?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

Microencapsulation improves the stability of liquid food by moving it to a free form of powder. In the current study, Nigella sativa Oil (NSO) emulsion mixture was spray dried under various operating conditions, including inlet air temperature (IAT) of 130, 145, and 160 °C, wall material (WM), 10, 15, and 20%; feed rate (FR), 6, 9, and 12 mL/min; and needle speeds (NS) of 6, 8, and 10 s. The conditions of 130 °C (IAT), 15% (WM), 9 mL/min (FR), and 6 s (NS) produced the highest encapsulation efficiency (EE) of 89.51 ± 0.90%. At 160 °C (IAT), 15% (WM), 9 mL/min (FR), as well as 8 s (NS), the minimum EE was observed to be 79.15 ± 0.61%, and the maximum model predicted value of (EE) was 89.46 ± 0.80%. IAT has a substantial impact on EE while improving the oxidative quality of spray-dried microcapsule (SDM) samples. The SDM sample sensory scores fell within acceptable limits. Therefore, the spray-drying method developed from Nigella sativa Oil can be recommended for different fortifying food products.

REVIEWING EDITOR:

1. Introduction

Nigella sativa L. is an annual herb that belongs to the Ranunculaceae family. It is commonly used as black cumin or black seeds (Majeed et al., Citation2021). Black seeds are mostly grown in South Europe, North Africa, and Southwest Asia. Additionally, it is cultivated in numerous countries, including Pakistan, India, Iran, Saudi Arabia, Turkey, and Syria (Srinivasan, Citation2018). Nigella sativa seeds are composed of different oil types, including fixed oils, unsaturated fatty acids, arachidonic, eicosadienoic, linoleic, linolenic, and saturated fatty acids (palmitic, stearic, and myristic) (Rahim et al., Citation2022). The seeds of Nigella sativa also contain some other compounds such as cholesterol, campesterol, stigmasterol, βsitosterol, α-spinasterol, citronellol, limonene, p-cymene, citronellyl acetate, carvone, nigellone, arachidic, linolenic, linoleic, myristic, oleic, palmitic, palmitoleic, and stearic acids (Rahim et al., Citation2022). Plant seeds and leaves have also been used as culinary and seasoning herbs (Wani & Kumar, Citation2018). In outdated medicine, black seed oil is frequently used to treat conditions such as piles, rheumatism, dyspepsia, jaundice, skin ailments, and helminthic infestations, and is also considered to have antidiabetic, antihypertensive, anticancer, antibacterial, analgesic, and anti-inflammatory effects (McClements & Rao 2018; Ahn et al., Citation2008). Ramadan and Wahdan (Citation2012) emphasized that one of the primary factors that degrades the overall quality of oils is storage stability, nutritive value, and sensory qualities. Encapsulation is performed to prevent the degradation of oils. Microencapsulation has been regularly used in manufacturing powdered edible oil products where functional oil (core material) is incorporated into the capsule wall material to extend the product shelf life. This microencapsulation procedure can improve the handling of oils by preventing oxidation (Ramadan and Wahdan, Citation2012). Maltodextrin and gum arabic were used as wall materials in the microencapsulation of NSO by spray drying (Edris et al., Citation2016). Spray drying is utilized for microencapsulation in the food and pharmaceutical industries (Alves et al., Citation2017; Morales-Medina et al., Citation2016; Sawale et al., Citation2017; Takeungwongtrakul et al., Citation2015). The stability of spray-dried products during storage is crucial to ensure their proper functioning in food applications. The spray-drying method has numerous benefits, including availability, low cost, high-quality powders, and process flexibility (Gupta et al., Citation2015). Spray drying of NSO is performed during encapsulation. Mohammed et al. (Citation2017) improved the process conditions for the encapsulation of NSO and proposed a comprehensive study of the stability of microencapsulated Nigella sativa Oil.

Spray-drying technology is widely used in the food-processing industry owing to its affordability and accessibility. The composition of the liquid feed, inlet and outlet temperatures, feed and aspiration rates, nozzle pressure, gas flow rate, droplet to particle conversion, and final dried extract are all operating factors in the spray drying process (Santos et al., Citation2018). Additionally, the growing interest among consumers and researchers in the production of fortified food products with higher nutritional value is increasing day by day.

However, the food sector faces significant challenges when using oil microcapsules in food items, because the encapsulated components cannot affect the sensory qualities of the product (do Amaral et al., Citation2019). Therefore, creating a formulation for capsules with optimal efficiency and sensory evaluation is the first stage of spray-drying. The primary objective of this study was operational parameters optimization to create microcapsule using the mixture NSO. Consequently, the microcapsules were assessed for encapsulation efficiency (EE), oxidative quality, and sensory acceptability.

