?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

There are a number of genotypes/varieties of kenaf (Hibiscus cannabinus L) fibre in Ghana. The kenaf fibre is used in both engineering and social products and its properties improve its choice. This paper reports the tensile strength and elongation of five genotypes of the kenaf fibre in Ghana. The fibres are cultivated and harvested at maturity and prepared with water retting. A gauge length of 20 mm was used and cardboard as the initial support. The fibre diameters are found for each genotype to be 34.2 µm, 40.4 µm, 38.2 µm, 43.2 µm and 39.2 µm for EB31, TN11, EN31, PN11 and HN11 respectively. The densities are 0.53 g/cm3 for EB31; 0.60 g/cm3 for TN11; 0.63 g/cm3 for EN31; 0.94 g/cm3 for PN11 and 1.00 g/cm3 for HN11. The tensile strengths are 734.53 MPa for EB31, 1292.37 MPa for TN11, 1241.53 MPa for EN31, 979.35 MPa for PN11 and 1365.14 MPa for HN11. The corresponding percentage elongations are found to be 10.88 for EB31; 12.23 for TN11; 14.66 for EN31; 15.81 for PN11 and 13.13 for HN11. These results will make the application of fibre in various engineering applications, especially in composites, more predictive in properties and performance.

PUBLIC INTEREST STATEMENT

Various varieties of Kenaf fibre are available and indigenous to Ghana. The kenaf fibre is used in both engineering and social products and its properties will help in decision making in using the fibre. The fibre is found to have an average diameter of 39.04 µm and density of 0.74 g/cm3. The average tensile strength of fibre from Ghana is 1122.5855 MPa and its percentage elongation is 13.3439. These results will make the application of these genotypes in various engineering applications, especially in composites, more predictive in properties.

1. Introduction

Bast fibres are the soft elongated phloem fibres which exert mechanical support to the stem of various plants, including flax, jute, hemp, ramie and kenaf. Kenaf (Hibiscus cannabinus L. Section Furcaria) is an upright, sparsely-branched, fast-growing, annual herbaceous fibre plant native to western Africa from where it was domesticated and used for food, fibre and medicinal value (Wilson & Menzel, Citation1964). Dalziel (Citation1948) reports the wide cultivation of kenaf in the region from Senegal to Nigeria, as a major fibre crop after cotton. Kenaf is also widely distributed in Eastern Africa and sub-tropical Asia and Africa. Under favourable weather and day length conditions, depending on the genotype, kenaf could grow up to a height of four to five meters in four months in Ghana, and up to 2.5 to 6.0 m in other regions.

Kenaf fibre is used for textiles, the production of ropes, twines, bags, rugs, door mats, automobile upholstery, building material, composites in electrical appliances, and fishing nets, as well as a jute substitute in the manufacturing of sacks for the bagging industry (Humphries, Citation2004). The engineering value of kenaf fibre in its vast uses is derived from its mechanical properties. Two major factors determine the mechanical properties of fibre, namely, first, the genotype-dependent fibre development process which occurs during the growth and development of the plant, and second, the postharvest retting process which separates the cellulosic fibre from the non-cellulosic components. The three-staged fibre development in kenaf involves initiation, elongation, and specialization (Mokshina et al. Citation2018). The genetic, biochemical, structural and hormone-driven meristematic activities of the primary and secondary cambium are followed by extension in cell length and cell width with overlaying of cellulose which determines the mechanical properties of the fibre. In terms of retting, the three methods of retting, namely, mechanical retting, dew retting, and water retting exert various effects on the fibre and influence fibre strength.

Glass fibres used as structural reinforcement in polymer composites have gained notable attention in the recent years (Rozyanty et al., Citation2021). However, the use of these materials poses diverse disadvantages which include non-renewability, high manufacturing energy consumption, non-recyclability, and non-biodegradability which can result in health complications when ingested (Cheung et al., Citation2009; Rozyanty et al., Citation2021). Natural fibres are increasingly being used in textile and polymer composites, specifically in the construction (building), automotive, packaging and furniture industries (Hasan et al., Citation2020). According to Negawo et al. (Citation2019), natural fibres are used because of their advantages of being affordable, environmentally friendly, renewable, biodegradable, lower carbon footprint, better waste management and their reasonable mechanical robustness.

