Abstract

Modern economies grapple with unprecedented challenges that yielded traditional supply chain resilience (SCR) ineffective, creating a race towards digital supply chain resilience (DSCR) through adopting Industry 4.0 (I4.0) strategies and technologies, with the primary goal to fortifying organizations’ capabilities in promptly and efficiently identifying, mitigating, and rebounding from disruptions. This shift highlights the critical differences between traditional SCR and the emerging DSCR paradigm. Nevertheless, the literature on DSCR, especially pertaining to precise investment strategies, remains notably limited. This research seeks to address this critical gap through an empirical investigation leveraging insights from seasoned supply chain experts in academia and industry. Distinguishing itself, the study meticulously navigates investment decisions, aiming for a striking delicate balance between avoiding over-investment risks jeopardizing profitability and steering clear of under-investment pitfalls exposing vulnerabilities. This research stands as a distinctive contribution to existing literature, offering actionable insights into the nuanced realm of DSCR, while highlighting the shifting dynamics between traditional SCR and emerging DSCR strategies. However, while insights from experienced experts offer valuable perspectives, the study is not immune to empirical challenges. Individual industry contexts may introduce variability in strategy applicability. Additionally, the dynamic landscape of technology and business practices implies findings may need periodic reassessment. Despite these limitations, the research’s implications are profound, serving as a roadmap for organizations navigating toward DSCR complexities, and for policymakers aiming towards providing efficient regulations and ecosystems that allow for harnessing I4.0 powers in enhancing an organization’s DSCR within financial constraints.

1. Introduction

The increasing integration of Industry 4.0 (I4.0) technologies in industry, logistics, and supply chains has revolutionized the way organizations approach new states of production and transportation activities towards the so-called high-performance supply chain management (SCM). Nevertheless, digital transformation (DT) projects are complex, interdisciplinary, and costly; hence, it has become an imperative prerequisite to evaluate the optimum I4.0 investments prior to embarking on such intricate projects (Al-Banna et al., Citation2022). This paper employs an empirical investigation analysis based on a comprehensive survey that received the necessary recognition and approvals from Institutional Review Board (IRB) under the number HBKU-IRB-2024-10, with the objective of evaluating perspectives from supply chain (SC) professionals in industrial (market, business) and academic environments about the impact of a wide range of I4.0 technologies on SCR. In addition, the paper validates participants’ inputs through a verification channel of seven layers with the acronym ‘GRACIAS’ (Al-Banna et al., Citation2023), offering valuable insights for organizations marching towards enhancing their DSCR. The findings of this paper emphasize the importance of carefully considering the resilience drivers and the aspects of vulnerabilities towards supply chain resilience (SCR) when making investment decisions in I4.0 technologies, in addition to other critical factors. The results highlight the crucial role that thorough evaluation of the factors contributing to SCR plays when investing in advanced technologies. It is important to recognize that SCR is a complex and dynamic concept influenced by various internal and external factors, such as regulatory environment, cybersecurity, scalability, among others. It is necessary to consider these and all relevant factors when making investment decisions. Therefore, the resilience drivers and the aspects of vulnerabilities of SCR must be taken into account, along with other critical factors, to ensure that investment decisions are well-informed and aligned with long-term strategic goals. This paper contributes to the existing body of knowledge on SCR and I4.0 by offering valuable insights on identifying I4.0 investments for enhanced SCR that falls within the SC resilience fitness space (RFS).

Today’s rapidly changing and unpredictable global markets can have serious impacts on an organization’s operations, reputation, revenues, and even survival. Hence, organizations have been investing in enhancing their SCR capability to minimize the risk of disruptions and augment their ability to detect, avoid, and recover efficiently and timely from a disruption. However, answering the questions of where to invest and how much to invest remains a challenge for organizations to conquer. Balancing the investment in enhancing SCR capabilities with investment and financial considerations is crucial in establishing the ideal RFS. On one hand, a significant investment in enhancing resilience can help organizations better prepare for and respond to disruptions. This can include as an example investing in risk management systems, contingency plans, and training and development programs for employees. While, on the other hand, excessive investment in resilience measures may not be financially feasible for some organizations since it can divert resources away from other critical areas of the business. Within the same context, a dearth of investment in SCR, misallocated investments towards unsuitable technologies, or investments of an insufficient scale in appropriate technologies can all engender heightened levels of vulnerability for an organization, impeding its ability to respond effectively to disruptions, whether natural, man-made or the recent black swan of COVID-19 pandemic (Carrillo et al., Citation2022). The ideal RFS is one where organizations invest in enhancing their SCR capability in a way that is both effective and financially responsible (Pettit et al., Citation2010). This requires organizations to engage in a comprehensive risk assessment process and prioritize their investments based on the likelihood and impact of potential disruptions. By carefully balancing their investment in resilience with financial and sustainable considerations, organizations can achieve a RFS that provides a solid foundation for risk management and response, while also ensuring their long-term financial viability. In summary, the concept of RFS as applied to SCM is an important consideration for organizations’ resilience and efficiency throughout raw material (crude oil, minerals, food, etc.) to product (gasoline, copper, etc.) value chains.

Capitalizing on the previous fundamentals of SC and in the wake of the rapid pace of technological advancements of the I4.0 age, the conventional investment in SCR does not suffice in combating today’s ever-increasing and evolving distributions and risks (Calabrese & Vervaeke, Citation2017). Hence, investment in I4.0 technologies is a critical necessity in today’s rapidly changing and interconnected global market. Investing in I4.0 technologies can help organizations improve their SC visibility, SC structure, SC information sharing, among other SCR drivers, allowing them to quickly identify and respond to disruptions.

Furthermore, to gain a comprehensive understanding of the benefits of investing in I4.0 technologies for supply chain resilience, it is essential to consider the perspectives of supply chain experts. While some organizations may be hesitant to invest in new technologies due to uncertainty about their potential benefits and costs, empirical research can provide valuable insights into these issues. By surveying supply chain experts, organizations can gain a better understanding of the specific benefits that I4.0 technologies can provide, and how investment in these technologies can improve their supply chain resilience.

Empirical research, including survey investigations, has long been recognized as a valuable methodology for gaining insights into complex phenomena (Creswell & Creswell, Citation2017). In the context of supply chain management, an empirical survey investigation can provide a unique opportunity to tap into the collective knowledge of supply chain experts and gain a deeper understanding of I4.0 technologies and investment in DSCR.

One of the key advantages of empirical survey investigations is their ability to generate quantitative data that can be analyzed using statistical methods to identify patterns and relationships between variables (Wolf et al., Citation2016). In the case of our research, a survey investigation can provide a wealth of quantitative data on supply chain experts’ perceptions of I4.0 technologies and their impact on DSCR. By analyzing this data, we can gain a clearer understanding of the factors that influence investment decisions in digital transformation for enhanced SCR and identify opportunities for improving supply chain performance through the adoption of I4.0 technologies.

Moreover, a well-designed survey investigation can enable us to draw inferences about the wider population of supply chain experts from which our sample is drawn. This can be achieved by using rigorous sampling techniques to ensure that our sample is representative of the population of interest, and by employing statistical techniques to control bias and confounding factors. By doing so, we can generate results that are generalizable beyond our sample since these results can contribute to the wider body of knowledge on the topic.

Another advantage of survey investigations is their ability to capture rich qualitative data through open-ended questions or structured interviews (Fowler, Citation2013). This allows us to gain a more nuanced understanding of supply chain experts’ perceptions and experiences, and to explore the reasons behind their attitudes and behaviors. In the context of our research, open-ended questions can be used to probe deeper into the factors that influence investment decisions in digital supply chain resilience and the challenges that organizations face when adopting I4.0 technologies.

