?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

Camel meat contains a high percentage of unsaturated fatty acids that are beneficial for cardiovascular health and controlling cholesterol levels. This aims to evaluate the effect of partially replacing camel meat with chickpea flour (CPF), soybean flour (SBF), and skimmed milk powder (SMP) on the physicochemical and sensory evaluation properties of camel meat burgers. Ten burger formulations were prepared by partially replacing the minced meat with CPF, SBF, and SMP at percentages of 10%, 20%, and 30%. Proximate composition, pH, color, water holding capacity, cooking loss, and sensory evaluation were conducted. Significant increases (p < 0.05) in protein contents were observed in all treated samples, as the initial protein value of the control (17.2 ± 2.5) was significantly increased to between 20.1 ± 2.6 and 26.5 ± 0.2. The moisture content of all treated samples decreased significantly (p < 0.05), while fat and ash levels remained unchanged without significant (p > 0.05) increases. However, the partial replacement of meat with the CPF, SBF, and SMP resulted in significant (p < 0.05) decreases in the cooking loss ranging from 18 to 30%, depending on the type and percentage of CPF, SBF, and SMP replaced. The replaced burgers obtained high overall acceptance scores ranging from 7.1 to 8.8 compared to the control. It is strongly recommended to partially replace the camel minced meat with CPF, SBF, and SMP to improve the physicochemical and sensory properties of the produced burger. Thus, the study proved that new burger formulations of CPF, SBF, and SMP significantly had high protein content and high consumption acceptability scores.

REVIEWING EDITOR:

Introduction

Camel meat is considered healthy and nutritious. It is recognized as a good source of minerals, low in fat content, and high in the levels of unsaturated fatty acids (Baba et al., Citation2021; Kadim et al., Citation2020). It has higher protein, moisture, vitamin, and mineral content compared to mutton, chicken, and beef with low cholesterol content (Mohammed el al., Citation2020). Camel meat products are excellent sources of valuable nutrients for human consumption, such as protein, phosphorus, zinc, and iron (Bohrer, Citation2017). The Kingdom of Saudi Arabia (KSA) is one of the largest Gulf States in terms of camel meat consumption (Selvanathan et al., 2015). KSA is also known as one of the top countries in camel meat production (Nation master, 2022). Al-Mahish et al. (Citation2018) reported that there is an increasing demand for red meat and especially camel meat for health reasons to fill the gap of increasing food demand in KSA. One of the current trends in KSA is the production of convenience foods such as camel burgers, which have recently been introduced to KSA markets. The camel meat is considered to be one of the most consumed meats in Saudi Arabia due to its good nutritional, physicochemical, and sensory properties (Suliman et al., Citation2020). In recent years, the major goals of the meat industry are to improve and develop healthier meat products (Salman et al., Citation2019) that containing healthier replaced ingredients (Bahmanyar et al., Citation2021; Rubio et al., Citation2020; Nadia et al., Citation2018; Pintado & Delgado-Pando, Citation2020; Ruiz-Capillas et al., Citation2021). In camel meat products such as burger several functional food-grade ingredients such as sweet lupine powder (Abdullah & Abass, Citation2019), chia seeds (Zaki, Citation2018); ginger, and papain extract (Abdel-Naeem & Mohamed, Citation2016) could be utilized in the formulations before shaping to improve the physicochemical, microbial, and sensory properties of the products. Binders and extenders such as chickpeas and soybeans flour and skimmed milk powder are ingredients used in meat products, such as burgers, to modify their texture, improve moisture retention, and enhance overall product quality. They are often less expensive than meat, can be used to increase the volume of the product without significantly impacting the cost. It’s important based to strike a balance to achieve the desired texture and sensory attributes. However, the effects of adding too many binders and extenders can lead to a gummy or rubbery texture in the final product, making it less palatable. Chickpeas and soybeans are considered an important food legume due to their good nutritional components. Many studies have focused on the importance of their physical, chemical, and nutritional properties and found that they can be used in proportions in meat products such as burgers these legumes must be processed into flour to increase their functionality for use as binders and extenders for meat. However, chickpea flour, soybean flour, and skimmed milk have been used in different meat products to improve their quality values in many research works (Bakhsh et al., Citation2021; Chandler & McSweeney, Citation2022; Ovuchimeru, Citation2020; Rezaei et al., Citation2019; Shen et al., Citation2022). In this research we observed that formulating camel meat burgers without adding functional materials such as CPF, SBF, and SMP could result in an unstable burger product which usually get collapsed during cooking. This research was conducted to evaluate the effect of adding CPF, SBF, and SMP on the physicochemical and sensory evaluation of camel meat burger. We believe that this research will produce new types of burgers in the Saudi Arabia markets with better physicochemical and sensory evaluation attributes because of mixing of CPF, SBF, and SMP with camel meat burger in the formulations. Furthermore, in addition to the availability of camel meat in Saudi Arabia, in today’s busy world, burgers are a portable food item, making them suitable for people, particularly those who are constantly on the move, because they can be eaten without the need for elaborate table settings or lengthy breaks. Therefore, this research is justified.

