?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.Abstract

Enhancing the quality of rice grains is essential to meet consumer demand and boost farmers’ income. Various factors, such as processing techniques and parboiling methods, play a crucial role in influencing the overall quality of rice grains. In this study, the effects of soaking and steaming durations on the parboiling process were studied on rice grains’ physical quality and appearance. The 10 kg of paddy grains of the two most consuming cultivars (Surkha Zurati and Barah) were soaked in natural water and then steamed for 15, 20, and 25 min under two covering methods: cloth + lid and cloth. The parboiled grains were dried (12–13%) and milled for a physical quality test. The results revealed that cloth + lids increased the amount of head rice and decreased broken and chalky grain production. The maximum head rice rate was recorded for 25 min, followed by 20 and 15 min of steaming for all treatments and cultivars. The lower broken and chalky grains were recorded after 25 min of steaming (cloth + lid), and the highest values were observed after 15 min (cloth) for both cultivars. The cloth + lid method produced darker yellow grains after parboiling compared to the cloth treatments only in both cultivars. Furthermore, the rice grain darkness increased with increasing steaming duration. Hence, head rice, chalkiness, broken grains, and discoloration can be managed through parboiling. This method can be useful for rice processors to improve rice grain quality using adequate parboiling technology.

REVIEWING EDITOR:

1. Introduction

Rice stands as a prominent global food crop, ranking as the second most produced staple grain annually, following wheat (Kakar et al., Citation2019c; Miah et al., Citation2002). Rice grain quality depends mainly on its physical and chemical properties (Kakar et al., Citation2019a). Post-harvest handling is a major factor affecting rice grain quality (Manandhar et al., Citation2018). Paddy rice parboiling is a post-harvest processing technique that is widely practiced worldwide, including in Afghanistan (Kakar et al., Citation2019b). Parboiling is a hydrothermal process applied to rice and other cereals, involving the use of water and heat to modify the treated grains (Rocha-Villarreal et al., Citation2018). It causes physicochemical modifications in the grain, leading to favorable alterations, such as easier de-husking, enhanced head rice yield, increased resistance to insects, firm cooked rice texture, and less solid losses (Ayamdoo et al., Citation2013; Miah et al., Citation2002).

Normally, the parboiling process involves three stages: (1) soaking the cleaned paddy to achieve quick and uniform water absorption, (2) gelatinization of rice starch by adding heat to moist kernels through steaming, and (3) drying the paddy to reduce moisture content for effective milling and storage (Kwofie & Ngadi, Citation2017). Champathi (Citation2018) reported that imperfect grains, chalkiness, and cracks were completely rectified, and many previous defects were cured when the paddy was properly parboiled. However, a common problem with the parboiling process, particularly in high-temperature and high-pressure operations, is the discoloration of rice grains and its consequent effect on consumer acceptability (Lamberts et al., Citation2006).

In Afghanistan, parboiling (soaking, roasting, drying, and milling) of paddy is conducted mostly in the northern region, and most rice farmers soak paddies for a long time (3-4 weeks). The soaked paddy is then roasted in a cast iron pan, leading to a longer processing time and increasing the percentage of broken grains, consequently reducing the grain quality (Noori et al., Citation2018). In addition, traditionally milled rice in Afghanistan has a poor quality and undesirable appearance (Kakar et al., Citation2019b). Therefore, the rice produced in Afghanistan cannot compete with imported rice in terms of cooking and eating quality. Hence, there is an urgent need to improve the grain quality of locally produced rice using a parboiling approach in both physical and chemical aspects to compete with imported rice. Thus, the research focused on two widely cultivated rice varieties, Surkha Zurati and Barah, which are prominent in the northern provinces of Afghanistan. The aim of this study was to establish fundamental data for standardizing the parboiling process and determining the optimal duration for parboiling (comprising both soaking and steaming) of paddy grains. This investigation paves the path for producers to enhance the quality and appearance of rice grains by employing an optimal parboiling approach.

