Figures & data

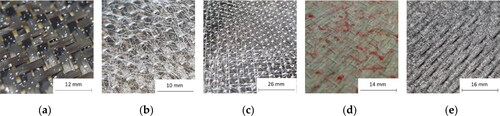

Figure 1. Tackifying agents; (a) Powder binder, e.g. E5390; (b) Textile veil, e.g. PA1541; (c) Adhesive film, e.g. SAER; (d) Hot-melt binder, e.g. PR685; (e) Spray adhesive, e.g. AIR2E.

Table 1. Description of tackifying agents characterized within this study.

Table 2. Curing cycles applied for different epoxy resins.

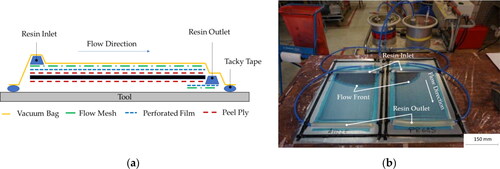

Figure 2. Manufacturing of CFRP specimen via LRI (a) Schematic VARI set-up (b) Experimental VARI-setup.

Table 3. Description of CFRP specimen.

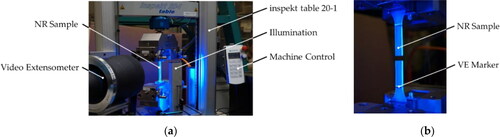

Figure 3. Tensile testing of neat resin samples acc. DIN EN ISO 527-2 (a) Test set-up (b) Detailed view of valid test specimen.

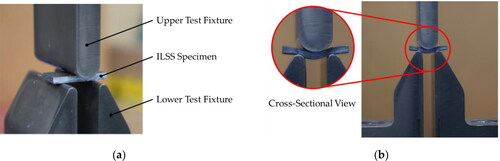

Figure 4. ILSS testing acc. DIN EN ISO 14130 (a) Test set-up before load application (b) Detailed cross-sectional view.

Table 4. DSC analysis of neat resin samples.

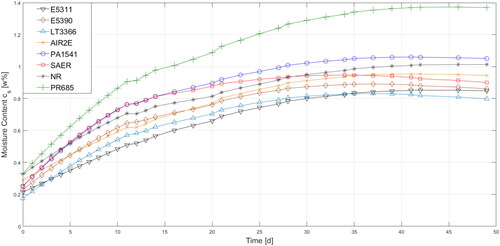

Table 5. Water absorption test analysis acc. Fick’s Law.

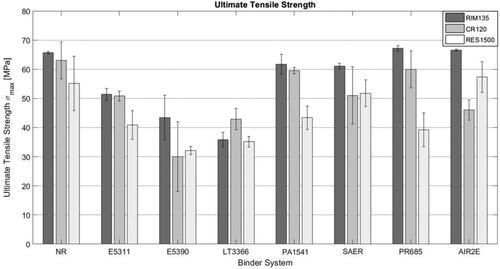

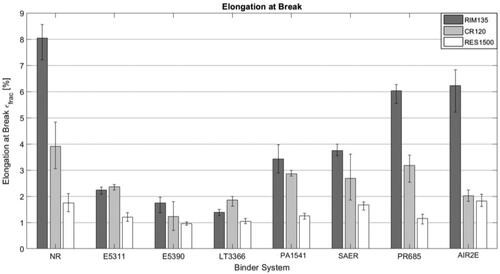

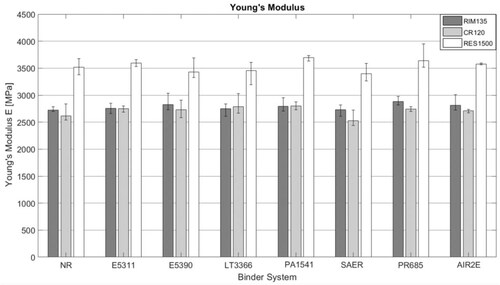

Table 6. Analysis of neat resin tensile properties acc. DIN EN ISO 527.

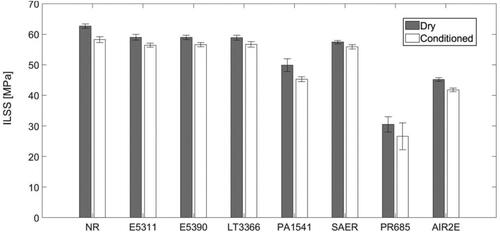

Table 7. ILSS assessment acc. DIN EN ISO 14130.

Data availability statement

The data that support the findings of this study are available from the corresponding author, FH, upon reasonable request.