Materials and methods

Camel meat samples

The meat from a thigh of a freshly slaughtered Najdi camel (one and a half-year-old) was purchased from the Central Meat Market, Al-Qassim, Saudi Arabia. The samples were packed in properly sterile polyethylene bags and transported under a complete aseptic condition in an icebox to the Laboratory, and transported to the Meat Laboratory of the College of Agriculture and Veterinary Medicine, Qassim University under high hygienic conditions for the preparation of the camel meat burgers.

Food ingredients and chemical reagents

Salt (sodium chloride), black pepper, CPF, SBF, and SMP were purchased from Al-Qassim spice market, Saudi Arabia. Other chemical reagents including sulfuric acid, hexane and boric acid used in the proximate composition analysis of this research were purchased from Sigma, USA.

Preparation of the control camel meat burger

The camel meat burger was prepared according to the method developed by Abdel-Naeem and Mohamed (Citation2016). The meat was first minced twice with an electric meat grinder through a 3 mm plate (Panasonic MK-ZJ 2700, Japan). The ground meat was then placed in a cutting bowl machine (Ulink Foodtech, LM-834, China). Salt (sodium chloride) and black pepper were added at a percentage of 1.5 for each and the cutting bowl machine was run for 5 min. The camel meat burgers were prepared by partially substituting CPF, SBF, and SMP in the percentages of 10%, 20%, and 30% for each formulation based on 1 kg minced meat. The control burger was prepared without the addition of CPF, SBF, and SMP. Ice cubes were added to maintain the temperature during the processing. Each formulation was individually mixed for 5 min in the bowl slicer, and the dough of each formulation was obtained, then a cylindrical-shaped burger weighing 80 g was shaped using a manual burger molder. Ten different camel meat burgers samples were prepared and analyzed.

Proximate composition analysis

The determination of moisture, protein, fat (ether extract), and ash was performed according to the methods of AOAC (2002).

pH measurement

The pH of the burger was measured according to the method of Elgadir et al. (Citation2011). Ten grams of the burger was mixed with 100 ml of distilled water in a ratio of 1:10 (meat: water) for 1 min in a Waring blender. The pH meter (portable pH meter, model HI 8314 membrane pH meter, Hanna Instrument, USA) was first standardized before use. The pH of each burger was then individually measured in triplicate.

Colour measurement

The colour was measured at room temperature individually on cooked burger using a Hunter Lab Scan model colorimeter (Minolta CR-300; Minolta Corp., Ramsey, NJ). The instrument was first calibrated before use. Three standard color slices were used for calibration (L* (lightness/darkness), b* (yellow + blue), and a* for redness) values to measure these values on the exterior as well as the diagonally internal surface of the meat sample. The samples were individually filled into plastic Petri dishes before conducting the measurement. It was noticed carefully that there were no gaps between the petri dish lids; the filled sample and the lens of the colorimeter touched the lid of the petri dish in each measurement. The color values were taken on the surface of each sample individually through each plastic Petri dish. An average of three replicates was taken.