Use and development of composite material for various applications has created a lot of research interest in the fibre properties. Both synthetic and natural fibres are in use in production of the various composites. Of recent, kenaf has been found to be an important source of natural fibre for composites, and other industrial applications ((Karnani et al., Citation1995)) (Rajak, Pagar, Kumar, et al., Citation2019). in their review encourage the use of natural materials as a constituent and proposed making its use compulsory in order to obtain a complete material degradable as environmentally friendly (Rajak, Pagar, Menezes, et al., Citation2019). in their work on composite material properties reported good potential and exceptional performance of fibre-reinforced composites in numerous fields of applications and this have made fibre-reinforced composite materials a promising alternative over solitary metals or alloys (Abbas et al., Citation2022). in their review indicated that Kenaf Fibre-Reinforced Cementitious Composites (KFRCC) can be used in the construction of road pavements, slabs and other similar applications with reasonable engineering properties under sustained bending loads (Ramesh & Nijanthan, Citation2016). proposed a hybrid application of kenaf and synthetic fibre in composites. Natural fibres like kenaf is, therefore, with a very high application potential in the composite material manufacturing industry.

The kenaf fibre as a material with high potential in various applications in engineering is characterised by various properties just like other materials. It is critical to have the knowledge of mechanical properties of any material to enhance its applicability (Mahjoub et al., Citation2014). reported that the average diameter of untreated kenaf fibre is 67.6 µm, with a density of 1.2 g/cm3 and tensile strength of 780 MPa. A density of 1.293 ± 0.006 g/ is reported by (Zimmerman & Losure, Citation2014). (Ramesh (Citation2015)) presented a compilation of various research results on the mechanical properties such that density ranges from 0.6 g/cm3 to 1.5 g/cm3, Tensile strength is from 131.6 MPa to 1191.0 MPa and Tensile Modulus between 2.14 MPa and 53 MPa). In fact, this presents a wide range of values influenced by variation in types of kenaf fibres used in terms of the place of origin, genotype, initial retting method and etcetera. Also, the nature of all natural fibres including kenaf fibre which has an irregular cross-sectional area that fluctuates along the length of the fibre may also be responsible for the property variation.

Although in the past, Ghana held a vibrant kenaf fibre industry, records on the mechanical properties of fibre from the kenaf are not known. It will, therefore, be prudent to investigate the properties of the fibre cultivated and processed in Ghana. The kenaf improvement programme of Kwame Nkrumah University of Science and Technology (KNUST), Kumasi, Ghana has characterised kenaf genotypes with the objective of improving fibre yield and quality. The selected genotypes for this study are identified as EB31, TN11, EN31, PN11 and HN11. This paper presents basic data, mainly, the tensile strength and elongation properties of the selected kenaf genotype present in Ghana. The fibre diameter and density are also made available. Availability of these basic data about the kenaf fibre will enhance its choice and utilisation in various applications including composite reinforcement. It will as well make property predictions of the composite materials with which it is integrated.

