?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

This paper aims to assess the effect of inventory control systems on performance of mining firms in Zimbabwe. A systematic literature review was used to review current and relevant scholarly work. The paper used a quantitative survey approach where a survey questionnaire was utilized to collect quantitative primary data from 203 respondents in mining companies. IBM SPSS AMOS version 22 statistical tool was used to conduct Structural Equation Modelling and Confirmatory Factor Analysis. SEM was used to test the formulated hypotheses and CFA was used to determine convergent and discriminant validities of measurement models. The results of this research reveal a positive direct and positive indirect effect of inventory control systems on performance of mining firms in Zimbabwe. Therefore, the research concludes that inventory control systems are used to optimize inventory levels to avoid high inventory ordering and holding costs and stockouts of raw materials and spare parts in mining firms. Thus, mining firms are recommended to use inventory control systems mentioned in this paper to optimize inventories of raw materials and spare parts to improve their performances. This paper also suggests the implementation of modern computerised inventory control systems for effective inventory control in mining firms in Zimbabwe.

Reviewing Editor:

1. Introduction

In Zimbabwe, the mining sector is one of the key drivers of the economy as it ranks among the top three contributors of Gross Domestic Product (GDP) (Zimbabwe Economic Report, Citation2018). The Chamber of Mines of Zimbabwe (2015) highlights that the mining sector has become one of the important drivers of economic turnaround since the economy has moved from being an agro-driven economy to being a ‘mining driven economy’. For that reason, it is important that more effort must be put into improving the performance of the mining sector. The Government of Zimbabwe (GoZ) has on several times mentioned the importance of improving the performance of all key sectors of the economy, particularly the mining sector, in order to achieve sustainable economic development. Improving the performance of the mining sector is important to support vision 2030 which was launched by the Government of Zimbabwe. Vision 2030 is the agenda of the Government of Zimbabwe to have an Upper - Middle - Income economy by the year 2030 (Mazikana, Citation2023). This is in line with the social and economic goals of the Sustainable Development Goals (SDGs). Therefore, in order to achieve vision 2030, the Government of Zimbabwe believes that the mining sector is one of the key sectors that has potential to assist it to achieve the goal of that agenda. However, mining firms face many problems, including the shortage of raw materials, mining equipment, spare parts and other procurement requirements on the local market. This greatly affects the performance of mining firms and the overall performance of the mining sector in Zimbabwe.

The problem of the deterioration of the economy of Zimbabwe due to fiscal and monetary misalignments and chronic foreign currency shortages, affects local suppliers of mining equipment, spare parts and consumables. This situation forces local suppliers of mining equipment and spare parts to increase prices and this compels the majority of mining firms to buy spares parts in large quantities in order to manage the volatility of prices and exchange rates (Zimbabwe Economic Report, Citation2018). The worst case is that, due to massive shortages of spare parts and other important materials on the local market, the operations of mining companies have been greatly affected. The unavailability of spare parts and consumables on the local market causes interrupted mining operations because of prolonged machine downtime and this negatively affects the performance of mining firms and the entire mining sector (Mining Zimbabwe Magazine, Citation2019). This corroborates well with the Confederation of Zimbabwe Industries Mining Sector Survey Report (Citation2018) which states that the underperformance of mining firms is attributed to factors such as capital shortage, very old machinery, frequent machine breakdowns, including the shortage and high cost of materials. These factors have been pointed as the limiting factors to capacity utilisation in the mining sector of Zimbabwe. As well, amongst the factors which have been blamed for undermining capacity utilisation in mining firms and the mining sector are high operating costs. High operating costs have been attributed to high inventory costs which are caused by the use of primitive inventory control systems which fail to help mining firms to maintain optimum inventory levels of raw materials, spare parts and other critical material. The use of primitive inventory control systems is inutile to maintain optimum inventory levels of raw materials, and spare parts in mining firms (Zimbabwe Mining Performance Report, Citation2019).

Most mining firms have been blamed for controlling their inventories of spare parts and other materials manually causing high inventory costs which contribute much to operating costs. Moreover, most mining firms are inefficient because they manage, report and reconcile their inventories using spreadsheets and other manual processes (Zuva and Choga, Citation2016). This causes a lot of machine breakdowns hence interrupting mining operations and negatively affecting the production output in mining firms. In addition, poor inventory control in mining firms is witnessed where inventories are reconciled and reported using manual processes and this causes longer lead times and inventory shortages, resulting in broken machinery being idle for long periods with no production being carried out. Thus, the use of efficient inventory control systems in mining firms is presumed to facilitate the timely delivery of machinery, other useful equipment and spare parts in order to service the machinery and mining equipment and keep the mining operations running. Therefore, the implementation of inventory control systems in mining firms is deemed important to maintain optimum inventory levels and minimise costs that are related to excess inventory and under stocking.

Inventory control plays an important role in enhancing the performance of firms. Atnafu and Balda (Citation2018) indicate that higher levels of inventory control can lead to improved organisational performance. The authors recommend that organisations should provide the necessary training to their staff to promote inventory management/control practice which will result in increased organisational performance. As well, the authors emphasized that improving organisational performance through the practice of inventory control enhances their contribution to the economic development of their country. Mining firms in Zimbabwe are faced with the problem of poor control of inventory levels which oftentimes cause inadequate inventory of spare parts, and high inventory ordering and holding costs. Inadequate inventory of raw materials and spare parts in mining firms has oftentimes led to machine breakdown and breaks in production schedule and thus hindering full capacity utilisation hence affecting firm performances. Given this situation, this research is crucial because it addresses a critical knowledge gap that needs to be filled urgently to inform decision making on the use of appropriate inventory control systems that must be used to optimize on inventory levels of raw materials and spare parts and improve the performance of mining firms in Zimbabwe. Therefore, it is against this background that the researchers were encouraged to carry out a study to investigate the effects of inventory control systems on performance of mining firms in Zimbabwe.

This paper is organised as follows; Section 1 is the introduction and Section 2 presents the related literature. The third section looks at the methodology which was adopted. Section 4 looks at the presentation, interpretation and discussion of the results while Section 5 looks at the conclusions, limitations and recommendations for future studies. The paper also provides sections with the acknowledgements and data availability statement.

2. Literature review

2.1. Introduction

This section provides a detailed account of the variables covered in the conceptual framework, presents the conceptual model and the development of hypotheses. The literature reviewed in this section was obtained through a systematic review framework. This involved a search for relevant literature based on key concepts and other dimensions as illustrated below.

2.2. Systematic literature review framework

A Systematic Literature Review (SLR) consisted of an independent academic review of existing literature on the practice of inventory control in the mining sector. This process focused on edifying the latest literature on inventory control systems used in mining firms. The process sought to pick out current scholarly work on inventory control systems. The process involved identification of search questions which in this case was to determine the effect of inventory control systems on performance of mining firms. The next step involved the selection of databases and sources. The main databases and sources used in this case were Scopus and ProQuest. This was followed by indemnifying search items which are inventory control systems, and performances of mining firms. A reach was then instituted which generated more 200 papers on inventory control systems in the mining sector. This step was followed by the application of inclusion and exclusion criteria to select the most relevant and current papers.