2. Materials and methods

2.1. Procedures of soaking and parboiling

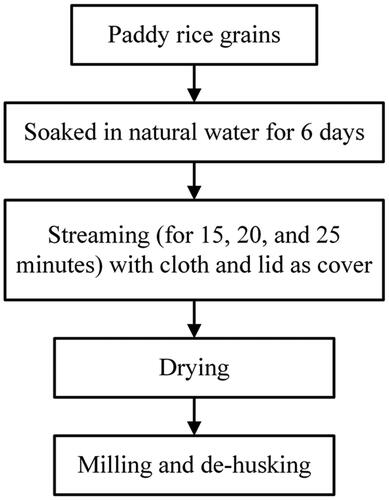

Two ponds (2 m × 3 m) were prepared and covered with a plastic layer to control water leakage and soak the paddy rice based on the traditional approach at the Kunduz Agricultural Research Center in 2021. Paddy grains (300 kg each) of two local cultivars (Surkha Zurati and Barah) were soaked in ponds with natural water (freshly received from a tube well) for 24 hours for six days and the water temperature remained consistently close during the soaking period across various ponds, ranging from 12.3 to 13.2 °C. The water temperature and paddy moisture content were measured twice a day (in the morning and afternoon) until the optimal moisture content was achieved by using a thermometer (Plato thermometer) and a moisture meter (Riceter F515, Kett Electric Lab., Tokyo, Japan), respectively. The soaked paddy grains were then removed from the ponds when they reached the optimal moisture content (30%) and were ready for the steaming and parboiling processes, as illustrated in .

2.2. Steaming pan and devices

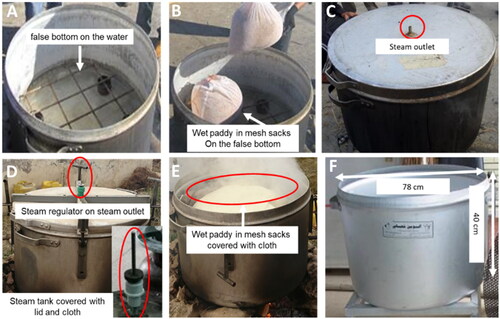

A round steaming pan (developed by the Rice-based Agriculture Development Project in Afghanistan (RIPA)) with a diameter of 78 cm and height of 40 cm was used. It consists of a lid and a false bottom made of a round iron bar placed 5 cm above the water inside the pan to place paddy mesh sacks on it. Furthermore, there was a steam outlet pipe on the lid and a steam regulator on the steam outlet pipe, as shown in .

2.3. Steaming duration and procedures

For each cultivar, 10 kg of soaked paddy grains were weighed in a mesh bag. They were steamed separately for 15, 20, and 25 min using boiling water in a steaming pan. The higher moisture content in the grains was used to gelatinize starch during the steaming process. The steam was distributed to reach all parts of the pan by covering the steaming pan with cloth + lid and without a lid (only cloth). This covering prevents easy volatilization of steam, thereby creating a partial pressure over the content that aids in the inward movement of molecules in each gelatinous grain. A steam regulator was adjusted for the steam outlet throughout the pan to indicate the proper steaming time and optimal duration for paddy cracking and de-husking. The heat produced in the pan also evaporates extra moisture from the grains and leaves concentrated nutrients in the grains. This method was developed by the Afghanistan (RIPA/JICA) through this study.

2.4. Drying of parboiled grains

Parboiled paddy grains spread quickly in an open area to dry. Excessive sunlight was avoided to prevent non-uniform drying, which causes grain breakage during milling. The dried paddy grains were packed in bags and properly labeled for milling at optimal moisture content (12–13%).

2.5. Milling process

Grain milling was performed using a milling machine (Engelberg Co., New York, USA). Before milling, the samples were conditioned to an equilibrium moisture content of approximately 12% using a moisture meter and weighed in each bag. Milling recovery was estimated using the following equation:

2.6. Physical quality

The milled rice grains were weighed to calculate the milling recovery. Furthermore, 200 g of milled rice from each treatment was separated to measure the head rice ratio (%), chalky grains (%), and broken grains (%) using the following formulas: The grain appearance of the different treatments was determined by visual observation.