2. Material and methods

2.1. Preparation of raw material

Nigella sativa was purchased from Metro Cash & Carry Store, Faisalabad, Punjab, Pakistan. The raw materials were cleaned to remove dirt and other foreign materials.

2.2. Black seed oil extraction

A machine (mini cold presser oil) model 6YL‐550 (Wuhan Acme Agro‐Tech Co., Ltd., Zhengzhou, Henan, China) was used to extract the NSO, as indicated in a previous study (Mohammed et al., Citation2017). Following extraction, the NSO was sieved at room temperature (25 ± 2 °C) to remove any remaining solid impurities. The cleaned oils were stored for 12 h. After purification, high-quality NSO is produced using several procedures, such as neutralization, bleaching, degumming, and deodorization (Mohammed et al., Citation2016). The NSO samples were kept in specialized cultured plastic bottles and maintained at room temperature in the dark.

2.3. Sample quality of extracted crude oil

2.3.1. Free fatty acids (FFA)

The proportion of free fatty acids in the crude oil samples was determined using the AOCS (Citation1998a, Citation1998b) Ca 5a − 40, dissolved CH3OH (Analytical Grade) (25 g) in an oil sample (1 g), and phenolphthalein (ACS grade) (50 ml) as an indicator. The 0.01 N NaOH (ACS grade) solution was treated until a faint but pink colour appeared.

2.3.2. Peroxide value (PV)

The Cd 8b-90 method, which is based on iodometric titration, was used to estimate the PV of the extracted crude oil (AOCS, Citation1998a). Briefly, KI (ACS grade) solution (0.5 ml of KI solution was added to 0.2 gram of extracted oil sample, which was then allowed to react in the dark for 1 min in 30 ml of CHCl3/CH3COOH (ACS grade) (2:3, v/v) mixture. Before adding 30 ml of pure water, the reaction mixture was agitated for approximately 1 min. After titrating the released iodine solution with 0.001 N Na2S2O3 (ACS grade) the until purple colour disappeared, 0.5 mL of a 1% starch indicator solution was added.

2.3.3. Thiobarbituric acid value (TBA)

With slight modifications, Dieffenbacher & Pocklington (Citation1992) determined the value of TBA in oil samples. The 5 g sample was dissolved in a 5 ml of pure C4H10O (HPLC grade) with in 25 ml volumetric flask (with less than 0.5% H2O). Then, 5 ml sample was poured into a test tube, along with 5 ml of the solution. A glass stopper was used to firmly close the test tube, and all the components were well mixed. For two hours, the solution was heated to 100 °C in a water bath. The test tube was placed after heating for a few minutes in cold tap water until it reached room temperature, which was 25 °C. Using a spectrophotometer set to 530 nm, the absorption of the reacting solution in a 10 mm sample chamber was measured. Finally, distilled water and empty reagent were added to the spectrophotometer. TBA values were calculated using the TBA determination formula.

Where;X = absorbance of reaction solutionY = absorbance of empty reagentM = Mass of test portion

2.4. Emulsion preparation

The Nigella sativa Oil was developed for spray-drying, and later, emulsions were made using a method described by Costa et al. (Citation2015). Soy lecithin, constituting 1% of the total solution weight, served as the emulsifier. In formulations involving oil mixtures (Hee et al., Citation2015), a homogenizer was used to thoroughly mix the wall material. The wall material, collected from a 1:1 ratio of maltodextrin (MD) and gum arabic (GA) (FSH-2A) in the emulsion samples, was chosen for its adhesive properties and homogeneity (Ferrari et al., Citation2011). The homogenization process lasted about five minutes at 10,000 rpm.

2.5. Spray drying of the emulsion sample

The suspension sample was standardized to produce spray-dried microcapsules (SDMs) using a tiny spray drier (Model: TPS-15, TOPTION, Shanghai, China). In this study, operating conditions for spray drying, including inlet air temperatures (IAT) of 130, 145,160 (°C), Feed rates (FR) of (6,9,12 mL/min), wall materials (WM) of 10%, 15%, 20%, and needle speeds (NS) of 6,8,10 s were determined ().

Table 1. The coded actual level of the independent variable for optimizing the response factor as determined by the central composite design.

2.6. Encapsulation efficiency (EE)

By dividing the mass of the encapsulating material by the total weight of the oil (de Melo Ramos et al., Citation2021). 2 grams of SDM samples were carefully weighed on a precise laboratory scale before being placed in a conical flask. The samples were dissolved in n-hexane, a solvent, by slowly stirring at room temperature for five minutes. Hexane extraction was then assessed to measure the overall oil content of the SDM samples. The solution was filtered using Whatman No. 1 filter paper. To extract the oil, the solvents were evaporated in an oven at 140 °C for three hours.

