?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.

?Mathematical formulae have been encoded as MathML and are displayed in this HTML version using MathJax in order to improve their display. Uncheck the box to turn MathJax off. This feature requires Javascript. Click on a formula to zoom.ABSTRACT

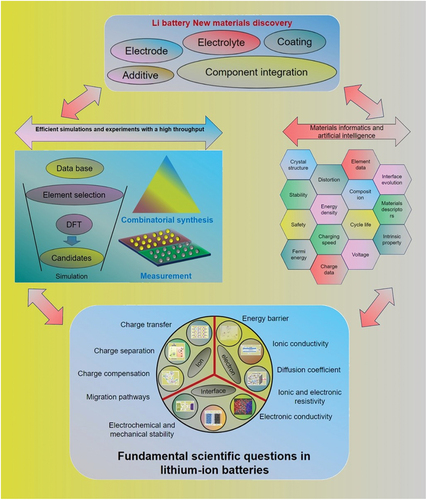

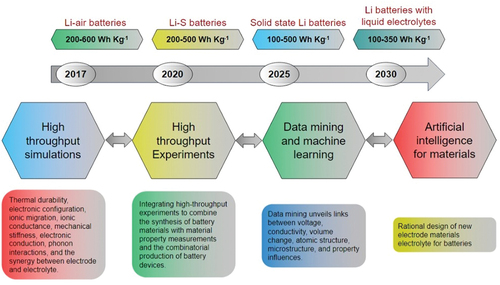

The acceleration of materials discovery has gained paramount importance due to its potential to overcome constraints in emerging technologies. Extensive exploration has been undertaken into three pivotal approaches: combinatorial synthesis, high-throughput characterization, and computational techniques, all aimed at unveiling new materials. This review article delves into recent progress in these domains. Combinatorial synthesis, especially in the development of thin-film materials libraries, emerges as a potent method for efficiently generating comprehensive multinary materials systems and composition gradients spanning the entire spectrum of required compositions. High-throughput characterization techniques play a pivotal role in assessing the compositional, structural, and functional attributes of materials within these libraries, yielding multidimensional datasets. Concurrently, recent advancements in computational materials science have notably expedited the discovery process by enabling high-throughput calculations and simulations of potential materials systems. These collective endeavors foster a more robust correlation between composition, processing, structure, and properties, facilitating the forecast and design of future materials through data-driven materials discovery. This approach allows for efficient optimization of newly identified materials. Furthermore, materials informatics, an integral element of this process, plays a crucial role in managing and extracting valuable insights from the vast data generated during materials discovery.

IMPACT STATEMENT

Combining high-throughput combinatorial methods, computational approaches, open-source libraries, and collaborative efforts leads to significant novelty, particularly in the discovery and understanding of new materials and their relationships between structure, properties, process, and composition.

1. Introduction

The discovery of new materials has been instrumental in driving significant technological advancements throughout history. Notable examples include the development of materials like bronze and steel in ancient times, as well as the advent of synthetic polymers in the twentieth century, all of which have had profound impacts on various industries and applications. However, it’s important to recognize the evolution of materials discovery over time. In Thomas Edison’s era, when he was searching for a suitable filament for the incandescent light bulb, the available options were limited, primarily relying on carbonized natural fibers. This historical context underscores the remarkable progress made in the field of materials science since then. In modern times, advanced materials frequently consist of complex combinations, including ternary, quaternary, or even more complex alloys. Furthermore, their properties can be finely tuned by manipulating factors like crystallinity, mesostructure, and layering arrangements. As a result, the process of screening and developing materials for contemporary applications often requires conducting a substantially greater number of experiments and necessitates a more advanced comprehension of material properties than what was sufficient a century ago. The ongoing quest for materials innovation remains a critical driving force for addressing urgent societal challenges, particularly in the realms of mitigating global climate change and securing a sustainable future energy supply. The development of novel materials with enhanced properties, such as heightened strength, improved energy efficiency, and superior environmental sustainability, is indispensable for advancing solutions in these vital areas. Thus, the relentless pursuit of materials discovery remains a foundational pillar for technological progress and is pivotal in tackling the most pressing challenges of our era [Citation1]. To make substantial advancements, it is crucial to carefully designate the materials systems for experimental exploration. This entails confining the selection of initial chemical elements to those that are abundant in the Earth, non-hazardous, and environmentally sustainable. Despite the immense potential in discovering new materials, a targeted approach is indispensable for achieving significant results. Despite the utilization of cutting-edge technologies, the process of materials discovery still relies heavily on extensive trial and error. Identifying a suitable material for a technological application can span decades of research, with additional time required for its optimization for commercial use. This prolonged journey primarily stems from the intricate and multifaceted nature of materials design, rendering it a formidable optimization challenge. Moreover, the absence of necessary data for making informed decisions regarding the prioritization of materials and experimental procedures further adds complexity to the materials discovery process [Citation2–9].

Materials used in engineering applications often have complex compositions and microstructures that consist of more than five elements. This is true for a variety of materials including steels, superalloys, bulk metallic glasses, and high-entropy alloys. In fact, the use of multinary materials is expected to increase in the future compared to materials composed of only one or two elements. However, the sheer number of possible combinations of chemical elements in multinary systems is vast, with over two million possible combinations for quinaries alone when using 50–60 starting elements. Achieving the exact composition, phase constitution, and microstructure required for specific applications is a difficult task [Citation10]. The vast and unexplored composition space is further expanded by the processing parameter space. Various manufacturing methods are employed to produce materials, leading to diverse material states, including metastable and stable forms, each characterized by distinct microstructures and properties that necessitate thorough investigation. Attaining the sought-after properties of multinary materials demands precise management of composition, processing techniques, and microstructural elements. To achieve these objectives, engineers and scientists must possess a profound comprehension of the fundamental physical and chemical principles governing these materials. This entails adopting an interdisciplinary approach that seamlessly integrates the fields of chemistry, physics, and materials science [Citation11–13]. Utilizing processing methods allows for the tailoring of materials’ microstructures and external attributes, including functional properties. The quest for novel materials involves a multidimensional exploration, encompassing intrinsic factors like composition and crystal structure, as well as extrinsic elements such as microstructure and functional properties. The identification of suitable properties for a particular application demands comprehensive investigation within this expansive and complex search domain [Citation3,Citation10,Citation14–23].

Quantum chemical approximations, like density functional theory (DFT), have proven highly effective in predicting a wide range of crucial materials properties with remarkable precision. Many scientific teams have harnessed high-throughput computational strategies to systematically evaluate thousands of compounds, assessing their potential suitability for emerging technological materials. This approach has significantly accelerated the exploration of novel materials with promising applications. This approach has been applied to a variety of fields, including solar water splitters, solar photovoltaics [Citation24], topological insulators [Citation25], scintillators, CO2 capture materials [Citation26], piezoelectrics, and thermoelectrics [Citation27]. The studies have suggested several new promising compounds for experimental follow-up [Citation28]. In the fields of catalysis, hydrogen storage materials [Citation29–31], and Li-ion batteries [Citation32], experimental ‘hits’ have already been reported from high-throughput computations [Citation2,Citation23,Citation33–37].

A promising trend that has emerged in recent years involves the integration of computational materials science with information technology. This integration encompasses the utilization of web-based dissemination, databases, and data-mining techniques to overcome the constraints typically associated with individual research groups [Citation2,Citation33]. Consequently, accessing computed materials datasets has become more accessible to new communities, fostering innovative collaborative approaches to materials discovery. Materials informatics, a field that utilizes prior knowledge stored in databases or extracted from electronic literature through computational methods, has the potential to enhance this filtering process. Theoretical and computational materials science can also formulate hypotheses regarding where to explore for new materials and provide predictions about novel materials. Computational techniques offer the advantage of assessing thousands of systems within a significantly shorter timeframe compared to experimental research. High-throughput computational materials science contributes invaluable insights by generating a practical inventory of prospective materials for subsequent combinatorial investigation. Utilizing computational methodologies for forecasting compositions serves as a means to refine the quest for new materials, transforming it from an extensive exploration to a curated selection of tens or hundreds of potential candidates. This streaterialsinformatics, a field that utilizes pamlined approach empowers researchers to channel their experimental endeavors towards a manageable roster of materials, thereby expediting the discovery of innovative materials tailored to meet specific application requirements [Citation35,Citation38–40].

