?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

Bread is extensively consumed food that could benefit from being supplemented with a variety of nutrients that are lacking. Making bread with samma leaf flour could be one way to combat malnutrition, particularly in regard to shortages in protein and minerals. The current study aimed to fortify wheat bread with samma leaves flour. The samma leaves flour (sun and oven dried) at three fortification levels [5, 10, and 15% (w/w)] were added using factorial experiment and were blended and co-fermented for bread baking using 100% wheat flour as a control. The breads were subjected to analysis of physical properties, proximate composition, minerals, vitamin C, β-carotene contents, and sensory evaluation. The results revealed that wheat bread substituted with samma leaves flour at 5, 10, and 15% showed a significant (p < 0.05) effect on the protein, crude fiber, ash, fat, minerals, vitamin C, and β-carotene contents. With an increase in samma leaves flour substitution levels, a significant increase in the protein, crude fiber, ash, minerals, β-carotene, and vitamin C contents of the breads was observed. Bread with high minerals, vitamin C, and β-carotene contents can be obtained by 15% samma leaves flour substitution. Bread sensory attributes were significantly (p < 0.05) influenced by samma leaves flour substitution levels. Bread crumb color, taste, and its texture, a key sensory attributes for breads were reduced from control bread with samma leaves flour blending increased. The outcome showed that 5% samma leaves flour substitution could result in breads with acceptable sensory qualities when compared to the control bread.

REVIEWING EDITOR:

1. Introduction

Samma (Urtica simensis) is an exclusive nettle species found solely in Ethiopia. This perennial dark green wild plant is widely consumed as pot herbs in certain regions of Ethiopia, utilizing both its leaves and young shoots (Bekele et al., Citation2015; Tsegaye et al., Citation2016). The plant’s year-round growth allows for harvesting at any required time. It has historically been consumed as food and used to treat both communicable and non-communicable disorders. The plant is effective in treating blood pressure, diabetes, prostate hyperplasia, rheumatoid arthritis, diarrhoea, allergic rhinitis, cough, and other issues (Keflie et al., Citation2015; Seifu et al., Citation2017), to name a few of its medicinal characteristics. The herb is frequently utilized as an emergency famine food in northern Ethiopia, particularly in the Gonder, Gojam, and Oromia regions near the Kofole area of the Arsi zone, as well as in the majority of the Sidama Zone’s highlands in the south (Bekele et al., Citation2015; Seifu et al., Citation2017). In comparison to other green leafy vegetables that are frequently grown and eaten in Ethiopia, samma has a high nutritional content (Seifu et al., Citation2017). Samma leaves provides a considerable amount of crude protein (21.4%), crude fiber (9.37–14.0%), fat (3.19–4.40%), ash (17.2–24.3%), minerals (mg/100 g, particularly calcium = 768.6–813.0, iron = 34.3–47.0, zinc = 1.3–5.8), and vitamin C, pro-vitamin A carotenoids, and additional bioactive components (phenolic compounds) (Alemayehu et al., Citation2016; Assefa et al., Citation2013; Bayba et al., Citation2020). Due to its high mineral and protein content, this green leaf vegetable serves as a low-cost yet high-quality source of nourishment (Alshuwayeb & Al-Khatib, Citation2013; Maietti et al., Citation2021). Its potential to improve human well-being in the areas of food security, nutrition, health, and revenue production is still largely untapped (Seifu et al., Citation2017).

To enhance the nutritional value of various starch-based food products, a combination of samma leaves flour and alternative flours has been suggested. This approach has been proposed in the production of noodles (Alemayehu et al., Citation2016), bread (Agrahar-Murugkar, Citation2020; Khoozani et al., Citation2020), biscuits (Agrahar-Murugkar, Citation2020), cake (Singha et al., Citation2021), as well as other gluten-free products (Türker et al., Citation2016). The incorporation of samma leaves flour in these food items aims to provide additional health benefits.

Bread is a staple food that is widely consumed worldwide and is essential to human nutrition. Wheat bread, in particular, is recognized as a valuable source of energy, carbohydrates, fats, and essential nutrients for the human body, particularly in developing countries (Dziki et al., Citation2014; Khoozani et al., Citation2020). Hence, there exists a promising prospect of utilizing samma leaves flour to enhance bread by boosting its nutritional content. While an extensive variety of bread options is available in the market, white bread continues to be the preferred preference for numerous consumers owing to its sensory characteristics. However, white bread lacks sufficient amounts of essential nutrients, such as protein, minerals, and vitamins (Ameh et al., Citation2013; Eshetu et al., Citation2018; O’Connor, Citation2012). According to Man et al. (Citation2017), bread made from refined flour has substantially worse nutritional quality and does not sufficiently satisfy the needs for numerous macro- or micronutrients. Although refined wheat flour contains certain necessary proteins and carbohydrates, it is deficient in other elements like dietary fiber, vitamins, and minerals like calcium, iron, and zinc (Agrahar-Murugkar, Citation2020; Alemayehu et al., Citation2016; Kumar et al., Citation2011). Nowadays, consumers are seriously concerned about their health issues. Thus, they are becoming more aware of the importance of consuming high-quality, nutritious foods that contain components that offer additional health advantages beyond the minimum nutritional requirements (Ndife et al., Citation2011). However, the chemical makeup of the raw ingredients and the baking techniques utilized determine the nutrient contents of bread products (Dako et al., Citation2016). By including dietary categories such legumes, oilseeds, herbs, etc., bakery products made with refined wheat flour can frequently have their nutritional quality improved (Agrahar-Murugkar, Citation2020). Additionally, using composite flour in bread production benefits developing nations since it supports native plant species with high yields, improves the nutritional content and sensory quality of the finished goods, and increases domestic agriculture production (Dako et al., Citation2016).

As per the World Health Organization (WHO), adopting a well-balanced diet that incorporates vegetables and fruits is crucial in safeguarding against malnutrition in its various forms (WHO, Citation2021). Malnutrition, especially undernutrition and hunger, are serious issues on a global scale. Around two billion people experience moderate to severe hunger worldwide (FAO et al., 2020), which largely contributes to the high rates of malnutrition observed globally. The nutritional benefits of vegetables are widely acknowledged, as they provide dietary fiber, minerals, vitamins, antioxidants, phytonutrients, and polyphenols. Consequently, it is essential to explore solutions that encourage the consumption of vegetables containing these health-promoting nutrients on a daily basis. Since bread is a staple food, enriching it with bioactive ingredients of natural origin presents an opportunity to enhance the daily intake of deficient nutrients in the human diet (Czarnowska-Kujawska et al., Citation2022). Numerous studies have been conducted to explore the fortification of bread with different plant components, aiming to enhance its nutritional value. Moreover, the growing demand for innovative and nutritious food options, coupled with the rise in lifestyle-related diseases, has significantly stimulated a new market for bread made with alternative flours to wheat (Lim et al., Citation2020).

