Figures & data

Table 1. Formula of signal-to-noise Ratio.

Table 2. Control factors and their levels.

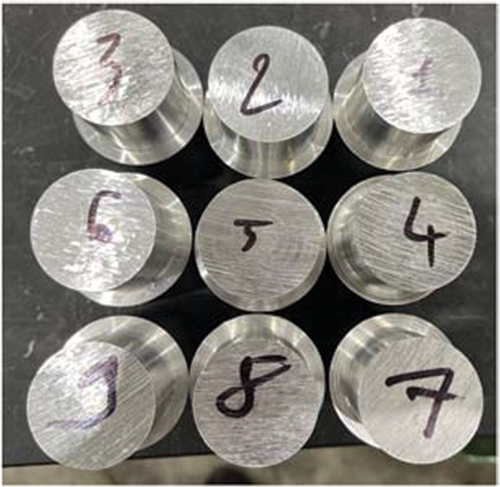

Table 3. L9 Taguchi design and experiment results.

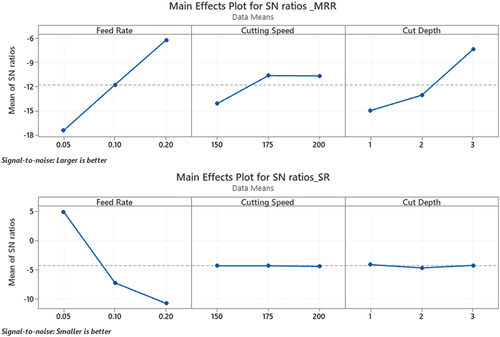

Table 4. S/N response table for MRR and SR.

Table 5. ANOVA table for MRR and SR.

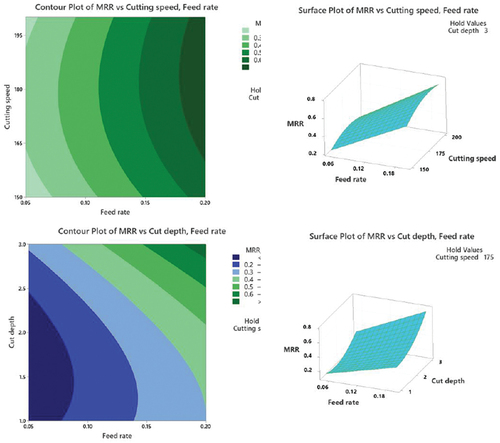

Figure 7. Contour and 3D surface plots depicting the main factor interactions on MRR (software minitab 19).

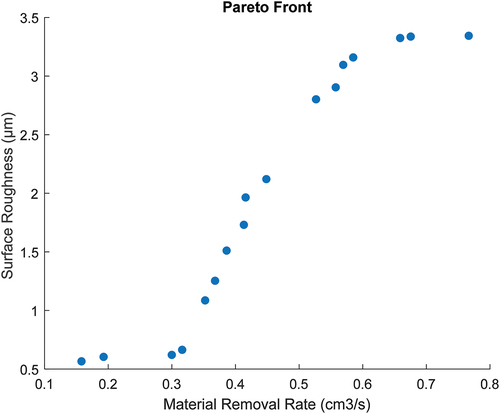

Table 6. Pareto-optimal set.

Data availability statement

The experimental datasets obtained from this research work and then the analysed results during the current study are available from the corresponding author on reasonable request.