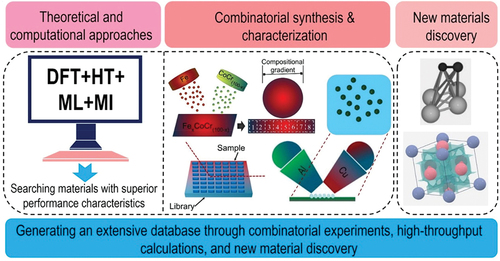

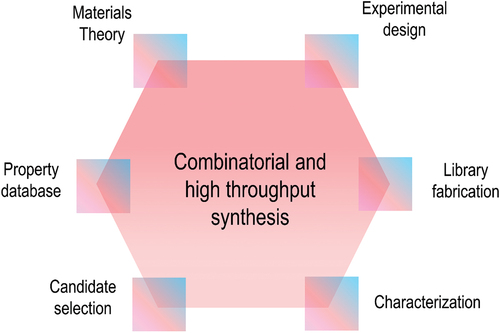

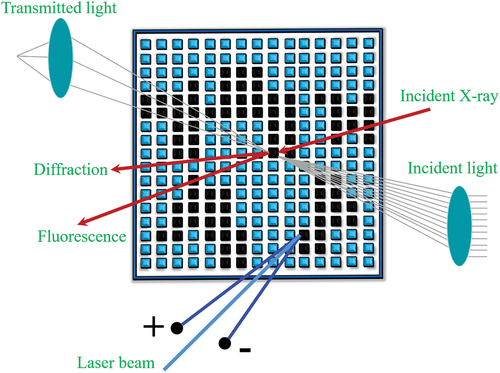

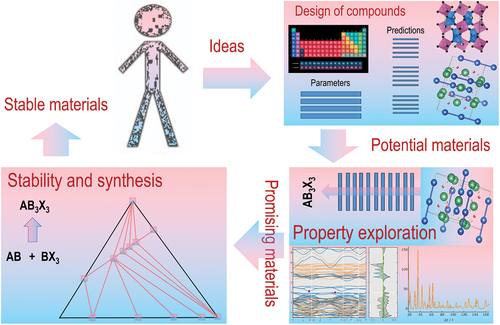

The perspective delves into the possibilities of employing combinatorial synthesis, high-throughput calculations, and high-throughput characterization, coupled with computational techniques, to effectively uncover novel materials within intricate search spaces. This strategy seeks to shift away from chance-based discoveries and transition toward a data-centric and streamlined approach to materials discovery. The article also addresses broader considerations regarding materials discovery and examines potential experimental avenues utilizing thin-film combinatorial materials science (CMS) [Citation1,Citation41–44]. However, to achieve efficient materials discovery and design, the expansion of CMS with computational methods and materials informatics is necessary [Citation44–46]. Computational techniques offer the capability to predict and screen novel materials, enabling researchers to focus their experimental endeavors on a smaller subset of materials possessing the desired properties, thereby resulting in time and resource savings. Additionally, materials informatics plays a pivotal role in refining the quest for new materials by amalgamating prior knowledge from databases and literature. delineates the crucial stages within the realm of high-throughput material synthesis and characterization, seamlessly integrating theoretical material theory, modeling, and the development of material databases. Expediency in the fabrication and analysis cycle is paramount for expediting the introduction of new materials into the market. illustrates an instance of a thin-film fabrication system and candidate selection, wherein a single thin-film fabrication experiment can yield a 16 × 16 matrix comprising 256 distinct materials, each with a thickness measured in a few hundred nanometers [Citation47].

Figure 1. Illustration of the general process of high throughput material synthesis and characterization, which involves combining theoretical material theory, modeling, and material database development. The diagram shows that this process typically involves multiple stages, such as design and synthesis, characterization, and data analysis.

Figure 2. Illustrates two different approaches to high throughput material synthesis and screening. A combinatorial thin film material synthesis method is shown, where the thin film fabrication process is integrated in parallel using spatially addressable arrays of samples. A high throughput semiconductor thin film material screening process is depicted on the left side. Adapted from reference with permission [Citation47]. Copyright © 2015 The Chinese Ceramic Society.

![Figure 2. Illustrates two different approaches to high throughput material synthesis and screening. A combinatorial thin film material synthesis method is shown, where the thin film fabrication process is integrated in parallel using spatially addressable arrays of samples. A high throughput semiconductor thin film material screening process is depicted on the left side. Adapted from reference with permission [Citation47]. Copyright © 2015 The Chinese Ceramic Society.](/cms/asset/37ddd4b5-f076-4d0b-8b6d-47cd565153da/tstm_a_2292486_f0002_oc.jpg)

2. Exploring materials in multidimensional spaces: the quest for discovery

Materials discovery involves identifying new phases or combinations of phases with unique properties resulting from previously undiscovered combinations of composition, crystal structure, phase constitution, microstructure, and properties. This is different from materials development, which focuses on optimizing known materials through adjustments in composition or processing to enhance their existing properties. Materials design, on the other hand, begins with the desired properties and aims to create a material that exhibits these specific characteristics. Materials discovery, in contrast, entails the exploration of a wide range of materials to uncover various properties. While materials discovery can lead to the identification of exceptional properties in previously unknown materials, the vast and uncertain nature of the search space presents significant challenges [Citation10,Citation48].

Historically, materials discoveries often occurred serendipitously, where researchers stumbled upon unexpected findings while pursuing different research objectives. In such cases, the ability to distinguish between erroneous measurements and genuine discoveries played a vital role. Remarkable properties have also emerged in materials where they were not initially anticipated, such as the discovery of high-temperature superconductivity in oxides. More recently, innovative combinatorial synthesis and characterization methods led to the identification of a noble-metal-free nanoparticulate electrocatalyst. Additionally, exploring multinary systems for properties without prior reported results has yielded exciting discoveries. A noteworthy achievement in the field of resistive random-access memories is the successful control of conductive filament formation in mixed Hf-Ta anodic oxides (). This has enabled the identification of Hf-Ta anodic memristors with enhanced properties and made it possible to investigate the feasibility of forming-free Hf-Ta/HfO2-Ta2O5/Pt memristors. The recently discovered unipolar memristors exhibit a uniform chemical composition in their local regions, unlike bipolar memristors [Citation49]. Similarly, flexible electronics is an emerging field characterized by the development of electronic components that are both thin and flexible, suitable for integration into various applications like wearable devices, medical sensors, and electronic skins. A significant challenge in this field is the need for a cost-effective and efficient fabrication method for these components. High-throughput synthesis offers a solution by enabling the swift synthesis and screening of numerous materials to pinpoint their desirable properties. Recently, this approach has been applied to the production of thin metal oxide combinatorial films, which have applications in electronic component manufacturing. These films can be synthesized and screened for electronic properties like resistivity, conductivity, and dielectric constant in a high-throughput fashion, expediting the identification of materials suitable for specific electronic components. The successful implementation of high-throughput synthesis and anodic printing has paved the way for exciting advancements in the realm of flexible electronics (). This technology not only facilitates the development of flexible electronic components but also offers cost-effectiveness, efficiency, and compatibility with a diverse array of applications. Its potential extends to reshaping the dynamics of human interaction with electronic devices and fostering innovative possibilities across multiple domains, spanning from healthcare to consumer electronics [Citation50,Citation51]. Therefore, materials discoveries can occur in unexplored composition spaces, as well as in known composition spaces where special functionalities have not yet been investigated.