The main inclusion criteria was on; inventory control systems, inventory control systems used in mining firms, the practice of inventory management and control in both developed and developing economies and on papers on the practice of inventory management that were published in the last ten years. On the other hand, the main exclusion criteria was on; literature on general supply chain management, papers that were published more than 10 years ago and papers focusing on inventory management and control in developed countries only. This process generated a total of 30 papers which were then reviewed in order to identify gaps that this study attempted to fill and hence increasing the knowledge base on inventory control systems in the mining sector.

2.3. Inventory control systems

There are numerous inventory control systems in practice that range from simple to complex that it is important for firms to ensure that they select and implement efficient and effective inventory control systems. This section looks at the following inventory control systems that are used by firms to manage their inventories;

2.3.1. Enterprise resource planning (ERP)

Enterprise Resource Planning (ERP) is an inventory control software that integrates business processes and allows for better order administration and control, the keeping of accurate inventory data, and it enhances workflow and supply chain management and greater business standardization. Many authors have explained the functions of the ERP and its use to manage inventories for organisations. For instance, Malik and Khan (Citation2020) posit that ERP allows intelligent information sharing by correlating data from one module to another within an organisation. According to Almajali et al. (Citation2022), ERP integrates and optimizes the process of businesses, utilizes a single database, it also incorporates information flow, and business processes, and allows organizations to collect and store data obtained from different departments and locations through a regular user interface. Furthermore, ERP enables organisations to use all resources effectively, including integrating financial data, managing orders and inventories, analyzing customer data, standardizing processes, and accelerating production (Akyurt et al., Citation2020). The main aim of ERP is to replace outmoded patchwork with a synchronized suite of applications that is enterprise-wise and brings standardization and harmonization, which increases productivity. This study recognizes the importance of the ERP inventory control software as literature provides evidence that it makes it easy for firms to manage data and information for effective control inventory purposes.

2.3.2. Continuous review system

Continuous Review System (CRS) implies that inventory status continues to be traced and ordered corresponding to the lot size when reorder point is reached, this system handles the conditions when there is high demand, but the loss of order quantity is variable (Irizkya et al., Citation2017). CRS is used when inventory items are replenished on a regular basis, and stock is governed using reorder point (R) which establishes the inventory level remaining when an order is being placed and the order quantity (Q) (Cobb, Citation2017). The use of the CRS to control inventory is important as it helps firms to reduce total cost of inventory, and to improve quality and the overall performance of firms (Kholil, Citation2022). Based on the available literature concerning the functions of CRS, this study acknowledges that CRS is one of the many inventory control systems that is used by many firms to control their inventories. The study also recognised the importance of CRS in inventory control as it is used to reduce total inventory costs which improves a firm’s performance.

2.3.3. Just in time technique

This study also looks at the Just in Time (JIT) inventory control technique and its use by firms to control inventories. Li (Citation2015) posits that JIT is an inventory management technique that is used to reduce waste and non-value-added items. With the JIT inventory management system, stock is delivered to the firm by the supplier when it is needed and this reduces unused inventory and inventory costs. In order for inventory control to be effective using the JIT inventory control system, there must be a close relationship between the firm and suppliers (Karkowski et al., Citation2017). However, the JIT inventory management system is not suitable in situations where the supply chains face severe disruptions. For instance, the world today is facing supply chain disruptions because of disasters and pandemics and this is creating shortages of supplies in both global and local supply markets (Chowdhury et al., Citation2021). In this situation, suppliers fail to supply the procurement requirements to firms right at the time they are needed. This study recognises the importance and advantages of the JIT inventory control system and its potential to help firms to minimise inventory costs.

2.3.4. Economic order quantity

The Economic Order Quantity (EOQ) is a mathematical model which was introduced by Harris in the year 1913 to solve inventory and production problems (Rabta, Citation2019). Despite the fact that the EOQ model as an inventory control system was introduced long back, it is still widely used today by many firms across sectors in many countries to control inventories because it is simple and effective. Sanni et al. (Citation2020) stress that there are assumptions that make an EOQ model effective in inventory control. The assumptions are; fixed demand rate, instantaneous replenishment, no shortages and that items must be homogenous, non-perishable and of perfect quality. All the mentioned assumptions must be there in order for the EOQ to be effective in maintaining optimum inventory levels and minimising inventory cost. Therefore, the current literature informs the researchers on the importance of the EOQ model and that it can be useful in mining firms in Zimbabwe to effectively control inventories.

2.3.5. Distribution requirements planning

Distribution Requirements Planning (DRP) is one of the important inventory control systems that is used by many firms (Ngatilah et al., Citation2019). Similar to materials requirement planning, distribution requirements planning establishes the planning requirements to replenish inventory and allows for a more coordinated delivery of supplies (Dayanti et al., Citation2019). DRP applies the centralized push system in inventory distribution management from the lowest level to the central distribution center in a network. The uniqueness of the DRP is that it is also used to anticipate future demand of the inventory that a firm requires, it gives a broader paradigm to solve complex inventory problems in the distribution network (Monica et al., Citation2022). Therefore, the anticipation of future demand helps firms to procure appropriate quantities of materials. This assists firms to maintain optimum inventory levels and minimise inventory holding costs. This study therefore recognises the importance of the DRP inventory control system in inventory control.

2.4. Purchasing performance

Belvedere et al. (Citation2018) opine that the procurement function is becoming increasingly relevant in the achievement of strategic objectives in many organisations. The authors therefore propose that it is important for firms to come up with a suitable performance measurement system to find out to what extent the procurement function contributes to the achievement of corporate objectives. As the purchasing function is considered a strategic function of a firm, it is imperative to enhance the performance of the purchasing. The purchasing function is tasked with the responsibility of procurement of the requirements in the organisation. In many firms, the procurement function is also responsible for managing inventory levels. This paper recognises the role that is played by the purchasing function in managing inventories in most mining firms in Zimbabwe. This paper uses order cycle time, inventory level, inventory requests, right materials, inventory satisfaction, and inventory distribution as the metrics to measure the performance of the purchasing function in the practice of inventory control in mining firms in Zimbabwe.

2.5. Organisational performance

According to Karabulut (Citation2015) as cited in a study by Kanyepe (Citation2023), performance refers to the outcomes of the company’s internal and external systems. Al-Matari et al. (Citation2014) ***posits that an organization’s success is primarily determined by its performance over a specified period. Therefore, performance measures adopted by mining companies should align with their strategic objectives, stakeholder expectations, and industry standards (Arthur et al., Citation2017). On the other hand, De Loecker and Goldberg (Citation2014) opine that the performance of a firm is usually determined using a set of non-financial and financial factors. Financial performance measures include profitability, which is measured using return on investment, working capital ratio, gross profit margin, and net profit after tax (Wijetunge & Pushpakumari, Citation2014). On the other hand, non-financial performance focuses on improving a company’s image, attracting new customers, and enhancing customer loyalty. Other aspects of non-financial performance include productivity, growth, market share, and customer satisfac-tion (Al-Matari et al., Citation2014). This paper uses metrics such as profitability, production costs and production output to measure the performance of mining firms as shown in the proposed conceptual model.