2.7. Statistical analysis

The obtained data were analyzed based on analysis of variance (ANOVA) using the language R 3.6.2. Data are presented as the mean ± standard error. Differences among means were considered using Tukey’s test at the 0.05% level.

3. Results

3.1. Water temperature and moisture content of paddy grains

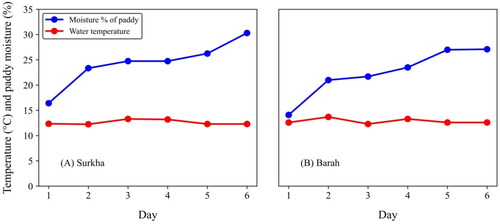

The water temperature of the ponds and the moisture content of the paddy grains for both cultivars are illustrated in . The water temperature remained consistently close during the soaking period across various ponds, ranging from 12.3 to 13.2 °C, maintaining uniformity from the beginning to the end of the soaking period for both cultivars (). However, there was variation in the moisture content between the cultivars. The moisture content increased from 16.4% to 30.3% within six days for Surkha Zurati () and from 13.8% to 27.1% for Barah () rice cultivars.

3.2. Physical properties of parboiled rice

The effects of the parboiling method and steaming duration on milled rice production and milling recovery are summarized in . There were identical and non-significant differences in milled rice weight and milling recovery between cultivars and treatments. Milled rice weight and milling recovery increased in the cloth + lid treatment for both cultivars. For the Surkha Zurati cultivar, employing the 25-min steaming duration with the cloth + lid method resulted in higher milled rice weight and milling recovery, measuring 35.7 kg and 72.1% as compared to the cloth treatment, respectively. Conversely, in the cloth treatment, after a 15-min steaming duration, both the milled rice weight and milling recovery were higher, reaching 35.2 kg and 73.6%, respectively. In addition, the milled rice weight and milling recovery were greater after 20 min of steaming of the Barah cultivar ().

Table 1. Effects of different soaking and steaming durations and methods on physical parameters of local rice cultivars.

The head rice, broken grain, and chalky grain ratios are listed in . The head rice weight ranged from 119.0 g – 175.5 g and 112.7 g – 163.7 g for Surkha Zurati and Barah rice cultivars in both cloth + lid and only cloth treatments, respectively. Generally, cloth + lid increased the amount of head rice and decreased the weight of broken and chalky grains compared with cloth alone. There were significant (P < 0.001) differences among steaming durations in terms of the head-rice ratio. A significant (P < 0.001) maximum head rice weight was recorded for 25 min, followed by 20 and 15 min of steaming, among all treatments and cultivars. In addition, the highest head rice ratio was 88.0%, obtained after 25 min of steaming (cloth + lid), and the lowest (60.0%) was observed after 15 min of steaming (cloth) (). There were significant (P < 0.001) variations in the broken and chalky grains among the steaming treatments. The lowest broken grains were recorded in 25 min steaming duration with cloth + lid treatment, which was 24.5 g and 36.3 g, and the highest was observed for 15 min steaming with only cloth treatment, which was 81.0 g and 87.3 g for Surkha Zurati and Barah cultivars, respectively (). Rice grain chalkiness was reduced with the cloth + lid treatment compared to that with cloth alone, and the chalky grain percentage decreased when the steaming duration was increased ().

Table 2. Physical characteristics of rice grains at different soaking and steaming duration and methods.

3.3. Grain appearances

There were differences in terms of the steaming duration (15, 20, and 25 min) and covering methods for rice grain color formation, as demonstrated in and . The cloth + lid treatment produced darker yellow rice grains after parboiling compared to the cloth-only treatments in both cultivars. Furthermore, the rice grain yellowness increased with increasing steaming duration. Dark yellow grains were produced after 25 min of steaming, while 15 min produced light white rice grains in both cultivars.