Finally, survey investigations can be a cost-effective way to collect data from a large and diverse group of respondents (Dillman et al., Citation2014). This is particularly important in the context of our research, where we aim to gather perspectives from a wide range of SC experts with different backgrounds and experiences. By administering the survey online, we can reach a geographically dispersed group of respondents and minimize the costs associated with data collection.

This paper endeavors to elicit the perspectives of erudite professionals and scholars in the fields of DSCR and I4.0 regarding the interplay between SCR and SCV drivers, as well as I4.0 technologies in the context of enhancing DSCR. One of the salient contributions of this paper to the extant knowledge base in this area is the presentation of a comprehensive and methodical roadmap that provides both academic and business domains with robust guidelines for progressing towards their DSCR objectives within the resilience fitness space (RFS). The guidelines emanate from the expertise and erudition of a cohort of supply chain and logistics professionals hailing from aviation, shipping, maritime, and logistics industries, along with distinguished academics and scholars from the field, acquired via a structured survey.

In order to ensure the validity and reliability of the survey, a thorough survey design and pilot study was conducted before the main data collection stage took place. The survey was designed based on a thorough review of the literature and input from experts in the field of supply chain resilience and I4.0 technologies. A sample of 30 supply chain professionals participated in the pilot study. The thirty participants where split equally between industry and academy, where 15 participants from each domain globally. The industry participants were split among; airlines, airports, shipping companies, seaports, and land transport. The authors have worked with renowned organizations in these sectors that enabled such a widespread and global reach. Each respondent was met individually, either physically or virtually for about fifteen minutes where detailed discussions took place about the survey background, motivation, design, the target perspectives to be addressed, the similarity among various SCR drivers and how to distinguish them for the survey respondents. Similarly, the pilot discussed the similarities among the various SCV drivers and ways to simplify them for the survey respondents. Next, the I4.0 technologies were discussed with the 30 pilot respondents, as well as the GRACIAS verification channels in detail (Al-Banna et al., Citation2023). The pilot survey assessment yielded a number of recommendations such as providing definitions for the SCR, SCV and GRACIAS. Next, another recommendation was to provide detailed definitions of I4.0 technologies, as the respondents believe that different SC experts could have different perceptions about each I4.0 technologies.

In addition to the aforementioned path the construction of the proposed survey (see in Appendix), this critical phase of the survey design identified and addressed some areas of improvements with respect to issues with survey wording, structure, and response gathering options. For the purpose of this paper, these cognitive interviews pilot survey approach were deemed the most appropriate methodology for evaluating survey question quality and identifying areas for improvement, given the valuable insights obtained by the SC experts.

In Section 2, a literature review is presented followed by a discussion of the I4.0 technologies considered for the empirical investigation analysis. In Section 3, the empirical investigation methodology is addressed. In Section 4, the empirical investigations, findings, and discussions are presented. In Section 5, the research implications and managerial perspectives are discussed. Finally, Section 6 presents the paper conclusions. The designed survey is found as Appendix.

2. Literature review and overview of the industry 4.0 technologies considered for the empirical investigation analysis

2.1. Literature review

Prior to delving into the key I4.0 technologies, the paper presents a summary of key papers that addresses and provides valuable contribution to the knowledge base of this topic. For example, Xu et al. (Citation2021) provide several key takeaways and recommendations regarding the implementation and perception of I4.0 and Industry 5.0 (I5.0) paradigms. Firstly, it highlights that I4.0 represents a transformative concept integrating advanced technologies such as the Internet of Things (IoT), Cyber-physical Systems (CPS), and Big Data Analytics (BDA), offering potential benefits such as increased productivity, improved quality, and enhanced customization capabilities. Secondly, the paper emphasizes that I5.0 builds upon I4.0 by recognizing the importance of human-machine collaboration and the integration of human skills with advanced technologies. It underscores the role of AI in facilitating seamless interaction between humans and machines. The paper further emphasizes the need to address challenges and barriers to successfully implement I4.0 and I5.0. It highlights concerns related to data security and privacy, which need to be adequately addressed. Furthermore, the importance of investing in workforce upskilling and training is stressed to ensure a smooth transition to these new paradigms. Furthermore, the perception and adoption of I4.0 and I5.0 are acknowledged to vary across industries and countries. Consequently, the paper recommends that organizations consider industry-specific needs, market conditions, and technological readiness when formulating implementation strategies. Collaboration and knowledge sharing among researchers, practitioners, and decision-makers are deemed crucial to drive the understanding and adoption of these paradigms. Platforms facilitating the exchange of best practices, lessons learned, and case studies are suggested to facilitate successful implementation. Lastly, the paper advises organizations to continuously monitor technological advancements and market trends to stay abreast of developments and adapt strategies accordingly. Regular assessment and evaluation of I4.0 and I5.0 initiatives are encouraged to identify areas for improvement and refine implementation approaches.

On the other hand, Singh et al. (Citation2023) offer valuable insights and recommendations regarding the use of Digital Twin technology to improve resilience and sustainability in food supply chains. The study employs a grey causal modelling (GCM) approach to analyze the relationships and causalities within the supply chain network. The key insights from this research include the identification of critical factors that impact the resilience and sustainability of food supply chains. The authors highlight the importance of understanding the complex interactions between these factors and propose the use of Digital Twin technology as a valuable tool for modeling and simulating supply chain operations. The study demonstrates that Digital Twin technology can provide a dynamic and real-time representation of the supply chain, enabling stakeholders to anticipate and respond to disruptions more effectively. Furthermore, the paper emphasizes the significance of resilience and sustainability in the context of food supply chains. It highlights the need for proactive strategies to mitigate risks and enhance the overall performance of the supply chain network. The authors suggest that Digital Twin technology can support decision-making processes by providing insights into potential bottlenecks, vulnerabilities, and opportunities for improvement. Based on their findings, the paper provides several recommendations for practitioners and policymakers. Firstly, organizations in the food industry should consider adopting Digital Twin technology as a means to enhance resilience and sustainability in their supply chains. This technology can facilitate real-time monitoring, predictive analytics, and scenario-based simulations, enabling proactive decision-making and rapid response to disruptions. Secondly, collaboration among stakeholders is crucial for effective implementation of Digital Twin technology. This includes sharing data and knowledge, aligning goals and objectives, and establishing partnerships to address common challenges in the food supply chain. Collaboration can help build a more resilient and sustainable ecosystem by fostering information exchange and coordinated decision-making. Lastly, policymakers are urged to create an enabling environment for the adoption of Digital Twin technology in the food industry. This includes developing supportive regulatory frameworks, incentivizing investments in digitalization, and promoting research and development activities in the field. Policymakers should also consider the ethical and privacy implications associated with the use of digital technologies in supply chain operations.

Furthermore, Ghobakhloo (Citation2020) present key insights, value adds, and recommendations regarding the intersection of I4.0, digitization, and sustainability. The study explores the potential of I4.0 technologies to contribute to sustainable development and addresses the challenges and opportunities associated with their adoption. One of the key insights of the paper is the recognition that I4.0 technologies, such as the IoT, BDA, and AI have the potential to enable significant sustainability improvements across various industries. These technologies offer opportunities for optimizing resource utilization, enhancing energy efficiency, reducing waste, and improving environmental performance. By leveraging digitalization, organizations can achieve more sustainable and environmentally friendly operations. The paper also highlights the value adds of adopting I4.0 technologies in terms of sustainability. It emphasizes that the integration of digital technologies with sustainable practices can lead to enhanced operational efficiency, increased competitiveness, and improved environmental and social outcomes. For example, real-time monitoring and data analytics can enable better decision-making and resource management, leading to reduced energy consumption and greenhouse gas emissions. The automation and connectivity enabled by I4.0 technologies can also contribute to safer working environments and improved labor conditions. Based on their analysis, the authors provide several recommendations for practitioners and policymakers. Firstly, organizations are encouraged to embrace a holistic approach to digital transformation, integrating sustainability considerations into their digitalization strategies. This includes adopting energy-efficient technologies, implementing circular economy principles, and prioritizing sustainable supply chain practices. By aligning digitalization efforts with sustainability goals, organizations can maximize the positive impact of I4.0 technologies. Secondly, collaboration and knowledge sharing among stakeholders are emphasized as critical enablers for sustainable I4.0 implementation. Partnerships between industry, academia, government, and civil society can foster innovation, facilitate technology transfer, and address challenges related to skills development and workforce transition. The paper suggests the creation of collaborative platforms, networks, and policy frameworks to support the exchange of best practices and promote collective action towards sustainability. Lastly, policymakers are urged to develop supportive regulations and incentives to encourage the adoption of sustainable I4.0 practices. This includes the establishment of standards for energy efficiency, waste reduction, and environmental performance. Policy interventions should also promote the development and deployment of sustainable technologies, provide financial support for sustainable initiatives, and encourage sustainable practices through regulatory frameworks.