2.6. The mining sector in Zimbabwe

The mining industry contributes substantially to capital creation, government revenue, foreign exchange, and infrastructure development in Zimbabwe, where it has become the cornerstone of economic growth (Kaseke, Chaminuka and Musingafi, 2015; Zimbabwe Economic Report, Citation2018; Nyakuwanika et al., Citation2021; Chikove & Shiri, Citation2021). This is supported by Tshuma (Citation2023) who opines that the mining sector is one of the major contributors to the Gross Domestic Product in Zimbabwe. According to Mutandwa and Genc (Citation2018), the mining sector accounts for about 60% of exports and contributes around 15% to the Gross Domestic Product making Zimbabwe a resource driven economy.

The mining sector in Zimbabwe is composed of artisanal miners, private owned mining firms and state owned mining companies. The mentioned companies mine key minerals such as gold, platinum group metals (PGM), nickel, chrome, diamonds, coal and lithium, among others (Tome, Citation2023). The Government of Zimbabwe encourages the setting up of new mines and the ramping up of production of existing mines to increase the contribution of the mining sector towards economic development. However, mining firms face many challenges that include, lack of capital, power outages, brain drain, and lack of foreign currency to buy raw materials and spare parts, among other challenges. These challenges negatively affect the operations of mining firms. Notably, the problem of shortage of foreign currency hinders mining firms from acquiring enough inventories of raw materials and spare parts and this affects them to achieve production targets as expected to contribute to economic development. This paper therefore builds on knowledge on the importance of improving the performances of mining firms through the practice of inventory control in order to ensure that they contribute to full capacity towards economic development in Zimbabwe.

2.7. Proposed conceptual framework and hypotheses development

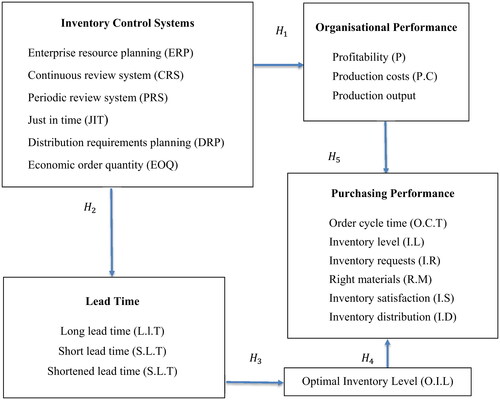

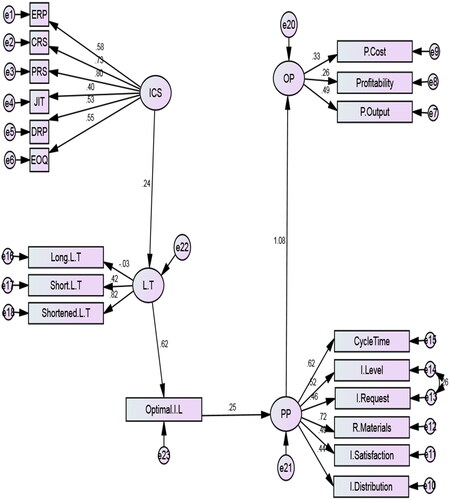

below shows the proposed conceptual framework for this study. The conceptual framework shows the relationship between the variables and the variables are postulated by theory. There are five hypothesised relationships among the following variables; inventory control systems, lead time, optimum inventory levels, purchasing performance and organisational performance.

2.7.1 Inventory control and organisational performance

A study conducted in Ethiopia by Atnafu and Balda (Citation2018) on “the impact of inventory management practice on firms’ competitiveness and organisational performance” concluded that higher levels of inventory control can lead to improved organisational performance. The study recommends firms to invest in the training of their staff on inventory control practices because it results in the improvement of organisational performance. Rashid and Rasheed (Citation2023) corroborate by highlighting that inventory management improves the overall form performance. The practice of inventory control provides firms with the opportunity to maintain optimum inventory levels which ensures uninterrupted production because of the availability of the right quantities of spare parts and raw materials. The maintenance of optimum inventory levels through inventory control also helps to reduce excessive inventory ordering and holding costs which minimises the operating costs of a firm. It is therefore hypothesized that:

: Inventory control systems have no direct positive effect on organisational performance.

Inventory control systems have no indirect positive effect on organisational performance.

2.7.2. Inventory control and lead time

The practice of inventory control requires consideration on the lead time orders take to be delivered from suppliers into the receiving organisation. Long lead times usually lead to delays in receiving of orders from suppliers which cause interrupted production as firms run out of inventories of raw materials and spare parts. On the other hand, shorter lead times are preferable as firms receive their orders from suppliers on time before running out of inventories of raw materials and spare parts. In a study by Zhu and Riezebos (Citation2020) it was indicated that inventory controllers need to keep buffer stocks in order to manage the variability between long and short lead times. The researchers also indicate that the management of lead times has a potential to reduce inventory costs. The length of a supply chain model used by a firm can also determine the lead time orders can take from suppliers to the receiving firms. For instance, the integration of a four level supply chain model that consist of a supplier, a producer, a wholesaler and multiple retailers or a three level supply chain model consisting of the online shop, website and the customer can determine the lead time orders take to reach purchasing firms from suppliers (Gharaei et al., Citation2023; Taleizadeh et al., Citation2023). The authors brought into light that, integrating a supply chain network has a potential to minimise costs and improve on the lead time orders take from suppliers to customers. Therefore, it can be hypothesized that:

Inventory control systems have no positive effect on lead time.

2.7.3. Lead time and inventory levels

The variability of the lead time affects inventory levels which an organisation maintains. Longer lead times lead to firms running out of stock and this negatively affects the operations. The shorter the lead time, the better it is for a firm to quickly replenish the dwindling inventories of raw materials and spare parts. Afrifa et al. (Citation2020) in their study indicate that maintaining optimal inventory levels by either decreasing abnormally high inventory or increasing abnormally low inventory improves operational and stock performance. Maintaining optimum inventory levels is made easy by managing the lead time in which orders of inventories are placed and received from suppliers. Mining firms are susceptible to experiencing excessive machine breakdowns since they conduct mining operations using mining equipment and machinery for a long time without stopping. Thus, the practice of maintaining optimum inventory levels of raw materials and spare parts is recommended as it avoids production interruptions as there will be adequate inventories of raw materials and spare parts in times of machinery breakdowns. Therefore, it can hypothesized that:

Lead time has no positive effect on optimal inventory level.

2.7.4. Inventory level and purchasing performance

The practice of inventory control is one of the responsibilities of a purchasing function in firms. Thus, a purchasing function aims to maintain optimal inventory levels to avoid the operations of a firm from being affected by stock outs and unnecessary inventory ordering and holding costs. According to Karim et al. (Citation2018), holding excessive inventory levels can result in capital being tied up, inventory deterioration, obsolescence, damage, and loss due to theft. Conversely, inadequate inventory levels can lead to production interruptions, poor customer relations, and underutilisation of equipment (Karim et al., Citation2018). It can be recommended that for a purchasing function to achieve good performance in the context of inventory management and control, optimal inventory levels must be maintained. Therefore, it can be hypothesized that:

Optimal inventory level has no positive effect on purchasing performance.

2.7.5. Purchasing performance and organisational performance

Literature reveals that improving purchasing performance is important to increase organisational performance. Many studies have outlined diverse activities of purchasing operations that help firms to achieve their objectives. Munyimi (Citation2019) put forward that procurement performance performance is achieved when goods and services are procured at the best possible cost to meet the needs of the purchaser in terms of quality, quantity, time and location. In that regard, organisational performance is achieved when a firm’s operating costs are minimised by way of less spending on procurement and when the right materials are bought in the right quantity. Therefore, it can be hypothesized that:

: Purchasing performance has no positive effect on organisational performance.