4. Discussion

Parboiling technology is the post-harvest processing of paddy grains that is widely practiced worldwide, including in Afghanistan (Kakar et al., Citation2019b). Parboiling treatment alters rice grains’ physical and chemical properties, ultimately affecting their eating and cooking quality (Meresa et al., Citation2020). Rice farmers in Afghanistan place rice grains in water for 20-30 days before the parboiling process, which is time-consuming, inefficient, and sometimes causes grain rot. We found that both rice cultivars achieved their optimal soaking time of 6 days, which is sufficient to obtain optimal moisture content (30%) and reduce the soaking duration. In the current study, the parboiling process did not significantly affect milled rice yield and milling recovery. However, significant (P < 0.001) differences were observed in head rice yield and broken and chalky grain production in both cultivars, with a high priority of cultivation in the northern provinces of Afghanistan. It is worth mentioning that the Surkha Zurati cultivar is well known for its taste owing to its high protein content, expansion after cooking, and high yield (Noori et al., Citation2018). The milling recovery of the Surkha Zurati cultivar was 72.0% after 25 min of steaming (cloth + lid) and 71.0% after 15 min of steaming (cloth + lid). There were identical and non-significant differences in milling recovery between cultivars and treatments.

The results of this study revealed that steaming duration affected head rice yield and broken and chalky grain percentages. The paddy grains parboiled by steaming for 25 min with cloth + lid showed a significantly (P < 0.001) higher head rice ratio in both rice cultivars. Meresa et al. (Citation2020) reported that the head-rice ratio of rice cultivars was enhanced as the steaming temperature and duration increased, which is consistent with our findings. In another study conducted by Bello et al. (Citation2006), hydrothermal treatments increased the head rice yield, consequently improving processed rice’s quality index. According to Bodie et al. (Citation2019), the head rice yield is the current and most important standard for assessing commercial rice milling quality. However, higher broken grain production reduces rice grain marketability and price (Muthayya et al., Citation2014). Ayamdoo et al. (Citation2013) reported the beneficial effects of parboiling on reducing the percentage of broken rice grains during milling. For instance, broken grains significantly decreased from 47% in the control samples to 9.5% in the parboiled samples. In addition, Buggenhout et al. (Citation2014) reported that the percentage of broken grains was significantly reduced from 27.2% (control grain) to 6.3% (parboiled grain). Similar results were also observed in the current study; when steaming duration increased, the number of broken grains decreased in both cultivars. Rice grain chalkiness is another important aspect of its physical properties and consumer acceptability (Chavan et al., Citation2018; Kondo, Citation2006). The chalky grain weight for Surkha Zurati cultivar ranged from 2.3 g to 7.4 g at 15 and 25 min steaming with cloth + lid treatment and from 7.9 g to 10.5 g at 15 and 25 min steaming with only cloth treatment, respectively. The chalky grain weight for the Barah cultivar ranged from 2.3 g to 5.0 g at 15 and 25 min (cloth + lid) and from 2.2 g to 6.1 g at 15 and 25 min steaming (only cloth). These results indicate that an increase in steaming duration using the cloth + lid parboiling method decreased chalky grain production. This means that endosperm translucency, which is a quality characteristic of rice grains, was improved after adequate parboiling method (Taghinezhad et al., Citation2016). The improvement in endosperm translucency during parboiling is mainly due to the pre-gelatinization of starch granules (Ferreira et al., Citation2017). The parboiling process completely or partially eliminates the presence of chalkiness, which may not have a direct impact on the cooking and eating qualities of rice grains (Oli et al., Citation2014); a large amount of chalkiness downgrades the physical characteristics, decreases milling recovery, and can reduce the attractiveness of a competitive price market (Peng et al., Citation2014; Xiong et al., Citation2017).