In the same connection, Rajesh (Citation2023) presents valuable inputs and recommendations with regards to the prediction of environmental sustainability performances of firms using a trigonometric grey prediction model. The study aims to develop a forecasting model that can assist in predicting the future environmental sustainability performances of firms, thereby supporting decision-making and facilitating sustainability planning. One of the key insights of the paper is the application of a trigonometric grey prediction model as a tool for predicting environmental sustainability performances. The authors highlight the importance of accurate prediction models in assessing and monitoring the environmental impact of firms. By utilizing the trigonometric grey prediction model, the study demonstrates the potential to forecast environmental sustainability performances and anticipate future trends, enabling proactive measures and informed decision-making. The value adds of this research lie in its contribution to the field of environmental sustainability performance prediction. The paper introduces a novel approach that combines trigonometric functions and grey forecasting techniques to improve the accuracy of predictions. The trigonometric grey prediction model offers a flexible and reliable framework for capturing the complex dynamics and interrelationships involved in environmental sustainability performances. The study also provides empirical evidence of the effectiveness of the proposed model through the analysis of real-world data. Based on their findings, the authors provide several recommendations for practitioners and policymakers. Firstly, firms are encouraged to adopt proactive measures in assessing and improving their environmental sustainability performance. The trigonometric grey prediction model can serve as a valuable tool for firms to monitor their progress, identify areas for improvement, and set realistic targets for sustainable practices. By leveraging predictive modeling, firms can anticipate future challenges and develop appropriate strategies to mitigate environmental impacts. Secondly, policymakers are urged to incorporate predictive modeling techniques, such as the trigonometric grey prediction model, into their policy-making processes. Accurate predictions of environmental sustainability performances can inform the development of effective regulations, incentives, and support mechanisms that encourage firms to adopt sustainable practices. Policymakers should also focus on fostering collaboration and knowledge sharing among firms to facilitate the implementation of sustainability initiatives and promote industry-wide environmental improvements. Lastly, the paper emphasizes the importance of further research and development in the field of environmental sustainability performance prediction. The authors suggest exploring advanced modeling techniques and integrating additional factors, such as social and economic indicators, into the predictive models. Continual refinement and validation of prediction models will enhance their reliability and applicability, enabling more accurate assessments of firms’ environmental sustainability performances.

Lastly, Sony and Naik (Citation2020) provide key insights, value adds, and recommendations regarding the evaluation of I4.0 readiness for organizations. The study aims to identify the essential components that contribute to an organization’s preparedness for I4.0 implementation through a comprehensive review of the existing literature. One of the key insights of the paper is the identification of key ingredients or factors that determine an organization’s readiness for I4.0. The authors emphasize that I4.0 readiness is not solely dependent on technological capabilities but also encompasses organizational, human, and strategic aspects. The study identifies a range of factors such as leadership commitment, organizational culture, digital infrastructure, data analytics capabilities, talent development, and strategic alignment that play a crucial role in determining an organization’s readiness for I4.0. The value adds of this research lie in its contribution to the understanding of I4.0 readiness evaluation. By synthesizing and analyzing the literature, the study provides a comprehensive framework that encompasses the multiple dimensions of readiness. This framework enables organizations to assess their strengths and weaknesses across various readiness factors, facilitating informed decision-making and targeted interventions to enhance their readiness for I4.0 adoption. Based on their analysis, the authors provide several recommendations for practitioners and researchers. Firstly, organizations are encouraged to conduct a thorough assessment of their readiness for I4.0 using a holistic approach. This involves evaluating not only technological aspects but also organizational and strategic factors. Organizations should leverage assessment tools and frameworks developed based on the identified key ingredients to gain insights into their current state and prioritize areas for improvement. Secondly, the paper highlights the importance of leadership commitment and organizational culture in fostering I4.0 readiness. Leaders and executive management should demonstrate a clear vision, commitment, and support for the digital transformation journey. They should also foster an innovative and agile culture that embraces change, experimentation, and continuous learning. Developing a shared understanding of the benefits and implications of I4.0 within the organization is crucial for successful implementation. Lastly, the study emphasizes the need for ongoing research and collaboration in the field of I4.0 readiness evaluation. Further empirical studies and case analyses are recommended to validate and refine the identified key ingredients and their impact on organizational readiness. Researchers are encouraged to explore the interdependencies and interactions among different readiness factors and develop practical tools and methodologies for assessing I4.0 readiness. The intricate and nuanced nature of these interdependencies, often delicately poised, seems to have been overlooked by scholarly scrutiny. Addressing and disentangling such complexities becomes notably challenging due to their elusive and frequently misconstrued character. This intricate landscape is further compounded by a prevailing dearth of comprehensive knowledge within both academic and business domains, a circumstance elucidated by Al-Banna et al. (Citation2023). The multifaceted interactions and dependencies between various elements necessitate a thorough exploration and understanding, wherein the dynamics of these relationships are intricately interwoven with both scholarly and practical dimensions. As we navigate this intricate terrain, it becomes evident that the limited comprehension of these interdependencies in academic and business contexts adds layers of intricacy to an already intricate web of relationships. The resulting confluence of factors underscores the critical need for a more nuanced and expansive comprehension of these intricacies to inform both scholarly inquiry and practical endeavors. This calls for an intensified focus on interdisciplinary collaboration and rigorous investigation to unravel the subtleties inherent in the interplay of factors, fostering a more comprehensive understanding that transcends conventional boundaries.

In summary, the explicated literature review proffers profound insights and discerning guidance for executives, practitioners, and researchers endeavoring to assess and augment their organizational preparedness for the adoption of I4.0. This comprehensive examination not only facilitates the strategic positioning of organizations but also imparts the requisite proficiency to adeptly navigate the intricate landscape rife with challenges and opportunities emblematic of the digital transformation era. By conscientiously adhering to the delineated recommendations, organizations can adroitly negotiate the intricate nuances associated with both I4.0 and I5.0, thereby harnessing the transformative potential inherent in these paradigms to achieve elevated levels of operational performance and competitive prowess.

Concomitantly, the literature unearths a discernible lacuna in the existing knowledge repository. This research, therefore, seeks to fill this void by undertaking a meticulous investigative approach, delving into the intricate terrain of investment decisions within the contextual ambit of I4.0. The literature notably lacks research that strikes a judicious equilibrium between the benefits, costs, and challenges intrinsic to I4.0 adoption. Consequently, this research assumes the onus of redressing this consequential gap, proffering recommendations imbued with value that can guide organizations in realizing their digital transformation objectives. This endeavor is particularly germane in mitigating the inherent risks associated with over-investing, which poses a potential compromise to organizational profitability, while concurrently averting the pitfalls of under-investment that might expose organizations to heightened vulnerabilities.

