?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

Interest in the use of composite flours for baked products to enhance nutrition, increase the health benefit and diversify utilization of by-products is rising. This study was conducted to determine the effect of proportion of wheat, germinated sorghum and pumpkin seed flour on flour functional properties and physicochemical and sensory properties of muffins using D-optimal mixture design. The water absorption index (WAI), oil absorption index (OAI) and swelling index (SWI) were significantly (p < 0.05) influenced by the blend proportions whereas bulk density (BD) was not significantly influenced. The protein content increased with increase in the proportion of pumpkin seed flour. The fiber content increased with increase in the proportion of sorghum and pumpkin seed flour. The sensory scores decreased with increase in the proportion of sorghum and pumpkin seed flour. Preferred results were found using up to 10% pumpkin seed flour and up to 21% sorghum flour. Using numerical optimization, a combination of 83% wheat flour, 10% pumpkin seed flour and 7% sorghum flour gave best results with a desirability value of 0.621. Pumpkin seed flour can be incorporated up 10% and sorghum flour up to 7% for an acceptable product.

REVIEWING EDITOR:

1. Introduction

The use of composite flours by replacing wheat with alternative cereals like sorghum in baked products to enhance nutrition and reduce cost is rising. Moreover, food application of by-products like pumpkin seeds from food processing in order to diversify their utilization and enhance food nutrition is gaining interest (Badjona et al., Citation2019; Bursa et al., Citation2021; Ginindza et al., Citation2022; Mahendran & Hariharan, Citation2018; Menon et al., Citation2015).

Sorghum (Sorghum bicolor (L.) Moenchis) is an indigenous African crop and has been the staple crop in many African countries for years (Sibanda et al., Citation2015). It has been used in developing baked (Cardone et al., Citation2021; Marston et al., Citation2014; Sharanagat & Nema, Citation2021; Sibanda et al., Citation2015) and other cereal-based products (Asma et al., Citation2006; Devi et al., Citation2013). The rate and extent of digestion of the starch in sorghum, particularly cooked sorghum, is low (Devi et al., Citation2013; Ezeogu et al., Citation2005). Thus, sorghum is a more sustained source of energy and is suitable for people who are at risk from type II diabetes. Many sorghum varieties have been reported to have appreciable quantities of phenolic compounds and exhibit antioxidant activities (Awika & Rooney, Citation2004; Dykes & Rooney, Citation2006). However, sorghum has a low protein content and quality, particularly with respect to lysine which can be overcome by adding other protein sources. Studies have indicated that digestibility of sorghum protein is reduced with wet cooking (Cardone et al., Citation2021; Duodu et al., Citation2003). Germination of sorghum was found to improve protein digestibility (Baba et al., Citation2012; Cardone et al., Citation2021) and also increase nutrient bio-availability by reducing anti-nutritional factors and improve the protein content (Baba et al., Citation2012; Tizazu et al., Citation2011). Inexpensive ingredients like sorghum need to be considered to reduce the cost of baked products like muffin by blending with wheat flour (Menon et al., Citation2015).

Pumpkin seeds are by-product from pumpkin pulp processing and are rich in some nutrients particularly protein, fat and ash (Białek et al., Citation2015; Bouazzaoui & Mulengi, Citation2018). Whole pumpkin seed flour is nutrient-dense having protein content of 25.9 – 35.5%, fat 38–49%, fibre 2.3% and ash 4.1–5.27% (Rodríguez‐Miranda et al., Citation2012; Saraswathi et al., Citation2018). Defatted pumpkin seed flour has protein content of 45.9–64.13%, fat 7.01–30.42%, fibre 1.59–4.03%, and ash 3.2–9.13% (Jukić et al., Citation2019; Rodríguez‐Miranda et al., Citation2012). Moreover, pumpkin seeds have been reported to have several health benefits and therapeutic values (Patel, Citation2013; Ramak & Mahboubi, Citation2018; Xanthopoulou et al., Citation2009). Studies have indicated that the pumpkin seed flour, the seed cake after extraction of oil and pumpkin seed oil have health benefits. These health benefits are attributed to their antioxidant activity, anti-inflammatory properties, anti-bacteria, antiviral activities, prevention of diabetic complications, cardio vascular protective effects and many others (Amin et al., Citation2020; Hussain et al., Citation2021; Lestari & Meiyanto, Citation2018; Ramak & Mahboubi, Citation2018). Studies on the physicochemical and functional properties of whole and defatted pumpkin seed meals have confirmed their potential as an alternative input in formulating nutritionally enhanced products (Rodríguez‐Miranda et al., Citation2012). Pumpkin seed flour has been incorporated in several baked products by replacing wheat flour in biscuits (Jukić et al., Citation2019, Syam et al., Citation2020; Saraswathi et al., Citation2018), cookies (Giami et al., Citation2005), and muffins (Białek et al., Citation2015).

The drive for valorisation of food processing waste or by-products for food application, among others, is population growth, decline in agricultural productivity, and presence of nutritious and health-benefiting components and underutilization of available resources (Bursa et al., Citation2021, Ginindza et al., Citation2022). A wide range of food by-products have been used to develop ingredients for the formulation of new products of enhanced nutrition and food products that have health benefits (Badjona et al., Citation2019; Ginindza et al., Citation2022; Gómez & Martinez, & 2018; Salehi & Aghajanzadeh, Citation2020). The enrichment of food products through valuable and innovative ingredients has been an important avenue to deal with nutritional deficiencies, prevent chronic diseases and promote health (Lemus-Mondaca et al., Citation2019).