3. Methodology

3.1. Research design

This paper used a quantitative survey approach to measure the effect of inventory control systems on performance of mining companies in Zimbabwe. The use of a quantitative survey approach was appropriate to accommodate a large sample size for statistical analysis and to tap into factors and relationships that were not directly measurable. Also, quantitative approach was used to finalize the results as a way of approving and disapproving the formulated hypothesis

3.2. Targeted population, sample size and sampling methods

The targeted population for this paper consisted of registered artisanal and small-scale miners and big mining companies that operate in the mining sector of Zimbabwe. Therefore, the total targeted population was 650 registered companies (State of The Mining Industry Survey Report, Citation2020).

The sample size used in this paper was determined using the Krejcie and Morgan table. Therefore a total sample size of 242 mining firms was determined and used for the study. The use of a larger sample size was helpful for the models to be able to do the correct estimation and to identify specification error (Teo, Tsai, and Yang, 2013).

Stratified and simple random sampling methods were used to select the respondents in mining firms. Stratified sampling was used to divide the targeted population of mining firms into two groups which are big mining firms and artisanal small-scale miners and the respondents from each group were selected randomly. Stratified and simple random sampling methods were used because they improve accuracy and efficiency in collecting data as with stratified sampling methods the population is divided into homogeneous strata and with simple random sampling method, all employees in mining firms had an equal chance of responding to the questionnaires.

3.3. Data collection instrument and questionnaire response rate

A structured questionnaire was used as a data collection instrument for the study. A questionnaire was used because it is cost effective and it yields standardized responses that makes it easy for the researcher to interpret data. Structured questions on demographics were organised using a Likert scale ranging from 0 to 1 points (0= female and 1= male) and other variables using a Likert scale ranging from 1 to 5 points (1= strongly disagree, 2= disagree, 3= Uncertain, 4= agree, 5= strongly agree). 242 questionnaires were distributed in mining companies and 203 completed questionnaires were returned to the researchers on time. Therefore, the questionnaire response rate was 83.88%.

3.4. Model and estimation procedure

3.4.1. Confirmatory factor analysis

The study used Confirmatory Factor Analysis (CFA) to confirm the factor structure of measurement models, and to evaluate construct, convergent and discriminant validity of measurement models. It is also important to mention that the Maximum Likelihood (ML) estimation method was used to maximize the likelihood that obtained values of the measurement variables and their dimensions will be correctly predicted.

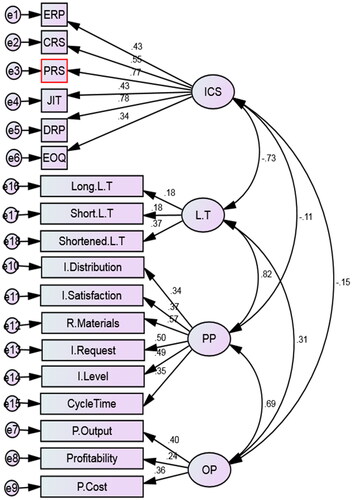

below shows output factor structures with standardised factor weights.

3.4.2. Structural equations model

The study also used the Structural Equation Model (SEM) to analyse the structure model and complex relationships among exogenous variables, endogenous variables and their indicators. SEM was also used to evaluate the construct validity of the structural model. Bootstrapping method was used to test the level of significance based on standard errors of estimation functions. The model of this study is supported by theory. It is valuable to mention that in the model used, inventory Control Systems (ICS) is an exogenous variable whilst Lead time (L.T), Purchasing performance (P.P) and Organisational performance (O.P) are endogenous variables. In addition, the Maximum likelihood (ML) estimation method was used to maximize the likelihood that obtained values of the measurement variables and their dimensions will be correctly predicted. Therefore, the proposed models of the study are as follows:

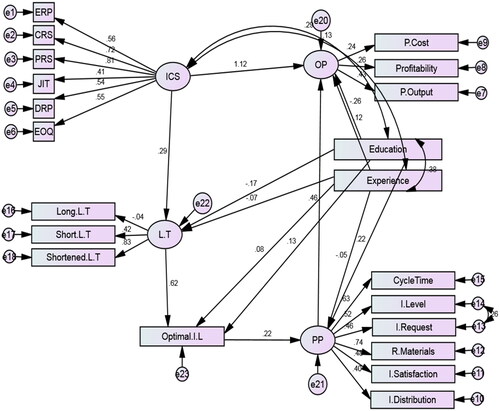

To find out whether the proposed model 1 in has the best fit, alternative models were created by dropping one or more of the links between the constructs at one time as shown in and below.

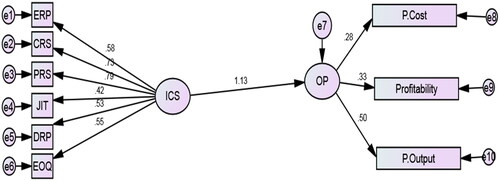

In above, a model with a direct link between inventory control systems and organisational performance was proposed. Therefore, the path indicates the possibility for inventory control systems in having an independent direct effect on organisational performance.

In above, the direct link between inventory control systems and organisational performance was dropped. The path coefficients between inventory control systems, lead time, optimal inventory level, purchasing performance and organisational performance became stronger.

3.5. Validity

Construct validity of structural and measurement models was assessed using the Goodness of Fit Index (GFI). The GFI on structural equation model and measurement model met the recommended cut off value hence they were successful to confirm the formulated hypotheses. This was in line with Hair et al. (Citation2020) who put forward that GFI must exceed 0.9 for a good model and also that a goodness of fit index of 0.85 is tolerable.

Furthermore, CFA was used to evaluate both convergent and discriminant validity of measurement models. The researchers calculated the Average Variance Extracted (AVE) for all factors; OP, ICS, PP and LT and the results showed there is convergent validity. This agrees with Hair et al. (Citation2020) who suggest that, to ensure there is convergent validity between indicator variables of a parent factor, the recommended measurement/cut off AVE value must be greater than 0.05.

To test discriminant validity, the square root of AVE was calculated for all factors and compared with the correlation between factors, and the results showed that there is discriminant validity between factors. This corroborates with Hair et al. (Citation2020), who opine that, on discriminant validity test, the correlation among constructs must be < 0.85 and the correlation between two factors should be less than the square root of the AVE value of each factor.

3.6. Ethical considerations

Informed consent was obtained from respondents before they participated in the study. The researchers asked for permission to carry out research and they explained the purpose of the research to respondents in mining companies. This was in line with Walliman (Citation2011) who is of the view that it is important for researchers to obtain informed consent from managers or other people with overall responsibilities and they must clarify the purpose of the study.

The researchers assured the respondents in mining companies that their responses will be treated with strictest confidentiality and the responses will be used solely for academic purposes. This was so because researchers have an obligation to treat the information collected from the respondents with strictest confidentiality and they should not use the information for the purpose it was not gathered for.