Water holding capacity (WHC) measurement

The water holding capacity was determined using the modified method described by Warner (Warner, Citation2014). One gram of the sliced burger was placed in a centrifuge tube and centrifuged at 920 grams for 10 min. The water released from the sample was collected and then extracted from the first weight and the result was calculated as a percentage of the weight.

Cooking loss

The burgers were cooked directly on a contact with a preheated electric grill at a temperature of 180 °C for 10 min (5 min for each side) until the burger was turned brown well-cooked colour. The percentage of the cooking loss was evaluated using the weight difference between the raw and cooked burgers using the following equation:

Sensory evaluation studies

The cooked burger from each treatment was evaluated by 25 untrained panelists who are experienced and regularly consumed burgers from the staff and students at the College of Agriculture and Veterinary Medicine, Qassim University, Saudi Arabia, who frequently consume camel meat. The sensory evaluation room had good light. Water was provided to rinse the mouth between the tests. Panelists were asked to evaluate the cooked burgers using a 9-point hedonic scale test (neither like extremely (1), neither like nor dislike (5) and like extremely (9) for flavor, color, texture, and overall acceptability attributes.

Statistical analysis

Analysis of the data was performed using one-way ANOVA. Multiple comparisons between treatments with significant differences tested in ANOVA were performed using LSD (least significant difference) at p < 0.05. Triplicate reading of each sample and 25 replicates for sensory evaluation were obtained. Minitab statistical software version 17.

Results and discussion

Proximate composition analysis

shows the results of the proximate analysis of the burgers. The addition of meat extenders resulted in a significant (p < 0.05) decrease in moisture levels. The moisture content of the treated burgers ranged from 29 ± 1.2 to 33 ± 1.6. The highest moisture value was observed in the control burger (34 ± 2.6), while the burger replaced with 30% of SMP had the lowest moisture content. The replacement of 10% CPF had no significant (p > 0.05) effect on moisture content compared to the control burger. It was observed that the replacement of CPF, SBF, and SMP resulted in significant increases (p < 0.05) in the protein levels of all the treated burgers compared to the control one. The initial protein value was 17.2 ± 2.5 in the control and significantly increased to between (20.1 ± 2.6 - 26.5 ± 0.2). Crude protein levels increased significantly (p < 0.05) in all substituted burgers, which could be due to additional protein levels from the extenders (Ziegler et al., Citation2020). The highest protein percentage was observed in the burger replaced with CPF in the percentage of 30%. It is noted that the partial replacement of the CPF, SBF, and SMP affected the burger composition, particularly moisture and crude protein levels in all treatments. There are no significant (p > 0.05) increases in either the fat or ash content values of the substituted burger samples.

Table 1. Proximate composition of the camel meat burger replaced with different percentages of CPF, SBF and SMP.