Figure 3. (a) Controlling formation of conductive filaments in hf-ta anodic oxides: a significant accomplishment in resistive random-access memories (b) revolutionizing flexible electronics: high throughput synthesis and anodic printing process, reproduced with permission [Citation49].

![Figure 3. (a) Controlling formation of conductive filaments in hf-ta anodic oxides: a significant accomplishment in resistive random-access memories (b) revolutionizing flexible electronics: high throughput synthesis and anodic printing process, reproduced with permission [Citation49].](/cms/asset/29b00040-d0f2-4154-9c9b-579c6b3a71f4/tstm_a_2292486_f0003_b.gif)

Given the vastness of the materials search space, achieving accurate predictions becomes paramount in identifying the most promising compositions or composition ranges for investigation. High-throughput computations offer an effective means of predicting potentially stable materials with intriguing properties from a pool of thousands of candidates. Subsequently, combinatorial materials science can step in to synthesize a limited number of compositions within materials libraries, strategically centered around the most promising predicted compositions. However, these predictions are often rooted solely in intrinsic properties and frequently lack precise and validated experimental data for validation. To overcome this limitation, high-throughput characterization of materials libraries becomes instrumental, serving the dual purpose of providing the missing datasets and validating the predictions. Through the generation of high-quality multidimensional data and its joint evaluation via high-throughput computations and experiments, researchers can enhance the accuracy of their predictions while also uncovering unexplored data points worthy of further exploration. In essence, this integrated approach holds significant potential for advancing materials discovery and expediting the development of cutting-edge technologies [Citation10,Citation52].

3. Synthesizing thin films through combinatorial approaches

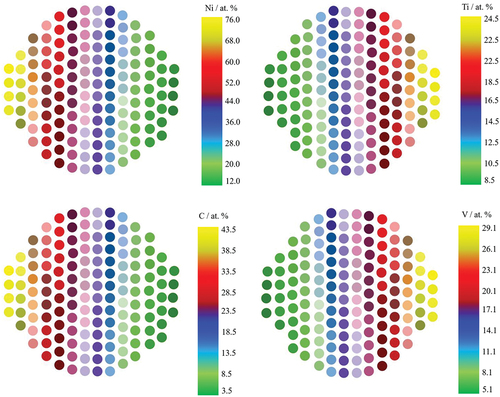

Combinatorial thin film libraries represent an approach for synthesizing and characterizing thin film materials with diverse compositions, thicknesses, and properties in a high-throughput manner. The primary objective behind creating such libraries is to expedite the discovery of new materials possessing sought-after characteristics applicable in various domains, including electronics, optics, and energy-related fields. This approach entails the precise deposition of a range of materials in a systematic and controlled manner. Each sample within the library comprises a specific combination of elements or compounds, resulting in the simultaneous and efficient synthesis of numerous distinct materials. This, in turn, facilitates the exploration of extensive regions within the materials phase diagram, opening up avenues for new material discoveries [Citation53]. Combinatorial thin film synthesis which was developed almost twenty years ago, has been used for screening materials for various applications, including high critical temperature superconductors and phosphors [Citation54,Citation55]. The method involves spatially selective deposition to create individual combinatorial material libraries using designed masks to delineate growth regions with different compositions. The most common method for depositing thin-film materials libraries is through (virtual) wedge-type films, which achieve well-defined composition gradients. This can be done by co-deposition from multiple sources or through multilayer deposition of nanoscale wedge-type layers. Combinatorial magnetron sputter processes are a useful method for fabricating materials libraries, as sputtering is a versatile process that can be applied in both scientific research and industrial applications. Findings from screening of sputtered materials libraries can be transferred to industrial thin-film applications. displays an example of how the composition of the four elements varies across the wafer in thermal co-deposition, with the different atomic percentages. These varying atomic percentages allow for the achievement of different target compositions, such as Ti12.2Ni58.5Cu25.2 V5.8. The distribution of these elements corresponds with the target gun positions for each element inside the sputtering chamber [Citation47]. Many examples regarding thin film combinatorial libraries can be found elsewhere [Citation14,Citation41,Citation45,Citation56].

Figure 4. The elemental distribution of Ni, Ti, Cu, and V on a si wafer, with each element’s composition indicated by a color scale ranging from high (yellow) to low (green) atomic percentage.

Another technique for creating thin-film materials libraries involves the development of ‘focused’ compositional gradient MLs (Materials Libraries). This method entails customizing the composition range within a limited region centered around a predicted composition of interest. To achieve this, co-deposition is employed, resulting in an atomic mixture within the deposited film. This approach is particularly suitable for producing metastable materials, especially when carried out at room temperature. Both the wedge-type and focused compositional gradient strategies guarantee comprehensive coverage of the composition space, ensuring that the compositions corresponding to any predicted phases are not overlooked, provided they are synthesizable. However, achieving synthesis requires variations in the conditions of both ML fabrication and processing, extending the combinatorial approach to encompass combinatorial processing libraries [Citation22].

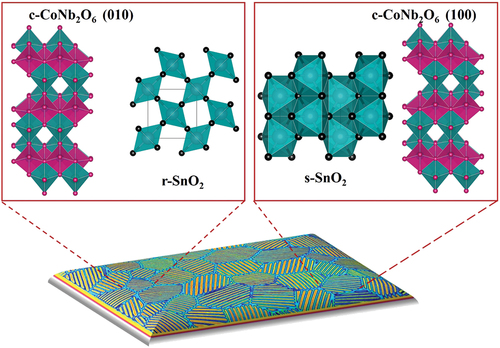

The orientation of the substrate’s crystal structure significantly influences the growth and crystallization of a thin film. When a substrate with a specific orientation structurally resembling the desired complex phase is employed, it can promote the formation of that desired polymorph or metastable phase. This approach enables the successful synthesis of phases that cannot be stabilized as bulk powders, as long as the appropriate growth template is provided for epitaxial stabilization. For example, illustrates the formation of the metastable scrutinyite-structured SnO2 rather than the stable rutile-structured SnO2 during epitaxial growth on polycrystalline CoNb2O6 substrates. The concept of combinatorial substrate epitaxy (CSE) was introduced as a potent method for determining the phase and orientation relationships between a substrate and a deposited film for all potential orientations. Polycrystalline substrates offer a broad spectrum of surface orientations, facilitating the investigation of the influence of orientation on film growth in a single experiment. The substrate’s orientation can be characterized using electron backscatter diffraction (EBSD) both before and after the deposition of a thin film onto the polycrystalline substrate [Citation57].

Figure 5. An illustration of a SnO2 film on a polycrystalline CoNb2O6 substrate, where each grain of the substrate allows the growth of SnO2 with a unique orientation relationship. The film consists of two types of SnO2: stable rutile (r-) SnO2 on some grains, and metastable scrutinyite-structured SnO2 on others.

4. Synthesizing nanoparticles through combinatorial approaches

The production of nanoparticles is a crucial technique for expediting material characterization and advancement. Nanoparticles possess distinctive physical and chemical characteristics owing to their minuscule dimensions, rendering them applicable in a wide array of fields such as catalysis, energy storage, and biomedical imaging. Among the prevailing techniques for crafting nanoparticles, chemical synthesis stands out as a widely employed method. This process entails the reduction of metal salts in the presence of both a reducing agent and a stabilizing agent. This method not only allows for precise control over nanoparticle size and shape but also facilitates the creation of tailored nanoparticles with properties optimized for specific applications [Citation58–60]. Another method for synthesizing nanoparticles is physical synthesis, which involves the use of high-energy sources such as laser ablation [Citation61], plasma sputtering [Citation62–64], and ball milling [Citation65,Citation66]. Physical methods for nanoparticle synthesis provide several advantages, including enhanced control over particle size and composition. These methods also offer the capability to create nanoparticles from a diverse array of materials. There are several reasons for the appeal of physical synthesis techniques in nanoparticle production [Citation67–69].