2. Materials and methods

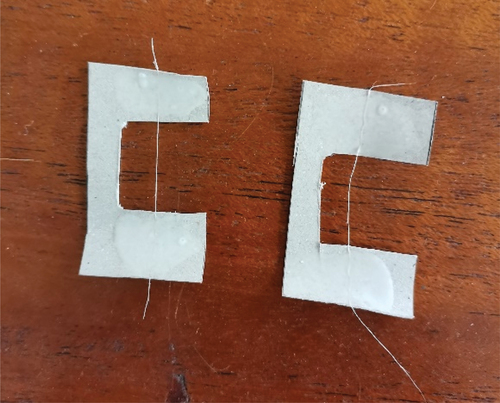

Five kenaf genotypes, namely, EB31, TN11, EN31, PN11 and HN11 obtained from the kenaf research field of KNUST were considered in this paper. Genotypes HN11 and TN11 are identified to have high seed yields of 800 to 1,570 kg/ha while PN11, EN11, EB31, and HN11 have high fibre yields of 30 to 33 t/ha. The genotypes were previously planted in a randomized complete block design in three replications. When the flowers were in bloom, the stems were harvested by cutting from the base of the plant. The defoliated and decorticated stems were folded into ribbons and water-retted for 14 days, washed under running tap water, and sun-dried (Figure ). The samples of fibres for tensile testing were randomly selected from the strand bundle of kenaf fibre. The selected fibre was carefully observed and a digital micrometre gauge was used to measure the diameter of the fibre. For the determination of the density, the sample was weighed and a displacement method of volume estimation was employed (Archimedes’ principle). In the tensile testing process, a tab for mounting the sample in the machine was prepared out of cardboard with a space/gauge length of 20 mm, Figure . The fibre was attached and glued to the prepared cardboard. The test was conducted according to the standard test method for the single fibre tensile test ASTM D 3379. The testing was done by mounting the card fitted sample on the tensile testing machine (Techstress). The card was cut at the mid-gauge length and testing initiated till sample failed.

Immense care was taken to ensure that the axis of the fibre was aligned with the axis of the cross-head in order to simulate a uniform stress condition over the cross-section of the fibre. A total of 10 tests were carried out per genotype.

3. Results

The aim is estimate the mechanical properties of the kenaf fibre genotypes in Ghana. The properties involve the diameter, density, tensile strength and percentage elongation. The properties are considered for single strands of the fibre.

3.1. Diameter

The diameter of the strands of various genotypes/varieties under investigation is measured with digital micrometre screw gauge. The diameter of the kenaf varieties are found to be for EB31, TN11, EN31, PN11 and HN11 as 34.2 µm, 40.4 µm, 38.2 µm, 43.2 µm and 39.2 µm respectively. The variations are such that, the diameter of EB31 ranges from 27 µm to 42 µm, TN11 from 27 µm to 49 µm and EN31 from 26 µm to 58 µm. For PN11, it varies from 37 µm to 55 µm and that of PN11 ranges from 20 µm to 59 µm. These are illustrated in Figure . The average diameter is 39.04 µm for kenaf fibre indigenous in Ghana.

3.2. Density

The densities of the various genotype are found to be 0.53 g/cm3 for EB31; 0.60 g/cm3 for TN11; 0.63 g/cm3 for EN31; 0.94 g/cm3 for PN11 and 1.00 g/cm3 for HN11. The density, therefore, ranges from 0.53 g/cm3 to 1.00 g/cm3. This compares well with the result of (Ramesh (Citation2015)) who presented the density to be 0.6–1.5 g/cm3.

3.3. Tensile strength

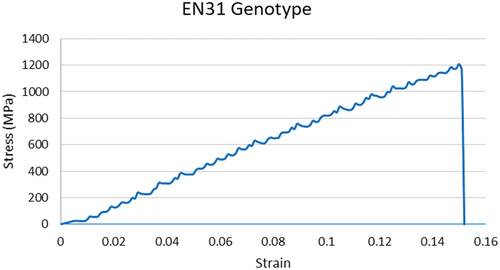

Tensile testing is a procedure performed to estimate and provides details of the tensile mechanical properties of a material. These properties can be plotted on a graph as a stress–strain curve to show details such as the point at which the material failed. Figure is the sample stress—strain plotted result of the EN31 fibre genotype.

The tensile strength can be defined as the maximum stress that a material can bear before breaking when it is allowed to be stretched or pulled. The tensile strength of the fibre strand was obtained from the test result and found to range from 734.53 MPa for EB31 to 1365.14 MPa for HN11. For the genotypes, the tensile strengths are found to be 734.53 MPa (EB31), 1292.37 MPa (TN11), 1241.53 MPa (EN31), 979.35 MPa (PN11) and 1365.14MPa (HN11). The tensile strength for the EB31 genotype ranges from 242.03 MPa to 1450.27 MPa; that of TN11 ranges from 630.28 to 2300.95 MPa; EN31 from 912.47 MPa to 2076.63 MPa; PN11 from 388.25 MPa to 2302.48 MPa and for the HN11 genotype, it ranges from 405.03 MPa to 2624.89 MPa. The tensile strength result is presented in Figure .