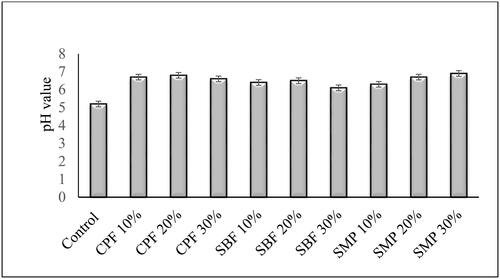

pH measurement

shows the results of the pH values of the burgers. The initial pH in the control burger was 5.2. The pH increased significantly (p < 0.05) from 5.2 to between 6.6–6.8, 6.1–6.5 and 6.3–6.9 in burgers replaced with CPF, SBF and SMP, respectively. The lowest pH was obtained in the burger replaced with the addition of 3% SBF, while the highest pH was observed in the burger replaced with the addition of 3% SMP, which might be due to the acidic nature of SBF and the alkaline nature of SMP (Sharma et al., 2012). Mahmoud et al. (Citation2017) claimed that such changes in pH could have a major impact on the physicochemical properties of the burger factors such as color, water holding capacity, sensory properties and thus consumer acceptability. However, it has been reported earlier that there are many factors, including post-mortem treatment, muscle physiology and pre-slaughter handling, that could influence changes in the pH of the muscle food diet pH (Mahmoud et al. Citation2017). These differences in camel meat pH and camel meat products could be due to the changes that occurred after slaughter, which is largely due to the differences in the amount of glycogen available that converted to lactic acid (Thompson, Citation2002). The pH results in this study disagreed with the finding of Kurt and Kilinççeker (Citation2012) who added 5% chickpea and soybean flour to the burgers and observed an increase in the pH value from 5.61 prior to the addition of chickpea and soybean flour to 5.78 with no significant (p > 0.05) differences. However, another author reported significantly (p < 0.05) increases in the pH values of various meat products with added meat extenders such as wheat and oat fibers (Huang et al., Citation2011).

Colour measurement

The colour of the control and the treated burgers are shown in . Increasing the percentages of the replaced CPF, SBF, and SMP resulted in significant (p < 0.01) increases in the values of the brightness (L*) of all replaced burgers. The same trend was observed for the yellow colour (b*) which increased significantly (p < 0.05) from 13.73 ± 0.05 to between 14.04 ± 0.15 and 17.07 ± 0.14 colour coordinates. The redness value of the control burger (a*) was 4.83 ± 0.12 and decreased significantly (p < 0.01) in the burger replaced with CPF and SMP in all their levels. No significant (p > 0.05) decreases in the red colour values was observed in the burgers replaced with SBF in all its levels. The lowest redness value was 3.11 ± 0.12 which was obtained in the burger treated with 30% of SMP. A similar trend was found in the study conducted by Wang et al. (Citation2021). These changes in the values of the colour parameters L* a* and b* indicate that the loss of redness is due to the conversion of oxymyoglobin to methemoglobin by free radicals (Hanula et al., Citation2022). However, Amoli et al. (Citation2021) reported that the decreases imn the red colour in the reformed burgers is not only due to the changes in myoglobin to methemoglobin but was also due to the effects of substitute used in the formulation.

Table 2. Coluor values of the camel meat burgers incorporated with different percentages of CPF, SBF and SMP.

The finding of burger colour agreed with the finding of Ibrahim et al. (Citation2017) who observed that increasing the added level of cowpea flour as a meat extender in percentages of 10%, 20%, and 30% in the incorporated camel meat burger resulted in a significant (p < 0.01) increases in the colour co-ordinates L* (brightness) and b* (yellowness) but the redness (a*) values of the replaced burger decreased significantly (p < 0.01).

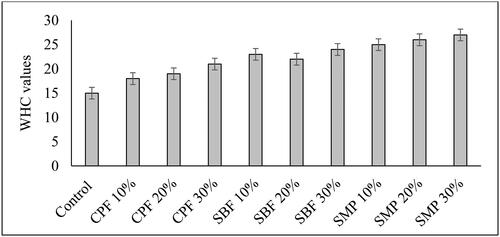

Water holding capacity (WHC) measurement

presents the values of WHC of the burger. The burger replaced with skimmed milk in all percentages had the highest WHC values ranging from 25% to 27% followed by the burger replaced with SBF and WHC, which ranging from 22% to 24%. The burgers replaced with CPF had the lowest WHC, which ranged from 18% to 21%. This results meant that the the partial replacement of meat with CPF, SBF, and SMP in the camel meat burger gave the burger the power to retain its water during the preparation and cooking stages. The water holding capacity (WHC) has been identified as one of the most important technological quality factors that can affect consumer preferences for meat and its products and may affect the sensory properties of cooked meat products (Wi et al., Citation2020). The result of WHC in this research is in good agreement with the fact reported by Amer (Citation2017) who observed significant (p < 0.05) increases in the WHC of camel meat burger formulated using dietary fibers. The control sample had a WHC of 15% and this value increased significantly (p < 0.05) in all meat extenders treated burgers to between (18–27%).