As a corollary, the research significantly contributes to the scholarly discourse by furnishing indispensable guidance for policymakers and decision-makers. It provides them with the necessary tools to cultivate resilient strategies, bespoke for the exigencies of I4.0, thereby deftly addressing the multifaceted challenges arising from the intersection of digital transformation and financial constraints. In essence, this scholarly endeavor stands as a distinctive and pragmatic contribution to the extant literature, offering nuanced insights into the realm of digital supply chain resilience within the expansive context of Industry 4.0 and its evolutionary trajectory.

2.2. Industry 4.0 technologies considered for the empirical study

Industry 4.0 (I4.0), also referred to as the Fourth Industrial Revolution, represents the integration of advanced digital technologies into traditional industrial processes. I4.0 is characterized by the widespread adoption of technologies such as artificial intelligence (AI), the internet of things (IoT), additive manufacturing (AM), cloud computing (CC), blockchain (BC), big data analytics (BDA), among others. These technologies are changing the way businesses interact with their customers, employees, and suppliers, leading to new opportunities and challenges (Hsu et al., Citation2022). In this paper, we will examine the details, potential applications, advantages, risks, and recommendations for each of these I4.0 technologies.

2.2.1. Artificial intelligence

Artificial Intelligence (AI) is the development of computer systems that can perform tasks that typically require human intelligence, such as visual perception, speech recognition, decision-making, and language translation. AI has a wide range of potential applications in various industries, including healthcare, finance, manufacturing, and retail. In healthcare, this can be used to diagnose diseases and analyze patient data to provide personalized treatment plans. In finance, AI can be used to identify fraud and predict market trends. In manufacturing, AI can optimize production processes, reduce waste, and improve quality control. In retail, it can provide personalized shopping experiences, improve SCM and better sales forecast (Gupta et al., Citation2022). The main advantage of AI is its ability to automate tasks that would otherwise require human intelligence, freeing up human capital time and resources for more complex and creative tasks. AI can also process large amounts of data faster and more accurately than humans, enabling businesses to make more informed decisions. Additionally, AI can reduce the cost of operations, increase efficiency, and improve product quality. On the other hand, one of the main risks of AI is the potential for job loss as automation replaces human workers. Additionally, AI systems can be biased if the data used to train them is biased, leading to inaccurate and discriminatory decisions. There is also the risk of AI systems being hacked and used for malicious purposes.

Recent research proposes a new approach to AI that focuses on integrating human-like intelligence and machine learning algorithms and suggests that the third generation of AI should be capable of reasoning and decision-making using both symbolic and sub symbolic techniques, allowing machines to handle complex and uncertain situations in a more efficient manner. Additionally, researchers emphasize the importance of integrating AI into a broader social and ethical context to address potential biases and unintended consequences of AI. The third generation AI has the potential to create significant benefits for society, but it will require a collaborative effort among researchers, policymakers, and other stakeholders to ensure its success (Belhadi et al., Citation2022). To maximize the benefits of AI while minimizing the risks, it is important to have proper regulations in place to ensure that AI systems are transparent and unbiased. Companies should also invest in training and development programs to help their employees’ transition to the new AI-driven workforce. Furthermore, businesses should prioritize cybersecurity to protect against potential threats to their AI systems since data is the main input for AI.

In the same context, the advancement and implementation of AI technologies may bring forth a plethora of hazards that demand attention in order to ensure their responsible and ethical usage. One of the most pressing concerns surrounding AI is the issue of bias and discrimination. AI systems rely on immense amounts of data for their training, and if this data is biased, the AI system will internalize and perpetuate these biases, potentially resulting in prejudiced outcomes such as the exclusion of certain groups from accessing services or the implementation of unjustly biased decisions against individuals or groups. To address this concern, it is crucial to ensure that AI systems are trained on inclusive and diverse data sets and to regularly assess and rectify any biases that may arise. Another risk associated with AI is job displacement, where the possibility of extensive automation leading to unemployment creates apprehension. To tackle this challenge, it is pivotal to provide aid to workers who face displacement due to AI adoption, by offering training and support to transition into new roles.

In the same connection, a key concern associated with AI is the lack of accountability. AI systems can make decisions that have significant impacts on people’s lives, but it is often difficult to determine who is responsible for these decisions and how they can be held accountable (Spieske & Birkel, Citation2021). To address this concern, it is important to develop AI systems that are transparent and explainable, so that their decision-making processes can be understood and evaluated. Finally, AI systems can also be vulnerable to hacking and cyberattacks, which can have serious consequences. To mitigate this risk, it is essential to ensure the security of AI systems, through the implementation of appropriate security measures and the use of secure development practices. To maximize the benefits of AI and minimize its associated risks, it is essential to develop AI in a responsible and ethical manner, taking into account the potential impacts of the technology on society. This requires a collaborative effort between policymakers, developers, and stakeholders, to ensure that AI is regulated and used in a manner that is consistent with ethical and social values (Zhang et al., Citation2022).

2.2.2. Internet of things

The Internet of Things (IoT) refers to the interconnected network of physical devices, engines, vehicles, industrial appliances, and other items that are embedded with electronics, software, and sensors, allowing them to collect and exchange data. IoT devices can be connected to the internet, allowing them to communicate with each other and with centralized systems. IoT is among the widely used I4.0 technologies with numerous potential applications (Irfan et al., Citation2022). For example, in the healthcare industry IoT can be used to monitor patients remotely, enabling healthcare providers to provide better care. In manufacturing, it can optimize production processes, reduce waste, analyze engines lubricant, and send notifications of necessary maintenance cycles, which improves industrial reliability and increases quality control. In energy systems, this can be used to manage energy usage and reduce waste, via smart lighting systems, among others. IoT’s key advantage steams from its ability to collect and analyze large amounts of data from various sources, enabling businesses to make more informed decisions.

While IoT brings about a range of benefits, there are also various risks associated with it. First, the security risks, due to the fact that IoT devices collect and transmit large amounts of data, they are vulnerable to hacking and cyberattacks. Hackers can exploit vulnerabilities in IoT devices to gain unauthorized access to sensitive information or control over the device itself. Similarly, IoT poses privacy risks as it collects and stores vast amounts of personal information, which could be accessed by unauthorized parties or used for malicious purposes. In addition, IoT could suffer from interoperability risks, where different IoT devices may use different protocols and standards, making it difficult for them to communicate and work together. This can lead to compatibility issues, system failures, and reduced efficiency. In the same connection, IoT has inherited reliability risks, due to its nature of relying on complex technologies, software and telecommunications and physical infrastructures, which can be subject to bugs and errors. If a device fails, it can cause disruptions in the system and impact the overall reliability of the IoT ecosystem (Sharma et al., Citation2020). Similarly, IoT poses legal risks, as it raises various legal questions, such as data protection, privacy, intellectual property, and liability.

To mitigate these risks and maximize the benefits of IoT technology, it is recommended to implement strong security measures with the objective to ensure that IoT devices are equipped with robust security protocols, such as encryption, firewalls, and secure authentication protocols. Similarly, it is advisable to regularly upgrade the software and firmware of IoT devices to address any potential vulnerabilities or bugs. In the same connection, it is recommended to review the type of personal information that is being collected and transmitted by IoT devices and take steps to ensure that this information is protected. Additionally, addressing the interoperability is key and encouraging the use of common standards and protocols to ensure that IoT devices can communicate and work together seamlessly.