The majority of the foods in low- to middle-income nations’ diets, including Ethiopia, are starchy staples. Additionally, most communities in these nations only eat a small amount of fruits, vegetables, and meals made from animal sources. This kind of diet is deficient in nutritional variety and may result in micronutrient deficits. Public health is affected by micronutrient deficiencies, particularly in underdeveloped nations like Ethiopia. Protein energy malnutrition, iodine, iron, zinc, and vitamin A and C deficiency are the most widely known types of malnutrition in Ethiopia (CSA & ICF, 2016). Since bread is a mainstay of the Ethiopian diet, enhancing bread by blending as a diet-based method may help reduce malnutrition. Blending wheat flour with various cereals, pulses, and root crops has been explored in the past to improve the nutritive and functional qualities of bread and to get around problems with the growth in the price of wheat grain (Malomo et al., Citation2011).

Despite the availability of scattered data, there is a lack of comprehensive and up-to-date information regarding the impact of replacing wheat flour with samma leaves flour on the technological properties, nutrient composition, and health benefits of bread. Furthermore, there is a deficiency in understanding the effects of different preparation methods of samma leaves flour on bread properties. Therefore, the objectives of this study were to investigate the influence of both sun and oven drying techniques, as well as varying levels of fortification with samma leaves flour, on the nutritional and physical properties of fortified bread, along with its consumer acceptability. Additionally, this research aims to provide valuable insights for researchers exploring the incorporation of samma leaves flour in the formulation of various bakery products.

2. Materials and methods

2.1. Sample collection

Wheat flour was procured from the local market in Bahir Dar City, Ethiopia. The young shoots of samma leaves (U. simensis) were gathered from Choke Mountain area, East Gojam zone, Ethiopia where this plant is highly consumed. This was done using our hands covered with gloves and transferred into plastic bags, tied, and transported to the place where drying and laboratory analysis were done.

2.2. Sample preparation

Samma leaves were sorted, crushed between two hides, then rubbed between a ‘sefed’ (big circular piece of wicker) and a ‘wenfit’ (sieve) in the lab to get rid of the stinging hairs that give the leaves their burning feeling. The non-edible section of the leaves was then removed, and the leaves were thoroughly combined, washed with tap water, rinsed with de-ionized water, and allowed to drip on sieves. The sample was dried using two different methods. The second batch was sun dried for 24 h, whereas the first batch was dried in an oven at 45 °C for 10 h to the prescribed humidity level (below 5%) (Assefa et al., Citation2013; Keflie et al., Citation2015). The sample was combined and sealed in airtight containers after drying. Using a pestle and mortar, the dried sample was crushed into a fine powder. The powder was then sieved through a 2.0 mm wire mesh for further investigation (Assefa et al., Citation2013).

2.2.1. Experimental design

The experiment was set up in a 2 × 3 completely randomized factorial design. Samma leaves flour with two levels (sun dried and oven dried) as its first factor. The second factor was samma leaves flour concentration, which was tested at three different levels (5, 10, and 15%). Each treatment was tested three times, for a total of 18 experimental runs, and bread made entirely of wheat flour was used as the control. The randomised fully block design (RCBD) was used to arrange the sensory evaluation data to eliminate any potential for error amongst panellists or within a panel.

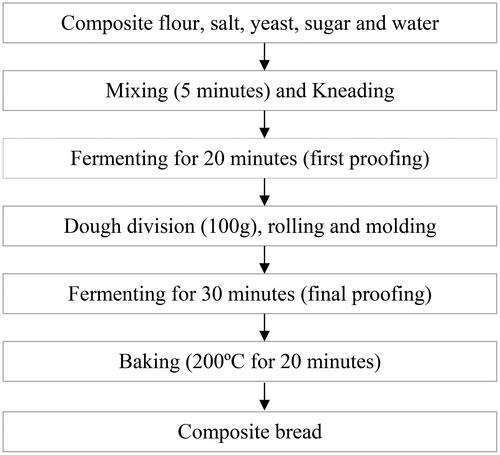

2.3. Bread making

The straight dough method employed by Anton (Citation2008) was the foundation for the formulation, preparation, and baking of the breads. Following weighing, all of the ingredients—flour (100%), salt (1%), sugar (1.5%), and yeast (2%)—were added at once and combined in a single mixing step (). The 250 g composite flours (wheat flour:samma leaves flour) were manually mixed for 5 min with water added in small amounts per the designed formulas, and then the dough was kneaded until it was uniform. The finished dough was divided into 100 g pieces, rolled out, and shaped after resting for 20 min at room temperature (first proofing). Each piece was put onto a metal pan, allowed to ferment for 30 min at room temperature (final proofing), and then baked for 20 min in an electrically heated oven at 200 °C. After baking, the breads were left to cool thoroughly at room temperature before undergoing evaluation. The height, volume, weight, and thickness of the crust of the bread were then measured. The bread was then packaged and submitted for additional testing. The cooled breads were crushed into a fine powder using an electric grinder (High-Speed sample machine model-FW100) till they passed through a 0.425 mm sieve mesh size. The breads were dried at 60 °C in an oven (DHG-9140 Drying oven, China) for 9 h. For additional analysis, this material was stored at room temperature in a low-density polyethylene bag.

2.4. Determination of proximate composition

The AOAC (Citation2005) method numbers 925.10, 923.03, 962.09, 979.09, and 920.39 were used to determine the raw materials and the bread samples moisture content, ash, crude fiber, crude protein, and fat levels, respectively. The total carbohydrate (CHO) and energy content were determined according to the AOAC (Citation2005) as cited by Khoozani et al. (Citation2020). The values were calculated via the following formula:

(1)

(1)

(2)

(2)

2.5. Determination of minerals and vitamins content

The Mineral contents, such as Ca, Fe, Zn, Mg, and Mn were analyzed by using Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) (Keflie et al., Citation2015).

According to Rodriguez-Amaya and Kimura (Citation2004), the high performance liquid chromatography (HPLC) method was used to measure the β-carotene. A homogenous representative sample weighing 1 g was added along with 50 ml of cold acetone, and the mixture was agitated for 5 min with a magnetic stirrer. After that, tissue paper was used to filter the collected sample into a 100 ml volumetric flask. The residue was filtered in a flask containing the extract after being cleaned with a tiny amount of acetone. Up till the residue was colourless, the extraction and filtration processes were repeated. The 500 ml separatory funnel containing petroleum ether was added, and the acetone extract was subsequently added. The lower aqueous acetone phase was removed after a little amount of distilled water was added to separate the two phases. The separator funnel was thoroughly cleaned by being scrubbed in water two to three times. The petroleum ether extract phase was then collected, dried (15 g) with anhydrous sodium sulphate, transferred to a drying flask, and evaporated in a rotary evaporator. 10 cc petroleum ether was used to clean the separatory funnel. About 1 ml of petroleum ether was used to dissolve the residue before the mixture was added to a chromatographic column. Petroleum ether was used to elute the column, and the β-carotene was then collected in a flask and allowed to act as a yellow pigment as it passed along the column. Last but not least, the absorbance at 450 nm in a spectrophotometer (Agilent Cary 60 UV-Vis Spectrophotometer, USA) was measured and the volume of β-carotene was determined using a measuring cylinder and EquationEquation (3)(3)

(3) .