Muffins are widely consumed and are characterized by a soft texture and sweet flavour. As popular products among the consumer, muffins are potential vehicles to deliver nutritional and functional ingredients to consumers. Given the nutritional and health benefits of germinated sorghum flour and pumpkin seed flour, there is a great potential to come up with nutritionally enhanced and potentially health benefiting muffin. Moreover, it is also critical to identify the optimal combination of the wheat, germinated sorghum and pumpkin seed flour that gives the best results and an acceptable product. The possibility blending these three ingredients to produce acceptable muffin with improved nutrition has not been reported in literature. The objectives of this study were to determine the effect of proportion of wheat, germinated sorghum flour and pumpkin seed flour on the functional properties of the composite flour, the physical and sensory properties of muffin made from the composite flour and to optimize the formulation of the composite flour for an acceptable product using D-optimal mixture design.

2. Material and methods

2.1. Preparation of sorghum and pumpkin seed flour

The sorghum grains (variety NS 5511) were cleaned to remove foreign materials and soaked at room temperature for 24 h and germinated for 48 h. The germination was followed by kilning at 50 °C for 24 hours to halt the germination and reduce the grain moisture content (Cardone et al., Citation2021; Sharanagat & Nema, Citation2021). The dried grains were ground using a heavy duty blender (KM-1500 MRC, Holon, Israel) and sieved using a 425 μm test sieve to obtain sorghum flour. The pumpkin seeds (variety MF Pumpkin Flat White) were removed from the pumpkin and roasted in an air oven (Incotherm, Labotech 926, Telaangana, India) at 180 °C until golden brown (Peng et al., Citation2021). The roasted seeds were manually dehulled to obtain the nuts. The nuts were ground using a blender (KM-1500 MRC, Holon, Israel) to get pumpkin seed flour (Saraswathi et al., Citation2018).

2.2. Functional properties of composite flour

2.2.1. Bulk density (BD)

The method described by Oladele and Aina (Citation2007) was used for the determination of bulk density. Flour samples (50 g) were weighed into a 100 ml measuring cylinder and tapped continuously until a constant volume was obtained. Bulk density was calculated using EquationEquation (1)(1)

(1) .

(1)

(1)

2.2.2. Water absorption index (WAI)

WAI was determined using the method outlined by Anderson et al. (Citation1969) where about 1 g of the composite flour was suspended in 15 ml distilled water in centrifuge tubes. The dispersions were allowed to stand at room temperature for 30 minutes and centrifuged at 3000 rpm for 5 minutes. The mass of the sample was measured before and after decantation of the supernatant. The WAI was computed as grams of adsorbed water per gram of the dry sample (EquationEquation (2)(2)

(2) ).

(2)

(2)

2.2.3. Oil absorption index (OAI)

The method used by Chandra et al. (Citation2015) was used to determine the OAI. About 1 g of sample (w0) was thoroughly mixed with 10 ml (v1) oil. The mix was allowed to stand for 30 min and centrifuged at 3000 rpm for 20 min. The volume of the supernatant was recorded (v2). The OAI was using EquationEquation (3)(3)

(3) .

(3)

(3)

2.2.4. Swelling index (SWI)

The method by Ukpabi and Ndimele (Citation1990) was used to measure the SWI. About 10 grams of sample was placed in 210 ml measuring cylinder. About 100 ml of distilled water was added and allowed to stand for 1 h and the supernatant was discarded. The SWI was calculated as the difference between the final and initial volume per gram of sample (EquationEquation (4)(4)

(4) )

(4)

(4)

2.2.5. Baking procedure

The ingredients including 31 g sugar, 50 g margarine, 1 pinch salt, 31 ml milk and 1.25 ml vanilla essence were used in the preparation of the muffins based on the formulations of the flours presented in . Sugar and margarine were creamed until all the sugar crystals were dissolved. Eggs were beaten in a bowl together with milk and poured into the creamed sugar. The dry ingredients were then sifted and added bit by bit while folding in until the right consistency was achieved. The dough was then put into the muffin tray using a spoon to ensure that the muffins were equal. The muffins were baked for 20-25 minutes at 180 °C (Giami et al., Citation2005). The muffins were then cooled, stored and used for nutrient analysis as well as sensory evaluation.

Table 1. Muffin formulations.

2.3. Physical properties of muffins

The height, diameter and weight were the parameters measured. A Vernier calliper was used to measure the product height and diameter to the nearest millimetres. The weight was measured in grams using an analytical scale (E.I.M series N17250, Milton Keynes, UK).

2.4. Proximate composition of muffins

The proximate composition of the composite flour muffins were analysed in terms of moisture, ash, protein, fat, and crude fibre content. Moisture and ash were measured using AACC (Citation2000) with method 934.01 and 942.05, respectively 08 01. Total dietary fibre and proteins were determined according to AOAC (Citation2000) method 985.29 and 968.06, respectively. Fat content was estimated using the Soxhlet method whereas the total carbohydrates were calculated using the difference method.

2.5. Sensory evaluation

Consumer acceptability in terms of color, taste, aroma, texture and overall acceptability was assessed using a 9-point hedonic scale acceptance with 1 representing (dislike extremely) and 9 representing (like extremely). Fifty assessors participated in the acceptability tests. Coded samples were presented randomly to assessors in random orders to indicate their level of liking.

2.6. Experimental design and data analysis

The study was conducted using D-optimal mixture design. A total of 16 runs were generated using Design-Expert Version 13.0 (Stat-Ease, Inc. Minneapolis, Minnesota) (). Mixture model (EquationEquation (5)(5)

(5) ) (Montgomery, Citation2001) was fitted to the data and the adequacy of the model was checked based on the values of R2 and adjusted-R2.