In the same connection, a noteworthy niche area where IoT is increasingly considered is in the value chain of the liquefied natural gas (LNG) industry, which has witnessed tremendous growth in recent years, driven by increasing demand for cleaner energy sources and the expansion of LNG infrastructure worldwide. However, the storage and transportation of LNG pose significant challenges, particularly due to the generation of boil-off gas (BOG). BOG is a natural phenomenon that occurs when LNG warms up, causing it to vaporize and generate gas. The generation of BOG can lead to the loss of valuable energy and pose safety risks, making it a critical issue in the LNG industry. The adoption of IoT in the LNG industry can play a crucial role in enhancing the control of LNG resilience and minimizing the generation of BOG.

IoT technology can provide real-time visibility and monitoring capabilities for the LNG supply chain. By using IoT sensors and devices, companies can monitor the temperature, pressure, and other critical parameters of LNG storage tanks and pipelines in real-time, identify potential leaks or malfunctions, and take corrective action before they escalate. For instance, IoT sensors can be used to detect minor temperature changes in the LNG storage tanks, allowing operators to adjust the cooling systems to prevent BOG generation. Similarly, IoT devices can be used to monitor the pressure levels in the pipelines, ensuring that they remain within safe limits and preventing the formation of hot spots (Kochunni & Chowdhury, Citation2019).

Furthermore, IoT technology can provide valuable insights that can be used to optimize LNG transportation, reduce costs, and ensure compliance with regulatory requirements. By collecting and analyzing data from IoT sensors and devices, companies can gain valuable insights into the behavior of LNG and its transportation, helping them to make informed decisions about how to optimize the logistics of the supply chain. For instance, IoT data can be used to identify the most efficient routes for LNG transportation, reduce the frequency of LNG truck movements, and optimize the operation of LNG regasification facilities.

In addition, IoT can enhance the resilience of the LNG supply chain by providing early warning signals and real-time alerts. IoT sensors and devices can detect potential malfunctions or anomalies in the LNG storage tanks and pipelines, triggering automatic responses or alerts that can prevent the escalation of problems, especially when the IoT are augmented with S-C-A capabilities, to sense, calculate and actuate. For instance, IoT devices can trigger an automatic shutdown of the LNG storage tank if the temperature or pressure levels reach a critical threshold, preventing the generation of BOG and ensuring the safety of the facility and personnel.

In conclusion, the adoption of IoT technology in the LNG industry has the potential to enhance the control of LNG resilience and minimize the generation of BOG. By providing real-time monitoring capabilities, data insights, and early warning signals, IoT can help companies optimize their LNG operations, reduce costs, and ensure compliance with regulatory requirements. Furthermore, IoT can enhance the resilience of the LNG supply chain by preventing the escalation of problems and ensuring the safety of personnel and facilities. The adoption of IoT in the LNG industry is therefore crucial to meeting the increasing demand for cleaner energy sources while ensuring the safety and sustainability of the LNG supply chain (Kurle et al., Citation2015).

2.2.3. Additive manufacturing

Additive Manufacturing (AM), also known as 3D printing, is a process that involves building objects layer by layer using materials such as plastic, metal, or ceramic. This process differs from traditional manufacturing methods, such as injection molding or machining, which involve removing material to shape an object (Dev et al., Citation2021).

Additive Manufacturing has a wide range of potential applications in numerous industries. For example, in aerospace, AM can be used to produce lightweight and complex components. In the automotive industry, it can be used to produce prototyping and low volume production parts. In healthcare, it is used to produce customized prosthetics, implants, and surgical tools, in the same connection, there are incipient attempts in the biomedicine produce some human tissues.

However, AM technologies pose some risks that need to be addressed to ensure optimum use of this revolutionary technology. Among these risks is the AM potential to violate intellectual property (IP) rights. As AM technologies become more accessible, it is becoming easier for individuals and organizations to produce counterfeit goods without the need for the original equipment manufacturer (OEM) consent. To mitigate this risk, it is essential to establish and enforce IP laws that protect the rights of inventors, designers, and manufacturers (Menezes et al., Citation2019). Similarly, a significant risk associated with AM is the potential for the production of hazardous or unsafe products. AM technologies could allow organizations to produce complex objects with intricate internal structures, but it is difficult to ensure the safety of these objects. For example, an AM-produced object may have internal structures that are not strong enough to support the weight of the object, or it may contain internal defects that make the object prone to failure. To mitigate this risk, it is essential to establish quality control measures and to ensure that AM-produced objects are tested and certified to meet safety standards (Kurpjuweit et al., Citation2021).

2.2.4. Cloud computing

Cloud computing is a technology that enables users to access computing resources, such as servers, storage, and applications, over a network, without the need to invest in expensive hardware and software. The resources are managed by cloud service providers and made available to users on a pay-per-use basis, providing organizations and individuals with a cost-effective and scalable way to access computing resources (Stergiou et al., Citation2018).

One of the main benefits of cloud computing is its potential for cost savings. By eliminating the need for organizations to invest in expensive hardware and software, cloud computing can help organizations reduce capital expenditures (CAPEX) and operational expenses (OPEX). Additionally, the pay-per-use pricing model allows organizations to only pay for the computing resources that they actually use, helping to reduce costs even further. Another benefit of cloud computing is its scalability. By providing organizations with access to a shared pool of computing resources, cloud computing enables organizations to quickly and easily scale up or down their computing resources as needed, without having to invest in additional hardware and software. This allows organizations to respond quickly to changing business needs, increasing efficiency and competitiveness. Cloud computing has a wide range of potential industrial applications, including data storage, big data analysis, software as a service (SaaS), platform as a service (PaaS), and infrastructure as a service (IaaS). For example, cloud computing can be used to store and analyze large amounts of data, such as customer data, sales data, and market data, to gain valuable insights into customer behavior and market trends (Ivanov et al., Citation2022). Additionally, cloud computing can be used to provide software and platform services, such as email, customer relationship management (CRM), and human resource management (HRM) systems, to organizations, allowing organizations to access these services without having to invest in expensive hardware and software (Srivastava & Khan, Citation2018).

Despite the many benefits of cloud computing, this technology also poses a number of risks that need to be addressed to ensure that cloud services are used in a responsible and safe manner. One of the main risks associated with cloud computing is security. As sensitive data is stored in the cloud, there is a risk that the data may be accessed by unauthorized individuals, stolen, or leaked. To mitigate this risk, it is essential to ensure that cloud service providers have strong security measures in place, such as encryption, firewalls, and access controls, and to conduct regular security audits to ensure that the security measures are effective (Tchernykh et al., Citation2019)

Another significant risk associated with cloud computing is the potential for data loss or corruption. As data is stored in the cloud, there is a risk that the data may be lost or corrupted, which can have serious consequences for organizations and individuals. To mitigate this risk, it is important to ensure that cloud service providers have robust backup and recovery processes in place, and to implement data backup and recovery strategies that are appropriate for the specific needs of the organization. Another risk associated with cloud computing is the potential for vendor lock-in. As organizations become dependent on cloud services, they may become locked into a specific vendor, which can limit their ability to switch to another vendor if the original vendor’s services become unavailable or if their prices increase. To mitigate this risk, it is important to ensure that cloud service providers have open and flexible platforms, and to implement strategies that allow organizations to easily switch between vendors if necessary.

2.2.5. Blockchain

Blockchain technology is a decentralized, distributed digital ledger that records transactions in a secure and transparent manner. It operates on a peer-to-peer network, where all participants have a copy of the ledger, and every new transaction is verified and added to the chain. This makes the data stored on the blockchain tamper proof.