(3)

(3)

Where X = is concentration of β-carotene from calibration curve (mg/L), V = is dilution volume (L), and W = is weight of the sample (g).

The Vitamin C content was determined by the 2,6-dichloroindophenol titrimetric method (AOAC, Citation1984).

2.6. Determination of physical properties of bread samples

The weight of the bread loaves was measured using a digital balance after a 1-h cooling period (Bakare et al., Citation2015). The height of bread samples was measured using a measuring ruler. The baking loss was determined by subtracting the loaf weight from the prebaked dough (100 g) and calculated as a percentage (Zhang et al., Citation2018). The specific volume of bread was determined by adopting the rapeseed replacement technique in accordance with AACC method 10-05.01 (AACC, Citation2000) and substituting finger millet seed for rapeseed. As soon as the loaf was taken out of the oven and weighed, the volume was determined by the displacement of finger millet seeds. The loaves were put into a known-volume container, and finger millet seed was added until the container was full. The loaf’s volume was determined by how much seed it displaced. The appearance of cracks will be assessed visually. LSV, or loaf specific loaf volume, was determined using the following formula:

(4)

(4)

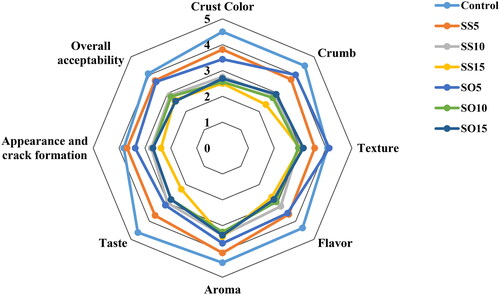

2.7. Sensory evaluation

By using a hedonic test, 20 untrained volunteer panellists (15 men and five women) assessed the sensory acceptability of bread samples. The coded bread samples were presented to the panellists in a random order, and they were asked to rate their likeness scores on sensory evaluation using a five-point hedonic rating scale. The scale ranged from 1 (dislike very much) to 5 (like very much). Various aspects, such as crust color, crumb texture, flavor, aroma, taste, appearance, crack formation, and overall acceptability were considered in the evaluation process.

2.8. Statistical data analysis

The data obtained from the physical qualities, nutritional composition, and sensory evaluation questionnaires were recorded in an Excel spreadsheet and meticulously verified for accuracy. The reported data in all tables represent the average of triplicate observations. Analysis of variance (ANOVA) was conducted using Minitab Version 19.2, employing the general linear model. Mean separation was carried out using the Tukey method, and statistical significance was considered at p < 0.05. The results were presented as mean ± standard deviation.

3. Results and discussion

3.1. Proximate composition, minerals, and vitamins content of flour

The proximate composition of the flour samples is presented in . On the proximate composition, there was a significant difference between the flours made from wheat and samma leaves (p < 0.05). The moisture content varied from 8.44% (oven-dried samma leaves) to 11.31% (wheat). Compared to samma leaves flour, wheat flour had a higher moisture and carbohydrate content (87.47%). The findings showed that when compared to wheat flour, dried samma leaves have a higher proportion of crude protein, ash, crude fiber, and fat. There was a significant difference (p < 0.05) in moisture, ash, crude fiber, and carbohydrate content of sun and oven dried samma leaves flour. Whereas there was no significant difference (p < 0.05) in crude protein, fat, or energy content between sun- and oven-dried samma leaves flour. There have been similar reports on proximate compositions of wheat flour by Dako et al. (Citation2016) and Gurung et al. (Citation2016), and samma leaves flour by (Alemayehu et al., Citation2016; Assefa et al., Citation2013; Seifu et al., Citation2017). Additionally, as compared to the results of the study by Bayba et al. (Citation2020), the samma leaves flour had reduced ash and carbohydrate content and higher levels of crude protein, fiber, and fat. This might be caused by variations in the degree of drying, leaf maturation stages, and growing environments. The dried samma leaves utilized in this investigation had a protein level of about 26%. The protein content of some pulses is compared to this. However, it exceeds the protein level of most fruits and vegetables, root crops, and cereals. The energy level of wheat flour was significantly higher compared to samma leaves flour. This study found that the energy value of samma leaves flour was higher than that found in earlier studies (Alemayehu et al., Citation2016; Assefa et al., Citation2013). The proximate analysis revealed that samma leaves flour may contribute high levels of protein, crude fiber, ash, and fat to the bread made by partially substituting wheat flour with samma leaves flour, whereas wheat flour can contribute high levels of carbohydrates to the bread. As the result shows, adding samma leaves generally increases the goods’ crude protein, crude fiber, ash, and fat contents, which raises their nutritional value.

Table 1. Proximate composition of wheat and samma leaves flours on dry wet basis.

shows the mineral, β-carotene, and vitamin C contents of flour. The soils that plants were grown in, their pH, and the amount of organic matter they contain all have a major impact on the mineral contents of plant products (Adeoye & Agboola, Citation1985; Maietti et al., Citation2021). The calcium content of wheat flour in the present study (26.82 mg/100 g) is higher than the calcium content of wheat flour (21.6 mg/100 g) of previous study findings (Gurung et al., Citation2016). But, the iron content of wheat flour in this study (2.72 mg/100 g) is similar to the iron level of wheat flour (2.71 mg/100 g) of the previous study reported by Gurung et al. (Citation2016). The Zn, Mg, and Mn contents of wheat flour in this study were 1.31, 4.44, and 0.64 mg/100 g, respectively. Dako et al. (Citation2016) reported that similar result for wheat flour in calcium, but higher in iron and lower in zinc levels as compared to this study. This difference could be due to differences in wheat variety, agro-ecological variations as well as differences in analytical techniques.

Table 2. Mineral, vitamin C, and β-carotene content of wheat and samma flours on dry wet basis (mg/100 g).

The mineral content of samma leaves is exceptionally high which makes this vegetable as an inexpensive but high quality nutrition source (Alshuwayeb & Al-Khatib, Citation2013; Seifu et al., Citation2017). The findings of this study showed that samma leaves flour has the highest amount of vitamin C, β-carotene, macro as well as micro minerals compared to wheat flour. There is a significant difference (p < 0.05) in Ca, Fe, Zn, Mg, and Mn content of wheat and samma leaves flour. A significant difference (p < 0.05) in mineral content was observed between sun-dried and oven-dried samma leaves flours. The calcium content of samma leaves flour in this study was found to be higher compared to previous studies conducted in Debrebrhan, Fitche, Ambo (Assefa et al., Citation2013), and the Chacha town of North Shewa Zone in the Amhara Region of Ethiopia (Keflie et al., Citation2015). However, the iron content of samma leaves flour in the present study is lower than the iron content of samma leaves flour of previous study findings (Assefa et al., Citation2013; Keflie et al., Citation2015). Similarly, the zinc content of samma leaves flour in this study is lower than the zinc content of samma leaves flours in previous study results (Assefa et al., Citation2013). However, it is higher than the zinc content of samma leaves flour in previous study findings (Keflie et al., Citation2015). This can be different drying techniques improve the calcium and zinc level of the leaves (Mbah et al., Citation2012). The findings indicate that samma leaves powder exhibits high levels of calcium and iron content, which holds particular significance in Ethiopia where there is a low intake of calcium and iron among children, adolescents, and women.