SDM’s effectiveness was calculated by Equationeq 1(1)

(1) .

(1)

(1)

A = Extracted oil or Total oil,Ao = an oily film Surface oil (by measuring the start and final weights of the solution, the surface oils of SDM was identified)

2.7. Spray-dried microcapsule oxidizing properties

The procedures described in Section 2.3 of the prior approach were used to calculate the FFAs, TBA, and PV values of the SDM samples.

2.8. Sensorial evaluation of spray-dried microcapsule samples

A 9–point sensory rating scale was used by professional evaluators to assess the SDM samples (Meilgaard et al., Citation2007) to classified the sensory ratings for the qualities of color, off-flavor, and general acceptability as ‘1 = disliked significantly’ and ‘9 = liked remarkably’. The SDM samples were distributed to the evaluators in random order, each with a label including a secret 3–digit code. The panellists were asked to rate their sensory attribute scores based on their impressions of coded samples.

2.9. Statistical estimation of experimental data

Using Stat − Ease (version 11.1.2.0, E Hennepin Ave, Minneapolis, MN) and MATLAB software (version 7.5.0.338; R2007a, Natick, MA), the results were calculated for their degree of significance (p < 0.05). The response surface methodology (RSM)’s central composite design (CCD) was used in this study to optimise the spray dryer’s operating parameters. Utilising Stat-Ease® and MATLAB Software®, the data obtained for EE (%) as a result of independent variables like inlet air temperature (IAT∼130, 145, 160, °C), wall material (WM∼10%, 15%, 20%), feed rate (FR, 6, 9, 12, mL/min), and needle speed (NS∼6, 8, 10, s) respectively, were analysed for their significance level (Montgomery, Citation2017).

3. Results and discussions

3.1. Quality of Nigella sativa Oil

The Nigella sativa Oil sample has FFA 2.3%, PV 3.43meqO2/kg and, the TBA 0.02 mg of malondialdehyde per kg. Similar results were seen in the sample of nutritive oil, which had FFAs of 2.1%, PV of 1.96 mg/dl O2/kg, as well as TBA values of 1.15 mg malondialdehyde/kg. According to Wahidu et al. (Citation2014; Singh et al., Citation2014), the FFAs and PV of Nigella sativa Oil decrease dramatically with an increase in temperature. The TBA values for NSO samples were 0.02 mg MA/kg. Moreover, a low PV 3.43-3.53meq O2/kg has been observed in NSO (Mohammed et al., Citation2017). High PV had been observed for mixed oil sample of the NSO. Additionally, it was within the allowable limit for edible oils (Makouie et al., Citation2021).

3.2. Model fitting for encapsulation efficiency

The NSO spray-drying method was developed using spray drying techniques. Thirty separate trials were conducted. To optimize the operating conditions for spray drying, a combination of Inlet Air Temperature IAT (°C), Feed Rate (FR) (mL/min), Wall Material (%), and Needle Speed (s) was utilized. The results of the EE experiment and anticipated values are listed in . Spray-dried microcapsule sample analysis of variance for the response variable is given in . The results indicated the highest encapsulation efficiency was obtained at run order 22 (89.51%), while the lowest microencapsulation efficiency was at run order of 10 (79.15%). Following the spray drying of every experiment, a regression equation was used to determine the model that best fit the data. The variable in the quadratic regression model was used to predict experimental results. The intended model showed a link between the independent and response values for encapsulation efficiency. The CCD of RSM, as described in EquationEquations (2–4), was systematically evaluated using the four independent factors at level −5.

Table 2. Optimizing spray drying operation parameters for better encapsulation efficiency.

Table 3. Spray-dried microcapsule sample analysis of variance for the response variable.