3.4. Percentage elongation

Elongation at break is a measure that shows how much a material can be stretched, as a fraction of its original dimensions, before it breaks. The percentage elongation is defined as a measure of the amount a material will plastically and elastically deform up to fracture. It is obtained by comparing the material’s change in length during the tensile process with its original length. The percentage elongation also illustrates the material’s ductility. The percentage elongation result from the test for the kenaf fibre ranges from 10% to 15% on average. For each genotype, the percentage elongations are found to be 10.88 for EB31; 12.23 for TN11; 14.66 for EN31; 15.81 for PN11 and 13.13 for HN11. The range of values for genotype variety are 2.6–24.5 (EB31), 9.9–15.5 (TN11), 9.7–20.3 (EN31), 10.2–21.1 (PN11) and 10.3–16.3 (HN11). The percentage elongation results are illustrated in the diagram of Figure .

4. Discussions

Kenaf Fibre is considered to have a huge potential to replace partially or fully man-made fibres in the field of composite materials (Naik et al., Citation2022). This is prosed by Rajak et al. (Citation2019) in order to obtain a complete material degradable as environmentally friendly composites. Kenaf fibre as natural fibre, has considerable advantages over man-made fibres. For example, kenaf fibre is cheap due to its low production cost (Hamidon et al., Citation2019). For the fibre to be fully utilised, its properties are expected to be known. The kenaf fibre indigenous to Ghana’s environment is not currently known by its mechanical properties despite its historic present in the country. Usually, the fibre diameter decides a fabric’s performance and hand (how it feels). Large diameter fibres are crisp, rough and stiff. Fine fibres are soft and pliable and fabric made of them drapes more easily. In natural fibres, fineness is one factor which determines fibres of better quality. The diameter of the fibre determines its fineness. The diameter of the kenaf fibre genotypes investigated varies from 34.2 µm to 43.2 µm. By genotype, the diameters are 34.2 µm, 40.4 µm, 38.2 µm, 43.2 µm and 39.2 µm respectively for EB31, TN11, EN31, PN11 and HN11. This can be considered to be low compared to the report of (Ramesh (Citation2015)) who reported the diameter of untreated kenaf fibre as 67.6 µm. The result, therefore, shows that the kenaf fibre indigenous to Ghana are finer with the average diameter being 39.04 µm.

Fibre density plays a direct part in affecting the weight of the products produces from the fibre, for example fabrics. It is also a useful parameter in fibre identification. The density of the fibre are estimated to be 0.53 g/cm3 for EB31; 0.60 g/cm3 for TN11; 0.63 g/cm3 for EN31; 0.94 g/cm3 for PN11 and 1.00 g/cm3 for HN11. This gives a range of 0.53 to 1.00 g/cm3. The density of the kenaf fibre reported by (Ramesh (Citation2015))0.6–1.5 g/cm3 compare favourably with fibres indigenous to Ghana. Comparatively, the density of kenaf fibre is lower than glass fibre (2.4 g/cm3), which is good in making light-weight composites. Due to the low density, there is an increase in demand for commercial use of natural fibre-based composite (Oksman et al., Citation2016)

Tensile strength is an important property of materials. It determines the materials’ mechanical performance. It is the ability of the material to resist tearing due to tension. The tensile strength obtained ranges from 734.53 MPa to 1365.14 MPa. For the respective genotypes, the tensile strength are 734.53 MPa for EB31, 1292.37 MPa for TN11, 1241.53 MPa for EN31, 979.35 MPa for PN11 and 1365.14 MPa for HN11. These compare well with that reported by (Ramesh, Citation2015) (131.6–1191.0 MPa), also (Mahjoub et al. (Citation2014)) reported tensile strength of 780 MPa from their work. The corresponding property, percentage elongations, are 10.88 for EB31; 12.23 for TN11; 14.66 for EN31; 15.81 for PN11 and 13.13 for HN11. The average properties are presented in Table .