The respondents were instructed not to write their names on questionnaires in order to protect their identity. Anonymity of respondents was necessary because of the sensitivity of the information which was sought as it is used for competitive and strategic purposes in mining companies. Also, anonymity allows for respondents to participate freely in research without any fear of punishment and so helping the researcher to obtain truthful information.

4. Data presentation, interpretation and discussion

Below are the presentation, interpretation and discussion of the findings of the study.

4.1. Results for the structural equation modelling

Structural Equation Model was used to test the proposed models. SEM was conducted using AMOS version 22 program to test the proposed relationships among the study variables. The researchers examined interrelationships among multiple dependent and independent variables at the same time using SEM. SEM was also used for data analysis because of its ability to test causal relationships amongst constructs with multiple measurement items (Hair et al., Citation2020). As well, SEM was used because it offers powerful and accurate statistical procedures to deal with complex models.

4.1.1. Results of proposed structural equation model and hypothesis testing

below shows the regression weights which show the results of hypothesis testing.

Table 1. Regression weights.

above shows the findings of the study on hypotheses which were formulated in literature review in chapter 2. The hypotheses are evaluated in the context of the proposed models. The first hypothesis , states that inventory control systems have a direct positive effect on organisational performance. The results on above support the hypothesis; which is shown by the standardised coefficient with a value of 0.641 which is statistically significant at p < .05 (0.010). Therefore, the implementation of inventory control systems directly helps to improve the performance of organisations in the mining sector of Zimbabwe through increasing profitability, output level, and cost efficiency. The results are consistent with the findings of a study by Ukpere, Victoria and Ogbo., (2014), in Nigeria that inventory management systems are important to achieving organisational performance.

The second hypothesis , states that inventory control systems have a positive effect on lead time. The results on above support the hypothesis which is confirmed by a standardised coefficient with a value of 0.119 which is statistically significant at p < .05 (0.020). Therefore, it means that the implementation of inventory control systems may have a positive and significant effect on lead time.

The third hypothesis states that lead time has a positive effect on optimal inventory level. The results on above support the hypothesis which is shown by a standardised coefficient with a value of 1.693 which is statistically significant at p < .05 (0.009). Therefore, using inventory control systems to control the lead time has a positive and significant effect on maintenance of optimal inventory level.

The fourth hypothesis states that optimal inventory level has a positive effect on purchasing performance. The results on support the hypothesis which is confirmed by a standardised coefficient with a value of 0.106 which is statistically significant at p < .05 (0.009). Therefore, the maintenance of optimal inventory levels by means of inventory control systems has a positive and significant effect on purchasing performance in supply chain departments of companies in the mining sector of Zimbabwe. The findings are consistent with the findings of a study in Kenya by NdiranguKung’u (Citation2016) who concluded that, companies should implement modern inventory control systems such as economic order quantity (EOQ) and just in time technique (JIT) since they help to maintain optimal inventory levels to enhance supply chain performance.

The fifth hypothesis states that purchasing performance has a positive effect on organisational performance. The results on support the hypothesis. The results are confirmed by the standardised coefficient with a value of 0.490 which is statistically insignificant at p < 0.05 (0.104). Therefore, the practice of inventory management by means of inventory control systems enhances the purchasing performance which in turn will positively but insignificantly improve general organisational performance in the mining sector of Zimbabwe.

below shows the results on the direct effect of inventory control systems on organisational performance.

Table 2. Direct effects - two tailed significance.

The results on above support hypothesis , which state s that inventory control systems have a direct positive effect on organisational performance. This is shown by the standardised coefficient with a value of 0.010 which is statistically significant at p < .05 (0.000). Therefore, the results also support the proposed structural equation model 2 which indicates that inventory control systems (ERP, PRS, CRS JIT, DRP and EOQ) have a direct positive effect on improvement of performance of organisations in the mining sector of Zimbabwe. The findings are consistent with the findings in a study conducted in Kenya by Sporta (Citation2018) who identified that inventory control systems have a direct positive effect on organisation performance.

below shows the results on the indirect effect of inventory control systems on organisational performance.

Table 3. Indirect effects - two tailed significance.

The results on above support hypothesis which states that inventory control systems have an indirect positive effect on organisational performance. This is confirmed by a standardised coefficient with a value of 0.021 which is significant at 0.05 (0.000). Therefore, the results also support the proposed structural equation model 3 which indicates that inventory control systems can indirectly enhance organisational performance in the mining sector of Zimbabwe. However, the findings show that organisational performance in the mining sector is less influenced directly by inventory control systems (0.010) but is more influenced indirectly through purchasing performance (0.021). The findings on are supported by the findings in a study that was conducted in Ethiopia by Atnafu and Balda (Citation2018) who identified that inventory management systems have an indirect effect on organisational performance through supply chain performance.

4.1.2. Convergent and discriminant validity of measurement models

Convergent and discriminant validity of the measurement model were assessed. For convergent validity, average variance extracted (AVE) was calculated and for discriminant validity, the square root of AVE was calculated and compared to all inter-factor correlations.

below shows calculated average variance extracted and square root of average variance extracted.

Table 4. AVE and square root of AVE statistics.

below shows the results of correlation estimates between latent variables.

Table 5. Correlations.

Discriminant validity was achieved by comparing the square roots of AVE shown on to all inter-factor correlations shown on . According to Hair et al., (2010), on discriminant validity test, the correlation among constructs must be < 0.85 and the correlation between two factors should be less than the square root of the AVE value of each factor.

Therefore, the findings on and show that the square root of AVE (0.381) on organisational performance (OP) is greater when compared to estimates of correlations between OP<–>L.T (-0.016). The square root of AVE (0.605) on inventory control systems (ICS) is greater when compared to estimates of correlations between ICS <–> L.T (-0.005). Furthermore, the findings show that the square root of AVE (0.561) on purchasing performance (PP) is greater when compared to estimates of correlations between L.T <–> PP (-0.006). Lastly, the findings show that, the square root of AVE (5.399) on lead time (L.T) is greater when compared to estimates of correlations between ICS<–> L.T (-0.005), PP<–>L.T (-0.006) and OP<–>L.T (-0.016). Therefore, the findings meet Fornell and Larcker discriminant validity criterion which means there is discriminant validity between constructs.

In addition, the findings on above show that the average variance extracted (AVE) on all factors is above the suggested value of 0.05. The AVE value on OP is 0.145, AVE value on ICS is 0.367, the AVE value on PP is 0.315 and the AVE value on LT is 29.15. This shows that there is convergent validity between indicator variables of each construct. Therefore, the results corroborate with Hair et al. (Citation2020) who suggest that the AVE value which is greater than 0.05 indicates that there is convergent validity between indicator variables of a parent factor.

5.1. Conclusions, limitations, managerial implications and future recommendations

Beneath are the conclusions, limitations and future recommendations of the study.

5.1.1. Conclusions

The researchers came up with conclusions based on the findings in this study. The findings of the of the study shows that all hypotheses were supported and they indicate that inventory control systems have a positive effect on lead time, optimal inventory level, purchasing performance and organisational performance in the mining sector in Zimbabwe. It can be concluded that both traditional and computer based inventory control systems that were analysed in this study are important as they are used to manage the lead time in which orders take to be received from suppliers. It can also be concluded that inventory control systems help mining firms to optimize on inventories of raw materials and spare parts which minimises inventory ordering and holding costs, mining equipment breakdown and production stoppages. Therefore, the paper finally concludes that inventory control systems that were analysed in this study lead to improved purchasing and organisational performances in the mining sector in Zimbabwe. Thus, the inventory control systems are used to optimize inventory levels of raw materials and spare parts of mining equipment which improve productivity in mining firms leading to enhanced performance of mining firms in Zimbabwe. The study further concludes that inventory control systems are also a key determinant of performance of mining firms. It is therefore critical for mining companies to put more effort and resources towards development of relevant inventory control systems.