(5)

(5)

Where:

Y = the predicted variable

X1,2,3 = the proportions of wheat, pumpkin and sorghum flour, respectively

β1, β2, β3 = the linear blend coefficients

β12, β13, β23 = binary blend coefficients

β123 = ternary blend coefficient

The optimization criteria were to maximize sensory attributes (be greater than or equal to 6 which is like slightly), height, diameter, fiber and protein contents. Graphical optimization was done by using an overlay plot of individual contour plots. Numerical optimization was done using the desirability function method. The overall desirability (D) as a function of the desirability value (di) of each response variable is given by EquationEquation (6)(6)

(6) (Montgomery, Citation2001).

(6)

(6)

3. Results and discussion

3.1 Functional properties of the composite flour

3.1.1. Water absorption index (WAI)

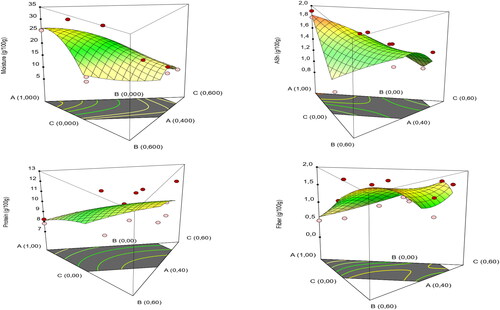

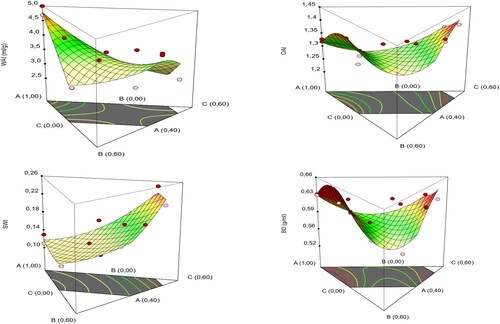

Composite flours with high WAI are preferred for baked products. The WAI was significantly (p < 0.05) influenced by the blend proportion and ranged from 5.0 ml/g for the control to 2.8 ml/g for 50:21:28% (W:P:S). The WAI in general increased with increase in wheat flour proportion (). The relationship between the WAI and the blend proportion was described by a quadratic model (R2 = 0.75, adjusted-R2 = 0.63). The linear mixture exhibited a significant influence on the WAI. Wheat and sorghum flour had a significant positive influence on the WAI which was evident from the positive linear blend coefficients. The pumpkin-sorghum binary blend had a strong positive influence on WAI (). The WAI obtained were within reported values of cereal-based protein enriched composite flours (Adeyeye et al., Citation2017; Asma et al., Citation2006; Awoyale et al., Citation2011; Manyatsi et al., Citation2020; Oyeyinka et al., Citation2020).

Figure 1. Functional properties of composite flour as a function of wheat (A), pumpkin (B) and sorghum (C) blend proportions.

Table 2. Model coefficients and degree of fit for the different parameters.

3.1.2. Oil absorption index (OAI)

The OAI ranged from 1.23 ml/g to 1.4 ml/g for samples with blend proportion 86:0:14% (W:P:S) and 40:19:50% (W:P:S), respectively and was significantly (p < 0.05) influenced by the blend proportions. The OAI increased with increase in the proportion of sorghum (). Pumpkin seed flour proportion had the least effect indicated by the small magnitude of the coefficient of pumpkin seed flour proportion compared to wheat and sorghum flour. The relationship between the OAI and the blend proportion was described by a special cubic model (R2 = 0.81, adjusted-R2 = 0.69). The linear blends had a positive significant effect whereas the wheat-sorghum binary blend had a significant negative effect on OAI (). Wheat and sorghum flour has been reported to have OAI of 0.9 g/g and 1.0 g/g, respectively (Rai et al., Citation2014) whereas the OAI of defatted and whole pumpkin seed meal has been reported to be 2.73 g/g and 1.27 g/g, respectively (Rodríguez‐Miranda et al., Citation2012). Earlier study indicated that germination of sorghum up to 48 h improved OAI (Cardone et al., Citation2021). Low OAI has been attributed to the presence of high-protein constituents and hydrophilic nature of such flours which supports the least effect of pumpkin seed flour on OAI (Menon et al., Citation2015). The OAI of flour is very important for improving the mouth feel texture and maintaining the flavour of food products (Du et al., Citation2014; Kaur & Singh, Citation2005; Kraithong et al., Citation2018).

3.1.3. Swelling index (SWI)

The SWI was significantly (p < 0.05) affected by the blend proportion. The SWI ranged from 0.1 mL/g to 0.25 mL/g for samples with 0.69:0.30:0.01% (W:P:S) and 50:0:50% (W:P:S), respectively. The SWI increased with increase in sorghum proportion as shown in the response surface () which was also evident from the magnitude of the linear blend coefficient for sorghum (). All the binary blends exhibited a negative effect on swelling index as demonstrated by the negative sign of the coefficients (). Amylose-to-amylopectin ratio has been reported as one of the major factors affecting swelling property of flours where a high amylose proportion reduces swelling power (Blazek & Copeland, Citation2008). The difference in the amylose-to-amylopectin ratio results in antagonistic effects of the binary blends. The high SWI with increase in sorghum flour suggests that sorghum starch has relatively lower amylose. A quadratic model adequately described the changes in SWI as a function of the blend proportions (R2 = 0.94, adjusted-R2 = 0.91). The SWI is an indicator of the water absorption index. High protein and fat content in flour has been reported to decrease SWI due to inhibition of starch gelatinization. This explains the reduction in SWI with increased content of pumpkin seed flour (Menon et al., Citation2015). The SWI was found to be within reported values for other cereal and protein source composite flours (Manyatsi et al., Citation2020). The SWI is considered a quality attribute of flours used in bakery products which shows the ability of starch to absorb water. SWI increases with increase in starch content (Awuchi et al., Citation2019).