Data were examined using the regression equation model in terms of coded factor Y1 and actual factor Y2

X0 = intercept; X1 = inlet air temperature (IAT); X2 = Wall Material (WM)

X3 = Feed Rate (FR); X4 = needle speed; X1 − X4 = Regression coefficient; IAT, WM, and FR

NS = independent variable

(2)

(2)

(3)

(3)

(4)

(4)

The EE oil power affected the wall-material concentration, temperature, and total solid content. Because MD and GA have emulsifying and film-forming properties, they have been utilized to microencapsulate oils (Aksoylu & Günç Ergönül, Citation2017). A considerable increase in EE when MD was used as the wall material during the spray-drying process showed a close correlation between the microcapsules and the wall material (Ramakrishnan et al., Citation2018). A comparative study on microencapsulation of NSO powder was carried out by Santiworakun et al. (Citation2022) and their findings demonstrated a significant difference in the EE% powder encapsulated at the various outlet temperature values for microencapsulation efficiency ranging from 79.15% to 89.51%. The MD formulation produced the lowest value, whereas the GA formulation produced the highest value. Because each barrier layer had a unique set of retention and film-forming characteristics, the variations in the microencapsulation effectiveness were related to the various wall materials used to prepare the emulsification for spray drying. Because gum arabic has good film-forming and emulsifying qualities and contains protein and polysaccharide moieties inside its highly branched arabinogalactan-protein structure, which enables film formation around the oil, it was able to achieve a high percentage of nano-emulsion efficiency (Adamiec et al., Citation2012). Mohammed et al. (Citation2017) stated that microencapsulation of Nigella sativa Oil (NSO) using various wall materials had no significant impact on the resulting powder characteristics. The efficiency of microcapsules and the amount of surface oil present were found to be influenced by the proportion of wall material.

The importance of the oil content is indisputable because of its role in human nutrition. A variety of seafood and soy products have been used to create novel and creative food products. These oils tend to be excellent sources of FAs, such as EPA and DHA. With functional foods, particularly those foods that had been fortified with LCPUFAs, the oxide layer has been identified as a limiting factor. To create high-quality functional food items, several foods must be prepared.

Processing food organizations prefer microencapsulated oils (Ferreira & Nunes, Citation2019). In addition, these LCPUFA-enriched oil microparticles have been approved as a potential source of defense against the development or onset delay of numerous disorders associated with living processes (Lane & Derbyshire, Citation2018).

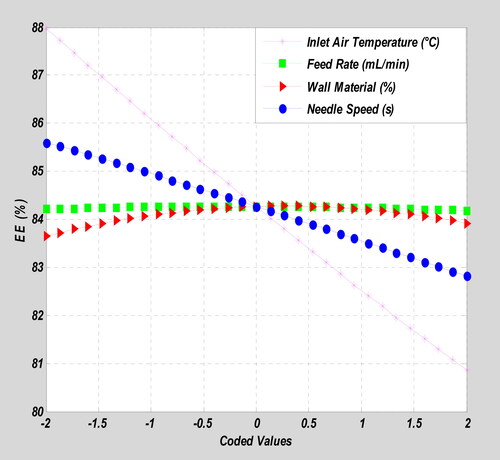

3.3. Analysis for single factor

In this analysis for a single factor, the regression equation for each independent variable was analyzed, which ranges from –1 and +1, respectively (). During the analysis of each variable, the other variables were fixed at the model values and rotated uniformly. The average values applied for the IAT, FR, WM, and NS were 145 °C, 9 mL/min, 15%, and 8 s, respectively. Independent variables, their mutual interaction and optimized values of response variables have been presented in The specific regression equations for each variable (IAT, FR, WM, and NS) are presented in whereas yield has been shown in . According to the results of the single-factor analysis, the independent variable IAT had a strong effect on the encapsulation efficiency of the spray-dried microencapsulation sample. The encapsulation efficiency rate increased at lower IAT, whereas the encapsulation efficiency rate decreased at higher IAT. The independent variables WM, NS, and FR had a minimal impact on EE. Furthermore, the independent variable NS demonstrated an inverse correlation with EE rate, while a positive increase in EE was seen for lower FR and WM.

Table 4. Independent variable, mutual interaction and optimized values of response variables.

Table 5. Regression equations for analysis of single factor variables.