Table 1. Summary of the properties

In summary, the kenaf fibre has a diameter range of 34.2 µm to 43.2 µm, the density is of the range of 0.53 to 1.00 g/cm3. The tensile strength varies from 734.53 MPa to 1365.14 MPa and the percentage elongation is 10.88 to 15.81.

5. Conclusion

Properties are very important parameters to be considered if a decision is to be taken regarding the choice and usage of materials, especially in scientific and or engineering applications. The tensile strength, in particular, is an important property that determines the mechanical performance of the material. It is the ability of a material to resist tearing due to tension. In most of the micromechanical analyses, the mean or average properties are used. The knowledge of the properties of materials gives confidence when it is selected to be used in any application. It is imperative to know the tensile strength of the kenaf fibre cultivated in Ghana. This will ensure it is the right choice for an application. The properties with average respective values of fibre diameters of 39.04 µm, density of 0.74 g/cm3, tensile strength of 1122.5855 MPa, and percentage elongation of 13.3439 presented in this paper become basic relevant information on the kenaf fibre indigenous in Ghana. With the knowledge of tensile strength and the percentage elongation, the use of fibre in composite materials becomes imperative and estimation of corresponding properties and performance of the products from the fibre would be predictable.

Disclosure statement

No potential conflict of interest was reported by the authors.

Additional information

Notes on contributors

George Ansong

George Ansong is a postgraduate student (MPhil in Mechanical Engineering) in the area of Applied Mechanics in Mechanical Engineering Department, Kwame Nkrumah University of Science and Technology, Kumasi. His research area of interest is strength of materials.

Yesuenyeagbe A.K. Fiagbe

Yesuenyeagbe A. K. Fiagbe is a Mechanical Engineer by profession and Senior Lecturer in Department of Mechanical Engineering, Kwame Nkrumah University of Science and Technology (KNUST), Kumasi. He holds a Ph.D. in Mechanical Engineering with special area of aerodynamic performance estimate in aircraft design. His research interests are in Technology development, Engineering system design, computational fluid dynamics, tribology and mechanical properties of natural fibres.

Antonia Y. Tetteh

Antonia Y. Tetteh is an Associate Professor in Plant Breeding & Genetics, and Biotechnology, with a Biochemistry background. She is the leader of the bast fiber crops breeding programme in Kwame Nkrumah University of Science and Technology, Kumasi, Ghana. Her research emphasizes recurrent selection for earliness, fibre yield, fibre quality, seed yield and seed quality in kenaf. Her objective is to provide the fibre industry with new traits for the development of improved cultivars, provide research information on the bast fiber crops, and provide training for kenaf field breeding.

Francis Davis

Francis Davis is an Associate Professor in Mechanical Engineering at the Department of Mechanical Engineering, Kwame Nkrumah University of Science and Technology (KNUST), Kumasi. He holds a Ph.D. in Mechanical Engineering from North Carolina Agricultural & Technical State University, Greensboro, USA.

References

- Abbas, A. N., Abdul Aziz, F. N. A., Abdan, K., Nasir, N. A. M., & Norizan, M. N. (2022). Kenaf fibre reinforced cementitious composites. Fibers, 10(1), 3. https://doi.org/10.3390/fib10010003

- Cheung, H., Ho, M., Lau, K., Cardona, F., & Hui, D. (2009). Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Composites Part B: Engineering, 40(7), 655–9. ISSN 1359-8368. https://doi.org/10.1016/j.compositesb.2009.04.014

- Dalziel, J.M. (1948). The useful Plants of West Tropical Africa (pp. 612). Crown agent for the colonies.