Discoloration of rice grains is an important quality indicator that varies among grains owing to the variation in steaming duration of the parboiling process, cultural practices, and genotypic differences (Islam et al., Citation2002). Parboiling technology influences the yellowness and redness of milled rice grains, in which yellow is more affected than red (Lamberts & Delcour, Citation2008). Generally, yellow-colored rice grains increase the market value and consumer acceptability worldwide, including Afghanistan, while such grains may not be preferred in some countries (Kam et al., Citation2012). Therefore, most rice producers use artificial colors with grains to recover grain chalkiness and cracks and produce preferred colored grains to catch consumer interest (Ashfaq et al., Citation2017). In this study, the grain color was changed by different steaming durations (15, 20, and 25 min) and parboiling methods (Cloth + lid and cloth only). An increase in steaming duration caused the grains to become darker yellow in both cultivars and treatments. Dark yellow grains were produced after 25 min of steaming, while 15 min produced light-colored rice grains in both cultivars. This means that the variation in the colors of parboiled rice grains can be managed by steaming duration and methods, which is a crucial option for rice producers and traders to use instead of coloring agents. Many investigators have examined the color value due to parboiling treatment (Islam et al., Citation2004; Sareepuang et al., Citation2008), they have reported that discoloration is mainly caused by Maillard type non-enzymatic browning and processing methods that determine the intensity of colors during parboiling. Furthermore, the husk pigment also diffuses into the endosperm during soaking and steaming (Onmankhong et al., Citation2021; Taghinezhad et al., Citation2015). To summarize, the processing steps in parboiling paddy grains vary considerably among practitioners, based on the locality and culture of the people concerned. Such variations in practice result in differences in the quality of the final product. Therefore, soaking paddy grains for 5-6 days and parboiling for 25 min using the cloth and lid method can improve rice grain quality, which might easily compete with imported rice.

5. Conclusion

This study examined the effects of parboiling technology on the physical quality and discoloration of two local rice cultivars. Soaked paddy grains to obtain approximately 30% moisture and steamed for 25 min using the cloth + lid method produced higher head rice and lower chalky and broken grains. Based on the results, this is an efficient method to reduce soaking time from 20-30 days to 5-6 days and improve the physical quality of rice grains. Increasing the steaming duration led to the production of dark yellow grains, which is a very important characteristic of consumer interest. We found that the color of the grains can be managed by the steaming duration during the parboiling process, which is one of the best options to alternate the artificial coloring process of the grains. Thus, soaking paddy grains in natural water (13 °C) for six days followed by 25 min steaming with the cloth + lid method can be recommended for rice producers and processors in Afghanistan to improve the physical quality and appearance of parboiled rice.

Authors’ contributions

Z.N. and S.F. assumed the idea, conducted the experiment, and wrote the manuscript. All authors Z.N., K.K., S.A., R.M, S.F, H.O.E., and M.A.E. analyzed the data, wrote, and revised the manuscript. All the authors have read and agreed to the latest version of the manuscript.

Acknowledgments

The authors appreciate the Rice-based Agriculture Development Project in Afghanistan (RIPA/JICA) and the Agricultural Research Institute of Afghanistan (ARIA) for providing funding for this study. The authors extend their appreciation to the Researchers Supporting Project number (RSP2024R182) of King Saud University, Riyadh, Saudi Arabia.

Disclosure statement

The authors declare no conflicts of interest and have proofread the final version of the manuscript.

Data availability statement

All data are available within this publication.

Additional information

Funding

References

- Ashfaq, M., Mubashar, U., Haider, M. S., Ali, M., Ali, A., & Sajjad, M. (2017). Grain discoloration: an emerging threat to rice crop in Pakistan. Journal of Animal and Plant Sciences, 27(3), 1–9.

- Ayamdoo, J. A., Demuyakor, B., Dogbe, W., & Owusu, R. (2013). Parboiling of paddy rice, the science and perceptions of it as practiced in Northern Ghana. International Journal of Scientific & Technology Research, 2(4), 13–18.