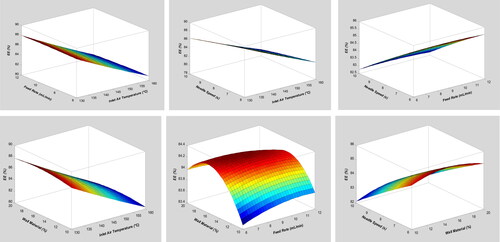

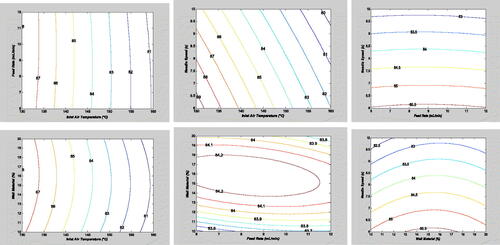

3.4. Mutual interaction effect

The mutual interaction influence between the spray dryer conditions for EE in the resulting samples was calculated by rotating two independent components and placing the other two elements at the coded zero level (). The mutual interaction impact of spray drying conditions on encapsulation efficiency of spray Nigella sativa Oil powder samples is given in . The shared effect of IAT and WM demonstrated that when the independent variables were at a lower level, the EE rate was higher. At lower levels of the interaction between FR and WM, the EE rate decreased. Furthermore, the findings demonstrated that EE increased at a higher level of mutual interaction between IAT and NS. Furthermore, as the mutual levels of (IAT, FR), (IAT, WM), and (WM, NS) decreased, so did the EE rate. From the data shown in , it is noteworthy that 89.51 ± 0.90% was the highest expected value of EE. Additionally, it was determined that increasing the wall material, needle speed, and inlet air temperature at a low feed rate boosts the encapsulation efficiency (EE) (Rahim et al., Citation2022). According to research, the response surface approach was utilized by microencapsulation of FO to optimize operating conditions, and the value of EE was recorded between 89.51% and 79.15%. Previous studies have shown that there is little difference between the expected and actual values for spray-dried oil samples (Ali et al., Citation2021).

Figure 3. The mutual interaction impact of spray drying conditions on Encapsulation Efficiency of spray Nigella sativa Oil powder samples.

Table 6. Coded and actual regression equations for response factors after spray drying process.

3.5. Spray-dried microcapsule oxidative quality

At run order 22, the highest PV of the SDM samples was found to be 3.68 meq O2/kg. Additionally, run 30 (3.32 mg/dl O2/kg) had the lowest PV value. According to these findings, SDM’s oxidative stability of SDM was much higher than that of the raw and oil mixture samples. Moreover, a considerable PV rise in the PV of the SDM sample was observed as the temperature increased. Similar trends were seen for TBA values, which were greater for SDM samples (0.06 mg malondialdehyde/kg) at elevated spray dryer temperature profiles compared to lowest TBA values (0.02 mg malondialdehyde/kg) at lower spray dryer process temperatures (Singh et al., Citation2014) had provided evidence of comparable outcomes (Mohammed et al., Citation2017). They assessed how NSO’s increased oxidative stability at low temperatures in combination with several types of core materials. In addition, their study showed that the PV of NSO microcapsules was improved after thermal extraction and preservation intervals compared with samples of crude oil (Mohammed et al., Citation2017). They concluded that, the stability of NSO microcapsules increased after the spray drying procedure.

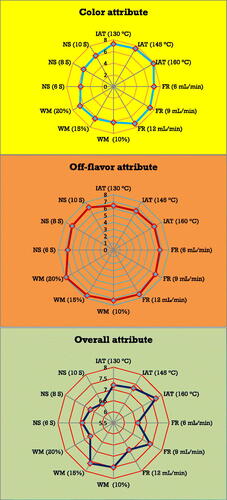

3.6. Spray-dried microcapsule samples’ sensory acceptability

Samples from a sensory examination of spray-dried microcapsules (SDM) are shown in . The current study’s sensorial results demonstrate that, depending on the spray drying conditions used during the development of SDM samples, the acceptability for sensorial qualities differs noticeably. When compared to their raw mixture, the samples’ colour, off flavour, and general acceptability were noticeably altered. On the other hand, SDM samples that were run at low or intermediate operating settings had relatively similar ratings for sensory qualities. When compared to other microcapsule samples, the Nigella sativa (NSO) microcapsules using dextrin as the wall material demonstrated a superior overall acceptance during storage (Abedi et al., Citation2016). In comparison to freeze-dried microcapsules, the NSO microcapsules prepared using spray drying and spray freeze-drying procedures were more palatable and of higher quality. The sensory quality and storage strength of emulsified NSO dry powder samples were enhanced by spray drying (Mohammed et al., Citation2017). Similarly, Barroso et al. (Citation2014) developed microencapsulated flaxseed oil samples with superior sensory values using modified starch as the material during the spray-drying process. According to Shahid et al. (Citation2020), the overall acceptance scores of spray-dried flaxseed oil samples were higher than those of raw flaxseed oil samples. Overall, the sensory scores of all SDM samples fell within acceptable limits.

4. Conclusion

The results of the investigation showed that the encapsulation efficiency (EE) ranged from 79.15 ± 0.60% lowest to 89.51 ± 0.90% for the highest value. Furthermore, the study’s findings unequivocally demonstrated that, in contrast to uncapsulated oil, which readily oxidised under accelerated storage, the microencapsulated oil possessed more oxidative stability. The SDM sample’s acceptability as a whole, colour, and off-flavor were all noticeably different from the raw oil combinations. Additionally, there was little difference in the sensory attribute scores between the SDM samples. NSO’s resistance to oxidation can be effectively increased and its shelf life can be prolonged by using the microencapsulation process. Moreover, short-term and long-term lab investigations are suggested to obtain comprehensive research data about microencapsulation, oxidation process and microencapsulated oil composition.