A significant difference (p < 0.05) was observed in the β-carotene and vitamin C contents between the wheat and samma leaves flour samples. These results illustrate that samma leaves flours have higher amount of β-carotene and vitamin C content than the wheat flour. The β-carotene and vitamin C values are compared favourably well with that reported by Abdulkadir (Citation2014) and Gurung et al. (Citation2016), respectively. However, the vitamin C level of this study is lower than the vitamin C level of samma leaves flour of previous study findings (Assefa et al., Citation2013; Keflie et al., Citation2015). Similarly, the β-carotene level of this study is lower than β-carotene level of samma leaves flour in previous study result (Keflie et al., Citation2015). Whereas no significant difference (p < 0.05) was observed in the β-carotene and vitamin C content between the sun-dried and oven-dried samma leaves flours. The possible explanation for these minerals and vitamins level differences could be due to variations in agro-climatic conditions across regions, nature of soil, plant type, and agriculture practices (Maietti et al., Citation2021). In addition, the drying techniques, differences in laboratory tests as well as sample differences, i.e. the present study utilized dried samma leaves for laboratory analysis. Whereas, the previous studies utilized raw samma leaves for laboratory analysis are source of variations. The results indicate that incorporating samma leaves flour into wheat flour has the potential to increase the calcium, iron, magnesium, manganese, vitamin C, and β-carotene contents of wheat bread.

3.2. Physical characteristic of bread samples

summarizes the variations in size-related parameters between wheat breads made with various samma leaf flours and the control loaves. Before baking, the dough (100 g) was weighed, and the final bread loaves were also weighed. Based on the results, there were significant differences (p < 0.05) in the physical characteristics of bread produced from wheat flour and samma leaves composite flour. These differences encompassed weight, height, volume, and specific volume. As the amount of samma leaves flour in the blend increases, the blending ratio among the weight of the bread samples was found to be significantly lower (p < 0.05) (). The decrease in the physical characteristics of bread produced from samma leaves flour compared to wheat flour could be attributed to the lower water absorption capacity of samma leaves flour (Zula et al., Citation2021). The volume of baked dough and the amount of moisture and carbon dioxide that diffuse out of the loaf during baking essentially determine the weight. The reduced weight of the composite bread samples can be attributed to the lower retention of carbon dioxide gas in the blended dough, leading to a denser texture in the bread (Julianti et al., Citation2017). Similar to this, when the level of samma leaves flour increased, the height of the bread reduced significantly (p < 0.05). Because wheat flour with higher alpha-amylase activity produces more fermentable sugars from starch, the maximum height for bread samples was suggestive of big air cells in the crumb (Bakare et al., Citation2015). The baking loss increases consistently with increases in samma leaves flour in the formulation. The observed behavior of the composite bread samples can be attributed to their low gluten content, which directly contributes to the production of heavier bread (Lagnika et al., Citation2019). The control bread had a lower baking loss as compared to the samma leaves flour fortified breads. The volume of the bread loaf is a vital physical characteristic that holds significance for both consumers and industries, as it serves as a measure of the quality and quantity of fresh bread. Consumers desire aesthetically light breads (Bakare et al., Citation2015; Odunlade et al., Citation2017). On the other hand, consumers identify some breads with lightness and high loaf volumes, whereas others are associated with low loaf volumes (Hathorn et al., Citation2008). There was a significant decrease (p < 0.05) in the loaf volume and loaf specific volume of the bread samples as the addition of samma leaves flour increased in the composite flour. The composite bread samples exhibited a range of loaf volumes, varying from 128.33 to 205.00 ml, and specific volumes ranging from 1.80 to 2.63 ml/g. comparatively, the breads incorporating samma leaves had lower loaf volumes and specific volumes compared to the control bread. It is worth noting that the literature generally adopts loaf specific volume as a more reliable measure of loaf size, as highlighted by Julianti et al. (Citation2017). The results of this study were agreed with other findings of bread made from moringa leaf and kenaf leaves powder Govender and Siwela (Citation2020) and Lim et al. (Citation2020), respectively. This can be due to samma leaves flour is low in gluten content and rich in fibers and thus the loaf reflects the gluten content of the bread (Manyatsi et al., Citation2020; Srirejeki et al., Citation2018), and fibers and polyphenols are added to the dough, which thins the gluten network and reduces CO2 retention (Pasrija et al., Citation2015). Additionally, interactions between fiber, water, and gluten on a physical and chemical level may result in a decrease in loaf volume (Pasrija et al., Citation2015). The strength of gluten in retaining carbon dioxide gas formed during fermentation directly influences the quality of bread obtained. The trend observed in the specific volume of bread loaves aligned with the trend observed in the loaf volume. Based on the results, it can be concluded that the fiber from samma leaves flour weakens the dough blends, primarily due to the dilution of gluten caused by the fibers (Babiker et al., Citation2013). Furthermore, a decrease in the quantity and quality of wheat proteins responsible for the structure formation, along with a reduced capacity of the dough to trap air during fermentation, can have a negative impact on the volume of bread (Bakare et al., Citation2015; Julianti et al., Citation2017; Malomo et al., Citation2011; Odunlade et al., Citation2017).

Table 3. Physical characteristics of bread samples.

3.3. Proximate composition, minerals, and vitamins content of bread

presents the proximate composition of samma leaves flour fortified bread. Moisture content plays a critical role in microbial growth and determining the shelf life of a product. In this study, the moisture content of the bread ranged from 8.16 to 11.21%. A significant difference (p < 0.05) was observed between the control bread and the bread made with samma leaves flour substitutions. The bread made with a 15% substitution of sun-dried samma leaves exhibited the highest moisture content. The moisture contents of the breads increased as the amount of samma leaves flour added to the wheat dough increased. The control bread had higher moisture content than samma leaves flour substituted bread except 10 and 15% sun dried samma leaves. This can be due to the higher moisture was triggered by the occurrence of more protein and fiber in the blend containing more samma leaves (Adegunwa et al., Citation2017; Bakare et al., Citation2015). Similar findings were reported in a study on noodles made from wheat and nettle leaves powder (Alemayehu et al., Citation2016). The protein content of the bread significantly increased (p < 0.05) with higher levels of samma leaves flour incorporation compared to the control sample. The protein content of the breads ranged from 9.63% (control sample) to 15.87% (15% oven-dried samma leaves fortified bread). Comparable results were also observed in bread made from wheat and green leafy vegetable powders (Odunlade et al., Citation2017) and moringa leaf powder (Govender & Siwela, Citation2020). The bread substituted with 15% samma leaves flour exhibited the highest crude protein content (p < 0.05), while the control bread had the lowest content.