- Hamidon, M. H., Sultan, M. T. H., Ariffin, A. H., & Shah, A. U. M. (2019). Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. Journal of Materials Research and Technology, 8(3), 3327–3337. ISSN 2238-7854. https://doi.org/10.1016/j.jmrt.2019.04.012

- Hasan, K. M. F., Horváth, P. G., & Alpár, T. (2020). Potential natural fiber polymeric nanobiocomposites: A review. Polymers, 12(5), 1072. https://doi.org/10.3390/polym12051072

- Humphries, M. (2004). Fabric reference (3rd Ed ed.). Pearson Education Inc. Upper Saddle River.

- Karnani, R., Krishnan, M., & Narayan, R. (1995). Biofibre reinforced polypropylene composites. Polym Eng Sci, 37(2), 476–483. 1997. https://doi.org/10.1002/pen.11691

- Mahjoub, R., Yatim, J. M., Sam, A. R. M., & Hashemi, S. H. (2014). Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Construction and Building Materials, 55, 103–113. https://doi.org/10.1016/j.conbuildmat.2014.01.036

- Mokshina, N., Chernova, T., Galinousky, D., Gorshkov, O., & Gorshkova, T. (2018). Key Stages of Fiber Development as Determinants of Bast Fiber Yield and Quality. Fibers, 6(2), 20. https://doi.org/10.3390/fib6020020

- Naik, V., Kumar, M., & Kaup, V. (2022). A review on natural fiber composite materials in automotive applications. Engineered Science, 18, 1–10. https://doi.org/10.30919/es8d589

- Negawo, T. A., Polat, Y., Buyuknalcaci, F. N., Kilic, A., Saba, N., & Jawaid, M. (2019). Mechanical, morphological, structural and dynamic mechanical properties of alkali treated Ensete stem fibers reinforced unsaturated polyester composites. Composite Structures, 207, 589–597. https://doi.org/10.1016/j.compstruct.2018.09.043

- Oksman, K., Aitomäki, Y., Mathew, A. P., Siqueira, G., Zhou, Q., Butylina, S., Tanpichai, S., Zhou, X., & Hooshmand, S. (2016). Review of the recent developments in cellulose nanocomposite processing, composites Part a. Applied Science and Manufacturing, 83, 2–18. ISSN 1359-835X. https://doi.org/10.1016/j.compositesa.2015.10.041

- Rajak, D. K., Pagar, D. D., Kumar, R., & Pruncu, C. I. (2019). Recent progress of reinforcement materials: A comprehensive overview of composite materials. Journal of Materials Research and Technology, 8(6), 6354–6374. 2019 ISSN 2238-7854. https://doi.org/10.1016/j.jmrt.2019.09.068

- Rajak, D. K., Pagar, D. D., Menezes, P. L., & Linul, E. (2019). Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers, 11(10), 1667. https://doi.org/10.3390/polym11101667

- Ramesh, M. (2015). Kenaf (Hibiscus cannabinus L.) fibre based bio-materials: A review on processing and properties. Progress in Materials Science, 78–79, 1–92. 2016 ISSN 0079-6425. https://doi.org/10.1016/j.pmatsci.2015.11.001

- Ramesh, M., & Nijanthan, S. (2016). Mechanical property analysis of kenaf–glass fibre reinforced polymer composites using finite element analysis. Bulletin of Materials Science, 39(1), 147–157. https://doi.org/10.1007/s12034-015-1129-z

- Rozyanty, A. R., Zhafer, S. F., Shayfull, Z., Nainggolan, I., Musa, L., & Zheing, L. T. (2021). Effect of water and mechanical retting process on mechanical and physical properties of kenaf bast fiber reinforced unsaturated polyester composites. Composite Structures, 257, 113384. ISSN 0263-8223. https://doi.org/10.1016/j.compstruct.2020.113384

- Wilson, F. D., & Menzel, M. Y. (1964). Kenaf (Hibiscus cannabinus), roselle (Hibiscus sabdariffa). Economic Botany, 18(1), 80–91. https://doi.org/10.1007/BF02904005

- Zimmerman, J. M., & Losure, N. S. (2014). Mechanical properties of Kenaf Bast fiber reinforced epoxy matrix composite panels. Journal of Advanced Materials, 30(2), 32–38.