Precision in Process Control: Physical synthesis techniques offer the advantage of precise control over various process parameters, including energy input, temperature, pressure, and duration. These controllable factors allow for the production of nanoparticles with tailored properties, such as size-dependent optical, electronic, or magnetic characteristics. This customization capability is invaluable for applications like drug delivery, catalysis, and sensors.

Mechanisms for Size Control: Physical synthesis methods directly influence nanoparticle size by adjusting specific parameters. For example, laser ablation can be fine-tuned by modifying laser parameters, while ball milling allows control over milling time, speed, and media, resulting in a well-defined size distribution of nanoparticles.

Versatility in Material Selection: Physical synthesis approaches are versatile and can be applied to a wide range of materials, including metals, ceramics, polymers, and composites. This versatility enables researchers to tailor nanoparticle properties to suit specific application requirements. For instance, refractory metals and alloys can be synthesized using methods like plasma sputtering, expanding the possibilities for various applications.

Minimized Chemical Reactions: Physical synthesis methods typically involve minimal chemical reactions, leading to reduced contamination and impurities in the final nanoparticle product. This results in nanoparticles characterized by higher purity and well-defined composition, which are particularly beneficial for electronics, catalysis, and biomedical applications.

Nonetheless, it is important to acknowledge that physical synthesis approaches may come with certain drawbacks. These can include increased complexity, higher costs in comparison to chemical synthesis methods, and the need for specialized equipment or facilities. The decision to opt for either physical or chemical synthesis methods for nanoparticles hinges on several considerations, including the targeted nanoparticle characteristics, the nature of the materials involved, available resources, and the precise demands of the intended application.

Combinatorial techniques, like matrix-assisted pulsed laser evaporation (MAPLE) and co-sputtering into ionic liquids, offer effective means of producing nanoparticle libraries in a high-throughput and efficient fashion, mirroring the principles employed in the creation of thin-film materials libraries. In the case of MAPLE, the procedure entails depositing a matrix material onto a substrate, followed by the utilization of a pulsed laser to ablate the matrix and generate nanoparticles [Citation68–71]. Control over the composition and characteristics of nanoparticles can be achieved by adjusting both the matrix material and the laser parameters, facilitating the combinatorial synthesis of a diverse array of nanoparticle compositions for high-throughput screening of nanoparticle properties. Additionally, another method called co-sputtering into ionic liquids utilizes sputtering as a physical synthesis technique to deposit nanoparticles onto an ionic liquid substrate [Citation72,Citation73]. A nanoparticle library is created when the ionic liquids are confined in wells across a plate. The composition and attributes of the nanoparticles can be finely controlled by altering the sputtering targets and the ionic liquids, enabling the synthesis of nanoparticles with diverse compositions in a combinatorial manner. However, employing combinatorial methods for nanoparticle synthesis presents a challenge in terms of requiring novel characterization techniques capable of handling the large number of nanoparticles with varying compositions produced in a single experiment. Conventional characterization methods like transmission electron microscopy (TEM) may not be suitable for the high-throughput characterization of combinatorial nanoparticle libraries. Hence, there is a pressing need to develop innovative characterization techniques capable of efficiently and accurately assessing the composition, size, shape, and other properties of nanoparticles in combinatorial libraries. This development would greatly facilitate rapid materials discovery and optimization. From a combinatorial standpoint, high-throughput screening (HTS) techniques can be employed to swiftly generate and analyze vast numbers of nanoparticles with diverse properties. For instance, HTS can be utilized to modify the size, shape, and surface chemistry of nanoparticles by adjusting synthesis conditions such as temperature, pressure, and reactant concentration. Subsequently, these nanoparticles can undergo screening using an array of techniques, including spectroscopic, microscopic, and analytical methods, to identify those exhibiting desired properties such as exceptional stability, biocompatibility, or catalytic activity [Citation72,Citation74–76].

5. High-throughput characterization of materials libraries

High-throughput characterization of multinary systems through the utilization of continuous composition spread thin-film multilayers serves as a potent technique for acquiring extensive and consistent datasets encompassing intrinsic and extrinsic properties. This method involves depositing thin films onto a substrate, incorporating composition gradients that continuously vary, thus enabling the comprehensive determination of material compositions, structures, and properties in a seamless manner. Notably, this approach surpasses conventional single-experiment methods in several ways. Firstly, the resultant datasets facilitate the efficient optimization of identified materials and expedite the discovery of new materials possessing the desired properties. Secondly, this methodology allows for the acquisition of expansive and reliable datasets pertaining to intrinsic and extrinsic properties, a feat unattainable through single-experiment procedures. These datasets contribute significantly to achieving a comprehensive understanding of the materials, encompassing their properties, microstructure, and processing parameters.

Multifunctional existence diagrams stand out as formidable tools for data visualization and decision support in the field of materials science. These diagrams offer a holistic perspective on the interplay among diverse material properties, processing variables, composition, and structure. By delineating regions within the materials domain where coveted properties manifest, they furnish valuable guidance for material enhancement and advancement. In the realm of high-throughput methods for materials exploration, it becomes paramount to prioritize data quality over measurement speed. Top-notch data holds the key to precise and meaningful analyses, ultimately expediting the materials discovery journey while curbing expenses. While this approach may demand time and resources, the ensuing datasets yield invaluable insights into material attributes and behaviors, thereby paving the path for the development of novel materials bearing the desired properties.

High-throughput techniques such as energy-dispersive X-ray analysis (EDX) [Citation77], wavelength-dispersive X-ray analysis (WDX) [Citation78] X-ray photoelectron spectroscopy (XPS) [Citation79], Rutherford backscatter spectroscopy (RBS) [Citation80,Citation81], and nuclear reaction analysis (NRA) [Citation82] can be used to measure the chemical composition of MLs. EDX is a fast method that can determine compositions of elements heavier than nitrogen with good accuracy while automated methods like WDX, XPS, RBS, and NRA can be used for heavier and lighter elements. These methods provide additional compositional information such as oxidation state [Citation79] and depth profiles [Citation81]. Combining techniques like XPS with RBS and NRA can allow determination of all elements in multinary systems, such as thin film Li-ion battery materials [Citation83,Citation84]. High-throughput X-ray diffraction (XRD) can be used to determine the phases present in a ML, with microfocus source and area detectors providing fast measurements with high good spatial resolution [Citation85–87].

shows the schematic principles of high throughput thin film composition and microstructure characterization, including the determination of the composition and microstructure using an integrated micro-beam X-ray fluorescence (XRF) technique and diffraction system (XRD) operated in a two-dimensional automatic scanning mode. An example of band-gap measurement for an oxide thin-film library and semiconductor transport property characterization approach based on ultrafast pulsed UV laser excitation can also be seen in the same library [Citation88–90].

Figure 6. Illustration of high throughput material characterization which shows a schematic of high throughput composition and microstructure characterization using micro-beam X-ray fluorescence and diffraction. High throughput band-gap characterization based on optical transmission and transport property characterization based on ultrafast pulsed laser excitation can also be seen.