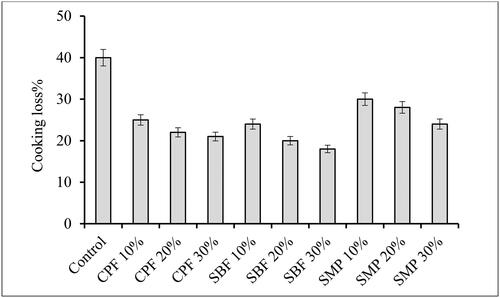

Cooking loss

showed the cooking loss of different camel meat burgers. It was observed that the partial replacement of the camel meat with CPF, SBF, and SMP significantly (p < 0.05) decreased the percentage of the cooking loss. The control burger lost 40% of its weight after cooking. This value was decreased to (18–24%) in the burgers treated with SMP followed by (21–25%) in the burgers treated with CPF and (24–30%) in the burgers treated with SMP. The camel burger treated with SBF showed the lowest cooking loss (18–24%), while the control burger showed the greatest cooking loss. The more percentage of CPF, SBF, and SMP replaced, the more decreases in cooking loss was observed. The partial replacement of the CPF, SBF, and SMP in their highest percentages caused considerable decreases in the cooking loss of 22%, 19%, and 16%, respectively.

Sensory evaluation studies

presents the sensory evaluation results of the camel meat burger. The results revealed considerable high scores for sensory attributes (taste, flavour, colour, and overall acceptability). The overall acceptability ranged from 7.1 to 8.8 and the burger in which 30% of CPF is used had the highest score of overall acceptability (8.7) followed by 8.6 which obtained in the burger formulated using SMP in percentages of 20% and 30%. Most burgers containing CPF, SBF and SMP with different partially replacement received higher overall acceptability scores, which revealed that the new burger formulations had high consumption acceptability scores. However, the burger prepared using SBF in the concentration of 30% received the lowest overall acceptability of 6.5. This may be attributed to the fact that the use of SBF at a high concentration in meat products is not recommended due to the changes that may occur in the flavour and texture of the meat products. The sensory evaluation results in this research agreed with the previous finding which reported that the addition of meat extenders such as textured soy protein, collagen and maltodextrin to the burger had higher acceptance for all attributes as well as overall acceptability (Carvalho et al., Citation2017). According to the study of Al-Khalifa and Atia (Citation1997), the sensory panelists preferred camel burgers with 10% fat and 6% soybean husks. Recently, Shehata et al. (Citation2022) developed the quality of camel meat burgers by replacing camel meat fat with two levels (5 and 10%) of barley grains and wheat bran as fat replacers. They found that the overall acceptability was significantly (p < 0.01) higher in the fat-replaced samples. This finding could be concluded as follows: using barley grains and wheat bran for producing camel meat burgers led to an improvement in quality characteristics and an improvement in the overall acceptability of the produced burger. They found the best camel burger prepared with 10% barley grain and 10% fat content to be the best one. The Saudi, Gulf, British, and Codex Standards have been set to consider in the preparation of partial replacement of meat with chickpea flour, soybean flour and skimmed milk powder depending on the permissible limits for adding legume flour to beef burgers. ‘A product labelled “beef burger” must contain at least 62% beef and an ‘economy beef burger’ must contain at least 47% beef’.

Table 3. Scores of sensory evaluation attributes of the camel meat burger replaced with different percentages of CPF, SBF and SMP.

Conclusions

A staple camel meat burger was produced using the partial replacement of CPF, SBF and SMP in the percentages of 10, 20 and 30%. The replaced CPF, SBF and SMP enhanced the proximate composition, water hooding capacity, cooking loss and sensory characteristics of the camel meat burger. Therefore, the partial replacement using the percentages of 10%-30% mentioned in this research for CPF, SMP and SBF in the percentages of 10% and 20% is highly recommended.