Table 4. Proximate composition of bread samples on dry wet basis.

Significant differences were observed in the ash, crude fiber, and fat contents of the bread samples due to the blending ratios. The ash content of the bread samples fortified with samma leaves flour increased significantly (p < 0.05) from 1.69 to 3.51%. The increase may be related to the ash level of green leafy vegetables. The lipid content of the bread samples made with enriched samma leaves flour, however, increased from 1.84 to 3.75%. The relative increase in the fat content of the enriched bread samples indicates that the bread would be distinctively palatable in taste than the control bread sample because fat improves palatability (Odunlade et al., Citation2017). Along with an increase in the amounts of samma leaves flour enrichment, the crude fiber content of the bread samples also increased significantly (p < 0.05) from 0.53 to 3.92%. There was a significant difference observed due to the effect of blending ratio and drying techniques on carbohydrate and energy contents of bread. The carbohydrate contents varied from (73.47–86.72%) of bread samples decreased with enrichment with samma leaves flour used. The observed decrease in carbohydrate content was also reported by Govender and Siwela (Citation2020) and Odunlade et al. (Citation2017) for bread enriched with moringa leaf powder and leafy vegetable powders enriched bread, respectively. Maietti et al. (Citation2021) reported similar findings in bread enriched with nettle leaves powder. The control bread exhibited low levels of protein, ash, fiber, and fat, but was high in carbohydrate and energy contents. However, when samma leaves were substituted up to 15% compared to the control bread, there was an increase in the crude protein, ash, fiber, and fat contents, along with a decrease in total carbohydrate and energy contents in the breads. This indicates that samma leaves have significant potential to enhance the protein, ash mineral, and fiber contents of breads. Similar observations have been reported in pan bread and noodles fortified with moringa leaf powder (El-Gammal et al., Citation2016; Sengev et al., Citation2013), as well as in a study by Zula et al. (Citation2021) on noodles. Bread prepared with 15% substitution of samma leaves flour exhibited the highest protein, fiber, and ash contents. The higher levels of ash, protein, and fiber in the breads made with a greater concentration of samma leaves flour can be attributed to the inherent higher mineral, protein, and fiber content of samma leaves flour, as reported by Assefa et al. (Citation2013) and Seifu et al. (Citation2017). There were significant differences (p < 0.05) in the proximate compositions of the breads when comparing the two forms (sun-dried and oven-dried) of samma leaves flour substitutions in terms of protein, ash, fiber, and fat contents, except for moisture and energy contents.

The mineral, vitamin C, and β-carotene composition for the bread samples is presented in . The mineral, vitamin C, and β-carotene contents of the bread exhibited a significant increase (p < 0.05) with higher levels of samma leaves flour in the composite flour bread, as shown in . This increase can be attributed to the high mineral, vitamin C, and β-carotene contents naturally present in samma leaves. A significant increase in calcium, magnesium and a moderate increase (p < 0.05) in iron, zinc, and manganese were observed in samma leaves of fortified bread. After samma leaves addition, calcium concentration increases more than ten times (from 27.33 to 252.83–655.16 mg/100 g) as the level of samma leaves flour increased in the proportion with wheat flour (). The iron, zinc, magnesium, and manganese content also increased significantly with increase in the addition of samma leaves flour. Similar results with a minor increase in the present study were observed in calcium, iron, and zinc in noodles fortified with nettle leaves powder (Alemayehu et al., Citation2016). The observed increase in Ca, Fe, Zn, and Mg was also reported by Govender and Siwela (Citation2020) and Odunlade et al. (Citation2017) for bread enriched with moringa leaf powder and leafy vegetable powders enriched bread, respectively. However, the range of iron, zinc, and manganese contents in this study is lower than Govender and Siwela (Citation2020) and Odunlade et al. (Citation2017) reported for moringa and leafy vegetables fortified bread.

Table 5. Mineral, vitamin C, and β-carotene content of samma flour substituted bread on dry wet basis (mg/100 g).

The vitamin C and β-carotene content of the breads exhibited significant variations (p < 0.05) with increasing levels of samma leaves flour in the composite flour. This finding is consistent with other literature reports, such as bread fortified with moringa leaf powder (Sengev et al., Citation2013). There was no significant difference (p < 0.05) observed between the two forms (sun-dried and oven-dried) of samma leaves substitution breads in terms of vitamin C and β-carotene contents. The results indicated that as the level of samma leaves substitution increased, there was a corresponding increase in the vitamin C and β-carotene contents of the breads. During the process of dough making, fermentation, and bread baking, there is a subtle change observed in the vitamin C and β-carotene contents, although a reduction in vitamin C content is likely due to the baking process (as shown in ). Among the samma leaves bread samples, the bread with a substitution level of 15% exhibited the highest vitamin C and β-carotene contents. Additionally, the sun-dried flour substituted bread had higher vitamin C and β-carotene contents compared to the oven-dried substituted bread. The overall higher vitamin C and β-carotene contents in the breads made from samma leaves flour substitution can be attributed to the natural richness of samma leaves in these nutrients.

As shown in , the mineral and vitamin contents of control bread, drastically improved after fortification with samma leaves flour (p < 0.05). A previous similar study (Alemayehu et al., Citation2016; Maietti et al., Citation2021) supported the findings of the present study. It also reported that nutritious as well as acceptable bread and noodle could be prepared by incorporating dried samma leaves flour into wheat. These evidences showed that fortification of staple foods with samma flour definitely improves the nutritional quality of the food items that ultimately enhances the nutritional as well as the health status of our people.