To gain a thorough understanding of materials, it’s imperative to assess a multitude of properties. High-throughput characterization techniques should be tailored to align with the particular objectives of material development and the targeted functional properties. It’s essential to establish appropriate screening parameters or descriptors corresponding to the properties of interest. In cases where a single parameter may prove inadequate, the design of machine learning models should encompass all the necessary parameters that require measurement. As an example, high-throughput electrical resistivity measurements serve as a valuable discovery tool and offer insights into phase zones and their demarcations [Citation91]. Temperature-dependent resistance measurements can also yield signatures for phase transformations, which can be analyzed using XRD for the few most interesting samples [Citation92,Citation93]. When it comes to determining magnetic properties, the magneto-optical Kerr effect is suitable for high-throughput measurements of magnetic hysteresis [Citation94,Citation95]. Basic optical properties can be determined through photography [Citation96,Citation97], while further properties require automated test-stands for optical transmission with a transparent substrate for MLs [Citation98]. Microstructure can be characterized using SEM [Citation99] and AFM [Citation100,Citation101], and mechanical properties can be measured using nanoindentation [Citation102,Citation103], taking into account microstructural variations over a ML that can influence measurement results. To uncover the crystal structure and properties of newly discovered materials, in-depth studies are necessary. One promising method, in addition to synchrotron measurements [Citation104–106], is advanced in situ transmission electron microscopy (TEM) [Citation107–109], such as automated diffraction tomography combined with precession electron diffraction [Citation109,Citation110]. Another approach involves studying the temperature and environment-dependent phase evolution of complex materials using combinatorial processing platforms [Citation10,Citation111]. These platforms are created by depositing multinary thin films on nanoscale Si-tip arrays, forming many identical nanoscale ‘reactor volumes’. This allows for fast diffusion and reaction, and immediate observation of the product phases on an atomic scale using atom-probe tomography (APT) and TEM [Citation111,Citation112]. With this approach, it is possible to rapidly map the phase space of multinary systems with regards to stability against decomposition into phases and reactions with the environment, such as oxidation of alloys [Citation113].

High-throughput techniques, like those employed in materials science, offer significant advantages in terms of efficiency and rapid assessment of material properties. However, it’s essential to recognize the limitations of current technology, such as Atomic Force Microscopy (AFM), Transmission Electron Microscopy (TEM), and radiation-based methods, and understand why they may not always meet unrealistic expectations for true high-throughput applications. These advanced techniques, while capable of providing incredibly high resolution and detailed insights, often come with complexities in terms of instrumentation, resolution versus speed trade-offs, sample size and preparation requirements, data handling and analysis challenges, resource intensity, experimental variability, safety concerns, and occasionally unrealistic expectations. While these techniques are indispensable for in-depth material characterization, achieving true high-throughput capabilities may necessitate the development of new tools and methodologies that can address these constraints effectively and align with the demands for automation and rapid data generation. Researchers should approach high-throughput characterization with a realistic understanding of the current technological limitations.

6. Data-intensive science: a paradigm shift in modern scientific exploration

In recent years, there has been a remarkable surge in the volume of data generated across various scientific disciplines. This data explosion owes much to the advancements in information technology, enabling scientists to collect and process vast datasets. Consequently, experimental, theoretical, and computational sciences are generating unprecedented volumes of data, presenting both a challenge and an opportunity. To harness this data effectively and extract valuable insights, scientists are required to adopt new methodologies, often drawing from the realm of data science. By embracing the principles of data science, scientists can analyze, interpret, and derive knowledge from extensive datasets, thereby advancing their research endeavors. This shift towards a data-driven approach holds the potential to transform the way we conduct scientific investigations, potentially leading to groundbreaking discoveries across diverse fields [Citation114,Citation115].

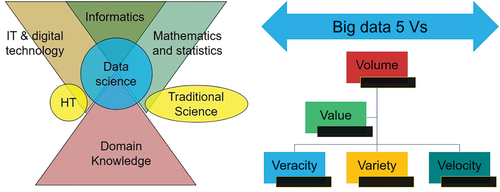

Traditionally, the scientific approach primarily focused on experimental and theoretical methods, yielding fundamental laws and equations. However, with the increasing complexity of theoretical models, the necessity for simulations emerged. These simulations have yielded copious amounts of data, supplemented by experimental observations obtained through sophisticated instrumentation. As a result, the scientific landscape has undergone a profound transformation. A new paradigm, often referred to as ‘data-intensive science’, or “Big Data’ has emerged, distinct from traditional computational science. () In this paradigm, the primary emphasis is placed on capturing and processing data, with scientists becoming more involved in the analytical stages during a later phase of the research process. This shift underscores the evolving nature of scientific exploration, marked by a heightened reliance on data acquisition, processing, and analysis, ultimately reshaping the scientific landscape [Citation116–118].

Figure 7. The left image illustrates the integrative role of data science, while the right image highlights the five defining characteristics of BigData.

Data Science is a multidisciplinary field that integrates mathematical and statistical techniques, computer science, programming skills, and domain expertise to extract valuable insights and knowledge from data. Its primary objective is to oversee the entire data analysis process, encompassing data collection, data cleaning, thorough analysis, and the derivation of meaningful conclusions. The emergence of Data Science is a response to the challenges posed by the era of Big Data, which refers to massive and intricate datasets that transcend the capabilities of conventional data analysis methods. Data Science also encompasses data mining, an advanced analytical approach aimed at uncovering concealed patterns and insights within datasets. This process is an integral part of a broader framework recognized as Knowledge Discovery in Databases. To excel in the field of Data Science, individuals must possess a diverse skill set. This includes technical proficiencies in data manipulation, programming, and statistical modeling, as well as domain expertise to comprehend the specific context in which the data was generated. Consequently, Data Scientists hail from various backgrounds, including mathematics, statistics, computer science, engineering, and social sciences [Citation116,Citation119,Citation120].

The process of analysis in Data Science presents unique challenges, primarily attributed to the distinctive attributes of Big Data. In stark contrast to conventional datasets, Big Data distinguishes itself by its substantial volume, diverse variety, rapid velocity, and the crucial factor of veracity, signifying data quality and reliability (). These characteristics collectively contribute to the complexity associated with its analysis. Addressing this formidable challenge necessitates the employment of an array of advanced analytical techniques, with a notable emphasis on machine learning (ML) algorithms. Originally conceived in the domains of artificial intelligence (AI) and expert systems, ML algorithms have been adapted for the purpose of autonomously uncovering patterns within data, constructing predictive models, and optimizing outcomes. Their applicability in the context of Big Data is particularly noteworthy, as these algorithms possess the capability to learn from data and refine their performance iteratively. This facilitates the identification of patterns and insights that may elude conventional analytical methods [Citation121–123].

However, the effective implementation of these algorithms demands substantial computational resources. Recent advancements in high-performance computing have made this resource-intensive aspect more manageable. A key advantage of Data Science lies in its expansive repertoire of algorithms and techniques that can be applied to diverse datasets. This versatility empowers Data Scientists to compare the efficacy of various models and explanations, allowing for the selection of the most suitable approach, or even a combination of approaches through ensemble techniques. This departure from the traditional approach, where techniques are chosen based on a priori knowledge of the data and method, is a hallmark of Data Science. The integration of machine learning algorithms into Data Science signifies a shift in the epistemological approach. Rather than testing pre-existing theories against data to align the data with a theory, Data Scientists can derive insights directly from the data. This means that they can uncover previously unknown patterns and relationships, fundamentally altering our understanding of the data. The convergence of extensive and intricate datasets, advanced analytical techniques, and a novel epistemological standpoint represents a paradigm shift in data analysis. The realm of Big Data analytics holds transformative potential, capable of revolutionizing decision-making processes, problem-solving methodologies, and ultimately driving improved business outcomes, heightened efficiency, and innovation across various domains [Citation119,Citation124,Citation125].

6.1. Advances in computational materials science: from DFT to ML

Recent advancements in experimental and computational techniques have led to the generation of extensive and intricate datasets. Machine learning methods have emerged as valuable tools for extracting knowledge and insights from this data by uncovering patterns and correlations. In this section, we outline the fundamental approaches in a logical sequence, commencing with Density Functional Theory (DFT), a widely employed computational method in materials science. Subsequently, we delve into the High-Throughput (HT) approach, which can generate substantial volumes of data automatically through experimental or computational means. Regardless of the data’s origin, the Machine Learning (ML) approach plays a pivotal role in extracting knowledge from identified patterns [Citation123,Citation126,Citation127].