Authors’ contributions

Abdalbasit Adam Mariod, and Mohamed Abd Elagdir conceptualization (equal); formal analysis (equal); funding acquisition (equal); investigation (equal); project administration (equal); resources (equal); methodology (equal); supervision (equal); validation (equal); visualization (equal); writing – original draft (equal); Writing – review and editing (equal).

Disclosure statement

No potential conflict of interest was reported by the author(s).

Additional information

Funding

Notes on contributors

Abdalbasit Adam Mariod

Abdalbasit Adam Mariod was classified among the top 2% of globally highly cited researchers in 2021, 2022, and 2023. He won the Abdul Hameed Shoman Award 2021, the Jeddah University Excellence Award, and the Researcher of the Year 2023. Won the Gourmand Award in November 2023. Published 290 articles & chapters, and 15 text and reference books.

Mohamed Abd Elagdir

Mohamed Abd Elagdir Mohamed Saeed currently is Associate Professor of Meat Science and Technology at Department of Food Science and Human Nutrition, Qassim University, Saudi Arabia from 2014 up to date. He received his both master and Ph.D. degrees from Faculty of Food Science and Technology, Universiti Putra Malaysia.

References

- Abdel-Naeem, H. H. S., & Mohamed, H. M. H. (2016). Improving the physico-chemical and sensory characteristics of camel meat burger patties using ginger extract and papain. Meat Science, 118, 1–9. https://doi.org/10.1016/j.meatsci.2016.03.021

- Abdullah, Q. S., & Abass, K. S. (2019). Effect of the procedure of the sweet lupine powder as an alternative to the camel meat on the quality and sensory characteristics of the manufactured burgers. Indian Journal of Public Health Research & Development, 10(10), 1900. https://doi.org/10.5958/0976-5506.2019.03123.1

- Al-Khalifa, A., & M. Atia, M. (1997). Effect of soy hull and fat on camel meat patties. Alexandria Science Exchange, 18, 303–312.

- Al-Mahish, M., Elzaki, R. M., & Al-Qahtani, N. K. (2018). Demand and nutrients elasticities of camel meat: An analysis of Kingdom of Saudi Arabia. Journal of Livestock Science, 9, 140–150.

- Amer, A. T. A. M. (2017). Production and evaluation of camel meat burger mixed with dietary fibers [Thesis]. Department of Food Science, Faculty of Agriculture, Cairo University.

- Amoli, P., Hadidi, M., Hasiri, Z., Rouhafza, A., Jelyani, A., Hadian, Z., Khaneghah, A., & Lorenzo, J. (2021). Incorporation of low molecular weight chitosan in a low-fat beef burger: Assessment of technological quality and oxidative stability. Foods, 10(8), 1959. https://doi.org/10.3390/foods10081959

- Baba, W. N., Rasool, N., Selvamuthukumara, M., & Maqsood, S. (2021). A review on nutritional composition, health benefits, and technological interventions for improving consumer acceptability of camel meat: An ethnic food of Middle East. Journal of Ethnic Foods, 8(1), 18. https://doi.org/10.1186/s42779-021-00089-1

- Bahmanyar, F., Hosseini, S. M., Mirmoghtadaie, L., & Shojaee-Aliabadi, S. (2021). Effects of replacing soy protein and bread crumb with quinoa and buckwheat flour in functional beef burger formulation. Meat Science, 172, 108305. https://doi.org/10.1016/j.meatsci.2020.108305

- Bakhsh, A., Lee, S.-J., Lee, E.-Y., Hwang, Y.-H., & Joo, S.-T. (2021). Characteristics of beef patties substituted by different levels of textured vegetable protein and taste traits assessed by electronic tongue system. Foods, 10(11), 2811. https://doi.org/10.3390/foods10112811