The concept of tamper-proofing in blockchain technology refers to the immutability and integrity of the data stored on the blockchain. In a blockchain network, once a block is added to the chain, it cannot be modified or deleted without the consensus of the network participants. This is achieved through the use of complex cryptographic algorithms that ensure that the data on the blockchain is tamper resistant. The data on the blockchain is stored in blocks, which are linked together in a linear chain. Each block contains a cryptographic hash of the previous block, forming a secure and unalterable chain (Mukherjee et al., Citation2022). Any attempt to modify a block would invalidate the hash of that block, making it apparent to the rest of the network that the block has been tampered with. Furthermore, in a decentralized blockchain network, each node in the network stores a copy of the blockchain, which makes it difficult for attackers to tamper with the data. To successfully modify the data, an attacker would need to modify all the copies of the blockchain stored on every node in the network simultaneously, which is practically impossible due to the distributed nature of the blockchain (Min, Citation2019). Overall, the combination of cryptographic hashing and distributed storage makes the data stored on a blockchain highly resistant to cyber-attacks, making it a secure and trustworthy way to store and transmit valuable information.

One of the most well-known applications of blockchain technology is cryptocurrencies, such as Bitcoin. However, the potential industrial applications of blockchain go far beyond financial services. Blockchain can be used in SCM, voting systems, digital identity management, and even healthcare. The transparency and security provided by blockchain make it an attractive solution for a variety of industries (Bambara et al., Citation2018).

Despite its potential, there are also risks associated with blockchain technology. One of the major challenges is scalability, as the number of users and transactions on the network increase, the speed and efficiency of the network can decrease. Another risk is the lack of standardization, which makes it difficult for different blockchain systems to interact with each other. In addition, there are concerns about privacy and security, as the public nature of blockchain can make it vulnerable to hacking and malicious actors. To mitigate these risks, it is recommended that organizations thoroughly evaluate the security measures in place for any blockchain solutions they are considering. This includes assessing the cryptography used, network architecture, and the level of decentralization.

In addition, organizations should consider the legal implications of using blockchain, as the regulatory environment for blockchain technology is still evolving. Furthermore, it is recommended that organizations implement best practices for secure key management and limit the amount of sensitive information stored on the blockchain. It is also important for organizations to keep up to date with the latest developments in blockchain technology and stay informed about new security risks and vulnerabilities as they arise.

2.2.6. Big data analytics

Big data refers to the large and complex datasets that are generated by various sources, including social media, mobile devices, and IoT devices. These datasets are characterized by their volume, variety, velocity, and veracity, making them difficult to manage and process using traditional data processing tools (Hariri et al., Citation2019). Big data technologies have the potential to transform a variety of industries, from healthcare to finance, by providing organizations with new insights and opportunities for growth. For example, in healthcare, big data can be used to analyze patient data to improve diagnosis and treatment, while in finance, big data can be used to detect fraud and improve risk management. However, there are also significant risks associated with big data technologies, including data privacy and security. With the increasing amount of personal information being stored and processed, it is critical that organizations have strong data protection measures in place to ensure that sensitive information is not compromised (Vassakis et al., Citation2018).

In addition, there are also concerns about data quality and accuracy. As the volume and variety of data increases, it becomes more difficult to verify the accuracy and completeness of the data. This can lead to incorrect conclusions and decision making, which can have serious consequences. To mitigate these risks, it is recommended that organizations implement strong data protection measures, including data encryption, access controls, and data privacy policies (Tamym et al., Citation2021). It is also important to have a robust data management strategy in place, which includes data quality and accuracy checks. Furthermore, organizations should consider using big data technologies that are compliant with industry specific regulations and standards. This will help ensure that the data being processed is accurate and trustworthy and will reduce the risk of legal or regulatory issues. In summary, big data technologies have the potential to revolutionize a variety of industries and provide organizations with new insights and opportunities for growth. However, it is important for organizations to be aware of the risks and implement appropriate measures to mitigate them. This includes implementing strong data protection measures, having a robust data management strategy, and using compliant big data technologies.

2.2.7. Cyber physical systems

Cyber physical systems (CPS) refer to the integration of physical processes with computing and communication systems, allowing for the exchange of data between the physical and virtual domains. These systems are designed to interact with and control the physical world, making decisions based on real-time data and sensor inputs. CPS technologies have the potential to transform a wide range of industries, from manufacturing to energy, by providing organizations with new opportunities for efficiency, automation, and improved decision making. For example, in manufacturing, CPS technologies can be used to optimize production processes and reduce waste, while in energy, CPS technologies can be used to manage and optimize energy usage. However, there are also significant risks associated with CPS technologies, including security and privacy. CPS systems are often connected to the Internet, making them vulnerable to hacking and cyber-attacks, which can compromise the security and privacy of sensitive data. In addition, CPS systems can be vulnerable to physical attacks, such as tampering or destruction, which can disrupt their operation and cause harm.

To mitigate these risks, it is recommended that organizations implement strong security and privacy measures when deploying CPS technologies. This can include encryption, access control, and network security, as well as physical security measures to protect against physical attacks. Furthermore, organizations should also consider the human factors associated with CPS technologies, such as the impact on employment and the role of humans in the decision-making processes. For example, the increased automation of processes may lead to job losses, and it is important for organizations to consider the social and economic implications of these changes.

In conclusion, to maximize the return on investment on I4.0 technologies, and minimize its associated risks, it is essential to deploy these technologies in a responsible and safe manner, considering the potential impacts of the technology on society and industries. This requires a collaborative effort between policymakers, developers, and stakeholders, to ensure that I4.0 technologies are regulated and used in a manner that is consistent with ethical and safety standards.

3. The digital transformation race and empirical investigation methodology

3.1. The digital transformation race

In the prevailing socioeconomic landscape, there exists a palpable eagerness among nations, organizations and executives to transition into the digital sphere. Paradoxically, certain countries find themselves ensnared in an intense digital race, driven by the pursuit of immediate gains but inadvertently compromising long-term advancements due to an inadequate understanding of digital transformation and its latent implications. Faixo (Citation2018) delves into this complexity, seeking to unveil imbalances over time among countries’ performances in digital realms and their corresponding gross value added. The study advocates for a comprehensive digital analysis that transcends mere technological considerations, emphasizing the imperative for public and private entities to incorporate non-technical variables into their programs. Faixo (Citation2018) underscores that genuine strides in digital transformation can only be achieved by recognizing and treating such endeavors as intricate ecosystem phenomena. Similarly, within the industrial domain, companies grapple with substantial pressure to undergo digital transformation and leverage emerging technologies such as the Industrial Internet of Things (IIoT). Ghosh et al. (Citation2022) contribute to this discourse by introducing a pioneering conceptual framework rooted in dynamic capability theory. Derived from qualitative interviews with elite executives from major multinational firms, the framework delineates three core capabilities—digital sensing, digital seizing, and digital reconfiguring—each manifesting through associated capabilities such as strategic sensing, rapid prototyping, organization structure, business model transformation, and cultural/mindset transformation. The study also underscores the role of internal and external contingencies as moderating factors in the relationship between IIoT, emerging technologies, and digital transformative capability development. This contribution enhances our comprehension of digital transformation by elucidating a novel framework that sheds light on the intricate process of digital transformation. This notion is scrutinized by Al-Banna et al. (Citation2023), who underscore, in this contemporary era marked by unprecedented challenges, the paramount importance for organizations to instill resilience across all processes, particularly within supply chain management. This proclamation occurs against the backdrop of the intensifying race for digital transformation, prompting organizations to adhere meticulously to structured roadmaps in building digital supply chain resilience (DSCR). Al-Banna et al. (Citation2023) advocate for a nuanced balance between supply chain resilience (SCR) and supply chain vulnerabilities (SCV), ensuring organizational profitability is not compromised and vulnerabilities are not exacerbated. The paper delineates the evolution of SCR, explores the intricate interplay between SCR and SCV drivers, and advocates for targeted investments in specific I4.0 enablers. Essentially, the work offers a holistic discussion on the complementary relationship between SCR and SCV drivers, a profound understanding of I4.0 technologies’ potential contributions to DSCR, and a forward-looking roadmap aiming to integrate SCR drivers and SCV within the resilience fitness space (RFS).