3.4. Sensory acceptability of bread

In new product development, conducting sensory acceptability tests to assess human responses is an essential activity that cannot be avoided. Alongside evaluating the nutrition, safety, and convenience of a product, understanding its sensory appeal is crucial (Alemayehu et al., Citation2016). In the present study, the sensory acceptability of samma leaves substituted wheat bread is shown in . The sensory evaluation results indicated that the sensory qualities of the bread samples declined as the amount of samma leaves flour increased. The control bread, made solely from wheat flour, was preferred over the bread samples with samma leaves flour in terms of all the sensory parameters evaluated. There was a significant difference (p < 0.05) observed among the bread made from composite flour and 100% wheat flour in terms of bread crust color, crumb texture, flavor, aroma, taste, appearance, crack formation, and overall acceptability. Odunlade et al. (Citation2017) reported similar findings in bread supplemented with leafy vegetable powders. The acceptability of bread color significantly decreased when samma leaves flour was added to white bread. This outcome was expected since samma leaves naturally have a dark green color due to their high chlorophyll content, leading to an undesirable color change (Govender & Siwela, Citation2020). This alteration can impact the traditionally accepted and preferred bright yellow translucent appearance of bread products. Additionally, the presence of fiber in the leaves contributed to a darker crumb color, as depicted in . This darker color may negatively impact consumer acceptability of bread fortified with samma leaves flour, as consumers are accustomed to bread having a golden-brown color. These findings align with a study conducted by Govender and Siwela (Citation2020), which observed a decrease in the lightness of bread crumb and crust as the concentration of moringa leaf powder increased. A similar result was reported by Alemayehu et al. (Citation2016) in noodles enriched with nettle leaves powder. Similarly, the addition of samma leaves flour to the breads made for this study considerably (p < 0.05) altered the aroma and taste, commonly referred to as flavour (). This might be because the increased protein in the breads made with samma leaves led to the development of unfavourable flavours. The incorporation of samma leaves flour as a fortification in the bread resulted in a noticeable sour taste and a slight bitter aftertaste. Alemayehu et al. (Citation2016) and Maietti et al. (Citation2021) reported that similar findings for nettle leaves powder substituted bread and noodle, respectively. The addition of Samma leaf flour in greater quantities significantly reduced the texture of the bread (p < 0.05). This may be because bread made with bread composite flour contains less gluten and has higher fiber content (around 15%) than bread made with samma leaves flour. Additionally, the very fine flour generated from samma leaves, which is made from the leaf, maybe the cause of the poorer texture. As the number of samma leaves in the bread preparation increased, there was a significant (p < 0.05) impact on the appearance and crack formation. Even while all of the breads made for the study scored higher than average (2.5) out of 5, the breads’ general acceptability decreased as samma leaf incorporation increased. This may be the result of the additive effects of the colour shift from regular bread, the reduction in gluten, the increase in fiber, and the alteration in flavour brought on by the addition of protein. As the concentration of samma leaves flour increased, particularly in the 10 and 15% substituted bread, the sensory acceptability significantly decreased. This decline in acceptability can be attributed to factors, such as the green color of samma leaves flour, its bitter taste, and the lack of familiarity among consumers who are accustomed to the normal color of bread.

Figure 2. Mean score values for sensory acceptability of bread made from different substitution levels of samma leaves flour.

Figure 3. Depicts the different bread samples: control and wheat flour substituted with samma leaves flour at 5 and 10% levels.

Overall, there was a significant difference in the acceptability of bread when samma leaves flour was substituted (although not for all attributes) compared to the control bread. Among the samma leaves flour-containing breads, the most acceptable option was the one with a 5% addition of samma leaves flour, when compared to the control bread. Based on the results of this study, bread made by substitution of samma leaves flour was accepted by consumers in most sensory attributes up to substitution level 5%. Results are in agreement with other the literature finding (Bourekoua et al., Citation2018; Maietti et al., Citation2021) used nettle leaves and moringa leaf powder to enrich bread, respectively. In addition, similar findings have been reported in studies where nettle leaves powder was used to enhance the nutritional content of various food products. However, the sensory acceptability of these products, such as noodles with higher protein, ash, and fiber contents, was found to be reduced (Alemayehu et al., Citation2016).

4. Conclusions

A dietary intervention that fortifies bread with samma leaves flour could increase the bread’s protein and mineral content. This study showed that the way of drying samma leaves (sun or oven) and the amount of samma leaf flour used in the bread had a substantial impact on the crude protein, crude fiber, ash, fat, minerals, vitamin C, and beta-carotene contents of samma leaf-substituted wheat bread products. Thus, samma leaves have the ability to provide both macro and micronutrients for human consumption. The inclusion of samma leaves in wheat flour resulted in a significant increase (p < 0.05) in the levels of crude protein, ash, dietary fiber, and fat. Moreover, the minerals (Ca, Fe, Zn, Mn, and Mg), vitamin C content, and beta-carotene content are dramatically increased with an increase in the amount of samma leaves in the bread product. On the contrary, it reduced the amount of gross calories and carbohydrates. Furthermore, with an increasing amount of samma leaves, the incorporation of nettle leaves into wheat flour significantly (p < 0.05) reduced the physical attributes and sensory acceptance of the loaves. Generally, wheat can be supplemented with dried samma leaves flour up to 5% weight for weight to produce a wholesome and satisfactory loaf. Based on our findings, samma leaves prove to be a valuable ingredient for developing enriched foods with enhanced nutritional and functional properties. Considering their affordability and nutrient-rich composition, samma leaves should be utilized in food supplements, fortification, and complementary feeding, especially for newborns. They serve as an inexpensive source of essential micronutrients and other beneficial nutrients. This can be done on a huge scale, like when manufacturing bread. The best foods to fortify with samma leaves flour require further study with the incorporation of samma leaves flour into other popular but nutrient-deficient foods.

Ethical approval

The panelists’ free consent was obtained for the product’s sensory evaluation.

Consent for publication

Not applicable.

Author contributions

The study was conceptualized by A.T. and A.A., who were also responsible for sample collection, laboratory analysis, compiling results, and contributing to the discussion and revision of the manuscript. A.T. and G.M. conducted the statistical analysis, interpreted and described the findings, and edited the manuscript. G.M. and A.A. provided interpretation of the findings, as well as material and technical support. All authors have thoroughly read and agreed to the published version of the manuscript.

Acknowledgments

The authors would like to extend their gratitude to the technical and academic staff of the Food Processing Laboratories for their valuable advice, support, and provision of necessary facilities to conduct this study. They also express sincere appreciation to the individuals who participated in the sensory evaluation of the bread samples, as their contribution was instrumental to the study.

Disclosure statement

No potential conflict of interest was reported by the author(s).

Data availability statement

All the data presented in the manuscript are available within the manuscript itself. However, if there is a need for additional data, it can be obtained from the corresponding author upon request via email.

Additional information

Funding

Notes on contributors

Abebaw Teshome Tiruneh

Abebaw Teshome Tiruneh is employed as a senior lecturer in the Department of Food Engineering, Bahir Dar University, Institute of Technology, Ethiopia. His research experience includes postharvest management, grain science and technology, food fortification, food product development and preservation, and value additions.

Getnet Mekuria Mengie

Getnet Mekuria Mengie is a senior lecturer in the Department of Applied Human Nutrition, Bahir Dar University, Institute of Technology, Ethiopia. His research interst is nutrition and public health.

Abebaw Ayele Negatu

Abebaw Ayele Negatu is a lecturer in Food Engineering Department at Bahir Dar Institute of Technology, Bahir Dar University, Ethiopia. He conducts research in Food Processing, Postharvest Technology, Food Preservation, Nutrition, and New Food Product Development.

References

- AACC. (2000). Approved methods of the American Association of Cereal Chemists. Guidelines for measurement of volume by rapeseed displacement (10th ed.). Method 10–05.01. Author.