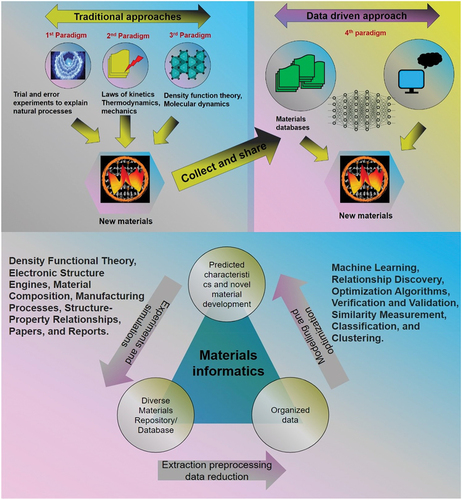

Computational materials science encompasses the utilization of computer simulations and calculations to investigate and comprehend the properties and behaviors of materials at the atomic and molecular levels. Over time, the methods employed in this field have evolved and can be categorized into three generations [Citation128].

First Generation: This generation centers on predicting material properties based on atomic structure. Local optimization algorithms, often reliant on Density Functional Theory (DFT) calculations, are used to forecast the properties of individual atoms and molecules. This approach remains influential, particularly for high-throughput calculations involving extensive material datasets.

Second Generation: The second generation focuses on predicting the crystal structure of a material while maintaining a fixed composition. Achieving this entails global optimization tasks, including genetic and evolutionary algorithms. This approach necessitates systematic execution of a substantial number of calculations and heavily relies on high-throughput methodologies.

Third Generation: The third generation of computational materials science embraces statistical learning. This approach harnesses the wealth of physical and chemical data available to expedite the discovery of novel compositions and the prediction of properties and crystalline structures. Machine learning (ML) algorithms are employed to analyze and learn from large datasets, enabling more precise predictions and discoveries at an accelerated pace.

These generational shifts underscore the dynamic evolution of computational materials science, with each stage representing a significant advancement in our ability to understand and manipulate materials for diverse applications [Citation128–130].

6.1.1. Density functional theory (DFT)

DFT is a prominent computational method in materials science employed to predict material properties based on their electronic structure. Operating on first-principles, it solves the Schrödinger equation to determine the electronic density of a material. DFT calculations offer insights into a material’s electronic structure, bonding, and can predict properties such as bandgap, electronic and magnetic attributes, as well as reaction energetics. Quantum Mechanics in the early 20th century revolutionized our understanding of material properties, with key concepts like Lewis model bonding stemming from Schrödinger equation solutions. However, this equation’s complexity for electron-electron interactions led to a computational shift. In the late 1920s, before computer availability, scientists devised approximations. In 1964, Hohenberg and Kohn introduced Density Functional Theory (DFT). Their theorems stated that the external potential V(r) for N electrons is uniquely tied to electronic density n(r) and that ground state energy E[n] minimizes for the exact density [Citation131,Citation132].

This equation signifies a many-electron system’s ground state energy as a functional of electronic density n(r). Its integration over space captures electron density variations. DFT, vital in condensed matter physics, materials science, and chemistry, offers versatile ab initio calculations. It assesses total energy, potential energy, and energy spectra in diverse systems, analyzes band structures, and determines structural properties. DFT’s accuracy has grown over time, becoming indispensable in materials research, drug development, and various applications [Citation133–135].

Density Functional Theory (DFT) has undergone substantial growth, emerging as a highly precise and predictive approach with notable contributions across various domains. DFT boasts versatile applications, enabling ab initio calculations in diverse systems. It encompasses assessments like total energy, potential energy, and energy spectra in crystalline structures, molecules, and organic complexes. DFT readily analyzes the band structures of metals, semiconductors, and insulators using plane-wave-based DFT equations, offering insights into electron and hole effective masses, band gaps, and optical transitions. Structural attributes, such as stress tensors, bulk modulus, and phonon spectra, are accessible via DFT, aiding material stability evaluations. While dispersion interaction isn’t inherently part of LSDA or GGA methods, many DFT codes now integrate parametrized models, enhancing its capability to describe non-covalent molecular bonding accurately. Overall, DFT’s evolution has rendered it increasingly precise and predictive, establishing it as a valuable tool spanning materials discovery, drug design, solar cell development, water splitting materials, and various other domains [Citation34,Citation136–142].

comprising commonly used DFT software tools for conducting electronic structure calculations in the realm of computational materials science.

Table 1. Compilation of software’s for conducting electronic structure calculations in the field of computational materials science.

6.1.2. The high-throughput (HT) approach

HT is a method for generating large amounts of data in an automated fashion. This can be done through either experimental or computational methods, or a combination of both. In materials science, HT experiments can involve synthesizing and characterizing large numbers of materials in a combinatorial fashion, while HT computational methods can involve running large numbers of simulations with varying input parameters to generate data on materials properties [Citation137,Citation158].

As computational power grows exponentially, the focus in materials science has shifted from lengthy calculations to streamlined simulation setup and analysis. Automation now allows for millions of parallel or sequential simulations, part of the high-throughput (HT) concept. HT entails generating vast electronic and thermodynamic data for real and hypothetical materials, enabling the discovery of desired materials. While HT doesn’t always include machine learning, the two are increasingly integrated. HT works with experimental, theoretical, and computational methods but faces the challenge of time-consuming individual calculations. The HT-DFT approach involves (i) calculations for many materials, (ii) systematic data storage, and (iii) data analysis for novel materials or insights. There’s been notable development of codes for managing simulations and repositories for sharing results, particularly in (i) and (ii). High-performance computers handle the calculations, and data management follows the FAIR concept. Material screening (iii) filters properties from repositories, but often researchers perform their own calculations to update databases. This has led to a surge in materials databases, including AFLOWLIB consortium, Materials Project, OQMD, NOMAD, and others () [Citation137,Citation139,Citation161,Citation169,Citation183–185].

Table 2. A comprehensive toolkit for high-throughput simulation results generation, manipulation, management, and analysis.

Materials screening is a vital step in high-throughput (HT) materials discovery workflows. This process entails filtering materials from a large database based on specific criteria or constraints. Typically performed after extensive data generation, materials screening involves using filters derived from various sources, including machine learning descriptors, theoretical models, or known materials properties. These filters are applied hierarchically to identify materials with desired attributes. Once materials pass through these filters, candidates with exceptional characteristics related to the desired properties are selected for further investigation, offering potential for novel applications or scientific insights. It’s important to note that the initial material selection plays a critical role in the materials screening process, whether it involves selecting materials with desired properties or excluding those with known unsuitable characteristics [Citation158].

6.1.3. Machine learning (ML)

The rapid expansion and achievements of machine learning (ML) have paved the way for its integration into various scientific fields, including material science. The continuous improvement of experimental methodologies has contributed to the accumulation of substantial data in material science, motivating researchers in this field to explore data-driven approaches for addressing scientific challenges. Despite the growing availability of resources for embarking on ML endeavors, there exists a scarcity of comprehensive guidance on navigating the intricate process of establishing a dependable and reliable ML solution. Machine learning (ML) techniques play a pivotal role in extracting knowledge and insights from extensive datasets by identifying correlations and patterns. In the field of materials science, ML serves as a fundamental tool for analyzing the large datasets generated by methods such as Density Functional Theory (DFT) or high-throughput (HT) approaches. These algorithms learn from data patterns, enabling predictions related to the discovery of novel materials with desired properties or the optimization of existing ones [Citation186].

Machine learning (ML) empowers computer programs to enhance their performance through three key elements: performance evaluation, task definition, and experience accumulation. In the context of materials science, the application of machine learning follows a structured framework referred to as Goal, Sample, Algorithm, and Model (GSAM). This framework involves the delineation of the problem, the selection of a relevant subset of data, the choice of an appropriate learning method, and the creation of a knowledge representation. However, before data can be effectively leveraged for machine learning, preprocessing steps are often essential. This preprocessing phase entails data cleansing, which involves identifying and eliminating incomplete, inaccurate, or extraneous information. While high-throughput (HT) methods have become indispensable for generating extensive datasets, the primary challenge lies in distilling valuable knowledge and insights from this abundance of information. Machine learning techniques excel in uncovering relationships and patterns within the data, even in high-dimensional spaces that surpass human reasoning capabilities [Citation187].