3.1.4. Bulk density (BD)

The BD ranged from 0.53 to 0.63 g/mL and was not significantly (p > 0.05) affected by the blend proportion. The BD values obtained are comparable with values reported for other cereal-based protein enriched composite flours (Awoyale et al., Citation2011; Oyeyinka et al., Citation2020).

3.2. Nutritional composition

3.2.1. Moisture content

The moisture content was significantly (P < 0.05) influenced by the blend proportion and increased with increase in wheat flour proportion. The wheat-pumpkin binary blending has a positive influence on the moisture content (). A special cubic model described the moisture content as a function of the blend proportion (R2 = 0.80, adjusted-R2 = 0.66). Moisture increment from 8.2% to 8.8% has been reported in cookies where the wheat was replaced up to 25% by pumpkin flours (Giami et al., Citation2005).

3.2.2. Ash

The ash content increased with increase in wheat and pumpkin flour proportion (). The ash content increased with increase in sorghum followed by a decrease with further increase (). A quadratic model described the relationship between the ash content and the blend proportion (R2 = 0.75, adjusted-R2 = 0.62) with a nonsignificant lack of fit. The proportion of wheat and the pumpkin-sorghum binary blend contributed significantly (P<0.05) to ash content (). Ash increment from 0.9% to 1.8% has been reported in cookies where wheat flour was replaced up to 25% by pumpkin seed flour (Giami et al., Citation2005) indicating the mineral contribution of pumpkin seed flour. The decrease in ash content with further increase in sorghum flour content is attributed to the relative reduction in the proportion of pumpkin seed flour which is rich in minerals (Rodríguez‐Miranda et al., Citation2012; Saraswathi et al., Citation2018).

3.2.3. Protein

The protein content ranged from 7.29% to 12.2% for samples with 50:0:50% (W:P:S) and 50:22:28% (W:P:S), respectively. The protein content increased with increase in the proportion of pumpkin seed flour (). Protein increment from 12.3% to 23.8% has been reported in cookies with replacement of wheat by pumpkin seed flour up to 25% (Giami et al., Citation2005) and increment of pumpkin seed flour from 0% to 50% increased the protein content from 6.5 to 17.9 g/100 g in biscuits (Białek et al., Citation2015). The increment in protein content with increase in pumpkin seed flour is attributed to high protein content (28-35.5 g/100g) in pumpkins seeds (Rodríguez‐Miranda et al., Citation2012, Jukić et al., Citation2019; Younis et al., Citation2000).

3.2.4. Fiber

The fiber content increased with increase in the proportion of sorghum and pumpkin seed flour. The value ranged from 0.49% to 2.0% for blend proportion of 100:0:0% (W:P:S) and 52:30:18% (W:P:S), respectively. The linear blends significantly influenced the fiber content. The effect of pumpkin seed flour was more pronounced than wheat and sorghum flours as exhibited by the magnitude of the linear coefficient for pumpkin seed flour () indicating the potential of pumpkin seed flour in formulating high fiber products .Substitution of wheat flour with 50% pumpkin seed flour resulted in two fold increase in fiber (Białek et al., Citation2015). The fibre content of pumpkin was reported to be 2.3 g/100 g (Rodríguez‐Miranda et al., Citation2012).

3.3. Physical properties of muffins

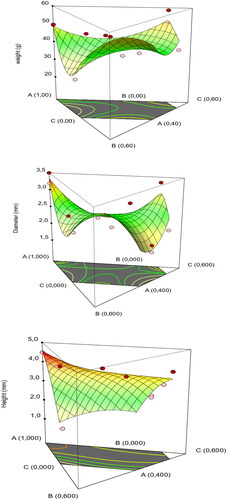

3.3.1. Weight

The results indicated that blend proportions significantly (p < 0.05) influenced the weight muffins. The weight of muffins ranged from 22.16 g to 58.7 g for samples with 84:11:5% (W:P:S) and 50%:0:50% (W:P:S), respectively. The changes in weight as a function of blend proportions is presented in the response surface (). In general, increase in sorghum flour proportion resulted in increase in weight. The reduction in the height of muffins with increase in pumpkin seed flour resulted in denser product which also implies increase in weight. Similar trend has been reported in cookies where wheat was replaced by pumpkin flour (Giami et al., Citation2005).

3.3.2. Diameter

The muffin diameter was significantly influenced by the blend proportion the maximum and minimum values were 1.9 cm and 3.35 cm for samples with 40:22:38% and 50:0:50% (W:S) (W:P:S%), respectively. Increase in wheat flour resulted in increased diameter (). A special cubic model described the relationship between the diameter and the blend proportions (R2 = 0.78, adjusted-R2 = 0.63). The linear and ternary coefficients showed a significant (p < 0.05) positive effect on the diameter whereas all the binary blend coefficients exhibited a significant (p < 0.05) negative influence where pumpkin-wheat and pumpkin-sorghum binary blends had a pronounced negative effect () indicating their antagonistic effects. Reduced diameter of cookies and biscuits with increased replacement of wheat with pumpkin seed flour has been reported (Giami et al., Citation2005; Jukić et al., Citation2019). The diameter is influenced by the extent to which the dough spreads and sets during baking and it is an indicator of the expansion quality of the dough (Kwaw et al., Citation2017).

3.3.3. Height

The muffin height was significantly influenced by the blend proportions. The height ranged from 4.5 cm for the control (100% W) to 1.8 cm for samples with the blend proportion of 69:30:1.0% (W:P:S). The changes in the height with respect to blend proportion are presented in the response surface (). Increase in the proportion of pumpkin seed flour resulted in decreased height whereas increase in the wheat and sorghum flour resulted in increase in height. This is also evident from the magnitude and sign of the linear blend coefficients (). A special cubic model adequately described the relationship between the blend proportions and height (R2 = 0.86, adjusted-R2 = 0.77). The linear blend coefficients exhibited a significant (p < 0.05) influence on the muffin height. A similar trend has been reported for cookies and biscuits made by replacing wheat flour with pumpkin seed flour (Giami et al., Citation2005; Jukić et al., Citation2019) and replacing wheat flour with blend of pumpkin and flax seed flour (Saraswathi et al., Citation2018). The reduction in height with increase in pumpkin seed flour could be due to the replacement of wheat protein by pumpkin seed protein that has lower elasticity properties (Devi et al., Citation2013).