- Abdulkadir, A. (2014). A study on some vitamins and minerals content of wheat flour samples commonly sold within Kano Metropolitant. International Journal of Science and Research, 3(9), 686–689. https://www.ijsr.net/archive/v3i9/CVNFUDE0MTE5.pdf

- Adegunwa, M. O., Adelekan, E. O., Adebowale, A. A., Bakare, H. A., & Alamu, E. O. (2017). Evaluation of nutritional and functional properties of plantain (Musa paradisiaca L.) and tigernut (Cyperus esculentus L.) flour blends for food formulations. Cogent Chemistry, 3(1), 1. https://doi.org/10.1080/23312009.2017.1383707

- Adeoye, G. O., & Agboola, A. A. (1985). Critical levels for soil pH, available P, K, Zn and Mn and maize ear-leaf content of P, Cu and Mn in sedimentary soils of South-Western Nigeria. Fertilizer Research, 6(1), 65–15. https://doi.org/10.1007/BF01058165

- Agrahar-Murugkar, D. (2020). Food to food fortification of breads and biscuits with herbs, spices, millets and oilseeds on bio-accessibility of calcium, iron and zinc and impact of proteins, fat and phenolics. LWT-Food Science and Technology, 130(May), 109703. https://doi.org/10.1016/j.lwt.2020.109703

- Alemayehu, D., Desse, G., Abegaz, K., Desalegn, B. B., & Getahun, D. (2016). Proximate, mineral composition and sensory acceptability of home made noodles from stinging nettle (Urtica simensis). Leaves and Wheat Flour Blends, 6(3), 55–61. https://doi.org/10.5923/j.food.20160603.02

- Alshuwayeb, M. H., & Al-Khatib, A. J. (2013). Molecular and chemical therapeutic features of Urtica species. European Journal of Scientific Research, 9(24), 253–261.

- Ameh, M. O., Gernah, D. I., & Igbabul, B. D. (2013). Physico-chemical and sensory evaluation of wheat bread supplemented with stabilized undefatted rice bran. Food and Nutrition Sciences, 4(43), 43–48 .

- Anton, M. (2008). Utilization of sweet potato starch, flour and fiber in bread and biscuits: physic-chemical and nutritional characteristics [A thesis submitted in partial fulfillment of the requirements for the degree Master of Technology in Food Technology]. Massey University.

- AOAC (1984). Official methods of analysis of AOAC International (14th ed.). Association of Official Analytical Chemists.

- AOAC (2005). Official method of analysis of the Association of Official Analytical Chemists. Method Nos: 925.10, 923.03, 962.09, 979.09 and 920.39.

- Assefa, E. S., Haki, G. D., & Demoz, G. A. (2013). Nutritional profile of samma (Urtica simensis Steudel) leaves grown in Ethiopia. International Journal of Science Innovations and Discoveries, 3(1), 153–160.

- Babiker, W. A., Sulieman, A. M. E., Elhardallou, S. B., & Khalifa, E. A. (2013). Physicochemical properties of wheat bread supplemented with orange peel by-products. International Journal of Nutrition and Food Sciences, 2(1), 1. https://doi.org/10.11648/j.ijnfs.20130201.11

- Bakare, A. H., Osundahunsi, O. F., & Olusanya, J. O. (2015). Rheological, baking, and sensory properties of composite bread dough with breadfruit (Artocarpus communis Forst) and wheat flours. Food Science & Nutrition, 4(4), 573–587. https://doi.org/10.1002/fsn3.321

- Bayba, K. B., Dubale, A. A., Mehari, B., & Atlabachew, M. (2020). Chemical composition of Urtica simensis grown in different regions of Ethiopia. Journal of Chemistry, 2020, 1–8. https://doi.org/10.1155/2020/9546178

- Bekele, B., Melesse, A., & Beyan, M. (2015). The effect of feeding stinging nettle (Urtica simensis S.) leaf meal on feed intake, growth performance and carcass characteristics of Hubbard broiler chickens. Global Journal of Science Frontier Research: D Agriculture and Veterinary, 15(3), 1–20.

- Bourekoua, H., Różyło, R., Gawlik-Dziki, U., Benatallah, L., Zidoune, M. N., & Dziki, D. (2018). Evaluation of physical, sensorial, and antioxidant properties of gluten-free bread enriched with Moringa oleifera leaf powder. European Food Research and Technology, 244(2), 189–195.

- CSA & ICF (2016). Central statistical agency [Ethiopia] and ICF International. Ethiopia Demographic and Health Survey.

- Czarnowska-Kujawska, M., Starowicz, M., Barišíc, V., & Kujawski, W. (2022). Health-promoting nutrients and potential bioaccessibility of breads enriched with fresh kale and spinach. Foods, 11(21), 3414. https://doi.org/10.3390/foods11213414

- Dako, E., Retta, N., & Desse, G. (2016). Effect of blending on selected sweet potato flour with wheat flour on nutritional, anti-nutritional and sensory qualities of bread. Global Journal of Science Frontier Research: D Agriculture and Veterinary, 16(4), 31–42.

- Dziki, D., Różyło, R., Gawlik-Dziki, U., & Świeca, M. (2014). Current trends in the enhancement of antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds. Trends in Food Science & Technology, 40(1), 48–61. https://doi.org/10.1016/j.tifs.2014.07.010

- El-Gammal, R. E., Ghoneim, G. A., & ElShehawy, S. M. (2016). Effect of moringa leaves powder (Moringa oleifera) on some chemical and physical properties of pan bread. Journal of Food and Dairy Sciences, 7(7), 307–314.

- Eshetu, M., Atlabachew, M., & Abebe, A. (2018). Quality assessment of wheat bread baked in Bahir Dar City, Ethiopia. Journal of Food Quality and Hazards Conrol, 5(2), 77–80. https://doi.org/10.29252/jfqhc.5.2.8

- FAO, IFAD, UNICEF, & WHO (2020). The state of food security and nutrition in the world. Transforming food systems for affordable healthy diets. FAO.

- Govender, L., & Siwela, M. (2020). The effect of Moringa oleifera leaf powder on the physical quality, nutritional composition and consumer acceptability of white and brown breads. Foods, 9(12), 1–17. https://doi.org/10.3390/foods9121910

- Gurung, B., Ojha, P., & Subba, D. (2016). Effect of mixing pumpkin puree with wheat flour on physical, nutritional and sensory characteristics of biscuit. Journal of Food Science and Technology Nepal, 9, 85–89. https://doi.org/10.3126/jfstn.v9i0.13142

- Hathorn, C. S., Biswas, M. A., Gichuhi, P. N., & Bovell-Benjamin, A. C. (2008). Comparison of chemical, physical, microstructural and microbial properties of breads supplemented with sweet potato flour and high-gluten dough enhancers. LWT-Food Science and Technology, 41(5), 803–815. https://doi.org/10.1016/j.lwt.2007.06.020

- Julianti, E., Rusmarilin, H., Ridwansyah, & Yusraini, E. (2017). Functional and rheological properties of composite flour from sweet potato, maize, soybean and xanthan gum. Journal of the Saudi Society of Agricultural Sciences, 16(2), 171–177. https://doi.org/10.1016/j.jssas.2015.05.005

- Keflie, T. S., Triller, S., Wald, J. P., Lambert, C., Nohr, D., & Biesalski, H. K. (2015). Stinging nettle (Urtica simensis): An indigenous but unrecognized micronutrient potential for combatting hidden hunger in Ethiopia. University of Hohenheim, 7(10). https://doi.org/10.1002/fsn3.259

- Khoozani, A. A., Kebede, B., Birch, J., & Bekhit, A. E. A. (2020). The effect of bread fortification with whole green banana flour on its physicochemical, nutritional and in vitro digestibility. Foods, 9(2), 152. https://doi.org/10.3390/foods9020152

- Kumar, P., Yadava, R. K., Gollen, B., Kumar, S., Verma, R. K., & Yadav, S. (2011). Nutritional contents and medicinal properties of wheat: A review. Life Sciences and Medicine Research, 2011(1), 22.