5.1.2. Limitations

The major limitation was that there is limited literature specifically on the topic of inventory control systems and their effect on performance of mining firms in developing countries in Africa. However, the researchers reviewed literature on inventory control systems and their effect on organisational performance in mining firms both in developing countries across the globe. Also, the researchers used literature on the effect of inventory management systems on firm performance in other sectors of economies across the globe. This helped the researchers to understand both traditional and modern computer based inventory control systems that can be used by firms to control inventories and enhance their performances.

5.1.3. Managerial implications

The practice of effective inventory management is key for firms seeking to keep ideal inventory levels of raw materials and other important items and paraphernalia to support their operations. The purpose of this paper is to help the management in mining firms in Zimbabwe to make rational decisions in choosing suitable inventory control systems that can help them to optimize on inventory levels and reduce unnecessary inventory ordering and holding costs and excessive stock outs that cause production stoppages. The study brings insight to the management in mining firms that optimising inventory levels of raw materials and spare parts reduces inventory ordering and holding costs and possibilities of stockouts. Managers will also benefit from the output of this study in terms of helping them to direct financial resources towards developing and adopting the relevant inventory control systems in the current business. The inventory decision matrix of managers will definitely improve on the basis of which inventory control system to adopt and the knowledge of the benefits of each inventory control system. The output of this study will also help managers to address the challenges of shortages of inventories of raw materials and spare parts which often cause equipment breakdown and production stoppages. Managers will also appreciate the need of using appropriate traditional and computer based inventory control systems which will help their companies to optimize inventory levels, reduce inventory costs, maximise production and improve organisational performance.

The entire knowledge hub on the impact of the inventory control systems in mining firms that emerged from this study will assist managers to improve the performance of their companies and hence making the mining sector impactful in its contribution to the Gross Domestic Product and economic development in Zimbabwe. In light of the conclusions in this study, it is also recommended that employees in the mining firms be trained on the use of computers in the management of inventory. The study recommends the establishment of the intranet link to create a database for mining spares which should be easy and be accessible to all intended users. This implies that additional computers will have to be acquired and induction and training would be needed. It is also recommended that stakeholders such as service providers to the mining engineering and stores departments be integrated into the intranet facility (extranet) so that they also improve their service provisions. It is also recommended that expansion and improvement of the intranet connections be done so as to accommodate the additional links. This will enhance the full utilisation of the various benefits of modern technology in the management of inventory throughout the mining firms to solve the problems of manually acquiring and checking mining spare parts balances and availability

5.1.4. Recommendations to mining firms and for future studies

Based on the findings of this study, it can be recommended that mining firms in Zimbabwe should implement and use inventory control systems that were assessed in this study for effective inventory control. There is a need to put more financial resources towards the transformation of the current practice of inventory control to reflect attributes and elements of the inventory control systems that were focused on in this study. In addition it is recommended that mining companies must employ modern computer based inventory control systems that will sustain their operations in a changing business environment. This will infuse technological development in the practice of inventory control to keep pace with changes in the global business environment. The inventory control systems that were analysed in this study have shown that they are effective to manage the lead time, optimise on inventory levels and to minimise inventory costs in mining firms in Zimbabwe. Importantly, the study recommends the adoption of inventory control systems of raw materials and spare parts to support sustainable mining operations. Future studies may focus on the contribution of each inventory control system to the profit margins of the companies in the mining sector. This will provide depth in terms of knowledge of the impact of each inventory control system on performance of mining firms. In addition, future studies may need to focus on the effect of inventory control systems on performance of firms in other sectors such as agriculture and the manufacturing sectors in Zimbabwe. This will cover literature gaps on the contribution of inventory control systems on organisational performance in firms across all sectors of the economy in Zimbabwe. As well, future studies are suggested to look at the contribution of modern computer based inventory control systems on inventory optimization in mining firms and in firms across all sectors of the economy of Zimbabwe. Since technology is always evolving, mining firms and firms in other sectors of the economy are expected to adopt modern computer based inventory control systems and move in line with technological development in the area of inventory management. This will assist mining firms to efficiently and effectively manage inventory levels, lead times and inventory costs in order to enhance the performance of the mining firms and the entire mining sector in Zimbabwe.

Acknowledgements

The researchers in this study would like to express their thankfulness to the respondents who completed the questionnaires on time which helped the researchers to complete the study within the planned time period. The researchers would also like to express their thankfulness to Mr Chigusiwa an economics lecturer at Bindura University of Science Education who taught them to analyse data using IBM SPSS AMOS. Finally, the researchers would like to express their gratitude to the reviewers of this paper. The comments of reviewers helped the researchers to improve on the quality of the paper.

Disclosure statement

No potential conflict of interest was reported by the author(s).

Data availability statement

The researchers confirm the availability of data that was used in the study.

Additional information

Funding

Notes on contributors

Dumisani Mawonde

Dumisani Mawonde holds a Master of Science Degree in Purchasing and Supply Chain Management and a Bachelor of Commerce Honours Degree in Purchasing and Supply which he both obtained from Bindura University of Science Education in Zimbabwe. He also holds a Higher National Diploma (HND) in Transport Management which he obtained from Harare Polytechnic College in Zimbabwe. Dumisani is a member of the Chartered Institute of Procurement and Supply (CIPS), United Kingdom. Currently he is studying for a PhD in Logistics and supply chain management. Dumisani is a full time lecturer and coordinator for supply chain management degree programmes in the department of business and management at Women’s University in Africa (WUA), Zimbabwe. Before joining Women’s University in Africa, Dumisani worked as a teaching assistant and later on as a supply chain management lecturer in the department of economics at Bindura University of Science Education (BUSE) in Zimbabwe. He also worked as a lecturer in the department of supply chain, insurance and risk sciences at Midlands State University (MSU) in Zimbabwe. His research interests are in humanitarian supply chain management, agricultural supply chain management, digital supply chain management, sustainable procurement, public sector procurement, logistics management and operations management. He has published papers in international peer reviewed and scopus indexed journals including Cogent Business and Management, Taylor & Francis Online.

Josphat Nyoni

Josphat Nyoni is a lecturer in Business Administration (MBA) in the department of business and management at Women’s University in Africa, Harare, Zimbabwe. He holds the a Doctorate in Business Leadership from the University of South Africa (UNISA), a Masters in Business Administration (MBA) from Zimbabwe Open University, a Bachelor of Arts Honours Degree in Economics from the University of South Africa, a Bachelor of Arts in Economics and Education from the University of South Africa, a Post Graduate Diploma in Curriculum from University of Zimbabwe (UZ). a Certificate in Education from University of Zimbabwe, a Certificate in International Economic Issues and Development Policy (IRS-India), a Certificate in Economic Modelling (ZIPARU) and a Certificate in PhD supervision (UNISA). Dr Nyoni is currently studying for a second Phd Degree in Economic modelling with the Women’s University in Africa. He has worked in the Universities for a total of 15 years in various capacities. Dr Nyoni also worked for the Zimbabwe Central Bank for five years, as a Director Economics in Government for five years and has been lecturing at the Women’s University in Africa for the past five years. He has published 30 papers in international peer reviewed and scopus indexed journals including Cogent Business and Management, Taylor & Francis Online. His research interests are in financial economics, sustainable economic development and growth, logistics and supply chain management and sustainable business management practices.