3.4. Sensory evaluation

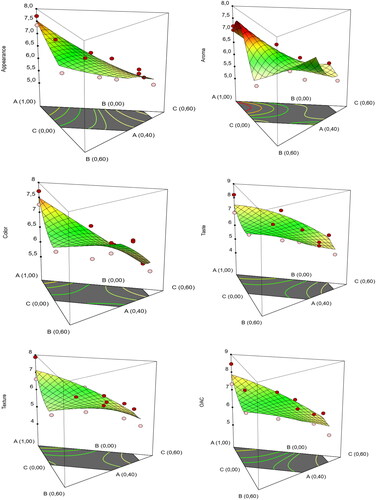

The sensory attributes were significantly (p < 0.05) influenced by the blend proportions. The sensory scores in general increased with increase in the proportion of wheat flour and decreased with increase in the proportion of sorghum and pumpkin seed flour as indicated in the response surfaces (). The maximum score for appearance, aroma, colour, taste, texture and overall acceptability were 7.7 (like very much), 7.3 (like moderately), 7.7 (like very much), 8.2 (like very much), 7.9 (like very much) and 8.5 (like extremely), respectively for muffins made from 100% wheat. The minimum scores were 5.3 (neither like nor dislike), 5.3 (neither like nor dislike), 5.5 (like slightly), 4.8 (neither like nor dislike), 4.7 (neither like nor dislike), and 5.2 (neither like nor dislike) for appearance, aroma, colour, taste, texture and overall acceptability, respectively for muffins made of composite flour with 40:10:50% (W:P:S) proportion. Inclusion of pumpkin flour up to 10% and sorghum flour up to 30% resulted in an acceptable product. Inclusion of pumpkin seed flour up to 33% for muffins (Białek et al., Citation2015) and up to 20% for biscuit (Syam et al., Citation2020) made from wheat-pumpkin seed flour composite flour has been reported. Similar trends of decrease in sensory attributes with increase in pumpkin seed flour content have been reported in earlier studies. A reduction in the sensory attributes of cookies and biscuits from wheat-pumpkin seed composite flour (Giami et al., Citation2005; Bialek et al., Citation2015) and biscuits from wheat-pumpkin seed oil press cake (Saraswathi et al., Citation2018), and biscuits from wheat-pumpkin seed flour (Jukić et al., Citation2019; Syam et al., Citation2020) with increase in the proportion pumpkin seed flour has been reported. Similarly decrease in the sensory attributes of baked product with increase in the proportion of sorghum has been reported (Mahendran & Hariharan, Citation2018; Sibanda et al., Citation2015).

Figure 4. Sensory attributes of muffins as a function of wheat (A), pumpkin (B) and sorghum (C) blend proportions.

A quadratic model described the relationship between the sensory attributes and the blend proportions with a non-significant (p < 0.05) lack of fit except for aroma where a reduced cubic model described the relationship. The degree of fit and the model coefficients are presented in . All the linear blends had a significant influence on all the sensory attributes. The wheat-pumpkin and wheat-sorghum binary blend had antagonistic effect on the appearance which was evident from the negative sign of the binary blend coefficients (). The wheat-sorghum binary blends have synergetic effects on the taste whereas wheat-pumpkin and sorghum-pumpkin binary blends exhibited antagonistic effects as indicated by the negative signs of the blend coefficients (). The wheat-pumpkin binary blend had a strong antagonistic effect whereas the wheat-sorghum and sorghum-pumpkin blend had a synergetic effect on texture as indicated by the positive blend coefficients (). The wheat-pumpkin binary blend had a strong antagonistic effect whereas the wheat-sorghum and sorghum-pumpkin blend had a synergetic effect on the overall acceptability ().

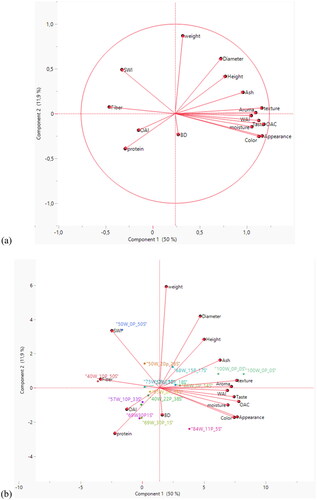

3.5. Principal component analysis

The principal component analysis showed the association between the variables. The analysis indicated that about 74% of the variation was explained by three principal components. The first (PC1), the second (PC2) and the third (PC3) principal components explained 50%, 11.9% and 11.6% of the variations, respectively. The loading plot () showed the correlation between the composite flour functional properties, the muffin physical properties and the sensory attributes. The sensory attributes are positively correlated with each other. The sensory attributes were positively correlated with muffin height, diameter, ash, moisture content, and WAI. Fibre content, OAI, SWI and protein content were positively correlated among each other whereas they were negatively correlated with all the sensory attributes. Rate of oil absorption has been reported to be high in foods with high protein content (Awuchi et al., Citation2019). The bi-plot () showed that the sensory attributes and high proportion of wheat were positively correlated. Moreover, the bi-plot indicated that fibre content was positively correlated with high sorghum proportion whereas high proportion of pumpkin seed flour was positively correlated with protein content.