Authors’ contributions

Conceptualization: M.I. and G.G.H.; methodology: M.H.A.; software and validation, M.K.K.; formal analysis: M.H.A.; writing—original draft preparation: F.A.; writing—review and editing: M.H.A., G.G.H., and M.I.; supervision: M.I. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The authors acknowledge support from the Department of Food Science, GCUF, for carrying out all research activities.

Disclosure statement

The authors declare that there are no conflicts of interest.

Data availability statement

All data related to this article are available in this manuscript.

Additional information

Funding

Notes on contributors

Fareed Afzal

Fareed Afzal is a PhD Scholar in the Department of Food Science, Government College University Faisalabad, Pakistan. His specialization is in spray drying of food products.

Muhammad Imran

Muhammad Imran (PhD) is working as Associate Professor in Department of Food Science, Government College University Faisalabad, Pakistan. His specialization is in chemistry of edible fats and oils.

Muhammad Kamran Khan

Dr. Muhammad Kamran Khan (PhD) is working as Associate Professor in Department of Food Science, Government College University Faisalabad, Pakistan. His area of interest is exploring novel food technologies for food applications.

Muhammad Haseeb Ahmad

Dr. Muhammad Haseeb Ahmad (PhD) is working as Assistant Professor in Department of Food Science, Government College University Faisalabad, Pakistan. His area of interest is data mining in food analytics.

Gebremichael Gebremedhin Hailu

Dr. Gebremicheal Gebremedhin Hailu (PhD) is working in Department of Food Technology and Process Engineering, Oda Bultum University, Chiro, Ethiopia. His area of interest is in the disciple of food technology and process engineering.

Reference

- Abedi, A. S., Rismanchi, M., Shahdoostkhany, M., Mohammadi, A., & Hosseini, H. (2016). Microencapsulation of Nigella sativa seeds oil containing thymoquinone by spray‐ drying for functional yogurt production. International Journal of Food Science & Technology, 51(10), 1–10. https://doi.org/10.1111/ijfs.13208

- Adamiec, J., Borompichaichartkul, C., Srzednicki, G., Panket, W., Piriyapunsakul, S., & Zhao, J. (2012). Microencapsulation of kaffir lime oil and its functional properties. Drying Technology, 30(9), 914–920. https://doi.org/10.1080/07373937.2012.666777

- Ahn, J. H., Kim, Y. P., Lee, Y. M., Seo, E. M., Lee, K. W., & Kim, H. S. (2008). Optimization of microencapsulation of seed oil by response surface methodology. Food Chemistry, 107(1), 98–105. https://doi.org/10.1016/j.foodchem.2007.07.067

- Aksoylu, Z., & Günç Ergönül, P. (2017). A review on encapsulation of oils. Celal Bayar Üniversitesi Fen Bilimleri Dergisi, 13(2), 293–309. https://doi.org/10.18466/cbayarfbe.313358

- Ali, M., Imran, M., Khan, M. K., Ahmad, M. H., & Muhammad, N. (2021). Functional and oxidative quality characterization of spray-dried omega-3-enriched milk powder. Journal of Food Quality, 2021, 1–15. https://doi.org/10.1155/2021/6693960

- Alves, A. I., Rodrigues, M. Z., Ribeiro Pinto, M. R. M., Lago Vanzela, E. S., Stringheta, P. C., Perrone, Í. T., & Ramos, A. M. (2017). Morphological characterization of pequi extract microencapsulated through spray drying. International Journal of Food Properties, 20(sup2), 1–8. https://doi.org/10.1080/10942912.2017.1343344

- AOCS. (1998a). American oil chemists’ society official method Cd 8b– 90. AOCS Press.

- AOCS. (1998b). American oil chemists’ society official method Ca 5a– 40. AOCS Press.

- Barroso, A. K. M., Pierucci, A. P. T. R., Freitas, S. P., Torres, A. G., & Rocha-Leão, M. H. M. D. (2014). Oxidative stability and sensory evaluation of microencapsulated flaxseed oil. Journal of Microencapsulation, 31(2), 193–201. https://doi.org/10.3109/02652048.2013.824514

- Costa, S. S., Machado, B. A. S., Martin, A. R., Bagnara, F., Ragadalli, S. A., & Alves, A. R. C. (2015). Drying by spray drying in the food industry: Micro- encapsulation, process parameters and main carriers used. African Journal of Food Science, 9(9), 462–470.