Percy Mabwe

Percy Mabwe is a logistics and supply chain management lecturer in the department of Supply Chain, Insurance and Risk Sciences at Midlands State University (MSU), Gweru, Zimbabwe. Percy worked at Zimbabwe Open University (ZOU), University of Zimbabwe (UZ) and in the private sector as a procurement practitioner before joining Midlands State University as a full time lecturer. He holds a Master of Science Degree in Supply Chain Management from Chinhoyi University of Technology (CUT) and a Bachelor of Commerce Honours Degree in Purchasing and Supply from Bindura University of Science Education in Zimbabwe. Percy also holds a Higher National Diploma (HND) in Purchasing and Supply from Harare Polytechnic College in Zimbabwe. His research interests are in digital supply chain management, public procurement, supply chain analytics, supplier relationship management, inventory management and supply chain agility and resilience.

Lillian Kamvumbi

Lillian Kamvumbi is a purchasing and supply chain management lecturer in the department of business management at Lupane State University (LSU), Bulawayo, Zimbabwe. Lillian worked as a procurement officer in the private procurement sector, as a teaching assistant specialising in supply chain management in the department of economics at Bindura University of Science Education (BUSE) and as a purchasing and supply chain management lecturer in the department of business management at Zimbabwe Ezekiel Guti University (ZEGU) before joining Lupane State University. She holds a Master of Science Degree in Purchasing and Supply Chain Management from Bindura University of Science Education, a Bachelor of Commerce Honours Degree in Purchasing and Supply from Lupane State University and a National Diploma (ND) in Purchasing and Supply from Bulawayo Polytechnic College in Zimbabwe. Lillian’s research interests are in public sector procurement, sustainable procurement, humanitarian supply chain management, inventory management and digital supply chain management.

References

- Afrifa, G. A., Alshehabi, A., Tingbani, I., & Halabi, H. (2020). Abnormal inventory and performance in manufacturing companies: Evidence from the trade credit channel. Review of Quantitative Finance and Accounting, 56(2), 1–20. https://doi.org/10.1007/s11156-020-00903-y

- Akyurt, I. Z., Kuvvetli, Y., & Deveci, M. (2020). Enterprise resource planning in the age of industry 4.0: A general overview. CRC Press.

- Almajali, D. A., Omar, F., Alsokkar, A., Alsherideh, A. S., Masa’Deh, R., & Dahalin, D. (2022). Enterprise resource planning success in Jordan from the perspective of IT-Business strategic alignment. Cogent Social Science.

- Al-Matari, E. M., Al-Swidi, A. K., & Fadzil, F. H. B. (2014). Audit committee characteristics and executive com-mittee characteristics and firm performance in Oman: Empirical study. Asian Social Science, 10(12), 98–113. https://doi.org/10.5539/ass.v10n12p98

- Al-Matari, E. M., Al-Swidi, A. K., & Fadzil, F. H. B. (2014). The measurements of firm performance’s dimensions. Asian Journal of Finance & Accounting, 6(1), 24–49. https://doi.org/10.5296/ajfa.v6i1.4761

- Arthur, C. L., Obro-Adibo, G., & Tackie, G. (2017). Corporate Social responsibility and performance: A case study of mining companies in Ghana. Journal of Economics & Sustainable Development, 8(20), 48–57.

- Atnafu, D., & Balda, A. (2018). The impact of inventory management practice on firms’ competitiveness and organizational performance: Empirical evidence from micro and small enterprises in Ethiopia. Cogent Business & Management, 5:1–16. https://doi.org/10.1080/23311975.2018.1503219

- Barwa, M. T. (2015). Inventory control as an effective decision-making model and implementations for company’s growth. 3:465–472. International Journal of Economics, Finance and Management Sciences.

- Bawa, S., Asamoah, G. E., & Kissi, E. (2018). Impact of inventory management on firm performance: A case study of listed manufacturing firms in Ghana. 7:83–96. https://doi.org/10.5923/j.ijfa.20180704.01

- Belvedere, V., Grando, A., & Legenvre, H. (2018). Testing the EFQM model as a framework to measure a company’s procurement performance. Total Quality Management & Business Excellence, 29(5–6), 633–651. https://doi.org/10.1080/14783363.2016.1224085

- Chikove, M., & Shiri, A. (2021). The effect of leadership style on employee commitment in the mining sector in Zimbabwe. American Journal of Industrial and Business Management, 11(10), 1023–1035. https://doi.org/10.4236/ajibm.2021.1110062.

- Chowdhury, P., Paul, S. K., Kaisar, S., & Moktadir, M. A. (2021). COVID-19 pandemic related supply chain studies: A systematic review. Transportation Research. Part E, Logistics and Transportation Review, 148, 102271. https://doi.org/10.1016/j.tre.2021.102271

- Cobb, B. R. (2017). Optimization models for the continuous review inventory system. International Journal of Operations Research and Information Systems, 8(1), 1–21. https://doi.org/10.4018/IJORIS.2017010101

- Confederation of Zimbabwe Industries Mining Sector Survey Report. (2018).

- Dayanti, A., Firdaus, A., Meinza, A., Indah, D. R., & Heryanto, A. (2019). Implementation of distribution requirement planning in the subsidized fertilizer management system. Advances in Intelligent Systems Research, 172, 532–538.

- De Loecker, J., & Goldberg, P. K. (2014). Firm performance in a global market. Annual Review of Economics, 6(1), 201–227. https://doi.org/10.1146/annurev-economics-080113-104741

- Gharaei, A., Amjadian, A., & Shavandi, A. (2023). An integrated reliable four-level supply chain with multi-stage products under shortage and stochastic constraints. International Journal of Systems Science: Operations & Logistics, 10(1):1–22. https://doi.org/10.1080/23302674.2021.1958023

- Gharaei, A., Hoseini Shekarabi, S. A., & Karimi, M. (2023). Optimal lot-sizing of an integrated EPQ model with partial backorders and re-workable products: an outer approximation. International Journal of Systems Science: Operations & Logistics, 10(1), 1–17. https://doi.org/10.1080/23302674.2021.2015007

- Hair, J. F., Howard, M. C., & Nitzl, C. (2020). Assessing measurement model quality in PLS-SEM using confirmatory composite analysis. Journal of Business Research, 109, 101–110. https://doi.org/10.1016/j.jbusres.2019.11.069

- Irizkya, I., Syahputri, K., Sari, R. M., Siregar, I., & Ginting, E. (2017). Comparison of periodic review policy and continuous review policy for the automotive industry inventory system . The 2nd Annual Applied Science and Engineering Conference (AASEC 2017). https://doi.org/10.1088/1757-899X/288/1/012085

- Kakeeto, F., Micheal, T., Pastor, K., & Osunsan, O. K. (2017). Inventory management and organizational profitability at Gumutindo Coffee Cooperative Enterprise Limited, Uganda. International Journal of Business and Management Invention. 6:1–8.