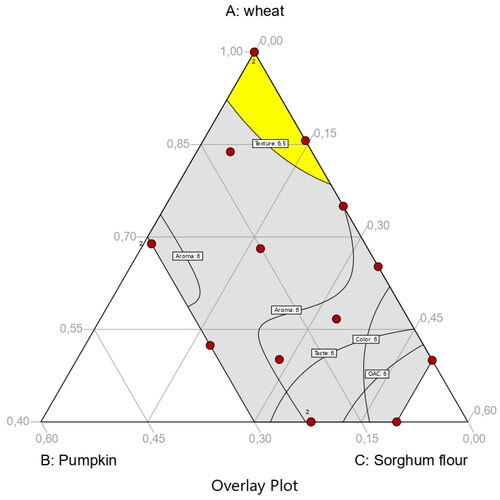

3.6. Optimization

Based on graphical optimization, best results were obtained using minimum of 79% of wheat flour, up to 10% pumpkin seed flour and up to 21% of sorghum flour. The yellow shaded region in depicts the optimal blend proportions for an acceptable product. Numerical optimization revealed that combination of 83% wheat flour, 10% pumpkin seed flour and 7% sorghum flour gave the best result with a desirability value of 0.621. Muffins with maximized protein content as a result of inclusion of pumpkin seed flour will address protein malnutrition by providing cheap source of protein. Moreover, consumers will also have health benefit from high fibre muffins.

4. Conclusion

High proportion of pumpkin seed flours brought about a decrease in the diameter and height of muffins resulting in denser product. The protein content increased with increase in the proportion of pumpkin seed flour. The fiber content increased with increase in the proportion of sorghum and pumpkin seed flour. The sensory scores decreased with increase in the proportion of sorghum and pumpkin seed flour. A positive correlation was observed between sensory attributes and muffin height, diameter, ash, moisture content, and WAI. Graphical optimization revealed that the best results were found using 79 to 100% of wheat, up to 10% pumpkin seed flour, and up to 21% sorghum whereas numerical optimization indicated that a combination of 83% wheat, 10% pumpkinseed flour and 7% sorghum flour gave best results with a desirability value of 0.621.

Disclosure statement

No potential conflict of interest was reported by the author(s).

Additional information

Notes on contributors

Hlengiwe Mdluli

Hlengiwe Mdluli a graduate in Food Science Nutrition and Technolgy from the University of Eswatini.

Solomon W. Kidane

Prof. Solomon W. Kidane is a professor in Food Process Engineering at the University of Eswatini. His research area includes food rheology, food process modelling and optimization and product development.

T. P. Nkambule

Dr T.P. Nkambule is a senior lecturer. Her research area includes food safety, food microbiology, food preservation, food quality assurance, among others.

J. S. Shelembe

Dr J.S. Shelembe is a Lecturer, and his research area includes food chemistry, product development, food processing and preservation technologies.

References

- AACC. (2000). Approved Methods of the American Association of Cereal Chemists (10th ed.). The American Association of Cereal Chemist Press.

- Adeyeye, S. A. O., Adebayo-Oyetoro, A. O., & Omoniyi, S. A. (2017). Quality and sensory properties of maize flour cookies enriched with soy protein isolate. Cogent Food & Agriculture, 3(1), 1. https://doi.org/10.1080/23311932.2017.1278827

- Amin, M. Z., Rity, T. S., Uddin, M. R., Rahman, M. M., & Uddin, M. J. (2020). A comparative assessment of anti-inflammatory, anti-oxidant and anti-bacterial activities of hybrid and indigenous varieties of pumpkin (Cucurbita maxima Linn.) seed oil. Biocatalysis and Agricultural Biotechnology, 28, 101767. https://doi.org/10.1016/j.bcab.2020.101767

- Anderson, R. A., Conway, H. F., Pfeifer, V. R., & Griffin, L. (1969). Gelatinization of corn grits by roll and extrusion cooking. Cereal Science Today, 14, 4–13.

- AOAC. (2000). Official Methods of Analysis (Vol. 2). Wilson.

- Asma, M. A., Fadil, E. B., & Tinay, A. H. (2006). Development of weaning food from sorghum supplemented with legumes and oil seeds. Food and Nutrition Bulletin, 27(1), 26–34. https://doi.org/10.1177/156482650602700104

- Awika, J. M., & Rooney, L. W. (2004). Sorghum physicochemicals and their potential impact on human health. Phytochemistry, 65(9), 1199–1221. https://doi.org/10.1016/j.phytochem.2004.04.001

- Awoyale, W., Maziya-Dixon, B., Sanni, L. O., & Shittu, T. A. (2011). Nutritional and sensory properties of a maize-based snack food (kokoro) supplemented with treated Distillers’ spent grain (DSG). International Journal of Food Science & Technology, 46(8), 1609–1620. https://doi.org/10.1111/j.1365-2621.2011.02659.x

- Awuchi, C. G., Igwe, V. S., & Echeta, C. K. (2019). The functional properties of foods and flours. International Journal of Advanced Academic Research Sciences, Technology and Engineering, 5(11), 139–160.

- Baba, G. M., Modu, S., Falmata, A. S., Hajiagana, L., & Ibrahim, Z. (2012). Evaluation of the nutritional value of sprouted sorghum fortified with cowpea and groundnut. Scholarly Journal of Agricultural Science, 2(11), 292–296.