- de Melo Ramos, F., Júnior, V. S., & Prata, A. S. (2021). Impact of vacuum spray drying on encapsulation of fish oil: Oxidative stability and encapsulation efficiency. Food Research International (Ottawa, Ont.), 143, 110283. https://doi.org/10.1016/j.foodres.2021.110283

- Dieffenbacher, A., & Pocklington, W. D. (1992). 1st supplement to the 7th edition of standard methods for the analysis of oils, fats and derivatives.

- do Amaral, P. H. R., Andrade, P. L., & de Conto, L. C. (2019). Microencapsulation and its uses in food science and technology: A microencapsulation: Processes, technologies and industrial applications, 93–105.

- Edris, A. E., Kalemba, D., Adamiec, J., & Piątkowski, M. (2016). Microencapsulation of Nigella sativa oleoresin by spray drying for food and nutraceutical applications. Food Chemistry, 204, 326–333. https://doi.org/10.1016/j.foodchem.2016.02.143

- Ferrari, C. C., Ribeiro, C. P., Liserre, A. M., Moreno, I., Germer, S. P. M., & de Aguirre, J. M. (2011). Spray drying of Blackberry juice using maltodextrin or gum arabic as carrier agents. Food Process, Bioprocessing and Food Quality Management, 1–4.

- Ferreira, C. D., & Nunes, I. L. (2019). Oil nanoencapsulation: development, application, and incorporation into the food market. Nanoscale Research Letters, 14(1), 9. https://doi.org/10.1186/s11671-018-2829-2

- Gupta, P. K., Jadhav, S. B., & Singhal, R. S. (2015). Development of shrikhand premix using microencapsulated rice bran oil as fat alternative and hydrocolloids as texture modifier. Food Hydrocolloids. 48, 220–227. https://doi.org/10.1016/j.foodhyd.2015.02.028

- Hee, Y. Y., Tan, C. P., Abdul Rahman, R., Mohd Adzahan, N., Lai, W. T., & Chong, G. H. (2015). Influence of different wall materials on the microencapsulation of virgin coconut oil by spray drying. International Journal of Food Engineering, 11(1), 61–69. https://doi.org/10.1515/ijfe-2014-0215

- Lane, K. E., & Derbyshire, E. J. (2018). Omega-3 fatty acids–A review of existing and innovative delivery methods. Critical Reviews in Food Science and Nutrition, 58(1), 62–69. https://doi.org/10.1080/10408398.2014.994699

- Majeed, A., Muhammad, Z., Ahmad, H., Hayat, S. S. S., Inayat, N., Siyyar, S. (2021). Nigella sativa L.: Uses in traditional and contemporary medicines–An overview. Acta EcologicaSinica, 41(4), 253–258. https://doi.org/10.1016/j.chnaes.2020.02.001

- Makouie, S., Alizadeh, M., Maleki, O., & Khosrowshahi, A. (2021). Investigation of physicochemical properties and oxidative stability of encapsulated Nigella sativa seed oil. Flavour and Fragrance Journal, 36(2), 233–242. https://doi.org/10.1002/ffj.3638

- McClements, D. J., & Rao, J. (2011). Food-grade nanoemulsions: formulation, fabrication, properties, performance, biological fate, and potential toxicity. Critical Reviews in Food Science and Nutrition, 51(4), 285–330. https://doi.org/10.1080/10408398.2011.559558

- Meilgaard, M., Civille, G. V., & B. T., Carr. (2007). Overall difference tests: Does a sensory difference exist between samples. Sensory Evaluation Techniques, 4, 63−104. https://doi.org/10.1201/9781003040729

- Mohammed, N. K., Manap, A., Yazid, M., Tan, C. P., Muhialdin, B. J., Alhelli, A. M., & Meor Hussin, A. S. (2016). The effects of different extraction methods on antioxidant properties, chemical composition, and thermal behavior of black seed (Nigella sativa L.) oil. Evidence-Based Complementary and Alternative Medicine: eCAM, 2016, 6273810–6273817. https://doi.org/10.1155/2016/6273817

- Mohammed, N. K., Meor Hussin, A. S., Tan, C. P., Abdul Manap, M. Y., & Alhelli, A. M. (2017). Quality changes of microencapsulated Nigella sativa Oil upon accelerated storage. International Journal of Food Properties, 20(sup3), S2395–S2408. https://doi.org/10.1080/10942912.2017.1371189

- Mohammed, N. K., Tan, C. P., Abd Manap, Y., Alhelli, A. M., & Hussin, A. S. M. (2017). Process conditions of spray drying microencapsulation of Nigella sativa Oil. Powder Technology, 315, 1–14. https://doi.org/10.1016/j.powtec.2017.03.045

- Montgomery, D. C. (2017). Design and analysis of experiments. JohnWiley& Sons.

