Figures & data

Table 1. Chemical composition of 6A02 Al matrix.

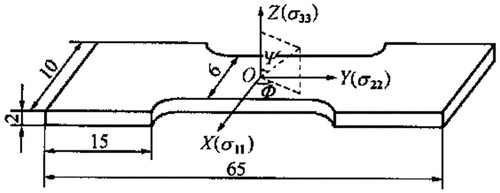

Figure 1. Dimensions (mm) of specimen of the composite and geometric relation in the X-ray stress measurement.

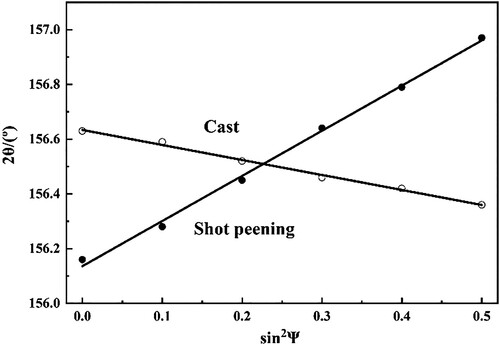

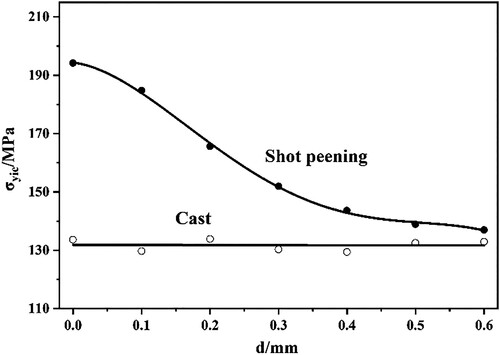

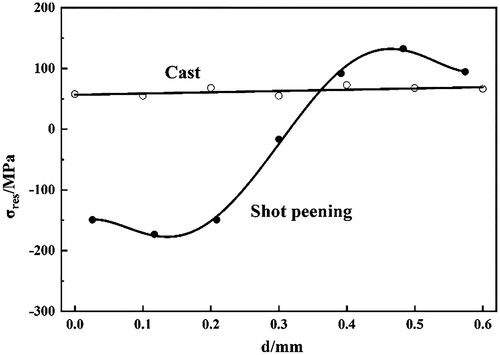

Figure 3. Residual stress (σres) in matrix vs depth (d) from surface of the 20%SiCw/6A02Al composite.

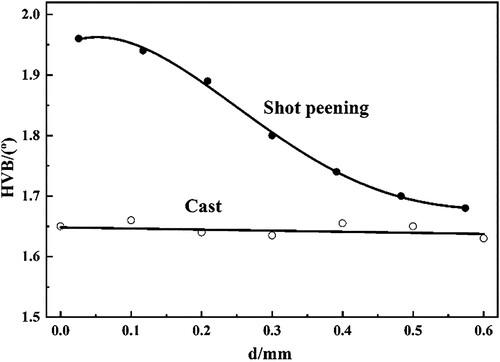

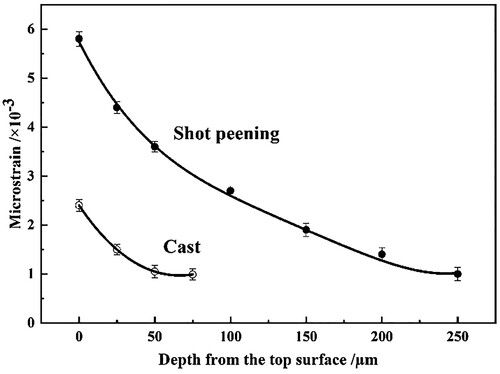

Figure 5. Half value breadth (HVB) of matrix for X-ray diffraction vs depth (d) from surface of the 20%SiCw/6A02Al composite.