- Kanyepe, J. (2023). Transport management practices and performance of diamond mining companies in Zimbabwe. Cogent Business & Management, 10(2), 2216429. https://doi.org/10.1080/23311975.2023.2216429

- Karabulut, A. T. (2015). Effects of innovation strategy on firm performance: A study conducted on manufac-turing firms in Turkey. Procedia - Social and Behavioral Sciences, 195, 1338–1347. https://doi.org/10.1016/j.sbspro.2015.06.314

- Karim, N. A., Nawawi, A. & Salin, A. S. A. P. (2018). Inventory control weaknesses – a case study of lubricant manufacturing company. Journal of Financial Crime, 25(2), 436–449. https://doi.org/10.1108/JFC-11-2016-0077.

- Karkowski, T. A., Karkowska, D., & Skoczylas, P. (2017). Just-in-time method in the management of hospital medication stock . Przedsie˛biorczos’c’ i Zarza˛dzanie 18.

- Kholil, M. (2022). Inventory control of vegetable oil products using continuous review system (Q) approach and periodic review system (P) methods in retail companies: A case study of Indonesia. International Journal of Scientific and Academic Research, 2(4), 11–16. https://doi.org/10.54756/IJSAR.2022.V2.i4.2

- Li, J. (2015). Just-in-time management in healthcare operations. digitalcommons.wku.edu.

- Malik, M. O., & Khan, N. (2020). Analysis of ERP implementation to develop a strategy for its success in developing countries. Production Planning & Control, 32(12), 1020–1035. https://doi.org/10.1080/09537287.2020.1784481

- Mazikana, A. T. (2023). Is logistics a key driver to global economic growth and a contributor to vision 2030 of zimbabwe? SSRN. Elservier. 1573–1601. http://dx.doi.org/10.2139/ssrn.4380990.

- Mining Zimbabwe Magazine. (2019). Retrieved October 22, 2023, from https://miningzimbabwe.com/wp-content/uploads/2019/05/Mining-Zimbabwe-magazine-MAY-2019_compressed.pdf.

- Monica, T., Hardnanerl, V. H., Gozali, L., & Ali, A. (2022). Application of distribution activity planning with distribution requirement planning method on pump products . In PT. XYZ, International Conference on Industrial Engineering and Operations Management (pp. 1 – 12 ) .

- Munyimi, T. F. (2019). The role of procurement quality controls in procurement performance in the energy sector in Zimbabwe. Cogent Engineering, 6(1), 1–18. https://doi.org/10.1080/23311916.2019.1631563

- Mutandwa, B., & Genc, B. (2018). Leveraging Zimbabwe’s mineral endowment for economic transformation and human development. Resources Policy, 58, 230–239. https://doi.org/10.1016/j.resourpol.2018.05.009

- Mwangi, L. (2016). The effect of inventory management on firm profitability and operating cash flows of Kenya breweries limited, beer distribution firms in Nairobi County: A research project submitted in partial fulfilment of the requirements for the award of the degree of master of science in finance. School of Business, University of Nairobi.

- NdiranguKung’u, J. (2016). Effects of inventory control on profitability of industrial and allied firms in Kenya. IOSR Journal of Economics and Finance, 7(6), 9–15.

- Ngatilah, Y., Rahmawati, N., Pujiastuti, C., Porwati, I., & Hutagalung, A. Y. (2019). Inventory control system using Distribution Requirement Planning (DRP) (Case Study: Food Company). Journal of Physics: Conference Series, 1569(3), 032005. https://doi.org/10.1088/1742-6596/1569/3/032005

- Nyakuwanika, M., Van der Poll, H. M., & Van der Poll, J. A. (2021). A conceptual framework for greener gold mining through environmental management accounting practices (EMAPs): The case of Zimbabwe. Sustainability, 13(18), 10466. https://doi.org/10.3390/su131810466

- Rabta, B. (2019). An Economic Order Quantity inventory model for a product with a circular economy indicator. Computers and Industrial Engineering. 140(2020), 106215. https://doi.org/10.1016/j.cie.2019.106215

- Rashid, A., & Rasheed, R. (2023). Mediation of inventory management in the relationship between knowledge. SAGE Open, 13(2), 215824402311645. https://doi.org/10.1177/21582440231164593

- Sanni, S., Jovanoski, Z., & Sidhu, H. S. (2020). An economic order quantity model with reverse logistics program. Operations Research Perspectives, 7, 100133. https://doi.org/10.1016/j.orp.2019.100133

- Sporta, F. O. (2018). Effect of inventory control techniques on organization’s performance at Kenya medical supplies agencies. The International Journal of Business & Management. 6. ISSN 2321–8916.

- State of The Mining Industry Survey Report. (2020). Retrieved October 22, 2023, from https://eurogeologists.eu/2020-mining-industry-survey-state-of-the-play/.

- Taleizadeh, A. A., Varzi, A. M., Amjadian, A., Noori-Daryan, M., & Konstantaras, L. (2023). How cash-back strategy affects sale rate under refund and customers’ credit. 23:1–69. Operations Research International. https://doi.org/10.1007/s12351-023-00752-2

- Tome, M. (2023). Mining sector in stellar quarterly performance. The Herald. Retrieved October 18, 2023, from https://www.herald.co.zw/mining-sector-in-stellar-quarterly-performance.

- Tshuma, S. (2023). Employee perception on sustainable environmental practices at mining firms in Zimbabwe. Zimbabwe Journal of Business, Economic and Management, 1(2), 143–160.

- Ukpere, W. I., Victoria, O. I., & Ogbo, A. I. (2014). The impact of effective inventory control management on organisational performance: A study of 7up Bottling Company Nile Mile Enugu, Nigeria. Mediterranean Journal of Social Sciences 5, 109–118. https://doi.org/10.5901/mjss.2014.v5n10p109

- Walliman, N. (2011). Research methods, the basics. Routledge.

- Wijetunge, W. A. D. S., & Pushpakumari, M. D. (2014). The relationship between strategic planning and busi-ness performance: An empirical study of manufacturing SMEs in Western Province in Sri Lanka. Kelaniya Journal of Management, 3(1), 23–41. https://doi.org/10.4038/kjm.v3i1.7476

- Yin, R. (1984). Case study research: Design and methods. Sage Publication.

- Zhu, S. X., & Riezebos, J. (2020). Inventory control with seasonality of lead times. Omega, 92, 102162. https://doi.org/10.1016/j.omega.2019.102162

- Zimbabwe Economic Report. (2018). Retrieved October 22, 2023, from https://www.zimfa.gov.zw/index.php/media-centre/downloads?download = 16:zimbabwe-economic-report-building-a-new-zimbabwe-targeted-policies-for-growth-and-job-creation

- Zimbabwe Mining Performance Report. (2019). Retrieved October 22, 2023, from https://pubs.usgs.gov/myb/vol3/2019/myb3-2019-zimbabwe.pdf

- Zuva, B., & Choga, F. (2016). Inventory management system and business performance: Case of Zimbabwean mining sector. IOSR Journal of Business and Management, 18(4), 102–122. https://doi.org/10.9790/487X-180402120122.