In the amalgamated discourse of Faixo (Citation2018), Ghosh et al. (Citation2022), and Al-Banna et al. (Citation2023), a recurring theme surfaces concerning the dual nature of digital transformation—an enticing opportunity fraught with formidable challenges. This paradox is exemplified by the global eagerness to embrace the digital realm for short-term gains. Paradoxically, however, the complexities of digital transformation remain elusive and often misunderstood, contributing to a pervasive vagueness in its conceptualization across nations, organizations, and executive echelons. This common thread underscores the predicament posed by the lack of a clear understanding of digital transformation, transforming this ostensibly promising venture into a profound dilemma and a substantial risk for the misallocation of time and resources. This challenge is further accentuated by Gartner’s forecast (Gartner, Citation2018), which warns that a staggering 85% of artificial intelligence projects in 2022 may face failure due to various reasons. These encompass data inconsistencies, inappropriate algorithms, inefficiencies in human capital utilization, and critical factors such as a lack of alignment among leadership teams, micromanagement versus mismanagement, limited control over vendors, inadequate training and competencies, and insufficient understanding of technologies and their capabilities, which amplify the risks inherent in digital transformation initiatives. The paramount significance of this topic for decision-makers is underscored by multiple factors. Firstly, the intricate and costly nature of digital transformation demands meticulous consideration. Secondly, the anticipated surge in global investment in Industry 4.0 further elevates the urgency of understanding and navigating the complexities of digital transformation. To contextualize this urgency, projections by Sava (Citation2022) estimate that global spending on digital transformation in 2026 is anticipated to surpass a US$ 3.4 trillion. The convergence of these factors accentuates the imperative for policy and decision-makers to approach digital transformation with a nuanced understanding, strategic foresight, and a comprehensive grasp of the potential pitfalls to ensure the realization of its promises and the mitigation of inherent risks.

3.2. The empirical investigation methodology

The research aims to source the perceptions of industrial (market, business) and academic experts in the fields of DSCR and I4.0 with respect to the interconnectedness between supply chain resilience (SCR) and supply chain vulnerabilities (SCV) drivers, as well as I4.0 technologies within the domain of enhancing DSCR. One of this paper addition to the base of knowledge in this field is that it presents the views and perceptions of both business and academic domains with robust guidelines that represent a structured and methodological roadmap for organizations marching toward achieving their DSCR that falls within the resilience fitness space (RFS). The guideline is built upon the intelligence and expertise of tens of the logistics and SC professionals from aviation, shipping, maritime and logistics industries, in addition to distinguished academics and scholars from the field through a structured survey.

3.2.1. Pilot survey and methodology assessment

To ensure the validity and reliability of the survey and respondents, a thorough survey design and pilot study were conducted prior to the main data collection. The survey was designed based on a comprehensive review of the literature and input from experts in the field of supply chain resilience and Industry 4.0 technologies. The pilot study involved a sample of 30 supply chain professionals who were asked to complete the survey and provide feedback on the clarity and relevance of the questions. The authors have had extensive work experience in a range of industries that included oil and gas, aviation, shipping, logistics and warehousing, among others. This breadth of experience has empowered the authors to engage with numerous seasoned executives in the business sector. Additionally, throughout the research duration, the authors have established direct connections with esteemed academic experts. This unique combination of practical industry knowledge and academic insights enriches the depth and perspective of the pilot survey and the overall research. Survey pilot results assessment could be conducted through a number of methodologies, such as descriptive statistics Rauch et al. (Citation2009), reliability analysis Alshawi et al. (Citation2017), and validity analysis Mohr and Webb (Citation2005).

In the context of this paper, cognitive interviews were identified as the ideal methodology to evaluate the quality of survey questions and identify areas for improvement, as it could provide valuable insights into the comprehension and relevance of the survey questions among supply chain experts. Given the complexity and technical nature of the topic of digital supply chain resilience and investment in Industry 4.0 technologies, cognitive interviews are especially relevant for assessing the pilot results responses. Supply chain academic and professional experts possess unique insights and perspectives that can help improve the survey instrument, including refining the wording and structure of the questions, identifying potential areas of confusion or misinterpretation, and providing feedback on the overall relevance of the survey topics.

Furthermore, cognitive interviews can also help identify potential gaps in knowledge or understanding that may exist among the supply chain experts. This can inform future research directions and highlight the need for targeted education and training initiatives to enhance supply chain experts’ understanding of digital supply chain resilience and Industry 4.0 technologies.

The cognitive interviews methodologies have been widely used in this domain, for example Schmidt and Rossmann (Citation2019) used the cognitive interview methodology to evaluate the understanding of supply chain executives about digital transformation and its impact on supply chains. The researchers used the results to identify common misconceptions and areas of confusion that needed to be addressed in future research, such as the need for more education and training on Industry 4.0 concepts and technologies. Similarly, Indorf and Hinz (Citation2018) used the cognitive interview methodology to evaluate the usability of digital supply chain management systems. The authors used the results to identify potential issues and improvements for the systems, such as the need for better visualization tools and improved data quality. Furthermore, Thomése et al. (Citation2016) used the same methodology to evaluate the usability of digital supply chain management systems. The researchers used the results to identify potential issues and improvements for the systems, such as the need for better visualization tools and improved data quality. The same is summarized in .

Table 1. Survey pilot results assessment methodologies.

These examples demonstrate the versatility and effectiveness of the cognitive interview methodology in evaluating the understanding and perceptions of respondents about complex concepts and technologies related to digital supply chain resilience, investment, and Industry 4.0. Hence, this paper adopted the cognitive interview methodology to assess the initial pilot responses and results of thirty SC experts from academic and business domains. This paper researchers were able to identify potential issues and areas of improvement, as well as ensure that the research questions are accurately understood by respondents. The cognitive interviews have proven to be valuable methodology for assessing the pilot results responses and enable the research to source deeper knowledge and insights from the supply chain academic and professional experts. This provides the enhanced survey updated questions with higher levels of clarity, comprehension, and relevance of the survey questions, as well as identify potential areas for improvement and future research directions.

3.2.2. Survey structure and its three distinct parts

Post conducting 30 comprehensive and thorough cognitive interviews with SC experts from the academic and business domains, the enhanced survey is built with three distinct parts, as illustrated in Appendix.

The first part of the survey focused on the criteria of inclusions and exclusions, where the target participants were shortlisted to be SC experts who either have knowledge about DSCR or I4.0, who have at least a bachelor’s degree, and have at least six years of experience, whom their organizations consider DSCR or I4.0 as strategic priorities to at least a minor extent. Respondents who do not fall within the aforementioned categories are ignored.

The second part of the survey requests the participants to identify the I4.0 technologies recommended to be invested in, and adopt to interconnect particular SCVs with the optimum SCR. The survey capitalizes on the research of Pettit et al. (Citation2010) on the RFS and Zhang et al. (Citation2021) on striking a balance between SCR and SCV in the cross-border e-commerce SC.

The outcome of this part of the survey is a table with seven rows and four columns, where a) the rows are the SCR drivers, namely; SC agility, SC structure, SC visibility, Information sharing, Risk and revenue sharing, SC geographical distribution, and Collaboration with SC partners. While b) the columns are SCV drivers, namely: Supply side risk, Operation process risk, Demand side risk, and Environmental risk.

This paper does not stop at obtaining the experts insights. However, the third part of the survey provides applies the previously introduced 7-layers verification channels, which carry the acronym GRACIAS developed by Al-Banna et al. (Citation2023), which encompasses the following:

G: Golden Triangle; refers to having the right people, the right Process, and the right technologies to guarantee investment and implementation success.

R: Regulatory Environment: refers to the organization’s operating environment, governing laws, regulations, and tax structure, among others

A: Age of the asset: refers to the point at which investment is considered with respect to the overall asset life.