- Bello, M., Baeza, R., & Tolaba, M. P. (2006). Quality characteristics of milled and cooked rice affected by hydrothermal treatment. Journal of Food Engineering, 72(2), 124–133. https://doi.org/10.1016/j.jfoodeng.2004.11.026

- Bodie, A. R., Micciche, A. C., Atungulu, G. G., Rothrock, M. J., Jr., & Ricke, S. C. (2019). Current trends of rice milling byproducts for agricultural applications and alternative food production systems. Frontiers in Sustainable Food Systems, 3, 47–52. https://doi.org/10.3389/fsufs.2019.00047

- Buggenhout, J., Brijs, K., Van Oevelen, J., & Delcour, J. A. (2014). Milling breakage susceptibility and mechanical properties of parboiled brown rice kernels. LWT - Food Science and Technology, 59(1), 369–375. https://doi.org/10.1016/j.lwt.2014.05.001

- Champathi, G. D. M. C. (2018). Application of two temperature hot water soaking for improving of paddy parboiling process. Agricultural Engineering International, 20(4), 164–168.

- Chavan, P., Sharma, S. R., Mittal, T. C., Mahajan, G., & Gupta, S. K. (2018). Effect of parboiling technique on physico-chemical and nutritional characteristics of basmati rice. Agricultural Research Journal, 55(3), 490–499. https://doi.org/10.5958/2395-146X.2018.00089.3

- Ferreira, A. R., Oliveira, J., Pathania, S., Almeida, A. S., & Brites, C. (2017). Rice quality profiling to classify germplasm in breeding programs. Journal of Cereal Science. 76, 17–27. https://doi.org/10.1016/j.jcs.2017.05.007

- Islam, M. R., Roy, P., Shimizu, N., & Kimura, T. (2002). Effect of processing conditions on physical properties of parboiled rice. Food Science and Technology Research, 8(2), 106–112. https://doi.org/10.3136/fstr.8.106

- Islam, M. R., Shimizu, N., & Kimura, T. (2004). Energy requirement in parboiling and its relationship to some important quality indicators. Journal of Food Engineering, 63(4), 433–439. https://doi.org/10.1016/j.jfoodeng.2003.09.002

- Kakar, K., Nitta, Y., Asagi, N., Komatsuzaki, M., Shiotsu, F., Kokubo, T., & Xuan, T. D. (2019a). Morphological analysis on comparison of organic and chemical fertilizers on grain quality of rice at different planting densities. Plant Production Science, 22(4), 510–518. https://doi.org/10.1080/1343943X.2019.1657777

- Kakar, K., Xuan, T. D., Haqani, M. I., Rayee, R., Wafa, I. K., Abdiani, S., & Tran, H. D. (2019b). Current situation and sustainable development of rice cultivation and production in Afghanistan. Agriculture, 9(3), 49–57. https://doi.org/10.3390/agriculture9030049

- Kakar, K., Xuan, T. D., Quan, N. V., Wafa, I. K., Tran, H. D., Khanh, T. D., & Dat, T. D. (2019c). Efficacy of N-methyl-N-nitrosourea mutation on physicochemical properties, phytochemicals, and momilactones A and B in rice. Sustainability, 11(23), 6862–6873. https://doi.org/10.3390/su11236862

- Kam, K., Murray, J. M., Arcot, J., & Ward, R. (2012). Fortification of parboiled rice with folic acid: Consumer acceptance and sensory evaluation. Food Research International, 49(1), 354–363. https://doi.org/10.1016/j.foodres.2012.07.064

- Kondo, M. (2006). Effects of air temperature during ripening and grain protein contents on grain chalkiness in rice. Japanese Journal of Crop Science, 75(2), 14–15.