- Badjona, A., Adubofuor, J., Amoah, I., & Diako, C. (2019). Valorization of carrot and pinapple pomaces for rock buns development. Scientific African, 6, e00160. https://doi.org/10.1016/j.sciaf.2019e00160

- Białek, M., Rutkowska, J., Adamska, A., & Bajdalow, E. (2015). Partial replacement of wheat flour with pumpkin seed flour in muffins offered to children. CyTA - Journal of Food, 14(3), 1–8. https://doi.org/10.1080/19476337.2015.1114529

- Blazek, J., & Copeland, L. (2008). Pasting and swelling properties of wheat flour and starch in relation to amylose content. Carbohydrate Polymers, 71(3), 380–387. https://doi.org/10.1016/j.carbpol.2007.06.010

- Bouazzaoui, N., & Mulengi, J. K. (2018). Fatty acids and mineral composition of melon (Cucumis Melo) and pumpkin (Cucurbita moschata) seeds. Journal of Herbs, Spices & Medicinal Plants, 24(4), 315–322. https://doi.org/10.1080/10496475.2018.1485125

- Bursa, K., Toker, O. S., Palabiyik, I., Yaman, M., Kian-Pour, N., Konar, N., & Kilicli, M. (2021). Valorization of hazelnut cake in compound chocolate: The effect of formulation on rheological and physical properties. LWT, 139, 110609. https://doi.org/10.1016/j.lwt.2020.110609

- Cardone, G., Rumler, R., Speranza, S., Marti, A., & Schönlechner, R. (2021). Sprouting time affects sorghum (Sorghum bicolor [L.] Moench) functionality and bread-making performance. Foods (Basel, Switzerland), 10(10), 2285. https://doi.org/10.3390/foods10102285

- Chandra, S., Singh, S., & Kumari, D. (2015). Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. Journal of Food Science and Technology, 52(6), 3681–3688. https://doi.org/10.1007/s13197-014-1427-2

- Devi, N. L., Shobha, S., Tang, X., Shaur, S. A., Dogan, H., & Alavi, S. (2013). Development of protein-rich sorghum-based expanded snacks using extrusion technology. International Journal of Food Properties, 16(2), 263–276. https://doi.org/10.1080/10942912.2011.551865

- Du, S.-K., Jiang, H., Yu, X., & Jane, J.-L. (2014). Physicochemical and functional properties of whle legume flour. LWT - Food Science and Technology, 55(1), 308–313. https://doi.org/10.1016/j.lwt.2013.06.001

- Duodu, K. G., Taylor, J. R. N., Belton, P. S., & Hamaker, B. R. (2003). Factors affecting sorghum protein digestibility. Journal of Cereal Science, 38(2), 117–131. https://doi.org/10.1016/50733-5210(03)00016-x

- Dykes, L., & Rooney, L. W. (2006). Sorghum and millet phenols and anti-oxidants. Journal of Cereal Science, 44(3), 236–251. https://doi.org/10.1016/j.jcs.2006.06.007

- Ezeogu, L. I., Duodu, K. G., & Taylor, J. R. N. (2005). Effects of endosperm texture and cooking conditions on the in vitro starch digestibility of sorghum and maize flours. Journal of Cereal Science, 42(1), 33–44. https://doi.org/10.1016/j,jcs.2005.02.002

- Giami, S. Y., Achinewhu, S. C., & Ibaakee, C. (2005). The quality and sensory attributes of cookies supplemented with fluted pumpkin (Telfairia occidentalis Hook) seed flour. International Journal of Food Science & Technology, 40(6), 613–620. https://doi.org/10.1111/j.1365-2621.2005.01008.x

- Ginindza, A., Solomon, W. K., Shelembe, J. S., & Nkambule, T. P. (2022). Valorisation of brewer’s spent grain flour (BSGF) through wheat-maize-BSGF composite flour bread: optimization using D-optimal mixture design. Heliyon, 8(6), e09514. https://doi.org/10.1016/j.heliyon.2022.e09514

- Gómez, M., & Martinez, M. M. (2018). Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked products. Critical Reviews in Food Science and Nutrition, 58(13), 2119–2135. https://doi.org/10.1080/10408398.2017.1305946

- Hussain, A., Kausar, T., Din, A., Murtaza, M. A., Jamil, M. A., Noreen, S., & Ramzan, M. A. (2021). Determination of total phenolic, flavonoid, carotenoid and mineral contents in peel, flesh and seeds of pumpkin (Cucurbita maxima). Journal of Food Processing and Preservation, 45(6), e15542.

- Jukić, M., Lukinac, J., Čuljak, J., Pavlović, M., Šubarić, D., & Koceva Komlenić, D. (2019). Quality evaluation of biscuits produced from composite blends of pumpkin seed oil press cake and wheat flour. International Journal of Food Science & Technology, 54(3), 602–609. https://doi.org/10.1111/ijfs.13838

- Kaur, M., & Singh, N. (2005). Studies on functional, thermal and pasting properties of flour from different chickpeas (Cicer arietinum L) cultivars. Food Chemistry, 91(3), 403–411. https://doi.org/10.1016/j.foodchem.2004.06.015

- Kraithong, S., Lee, S., & Rawdkuen, S. (2018). Physicochemical and functional properties of Thai organic rice flour. Journal of Cereal Science, 79, 259–266. https://doi.org/10.1016/j.jcs.2017.10.015

- Kwaw, E., Apaliya, M. T., Sackey, A. S., Tchabo, W., & Mahunu, G. K. (2017). Application of D-optimal design for optimizing Paprika biglobosa flour-based cookie. Journal of Food Measurement and Characterization, 11(4), 1569–1577. https://doi.org/10.1007/s11694-017-9536-z

- Lemus-Mondaca, R., Marin, J., Rivas, J., Sanhueza, L., Soto, Y., Vera, N., & Puente-Díaz, L. (2019). Pumkin seeds (Cucurbita maxima). A review of functional attributes and by-products. Revista Chilena de Nutrición, 46(6), 783–791. https://doi.org/10.4067/S0717-75182019000600783

- Lestari, B., & Meiyanto, E. (2018). A review: The emerging nutraceutical potential of pumpkin seeds. Indonesian Journal of Cancer Chemoprevention, 9(2), 92–101. https://doi.org/10.14499/indonesianjcanchemoprev9iss2pp92-101