- Bohrer, B. M. (2017). Review: Nutrient density and nutritional value of meat products and non-meat foods high in protein. Trends in Food Science & Technology, 65, 103–112. https://doi.org/10.1016/j.tifs.2017.04.016

- Carvalho, G. R., Milani, T. M., Trinca, N. R., Nagai, L. Y., & Barretto, A. C. (2017). Textured soy protein, collagen and maltodextrin as extenders to improve the physicochemical and sensory properties of Beef Burger. Food Science and Technology, 37(suppl 1), 10–16. https://doi.org/10.1590/1678-457x.31916

- Chandler, S. L., & McSweeney, M. B. (2022). Characterizing the properties of hybrid meat burgers made with pulses and chicken. International Journal of Gastronomy and Food Science, 27, 100492. https://doi.org/10.1016/j.ijgfs.2022.100492

- Elgadir, M. A., Mariod, A. A., Abdelwahab, S. I., Jamilah, B., Rahman, R. A., & Che Man, Y. B. (2011). Physicochemical and microbial attributes of organic infused beef cuts (Longissmus dorsi). Journal of Food Safety, 31(3), 326–333. https://doi.org/10.1111/j.1745-4565.2011.00304.x

- Hanula, M., Szpicer, A., Górska-Horczyczak, E., Khachatryan, G., Pogorzelska-Nowicka, E., & Poltorak, A. (2022). Quality of beef burgers formulated with fat substitute in a form of freeze-dried hydrogel enriched with Açai Oil. Molecules, 27(12), 3700. https://doi.org/10.3390/molecules27123700

- Huang, S. C., Tsai, Y. F., & Chen, C. M. (2011). Effects of wheat fiber, oat fiber, and inulin on sensory and physico-chemical properties of Chinese-style sausages. Asian-Australasian Journal of Animal Sciences, 24(6), 875–880. https://doi.org/10.5713/ajas.2011.10317

- Ibrahim, G. A., Abushulukh, E. S., Nour, I., & Dayain, B. A. (2017). Physicochemical and sensory characteristics of burger manufactured from camel meat with different levels of cowpea. The Third international scientific conference of camel research and production. Sudan University of Science and Technology.

- Kadim, I. T., Purchas, R., Al-Amri, I., Alkindi, A., & Abbas, G. (2020). Handbook of research on health and environmental benefits of camel products (pp. 285–305). IGI Glob.

- Kurt, S., & Kilinççeker, O. (2012). The effects of cereal and legume flours on the quality characteristics of beef burgers. Kafkas Universitesi Veteriner. Fakultesi Dergisi, 6013, 726–730.

- Mahmoud, M. H., Abou-Arab, A. A., & Abu-Salem, F. M. (2017). Quality characteristics of beef burger as influenced by different levels of orange peel powder. American Journal of Food Technology, 12(4), 262–270. https://doi.org/10.3923/ajft.2017.262.270

- Mahmoud, F. S. A., Kodous, S. S., Gabal, S. S., & Sayed-Ahamed, E. F. (2019). Improvement of functional properties of soybean replaced meat beef burger. World Journal of Dairy & Food Sciences, 14(2), 222–229.

- Mohammed, H. H. H., Jin, G., Ma, M., Khalifa, I., Shukat, R., Elkhedir, A. E., Zeng, Q., & Noman, A. E. (2020). Comparative characterization of proximate nutritional compositions, microbial quality and safety of camel meat in relation to mutton, beef, and chicken. LWT, 118, 108714. https://doi.org/10.1016/j.lwt.2019.108714

- Nadia, B., Abd-El-Aziz, A., El-Razek, M., & F. Abdel-Salam, F. (2018). Effect of replacing soybean concentrate with bulgur (wheat groats) flour on quality and storage stability of beef burger. Alexandria Journal of Food Science and Technology, 15(2), 21–32. https://doi.org/10.21608/ajfs.2018.28616