- Kwofie, E. M., & Ngadi, M. (2017). A review of rice parboiling systems, energy supply, and consumption. Renewable and Sustainable Energy Reviews, 72, 465–472. https://doi.org/10.1016/j.rser.2017.01.014

- Lamberts, L., & Delcour, J. A. (2008). Carotenoids in raw and parboiled brown and milled rice. Journal of Agricultural and Food Chemistry, 56(24), 11914–11919. https://doi.org/10.1021/jf802613c

- Lamberts, L., De Bie, E., Derycke, V., Veraverbeke, W. S., De Man, W., & Delcour, J. A. (2006). Effect of processing conditions on color change of brown and milled parboiled rice. Cereal Chemistry, 83(1), 80–85. https://doi.org/10.1094/CC-83-0080

- Manandhar, A., Milindi, P., & Shah, A. (2018). An overview of the post-harvest grain storage practices of smallholder farmers in developing countries. Agriculture, 8(4), 57–65. https://doi.org/10.3390/agriculture8040057

- Meresa, A., Demissew, A., Yilma, S., Tegegne, G., & Temesgen, K. (2020). Effect of parboiling conditions on physical and cooking quality of selected rice varieties. International Journal of Food Science, 2020, 8810553–8810559. https://doi.org/10.1155/2020/8810553

- Miah, M. K., Haque, A., Douglass, M. P., & Clarke, B. (2002). Parboiling of rice. Part I: Effect of hot soaking time on quality of milled rice. International Journal of Food Science & Technology, 37(5), 527–537. https://doi.org/10.1046/j.1365-2621.2002.00610.x

- Muthayya, S., Sugimoto, J. D., Montgomery, S., & Maberly, G. F. (2014). An overview of global rice production, supply, trade, and consumption. Annals of the New York Academy of Sciences, 1324(1), 7–14. https://doi.org/10.1111/nyas.12540

- Noori, Z., Mujadidi, M. W., & Amin, M. W. (2018). Physicochemical properties and morphological observations of selected local rice varieties in northern Afghanistan. Int J Agric Environ Food Sci, 2(3), 99–103.

- Oli, P., Ward, R., Adhikari, B., & Torley, P. (2014). Parboiled rice: Understanding from a materials science approach. Journal of Food Engineering, 124, 173–183. https://doi.org/10.1016/j.jfoodeng.2013.09.010

- Onmankhong, J., Jongyingcharoen, J. S., & Sirisomboon, P. (2021). The influence of processing parameters of parboiled rice on its physiochemical and texture properties. Journal of Texture Studies, 52(2), 219–227. https://doi.org/10.1111/jtxs.12576

- Peng, B., Wang, L., Fan, C., Jiang, G., Luo, L., Li, Y., & He, Y. (2014). Comparative mapping of chalkiness components in rice using five populations across two environments. BMC Genetics, 15(1), 49. https://doi.org/10.1186/1471-2156-15-49

- Rocha-Villarreal, V., Serna-Saldivar, S. O., & García-Lara, S. (2018). Effects of parboiling and other hydrothermal treatments on the physical, functional, and nutritional properties of rice and other cereals. Cereal Chemistry, 95(1), 79–91. https://doi.org/10.1002/cche.10010

- Sareepuang, K., Siriamornpun, S., Wiset, L., & Meeso, N. (2008). Effect of soaking temperature on physical, chemical and cooking properties of parboiled fragrant rice. World Journal of Agricultural Research, 4(4), 409–415.

- Taghinezhad, E., Khoshtaghaza, M. H., Minaei, S., & Latifi, A. (2015). Effect of soaking temperature and steaming time on the quality of parboiled Iranian paddy rice. International Journal of Food Engineering, 11(4), 547–556. https://doi.org/10.1515/ijfe-2014-0296

- Taghinezhad, E., Khoshtaghaza, M. H., Minaei, S., Suzuki, T., & Brenner, T. (2016). Relationship between degree of starch gelatinization and quality attributes of parboiled rice during steaming. Rice Science, 23(6), 339–344. https://doi.org/10.1016/j.rsci.2016.06.007

- Xiong, D., Ling, X., Huang, J., & Peng, S. (2017). Meta-analysis and dose-response analysis of high temperature effects on rice yield and quality. Environmental and Experimental Botany, 141, 1–9. https://doi.org/10.1016/j.envexpbot.2017.06.007