- Mahendran, T., & Hariharan, G. (2018). Optimization of wheat-sorghum composite flour for the production and enhanced storability of leavened flat bread naan. Tropical Agricultural Research and Extension, 21(1–2), 7–13. https://doi.org/10.4039/tare.v21i1-25460

- Manyatsi, N. T., Solomon, W. K., J. S., & Shelembe, J. S. (2020). Optimization of blending ratios of wheat-maize-sprouted mungbean (Vigna Radiata L.) composite flour bread using D-optimal mixture design. Cogent Food & Agriculture, 6(1), 1824304. https://doi.org/10.1080/23311932.2020.1824304

- Marston, K., Khouryieh, H., & Aramouni, F. (2014). Evaluation of sorghum flour functionality and quality characteristics of gluten-free bread and cake as influenced by ozone treatment. Food Science and Technology International = Ciencia y Tecnologia de Los Alimentos Internacional, 21(8), 631–640. https://doi.org/10.1177/1082013214559311

- Menon, L., Majumdar, S. D., & Ravi, U. (2015). Development and analysis of composite flour bread. Journal of Food Science and Technology, 52(7), 4156–4165. https://doi.org/10.1007/s13197-014-1466-8

- Montgomery, D. C. (2001). Design and analysis of experiments (5th ed.). John and Wiley and Sons Inc.

- Oladele, A. K., & Aina, J. O. (2007). Chemical composition and functional properties of flour produced from two varieties of tigernut (Cyperus esculentus). African Journal of Biotechnology, 6(21), 2473–2476. https://doi.org/10.5897/AJB2007.000-2391

- Oyeyinka, S. A., Adebayo, A. I., Oyeyinka, A. T., Akeem, A. O., Garuba, T., & Oladunjoye, A. O. (2020). Flour functionality physicochemical and sensory properties of steamed and baked maize meal enriched with defatted soybean. Journal of Food Processing and Preservation, 44, e14389. https://doi.org/10.1111/jfpp.14389

- Patel, S. (2013). Pumpkin (Cucurbita sp.) seeds as nutraceutic: a review on status quo and scopes. Mediterranean Journal of Nutrition and Metabolism, 6(3), 183–189. https://doi.org/10.1007/s12349-013-0131-5

- Peng, M., Lu, D., Liu, J., Jiang, B., & Chen, J. (2021). Pumpkin (Cucurbita pepo L.) seeds. Frontiers in Nutrition, 8, 647354. https://doi.org/10.3389/fnut.2021.647354

- Rai, S., Kaur, A., & Singh, B. (2014). Quality characteristics of gluten free cookies prepared from different flour combinations. Journal of Food Science and Technology, 51(4), 785–789. https://doi.org/10.1007/s13197-011-0547-1

- Ramak, P., & Mahboubi, M. (2018). The beneficial effects od pumpkin (Cucurbita peo L.) seed oil for health condition of men. Food Reviews International, 35(2), 166–176. https://doi.org/10.1018/87559129.218.1482496

- Rodríguez‐Miranda, J., Hernández‐Santos, B., Herman‐Lara, E., Vivar‐Vera, M. A., Carmona‐García, R., Gómez‐Aldapa, C. A., & Martínez‐Sánchez, C. E. (2012). Physicochemical and functional properties of whole and defatted meals from Mexican (Cucurbita pepo) pumpkin seeds. International Journal of Food Science & Technology, 47(11), 2297–2303. https://doi.org/10.1111/j.1365-2621.2012.03102.x

- Salehi, F., & Aghajanzadeh, S. (2020). Effect of dried fruits and vegetables powder on cakes quality: A review. Trends in Food Science & Technology, 95, 162–172. https://doi.org/10.1016/j.tifs.2019.11.011

- Saraswathi, D., Renu, R., & Maloo, S. (2018). Development and quality evaluation of pumpkin seed and flaxseeds powder incorporated biscuits. International Journal of Food Sciences and Nutrition, 3(2), 78–83.

- Sharanagat, V. S., & Nema, P. K. (2021). Bread preparation by partial replacement of wheat by germinated sorghum. Food Science and Technology International = Ciencia y Tecnologia de Los Alimentos Internacional, 29(1), 13–24. https://doi.org/10.1177/10820132211058002

- Sibanda, T., Ncube, T., & Ngoromani, N. (2015). Rheological properties and bread making quality of white grain sorghum-what flour composites. International Journal of Food Science and Nutrition Engineering, 5(4), 176–182.

- Syam, A., Kurniati, Y., Ulfasari, I., Ishak, A., & Akhmar, A. M. 2020. Preference test of biscuit products from pumpkin seeds (Cucurbita sp.). Enfermería Clínica, 30(4): 375–378 https://doi.org/10.1016/j.enfcli.2019.10.115

- Tizazu, S., Urga, K., Belay, A., Abuye, C., & Ibrahim, Z. (2011). Effect of germination on mineral bioavailability of sorghum-based complementary foods. African Journal of Food, Agriculture, Nutrition and Development, 11(5), 1–13.

- Ukpabi, U., & Ndimele, C. (1990). Evaluation of the quality of gari produced in Imo state. Nigerian Food Journal, 8, 105–110.

- Xanthopoulou, M. N., Nomikos, T., Fragopoulou, E., & Antonopoulou, S. (2009). Antioxidant and lipoxygenase inhibitory activities of pumpkin seed extracts. Food Research International, 42(5–6), 641–646. https://doi.org/10.1016/j.foodres.2009.02.003

- Younis, Y. M., Ghirmay, S., & Al-Shihry, S. S. (2000). African Cucurbita pepo L: properties of seed and variability in fatty acid composition. Phytochemistry, 54(1), 71–75. https://doi.org/10.1016/s0031-9422(99)00610-x