- Ovuchimeru, A. (2020). Nutritional effects of full-fat soy flour as an extender on cooked beef sausage quality. Asian Food Science Journal, 17, 44–53. https://doi.org/10.9734/afsj/2020/v17i330195

- Pintado, T., & Delgado-Pando, G. (2020). Towards more sustainable meat products: Extenders as a way of reducing meat content. Foods, 9(8), 1044. https://doi.org/10.3390/foods9081044

- Rezaei, R., Nasrin, Z., & Aghajani, A. (2019). Pre-gelatinized starch potato and chickpea flour impact on the physical and chemical properties of hamburger meat by 60 percent during the storage. Journal of Innovation in Food Science and Technology, 11(2), 143–151.

- Rubio, N. R., Xiang, N., & Kaplan, D. L. (2020). Plant-based and cell-based approaches to meat production. Nature Communications, 11(1), 6276. https://doi.org/10.1038/s41467-020-20061-y

- Ruiz-Capillas, C., & Herrero, A. M. (2021). Development of meat products with healthier lipid content: Vibrational spectroscopy. Foods, 10(2), 341. https://doi.org/10.3390/foods10020341

- Salman, Z. O., Alwash, B. M. J., & Kadhim, E. J. (2019). Effect of essential oil of Cestrum nocturnum flowers cultivated in Iraq as antioxidant and elongation cold storage period of minced meat. The Iraqi Journal of Agricultural Science, 50(2), 601–607.

- Shehata, M., Salama, N., Helmy, S., & Mohamed, A. (2022). Quality improvement of camel meat burger formulated with fat replacers during frozen storage. Egyptian Journal of Nutrition and Feeds, 25(1), 53–66. https://doi.org/10.21608/ejnf.2022.236558

- Shen, Y., Hong, S., Du, Z., Chao, M., O’Quinn, T., & Li, Y. (2022). Effect of adding modified pea protein as functional extender on the physical and sensory properties of beef patties. LWT, 154, 112774. https://doi.org/10.1016/j.lwt.2021.112774

- Suliman, G. M., Al-Owaimer, A. N., Hussein, E. O., Abuelfatah, K., & Othman, M. B. (2020). Meat quality characteristics of the Arabian camel (Camelus dromedarius) at different ages and post-mortem ageing periods. Asian-Australasian Journal of Animal Sciences, 33(8), 1332–1338. https://doi.org/10.5713/ajas.19.0589

- Thompson, J. (2002). Managing meat tenderness. Meat Science, 62(3), 295–308. https://doi.org/10.1016/s0309-1740(02)00126-2

- Wang, W., Dong, L., Zhang, Y., Yu, H., & Wang, S. (2021). Reduction of the heterocyclic amines in grilled beef patties through the combination of thermal food processing techniques without destroying the grilling quality characteristics. Foods, 10(7), 1490. https://doi.org/10.3390/foods10071490

- Warner, R. (2014). Measurement of meat quality | measurements of water-holding capacity and color: Objective and subjective. Encyclopedia of Meat Sciences, 2,164–171. https://doi.org/10.1016/b978-0-12-384731-7.00210-5

- Wi, G., Bae, J., Kim, H., Cho, Y., & Choi, M.-J. (2020). Evaluation of the physicochemical and structural properties and the sensory characteristics of meat analogues prepared with various non-animal based liquid additives. Foods, 9(4), 461. https://doi.org/10.3390/foods9040461

- Zaki, E. F. (2018). Impact of adding chia seeds (Salvia hispanica) on the quality properties of Camel Burger “camburger” during cold storage. International Journal of Current Microbiology and Applied Sciences, 7(03), 1356–1363. https://doi.org/10.20546/ijcmas.2018.703.162

- Ziegler, V., Ugalde, M. L., Veeck, I. d., & Barbosa, F. d (2020). Nutritional enrichment of beef burgers by adding components of non-conventional food plants. Brazilian Journal of Food Technology, 23, e2019030. https://doi.org/10.1590/1981-6723.03019