-chamber EF system. Under the same OD600 of Lactobacillus bulgaricus cells, the EF process for the diary whey was optimized to achieve the intended product in terms of L-LA yield of 19.5 g/L and bioelectricity with an optimum power density of 288.12 mW/m2 [Citation113]. Similarly, an EF system with Lactobacillus lactis DLP27 strain as anodic-respiring bacteria has been explored with a bioconversion yield of up to 212 mW/m2 from glucose medium for bioelectricity production [Citation73]. This is mainly due to the fact that L. lactis can excrete liposoluble quinones (2-amino-3-carboxyl-1,4-naphthoquinone) to facilitate the EET by connecting the intracellular metabolism of the cell to extracellular redox reactions [Citation125]. Mechanistically, LAB present in the electron-rich substrate, such as hydrolyzate comprising glucose molecules, will manipulate PTS to transport the glucose molecules to its cytoplasm for metabolism reaction. Once the glucose molecules are at the cytoplasm, LAB will proceed with either homolactic or heterolactic fermentation to produce L-LA as the end product. Glycolysis of glucose molecules drives the production of electrons within the cell, resulting in an imbalance of ORP level. For 100% coulombic efficiency, 24 electrons will be produced per glucose molecule. In order for the cell to maintain a balance ORP level, it will excrete liposoluble quinones as an endogenous mediator to shuttle the electron away from the cell to the electrode surface (). In brief, LAB will metabolize the glucose molecules, abstracting L-LA and electrons. The electrons are then transferred from the LAB cell to the electron mediator and subsequently to the electrode, generating an electrical current in the external circuit of the EF system [Citation97].

Figure 10. Schematic principle of a microbial fuel cell with lactic acid bacteria as biocatalyst for co-production of L-lactic acid and bioelectricity [Citation126].

![Figure 10. Schematic principle of a microbial fuel cell with lactic acid bacteria as biocatalyst for co-production of L-lactic acid and bioelectricity [Citation126].](/cms/asset/35fd5b25-dd9e-4e68-87c8-7b663dd799fc/kbie_a_2236842_f0010_oc.jpg)

Although research is emerging in the pure microbial culture EF system, all these methods are extendable to fermenters and electroactive bacteria co-culture for supplementary benefits [Citation118,Citation119]. A comparative study has been reported on pure culture and co-culture for bioelectricity production from glucose medium as an anolyte in the EF process (). The yield of bioelectricity in terms of current density was enhanced by 141.92% with co-culture using B. subtilis as an electroactive bacteria and Saccharomyces cerevisiae as a fermenter [Citation116]. This is mainly contributed by the syntrophic interaction among the bacteria strains, which offers an interspecies electron transfer (IET) between the bacteria, either directly via conductive pili or indirectly via diffusion of redox mediator [Citation127]. In this case, B. subtilis excreted flavins as mediators via respiration to induce the EET in the anode and reduce the internal resistance of the EF system. Subsequently, S. cerevisiae transmits electrons through the flavins produced to reduce the resistance of electron transfer as well as a direct contact mechanism. Finally, the bioproducts produced by the decomposition of glucose by S. cerevisiae via metabolism served as an electron donor and carbon source for B. subtilis. The bioproduct consumption by B. subtilis in the biofilm through IET mechanisms facilitates the EF process and increases the purity of the intended products [Citation116]. Further, Abdel-Gelel et al. [Citation117] developed a co-culture EF system by utilizing a combined LAB strain of L. lactis and Lactobacillus acidophilus for bioelectricity production from a glucose medium. A pure culture EF system was conducted as a standard reference, where pure L. lactis and co-culture produced a power density of 152 mW/m2 and 405 mW/m2, respectively [Citation117]. The presence of cyclic diguanylate monophosphate in the intracellular of L. acidophilus stimulates biofilm formation and promotes L. lactis to produce more liposoluble quinones for EET to minimize the internal resistance and increase the output voltage of the EF system [Citation117].

3.2. CO2 capture and conversion

Associated with the EF reaction in the MFC system is the generation of hydrogen (H+) and hydroxyl (OH−) ions in the anolyte and catholyte, respectively, which creates a pH imbalance in the system as the H+ ions mass transfer is sluggish that will be accumulated in the anode causes anolyte acidification [Citation93]. Experiments have shown that acidic or basic pH significantly decreases the current density, voltage efficiency, and resultant power output by detrimentally affecting the electroactive bacteria metabolism via Le Chatlier’s principle [Citation128,Citation129]. From an electrochemical perspective, pH imbalance also increases concentration overpotential for substrate oxidation and potential loss for the whole EF system [Citation129]. Chen et al. [Citation130] revealed that inorganic carbons (carbonic acid, H2CO3; carbonate ions, CO32-; bicarbonate ions, HCO3−) produced through the reduction of nearly 100% CO2 generated during microbial respiration are indispensable in EF to offer ionic conductivity and retain stable pH conditions of the electrolyte. The CO2 generated in the system reacted with OH− ions to form inorganic carbons, which became the highest concentration of anions in the catholyte. With an anion exchange membrane, the inorganic carbons were transported from the cathode to the anode to retain electroneutrality and catalyzed the diffusion flux of anion ions [Citation93].