Figures & data

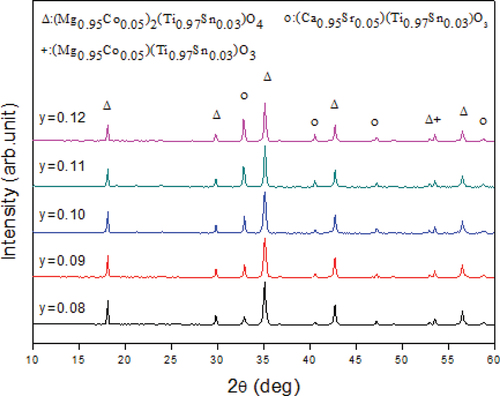

Figure 2. X-ray diffraction patterns of (1-y)(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4 - y(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics sintered at 1325°C for 4 h.

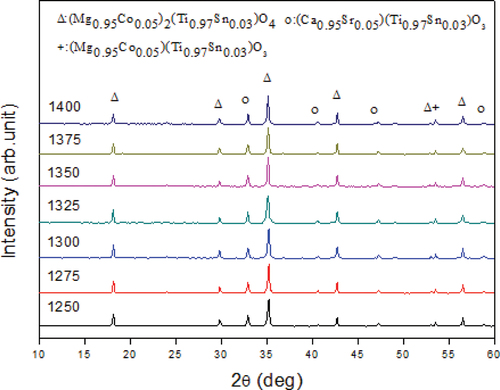

Figure 3. X-ray diffraction patterns of a 0.92(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4-0.08(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramic sintered at various temperatures.

Figure 4. SEM micrographs of 0.92(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4 - 0.08(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics sintered at various temperatures.

Figure 5. The marks of SEM for the 0.92(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4 - 0.08(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics sinter at 1375°C.

Table 1. EDX data of 0.92(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4- 0.08(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics for areas A and B.

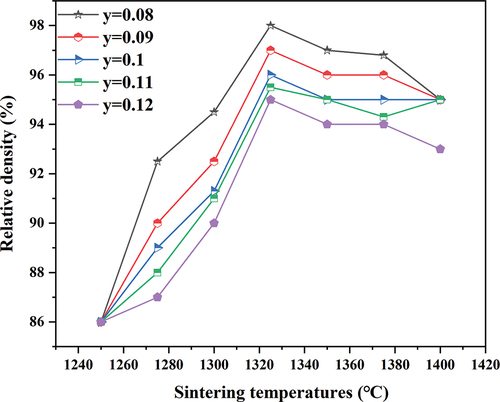

Figure 6. Relative density of (1-y)(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4 - y(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics sintered at various temperatures.

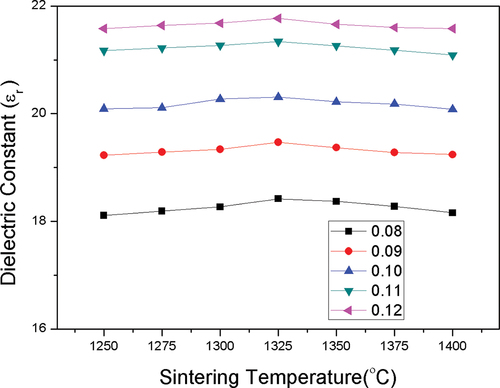

Figure 7. Dielectric constant curves of (1-y)(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4- y(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics sintering at different temperatures for 4 hrs.

Table 2. Microwave dielectric properties of the (1-y)(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4- y(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics sintered at 1325°C for 4 hrs.

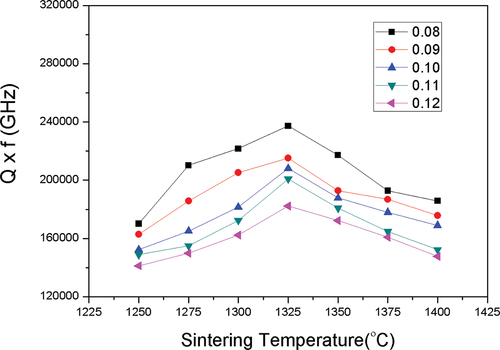

Figure 8. Q×f values of (1-y)(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4 - y(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramics sintered at various temperatures for 4 h.

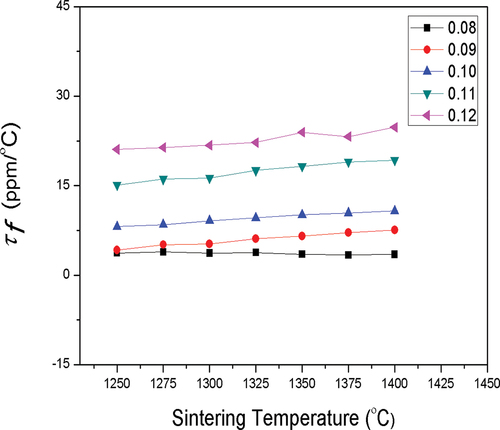

Figure 9. τf values of (1-y)(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4 - y(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 system sintering at different temperatures for 4 h.

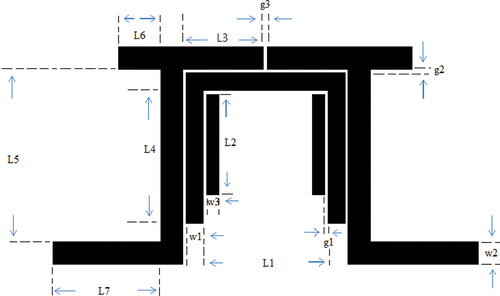

Figure 10. Layout of a band-pass filter with a (1-y)(Mg0.95Co0.05)2(Ti0.97Sn0.03)O4 - y(Ca0.95Sr0.05)(Ti0.97Sn0.03)O3 ceramic substrate.

Table 3. Simulation results of the Band-Pass Filters Using Different Dielectrics.

Data availability statement

The data supporting the findings of this study are openly available to the reviewers.