The process of classifying materials based on their performance benefits greatly from the use of filters. These filters help systematically categorize materials, identifying those that exhibit the desired behavior at an exceptional level as potential candidates for further exploration. This approach has proven highly effective in uncovering new technological and scientific applications. The fifth ‘V’ of big data, which revolves around extracting value from data, plays a crucial role in the success of this method. Machine learning (ML) has played a pivotal role in this process by providing automated tools for data analysis capable of identifying patterns within the data. In simple terms, ML is a technology that empowers computers to learn and improve their performance on tasks without requiring explicit programming. This technology is rooted in artificial intelligence (AI), a branch of computer science dedicated to creating intelligent machines capable of performing tasks typically associated with human intelligence. AI encompasses various subfields, including machine learning and deep learning. Since its inception in the 1950s, AI has made significant advancements in statistics, computer science, technology, and neuroscience. Today, ML has reached a more advanced level, offering a wide range of algorithms and techniques, including supervised learning, unsupervised learning, semi-supervised learning, and reinforcement learning [Citation188].

Machine learning (ML) algorithms have found diverse applications across various domains, including finance, navigation control, speech processing, computer vision, and bioinformatics, among others. Artificial intelligence (AI) encompasses a range of techniques that enable computers to mimic human intelligence. This emulation can be achieved not only through ML but also by employing less flexible, rule-based strategies like decision trees, if-then rules, knowledge bases, and computer logic. In recent years, deep learning (DL) has gained significant prominence within the ML field due to its remarkable achievements in various domains. DL involves representation learning and is loosely inspired by biological neural networks, featuring multiple layers between input and output layers. Data science is inherently intertwined with machine learning as it provides the essential data required for algorithms to learn. Data science encompasses a wide spectrum of techniques, including data mining, statistical analysis, and machine learning, all aimed at extracting knowledge and insights from complex datasets. By acquiring, processing, and analyzing large datasets, data science empowers organizations to make informed, data-driven decisions that were previously challenging with traditional methods. Therefore, data science is an indispensable component of machine learning, playing a pivotal role in enabling organizations to extract valuable insights from intricate data collections [Citation209]. For a list of libraries and platforms dedicated to materials prediction and machine learning, please refer to .

Table 3. Compilation of libraries and platforms for machine learning and materials prediction.

Creating machine learning (ML) models for materials involves a structured series of essential steps. Initially, data collection is paramount, where a diverse dataset containing various materials and their corresponding properties is collected from multiple sources. This dataset serves as the basis for training the ML model. Next, comes feature extraction, a crucial process for identifying pertinent material characteristics essential for determining material properties. These features typically encompass aspects like the material’s structure, composition, symmetry, and the properties of its constituent elements. The selection of the appropriate ML model is a pivotal step, contingent on the specific problem being addressed, whether it involves regression or classification, and the inherent characteristics of the data. Once the model is chosen, the training phase begins. During training, the selected model is fine-tuned using the extracted features and corresponding material properties from the training dataset. The objective is to optimize the model’s parameters to minimize the difference between predicted and actual properties. Subsequent to training, model validation takes center stage, where an evaluation of the trained model’s performance occurs. This evaluation is conducted on a validation set, which is a subset of the original dataset that was not used during training. Various metrics like accuracy, precision, recall, and F1-score are employed to assess the model’s performance. If the model fails to meet the desired performance criteria, optimization steps are implemented. These might involve adjusting hyperparameters, modifying the model architecture, or incorporating additional data. Once the model is well-tuned and successfully validated, it can be deployed to predict the properties of new materials. This is accomplished by inputting the features of these new materials into the model, which then generates predictions about their properties as output. Finally, the results produced by the model are meticulously analyzed to extract valuable insights into the underlying relationships between material features and properties. These insights are instrumental in guiding the design of new materials customized to possess specific desired properties [Citation209–213].

represents a typical machine learning project. This process begins with data loading and preprocessing, followed by data splitting, feature engineering, the application of various machine learning models, performance assessment of these models, comparison of performance among different models, and finally, visualization of the results [Citation214].

Figure 8. A visual representation depicting the application of machine learning in materials science. Modified with permission from reference [Citation214].

![Figure 8. A visual representation depicting the application of machine learning in materials science. Modified with permission from reference [Citation214].](/cms/asset/a3907606-8cd0-4b65-a146-da0dda4643ee/tstm_a_2292486_f0008_oc.jpg)

It’s crucial to emphasize that the choice of a machine learning algorithm should be tailored to the specific problem and dataset under analysis. Each algorithm comes with its own set of strengths and weaknesses, making it imperative to select the most suitable one to yield optimal results. Probability estimation algorithms like Bayesian networks and support vector machines find common application, particularly in the quest for new materials. These algorithms excel in estimating the likelihood of a material exhibiting specific properties based on existing data. Regression algorithms, such as linear regression and neural networks, are harnessed to predict material properties at both macro and micro levels. They leverage the intricate relationship between input features and output values to make precise predictions. Clustering algorithms like k-means and hierarchical clustering are employed to group materials based on their resemblances and distinctions, facilitating the identification of trends and patterns within extensive datasets. Classification algorithms, including decision trees and random forests, prove invaluable for categorizing materials according to their features. This is instrumental in tasks like identifying materials with particular properties or classifying new materials based on their inherent characteristics. Furthermore, the fusion of machine learning methodologies with intelligent optimization algorithms like genetic algorithms and particle swarm optimization enhances the accuracy and efficiency of material property prediction and optimization endeavors [Citation215].

As a tangible illustration of the practical application of machine learning (ML), the work conducted by D. Xue and colleagues exemplifies the fusion of ML techniques and experimental testing to uncover novel materials with outstanding thermal properties [Citation216]. Their approach commenced with a dataset featuring established materials alongside their thermal characteristics. Utilizing a machine learning model, they made predictions regarding the performance of various material compositions (see ). These predictive insights steered the selection of materials for real-world testing. Following each round of experiments, the outcomes were integrated back into the dataset, progressively refining the accuracy of their predictions. In this iterative process, tailored to address their specific design challenge, they meticulously followed a systematic sequence: (i) They initiated with an initial dataset that encompassed experimental data on diverse alloys, including known thermal dissipation (DT) values and essential material descriptors. This dataset served as the model’s input. (ii) Subsequently, the model underwent training and cross-validation using this initial alloy dataset. (iii) They introduced a separate dataset comprising unexplored alloys, thereby defining an extensive search space teeming with potential candidates. (iv) Leveraging the knowledge imparted by the trained model from step (ii), they applied it to predict DT values for all alloys within this uncharted dataset (iii). (v) The design phase encompassed the discerning selection of the ‘best’ four candidates for subsequent synthesis and characterization. Through this iterative approach, they successfully identified the most optimal combination for thermal behavior among the novel materials they discovered, surpassing the previously established benchmarks. This methodology brilliantly underscores the immense potential of amalgamating artificial intelligence with laboratory experiments, propelling the horizons of materials science and ushering in exciting prospects for material design and discovery [Citation215,Citation217].

Figure 9. Feedback derived from the experiments included the augmentation of the dataset with the addition of four newly discovered alloys. Modified with permission from reference [Citation216].