- Lagnika, C., Houssou, P. A. F., Dansou, V., Hotegni, A. B., Amoussa, A. M. O., Kpotouhedo, F. Y., Doko, S. A., & Lagnika, L. (2019). Physico-functional and sensory properties of flour and bread made from composite wheat-cassava. Pakistan Journal of Nutrition, 18(6), 538–547. https://doi.org/10.3923/pjn.2019.538.547

- Lim, P. Y., Sim, Y. Y., & Nyam, K. L. (2020). Influence of kenaf (Hibiscus cannabinus L.) leaves powder on the physico‑chemical, antioxidant and sensorial properties of wheat bread. Journal of Food Measurement and Characterization, 14(5), 2425–2432. https://doi.org/10.1007/s11694-020-00489-y

- Maietti, A., Tedeschi, P., Catani, M., Stevanin, C., Pasti, L., Cavazzini, A., & Marchetti, N. (2021). Nutrient composition and antioxidant performances of bread-making products enriched with stinging nettle (Urtica dioica) leaves. Foods, 10(5), 938. https://doi.org/10.3390/foods10050938

- Malomo, S. A., Fashakin, J., & Eleyinmi, A. (2011). Chemical composition, rheological properties and bread making potentials of composite flours from breadfruit, breadnut and wheat. African Journal of Food Science, 5(7), 400–410.

- Man, S., Păucean, A., Muste, S., Pop, A., Sturza, A., Mureșan, V., & Salanță, L. C. (2017). Effect of incorporation of sunflower seed flour on the chemical and sensory characteristics of cracker biscuits. Bulletin of University of Agricultural Sciences and Veterinary Medicine Cluj-Napoca. Food Science and Technology, 74(2), 95. https://doi.org/10.15835/buasvmcn-fst:0018

- Manyatsi, N. T., Solomon, W. K., & Shelembe, J. S. (2020). Optimization of blending ratios of wheat-maize-sprouted mungbean (Vigna radiata L.) composite flour bread using D-optimal mixture design. Cogent Food & Agriculture, 6(1), 1824304. https://doi.org/10.1080/23311932.2020.1824304

- Mbah, B. O., Eme, P. E., & Paul, A. E. (2012). Effect of drying techniques on the proximate and other nutrient composition of Moringa oleifera leaves from two areas in eastern Nigeria. Pakistan Journal of Nutrition, 11(11), 1044–1048. https://doi.org/10.3923/pjn.2012.1044.1048

- Ndife, J., Abdulraheem, L. O., & Zakari, U. M. (2011). Evaluation of the nutritional and sensory quality of functional breads produced from whole wheat and soya bean flour blends. African Journal of Food Science, 5(8), 466–472. http://www.academicjournals.org/ajfs

- O’Connor, A. (2012). An overview of the role of bread in the UK diet. Nutrition Bulletin, 37(3), 193–212. https://doi.org/10.1111/j.1467-3010.2012.01975.x

- Odunlade, T. V., Famuwagun, A. A., Taiwo, K. A., Gbadamosi, S. O., Oyedele, D. J., & Adebooye, O. C. (2017). Chemical composition and quality characteristics of wheat bread supplemented with leafy vegetable powders. Journal of Food Quality, 2017, 1–7. https://doi.org/10.1155/2017/9536716

- Pasrija, D., Ezhilarasi, P. N., Indrani, D., & Anandharamakrishnan, C. (2015). Microencapsulation of green tea polyphenols and its effect on incorporated bread quality. LWT-Food Science and Technology, 64(1), 289–296. https://doi.org/10.1016/j.lwt.2015.05.054

- Rodriguez-Amaya, D. B., & Kimura, M. (2004). HarvestPlus hand-book for carotenoid analysis. HarvestPlus technical monograph 2. International Food Policy Research Institute.

- Seifu, T., Mehari, B. Á., Atlabachew, M., & Chandravanshi, B. (2017). Polyphenolic content and antioxidant activity of leaves of Urtica simensis grown in Ethiopia. Latin American Applied Research-An International Journal, 47(1), 35–40. https://doi.org/10.52292/j.laar.2017.295

- Sengev, A. I., Abu, J. O., & Gernah, D. I. (2013). Effect of Moringa oleifera leaf powder supplementation on some quality characteristics of wheat bread. Food and Nutrition Sciences, 4(3), 270–275. https://doi.org/10.4236/fns.2013.43036

- Singha, D., Jubayer, M. F., Devnath, K., Akhter, D., Ranganathan, T. V., Rahman, M. T., & Mazumder, M. A. R. (2021). Nutritional, textural, and sensory quality of Aloe vera leaf gel powder fortified plain cake. J-Multidisciplinary Scientific Journal, 4(3), 430–443. https://doi.org/10.3390/j4030033

- Srirejeki, S., Manuhara, G. J., Amanto, B. S., Atmaka, W., & Laksono, P. W. (2018). The effect of water volume and mixing time on physical properties of bread made from modified cassava starch-wheat composite flour. IOP Conference Series: Materials Science and Engineering, 333(1), 012072. https://doi.org/10.1088/1757-899X/333/1/012072

- Tsegaye, W., Urga, K., & Asres, K. (2016). Antidiabetic activity of samma (Urtica simensis Hochst. ex. A. Rich.) in streptozotocin-induced diabetic mice. Ethiopian Pharmaceutical Journal, 27. https://doi.org/10.4314/epj.v27i2.58265

- Türker, B., Savlak, N., & Kaşıkcı, M. (2016). Effect of green banana peel flour substitution on physical characteristics of gluten-free cakes. Current Research in Nutrition and Food Science Journal, 4(Special-Issue-October), 197–204.

- World Health Organization (2021). The European health report 2021. Retrieved August 17, 2022, from https://apps.who.int/iris/bitstream/handle/10665/352131/9789289057608-eng.pdf

- Zhang, Y., Li, D., Yang, N., Jin, Z., & Xu, X. (2018). Comparison of dextran molecular weight on wheat bread quality and their performance in dough rheology and starch retrogradation. LWT-Food Science and Technology, 98, 39–45. https://doi.org/10.1016/j.lwt.2018.08.021

- Zula, A. T., Ayele, D. A., & Egigayhu, W. A. (2021). Proximate composition, antinutritional content, microbial load, and sensory acceptability of noodles formulated from moringa (Moringa oleifera) leaf powder and wheat flour blend. International Journal of Food Science, 2021, 1–6, 6689247. https://doi.org/10.1155/2021/6689247