C: Cybersecurity: refers to the security of data creation, sharing, and storing in digital cyberspace, in relation to ISO 27001.

I: Investment: refers to the expected return on investment, payback period, and other financial aspects of the considered technology.

A: Agnosticism: refers to the solution’s ability to integrate, interact, exchange data and information and operate seamlessly with the organization enterprise resources planning (ERP) system.

S: Scalability: refers to the importance of building future expansion capability in the soon-to-be-acquired digital technologies and/or eco-system.

The paper emphasizes that making digital transformation decisions without taking into consideration these verification channels, risks an organization of directly falling into profits erosions or getting exposed to increased risks.

4. Empirical investigations findings and discussions

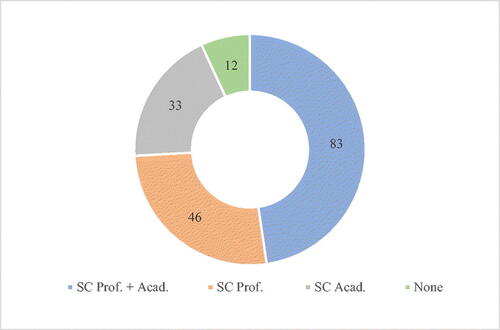

The survey attracted SC experts professionals from academic and industrial domains, in total 174 respondents answered the survey, virtually through the SurveyMonkey portal, and physically through face-to-face meetings, and remotely through phone calls and e-meetings conducted via MS Teams, Webex and Zoom platforms. Majority of the survey respondents belong to the category that consists of SC professionals who are also SC educated, which are 83 respondents. This high number provides a higher level of confidence in the survey outcome, as it represents professionals who are SC educated, and are working in organizations and occupations that are engaged in SC, in aviation, shipping, logistics, maritime, among others.

The second biggest category of respondents belongs to the SC professionals, who are respondents working in SC occupations and organizations but are not SC educated, at 46 respondents. The third category of respondents are SC academics who are not working in SC occupations nor organizations, at 33 respondents. The last category of respondents does not belong to any of the aforementioned categories; hence they are excluded, at 12 respondents. The survey respondents are shortlisted to 162 respondents. As illustrated in .

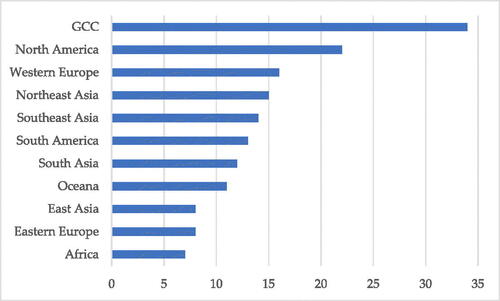

All the 162 respondents have at least a Bachelor’s degree, have at least 6 years of experience and are working in organizations that consider DSCR and I4.0 as strategic priorities, at least at minor levels. The respondents’ geographical distribution is illustrated in . Most of the respondents are from the Gulf Cooperation Council, at 34 respondents, which comprises Kuwait, Saudi Arabia, Qatar, Bahrain, United Arab Emirates and Oman. This concentration could be attributed to the fact that the authors belong to organizations that reside in this geographical location. The subsequent three major geographical categories are North America, Western Europe, Southeast Asia, at 22, 16, and 15 respectively.

4.1. SCR and SCV drivers’ intersections

In today’s fast-paced and volatile business environment, the ability of SCs to respond to disruptions and changes aptly and effectively is critical for maintaining a competitive advantage. The conducted survey of SC professionals from the academic and industrial fields aims to better understand how I4.0 technologies can be deployed with the objective to address a pre-identified SCV aspect by augmenting a particular SCR driver. Using the results of this survey, seven stacked-column graphs are created that plot the relative SC academic and industrial professionals’ preferences of the seven I4.0 technologies against each of the four SC vulnerabilities for each of the seven SC domains. Our findings indicate that the use of I4.0 technologies can significantly enhance SCR by mitigating the various risks associated with each SC vulnerability.

Stacked column graphs are selected to plot the survey respondents’ data for the SCR drivers, SCV drivers, and I4.0 technologies for several reasons:

Comparison: effective in visually comparing the relative importance of different categories or subcategories. In the case of the research on SCR and vulnerabilities, the stacked column graphs can clearly show which drivers are considered more important by the survey respondents and how the subcategories are weighted.

Clarity: easy to read and interpret, as the bars are visually distinct from each other and are clearly labeled with the corresponding subcategory.

Efficiency: compact way to represent data for multiple categories and subcategories in a single graph, making them efficient in terms of space and time.

Overall, stacked column graphs are a versatile and effective tool for communicating research data, particularly when comparing multiple categories and subcategories. They can clearly and efficiently communicate complex information to a broad audience.

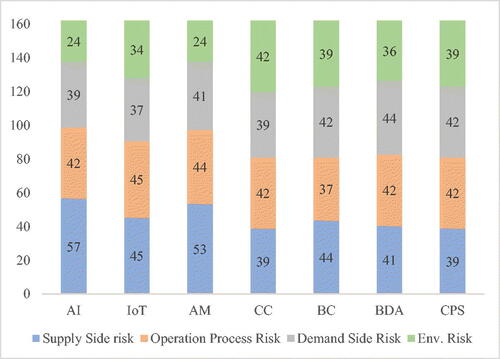

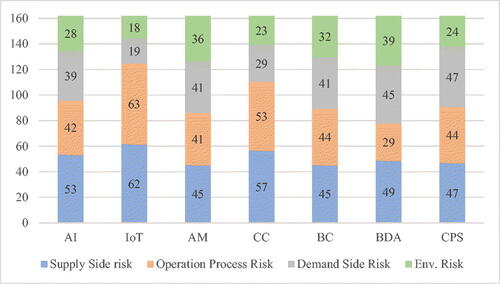

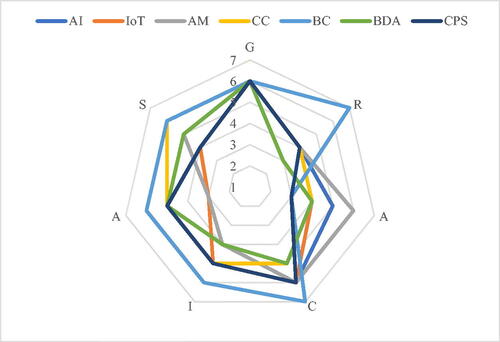

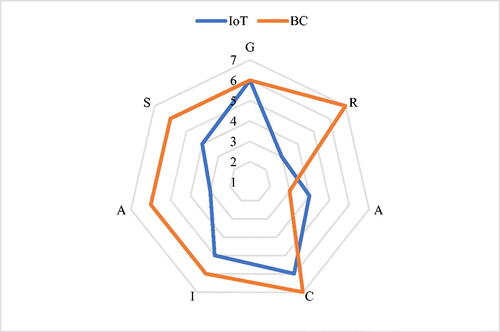

In the domain of SC agility, majority of the respondents perceived AI as the optimum I4.0 technology to consider for investment. Followed by additive manufacturing, and internet of things (IoT). This result confirms the strong and intricate relationship between SC agility and emerging technologies such as artificial intelligence, additive manufacturing, and IoT. These technologies enable SCs to be more flexible, efficient, and responsive to changes in demand, market conditions, and disruptions. Artificial intelligence enables SC managers to predict demand and optimize inventory levels, while additive manufacturing allows for faster and more cost-effective production of customized products. IoT provides real-time visibility into the movement of goods and the condition of assets, allowing for greater control and optimization of SC operations. Together, these technologies can transform SCs into agile and resilient systems that can adapt to changing circumstances and deliver greater value to customers. As illustrated in .