![Figure 9. Feedback derived from the experiments included the augmentation of the dataset with the addition of four newly discovered alloys. Modified with permission from reference [Citation216].](/cms/asset/be8c2204-69b9-4091-941b-89fa2208ed3c/tstm_a_2292486_f0009_oc.jpg)

6.1.4. Materials informatics

Materials Informatics is a specialized subfield within materials science that employs machine learning and data-driven techniques to uncover relationships between known material attributes and their properties. These attributes typically encompass a material’s structure, composition, symmetry, and the properties of its constituent elements. In Materials Informatics, the primary objective revolves around determining a material’s properties based on its inherent attributes. This process involves training machine learning models using existing datasets of materials and their respective properties. These models are then used to predict the properties of new materials not present in the original dataset. Furthermore, Materials Informatics can address the reverse query of identifying materials with specific desired properties. The overarching goal of Materials Informatics, also referred to as data-driven materials science, is to apply powerful tools from data mining, machine learning, and mathematical optimization to systematically unveil relationships between materials processing, structure, properties, and performance (PSPP) [Citation218,Citation219]. Once these PSPP relationships are unveiled, they can serve as a driving force behind predictive discovery and the design of innovative materials, as well as the optimization of manufacturing processes [Citation220–221]. This shift toward data-driven discovery aligns with the broader trend in modern research known as the fourth paradigm of science [Citation118,Citation122,Citation222]. Coined by Jim Gray in 2007, this term signifies the evolution of scientific methods from empirical science (the first paradigm) to theoretical science (the second paradigm), then computational science (the third paradigm), and now data-driven science (the fourth paradigm) [Citation223,Citation224] (). The rapid rise of materials informatics coincided with the introduction of the US Materials Genome Initiative (MGI) in 2011. This initiative explicitly emphasized the importance of digital data and associated software tools in materials research. Following the launch of MGI, materials informatics has played a pivotal role in facilitating laboratory discoveries related to materials and manufacturing processes. These discoveries have spanned diverse fields, including thermoelectrics and hydrothermal synthesis. Furthermore, there has been a notable surge in research publications featuring the development of various materials informatics-based models to elucidate relationships within the processing-structure-properties-performance (PSPP) framework.

Figure 10. Materials informatics workflow depicting the progression through traditional paradigms to the fourth paradigm shift.

Illustrated in is a generic materials informatics workflow. This analysis commences with the extraction and preprocessing of data, a phase where the essential elements of the dataset are identified and selected. The refined dataset is then subject to further scrutiny to unveil relationships among the components of interest. These discovered relationships serve as the foundation for creating what are known as inverse and forward models. The former enables the design of materials with specific desired properties, while the latter supports predictive analytics. To complete the cycle, experiments and computer simulations, guided by theoretical models, are employed to generate fresh data for the materials databases. This process effectively closes the loop, ensuring that the materials informatics workflow remains dynamic and continuously evolves.

In materials informatics, ML models serve as approximate functions that take inputs (materials features) and generate outputs (material properties). These models can be considered as phenomenological or empirical, as they offer heuristic functions that describe available data. The primary objective of machine learning in this context is to unveil feature-property relationships that might elude human researchers. It’s important to distinguish these machine learning models from theoretical models used in traditional materials science, which aim to comprehend the fundamental physics underlying material properties. ML models in materials informatics are not focused on understanding physics intricacies but rather on predicting properties based on material features. Nonetheless, the insights gleaned from materials informatics can eventually contribute to the development of theories and a deeper understanding of the fundamental physics governing material properties [Citation225].

The materials informatics workflow closely mirrors the general machine learning workflow, albeit with some specialized components. This workflow includes problem definition, data collection, representation of materials, and the selection, evaluation, and optimization of machine learning algorithms. Problem definition entails specifying the desired machine learning outcome and identifying the necessary input variables. Adequate data collection is crucial to comprehensively address the problem. The representation of materials is a critical step, as it significantly influences the performance of the machine learning algorithm. Machine learning algorithms must be chosen and assessed based on factors such as accuracy, training time, and model complexity or interpretability [Citation226–228].

Expanding on our previous discussion from materials perspective, illustrates the intricate interplay between materials informatics and the machine learning workflow employed for the prediction of mechanical deformation properties. This diagram delineates the various stages integral to this process. Starting from the left-hand side of the illustration, we observe the establishment of databases stemming from microscopy and (nano)mechanics experiments. These databases serve as invaluable repositories of data pertaining to the mechanical behavior of materials when subjected to diverse conditions, encompassing factors such as stress, strain, and temperature. In the subsequent stage, multiscale modeling simulations assume a pivotal role, providing essential descriptors and predictors that elucidate the underlying physical mechanisms governing the behavior of these materials [Citation229].

Figure 11. Materials informatics and the workflow involving machine learning for mechanical deformation strategy. Adopted with permission [Citation229].

![Figure 11. Materials informatics and the workflow involving machine learning for mechanical deformation strategy. Adopted with permission [Citation229].](/cms/asset/bdf6f7c1-79bd-47f5-91b2-971d2c6161c7/tstm_a_2292486_f0011_oc.jpg)

These descriptors encapsulate information about the material’s microstructure, crystal arrangement, defects, and other characteristics that exert influence on its mechanical properties. Transitioning to the center of the figure, these generated descriptors and predictors become indispensable for the training and validation of machine learning algorithms. These algorithms harness the extensive data derived from both the databases and simulations to formulate predictions concerning the mechanical properties of materials. These predictions offer crucial insights into various facets of material deformation, including critical parameters like strength, ductility, and toughness. It’s important to note that these predictions are not merely abstract outcomes; they find practical applications in structural characterization, materials design, and discovery. By elucidating how materials respond under diverse conditions, this approach equips materials scientists and engineers with a rapid and effective means to evaluate potential materials, identifying those with promise for specific applications. In essence, outlines a streamlined pathway that expedites the process of materials screening and the identification of optimal candidates tailored to meet specific mechanical requirements [Citation229].

provides an illustration of the implementation of a machine learning (ML) approach, highlighting two pivotal steps: the detection of patterns within input experimental or simulation data and subsequent predictions. These steps are of utmost importance in gaining a comprehensive understanding of the fundamental properties of materials. To effectively detect patterns in input data, a substantial volume of data is essential, often sourced from diverse origins. These sources encompass data generated through various means, including high-throughput simulations (such as ab initio, atomistic, and continuum-based simulations), extensive experimentation (such as mechanical testing and microscopy), and pre-existing materials databases. These repositories of data yield valuable insights into the properties and behaviors of materials under various conditions. In the quest to uncover structure-property relationships, a pertinent material dataset is defined by a feature space that comprises a set of atomic and/or local structural descriptors. These descriptors play a pivotal role in capturing essential physical mechanisms and microstructural intricacies relevant to a specific group of materials. This wealth of features serves to characterize the materials and unveil latent patterns within the data, potentially revealing underlying connections between these features and material properties. With these identified patterns at hand, machine learning algorithms come to the forefront, facilitating predictions related to uncharted materials. The ultimate goal is to harness these discerned patterns for the precise prediction of properties associated with new or unexplored materials. This methodology empowers materials scientists by streamlining the screening process for a wide range of potential materials, significantly reducing the time and resources required for the development of novel materials tailored to specific properties.

When deciding whether to apply machine learning (ML) to a research problem, it’s paramount to assess the availability of sufficient, consistent, validated, and representative data related to the specific behavior of interest. It’s worth noting that data generation is often better suited to traditional or high-throughput methods, particularly in the initial stages of research. Additionally, ML techniques excel at navigating high-dimensional spaces to uncover patterns in data, and they have the capacity to explicitly encode these discovered patterns, creating computational models that can be manipulated. Therefore, ML methods are most valuable when tackling problems that prove challenging for traditional approaches, where human intuition may not suffice to develop a physical model. In general, ML methods can offer significant utility in problems that fall within one of the following categories, arranged in increasing order of added value and complexity:

Replacing the collection of challenging, intricate, or expensive properties or data.

Generalizing a pattern observed in a dataset to a similar class of data.

Revealing relationships between correlated variables, particularly when the links are unknown or indirect, surpassing the scope of intuition or domain knowledge.

Establishing a comprehensive approximate model for a complex, poorly understood property or phenomenon that lacks fundamental theories or equations.