- Morales-Medina, R., Tamm, F., Guadix, A. M., Guadix, E. M., & Drusch, S. (2016). Functional and antioxidant properties of hydrolysates of sardine (S. pilchardus) and horse mackerel (T. mediterraneus) for the microencapsulation of fish oil by spray-drying. Food Chemistry, 194, 1208–1216. https://doi.org/10.1016/j.foodchem.2015.08.122

- Rahim, M. A., Imran, M., Khan, M. K., Ahmad, M. H., & Ahmad, R. S. (2022). Impact of spray drying operating conditions on encapsulation efficiency, oxidative quality, and sensorial evaluation of chia and fish oil blends. Journal of Food Processing and Preservation, 46(2), e16248. https://doi.org/10.1111/jfpp.16248

- Ramadan, M. F., & Wahdan, K. M. M. (2012). Blending of corn oil with black cumin (Nigella sativa) and coriander (Coriandrum sativum) seed oils: Impact on functionality, stability and radical scavenging activity. Food Chemistry, 132(2), 873–879. https://doi.org/10.1016/j.foodchem.2011.11.054

- Ramakrishnan, Y., Adzahan, N. M., Yusof, Y. A., & Muhammad, K. (2018). Effect of wall materials on the spray drying efficiency, powder properties and stability of bioactive compounds in tamarillo juice microencapsulation. Powder Technology, 328, 406–414. https://doi.org/10.1016/j.powtec.2017.12.018

- Santiworakun, N. Y., Suksuwan, A., Sirikwanpong, S., Dahlan, W., & Ariyapitipun, T. (2022). Physicochemical characterization of microcapsules containing cold pressed black cumin seed oils (Nigella sativa L.) as an alternative nutrient source in a functional diet. LWT, 157, 113045. https://doi.org/10.1016/j.lwt.2021.113045

- Santos, D., Maurício, A. C., Sencadas, V., Santos, J. D., Fernandes, M. H., & Gomes, P. S. (2018). Spray drying: An overview. Pignatello, R. (Comp.). Biomaterials- physics and chemistry- new edition (pp. 9– 35). InTech.

- Sawale, P. D., Patil, G. R., Hussain, S. A., Singh, A. K., & Singh, R. R. B. (2017). Release characteristics of polyphenols from microencapsulated Terminalia arjuna extract: Effects of simulated gastric fluid. International Journal of Food Properties, 20(12), 3170–3178. https://doi.org/10.1080/10942912.2017.1280677

- Shahid, M. Z., Imran, M., Khan, M. K., Ahmad, M. H., Nadeem, M., Muhammad, N., & Yasmin, A. (2020). OMEGA-3 Fatty acids retention, oxidative quality, and sensoric acceptability of spray-dried flaxseed oil. Journal of Food Quality, 2020, 1–13. https://doi.org/10.1155/2020/7286034

- Singh, S., Das, S. S., Singh, G., Schuff, C., de Lampasona, M. P., & Catalán, C. A. N. (2014). Composition, in vitro antioxidant and antimicrobial activities of essential oil and oleoresins obtained from black cumin seeds (Nigella sativa L.). BioMed Research International, 2014, 918209. https://doi.org/10.1155/2014/918209

- Srinivasan, K. (2018). Cumin (Cuminum cyminum) and black cumin (Nigella sativa) seeds: traditional uses, chemical constituents, and nutraceutical effects. Food Quality and Safety, 2(1), 1–16. https://doi.org/10.1093/fqsafe/fyx031

- Takeungwongtrakul, S., Benjakul, S., & H‐kittikun, A. (2015). Wall materials and the presence of antioxidants influence encapsulation efficiency and oxidative stability of micro‐encapsulated shrimp oil. European Journal of Lipid Science and Technology, 117(4), 450–459. https://doi.org/10.1002/ejlt.201400235

- Wahidu, Z., Silvia, D., Wan, N., & Yang, T. A. (2014). Physicochemical and quality characteristics of cold and hot press of Nigella sativa L seed oil using screw press. Journal of Applied Sciences Research, 10(12), 36–45.

- Wani, S. A., & Kumar, P. (2018). Fenugreek: A review on its nutraceutical properties and utilization in various food products. Journal of the Saudi Society of Agricultural Sciences, 17(2), 97–106. https://doi.org/10.1111/jfpp.16248